Professional Documents

Culture Documents

1299 - Ec0176

1299 - Ec0176

Uploaded by

Deipak HoleCopyright:

Available Formats

You might also like

- Hvac PM Service Checklist ContractorDocument1 pageHvac PM Service Checklist Contractorudupiganesh3069100% (2)

- Astm C 423Document12 pagesAstm C 423Abhinav AcharyaNo ratings yet

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- Geriatric Consideration in NursingDocument31 pagesGeriatric Consideration in NursingBabita Dhruw100% (5)

- 694Document1 page694Mauricio Ramirez100% (1)

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5armin heidariNo ratings yet

- Pricing Your Work Corporate and Industrial PhotographyDocument15 pagesPricing Your Work Corporate and Industrial PhotographyManu Mnau MnauNo ratings yet

- 1299 - Ec0583Document5 pages1299 - Ec0583Deipak HoleNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- 1485 - Ec0208Document5 pages1485 - Ec0208Deepak HoleNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1426 Ec1942Document3 pages1426 Ec1942Deipak HoleNo ratings yet

- 1485 - EC2092-signedDocument4 pages1485 - EC2092-signedDeepak HoleNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- HT 003Document1 pageHT 003Sam RajaNo ratings yet

- HT 002Document1 pageHT 002Sam RajaNo ratings yet

- Test Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerDocument1 pageTest Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerMehulkumar PatelNo ratings yet

- Specification Main PartsDocument8 pagesSpecification Main PartsvalveNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- MTC - A335 P22 Seamless PipeDocument1 pageMTC - A335 P22 Seamless PipeSri GangaNo ratings yet

- Material Test Report: Cert No: 697430Document1 pageMaterial Test Report: Cert No: 697430Abozar BilanNo ratings yet

- Gate Valve 3in 150 XMK1020754308-27Document5 pagesGate Valve 3in 150 XMK1020754308-27Mygame 1402No ratings yet

- Certificate of Analysis & Testing: P.O. No. P.O. DateDocument1 pageCertificate of Analysis & Testing: P.O. No. P.O. DateFundary ShopNo ratings yet

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocument1 pageM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarNo ratings yet

- tc_amr (1)Document1 pagetc_amr (1)balaNo ratings yet

- XQT190001050101 HTHDocument10 pagesXQT190001050101 HTHvalveNo ratings yet

- 21app0808 MTR-14Document1 page21app0808 MTR-14gmendoza.logistica3No ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- 7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913Document1 page7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913魏利强No ratings yet

- Inspection Report - Motor+16701004051+KT - 12V1600G80SDocument1 pageInspection Report - Motor+16701004051+KT - 12V1600G80SChristopherNo ratings yet

- 0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611Document2 pages0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611JORGE BAENANo ratings yet

- 21-Thermometer Calibration CartificateDocument1 page21-Thermometer Calibration CartificateCustomer SupportNo ratings yet

- Specification Main PartsDocument8 pagesSpecification Main PartsvalveNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- Ab 2501 24 MTCDocument3 pagesAb 2501 24 MTCVISHNU KKNo ratings yet

- Ad 1005 WB1Document5 pagesAd 1005 WB1billylu06No ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Page 3 Tsi MTC Plate (MTC - 249)Document2 pagesPage 3 Tsi MTC Plate (MTC - 249)trayojam.rilNo ratings yet

- NE6188CZDocument9 pagesNE6188CZhobolghaniNo ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Cricri CriNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5abdulNo ratings yet

- NST 3.1 PDFDocument1 pageNST 3.1 PDFPankaj RaneNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- 1335 - Ec1904Document1 page1335 - Ec1904Deipak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- Wifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDocument3 pagesWifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDeipak HoleNo ratings yet

- Quotation Yoke WIFL Sanaswadi 201718Document4 pagesQuotation Yoke WIFL Sanaswadi 201718Deipak HoleNo ratings yet

- StdReport10286 (7) 13.07.2019Document695 pagesStdReport10286 (7) 13.07.2019Deipak HoleNo ratings yet

- Cameron CompDocument14 pagesCameron CompDeipak HoleNo ratings yet

- MQC RM Approval ModuleDocument5 pagesMQC RM Approval ModuleDeipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- Customer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDocument1 pageCustomer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDeipak HoleNo ratings yet

- Al 111 2377-00 Rev 20 28-5-18Document2 pagesAl 111 2377-00 Rev 20 28-5-18Deipak HoleNo ratings yet

- मतदाता सूचना/Voter InformationDocument1 pageमतदाता सूचना/Voter InformationDeipak HoleNo ratings yet

- Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDocument1 pageWestern India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDeipak HoleNo ratings yet

- Wifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDocument2 pagesWifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDeipak HoleNo ratings yet

- Die No Product TP Req Cust Po No Line Item No Cust PO Date Andritz Hydro Private LimitedDocument6 pagesDie No Product TP Req Cust Po No Line Item No Cust PO Date Andritz Hydro Private LimitedDeipak HoleNo ratings yet

- WIF Laboratory Plan For 2019-2020Document30 pagesWIF Laboratory Plan For 2019-2020Deipak HoleNo ratings yet

- CGF FPC Palm Oil RoadmapDocument31 pagesCGF FPC Palm Oil RoadmapnamasayanazlyaNo ratings yet

- 4 Thematic Analysis TemplateDocument19 pages4 Thematic Analysis Templateapi-591189885No ratings yet

- Cognizant Test 1Document20 pagesCognizant Test 1Veeraragavan SubramaniamNo ratings yet

- Stable Fixed Points of Card Trick FunctionsDocument10 pagesStable Fixed Points of Card Trick FunctionsDerekNo ratings yet

- Types of ParentingDocument13 pagesTypes of ParentingViseshNo ratings yet

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument3 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- JTB Unitization Gas Project: Electrical Equipment/ Tools Inspection ChecklistDocument1 pageJTB Unitization Gas Project: Electrical Equipment/ Tools Inspection ChecklistAK MizanNo ratings yet

- Fs Tco Battery Diesel Delivery Trucks Jun2022Document3 pagesFs Tco Battery Diesel Delivery Trucks Jun2022The International Council on Clean TransportationNo ratings yet

- $50SAT - Eagle2 - Communications - Release Version V1 - 2Document25 pages$50SAT - Eagle2 - Communications - Release Version V1 - 2Usman ShehryarNo ratings yet

- Simulation and ModulationDocument89 pagesSimulation and ModulationGuruKPO67% (6)

- Capitalisation AssignmentDocument5 pagesCapitalisation AssignmentFayis FYSNo ratings yet

- Brother 1660e Service ManualDocument117 pagesBrother 1660e Service ManualtraminerNo ratings yet

- Ccc221coalpowerR MDocument58 pagesCcc221coalpowerR Mmfhaleem@pgesco.comNo ratings yet

- Statement of Purpose Name: Krishna Teja SwarnaDocument2 pagesStatement of Purpose Name: Krishna Teja SwarnaMohammadRahemanNo ratings yet

- Assignment 04 Solved (NAEEM HUSSAIN 18-CS-47)Document7 pagesAssignment 04 Solved (NAEEM HUSSAIN 18-CS-47)NAEEM HUSSAINNo ratings yet

- Current ElectricityDocument93 pagesCurrent ElectricitySurya SNo ratings yet

- MSFS Cessna Citation CJ4 Model 525C Operator's Guide (v1)Document92 pagesMSFS Cessna Citation CJ4 Model 525C Operator's Guide (v1)Matheus RochaNo ratings yet

- XXX (Topic) 好处影响1 相反好处 2. 你⾃自⼰己的观点,后⾯面会展开的Document3 pagesXXX (Topic) 好处影响1 相反好处 2. 你⾃自⼰己的观点,后⾯面会展开的Miyou KwanNo ratings yet

- Jon FosseDocument4 pagesJon FosseNoe CarNo ratings yet

- Biophilic Design: ARC407 DissertationDocument4 pagesBiophilic Design: ARC407 DissertationAaryan JainNo ratings yet

- Drug Dosage and IV Rates Calculations PDFDocument6 pagesDrug Dosage and IV Rates Calculations PDFvarmaNo ratings yet

- MAD Practical 6Document15 pagesMAD Practical 6DIVYESH PATELNo ratings yet

- Tle 7-1st Periodic TestDocument2 pagesTle 7-1st Periodic TestReymart TumanguilNo ratings yet

- SBT Sekolah Berprestasi Tinggi (HPS) High Performing SchoolsDocument14 pagesSBT Sekolah Berprestasi Tinggi (HPS) High Performing SchoolsAminNo ratings yet

- Final Simple Research (BS CRIM. 1-ALPHA)Document5 pagesFinal Simple Research (BS CRIM. 1-ALPHA)Julius VeluntaNo ratings yet

- Taylor Swift LyricsDocument2 pagesTaylor Swift LyricsElsie DomeNo ratings yet

1299 - Ec0176

1299 - Ec0176

Uploaded by

Deipak HoleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1299 - Ec0176

1299 - Ec0176

Uploaded by

Deipak HoleCopyright:

Available Formats

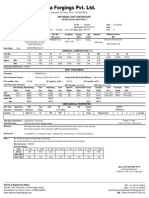

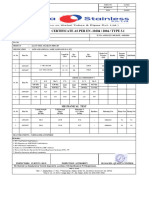

MATERIAL TEST CERTIFICATE

AS PER STD EN 10204 TYPE 3.1

Customer : TechnipFMC TC No. : EC0176 Date : 22.05.2022

Invoice No.:WIF/EX/22-23/ Date :

P.O. No.: 4500620576 Line Item: 0020 PO Date : 13.12.2021 Spec. Ref.: M25070 Rev. : F (Date:16.07.2021)

Die No. Description Part No. Condition Forging Qty Material Melting Practice

Drg. No. 502 PSL Level Ratio Sr.No. Mill

BODY FORGING, ULT PLUG F/

1299 VALVE 1 ULT150 F/3 IN 3257105 Rev K NQT/SB 24.25 88 Nos. AISI 4140 BF-EOF-LRF-VD-CCM

UNION ENDS AISI 4140

- JSW STEEL LIMITED

Heat Code: LPC DU500001271 Rev B

CHEMICAL COMPOSITION ( % )

Heat No :- C Mn Si S P Cr Mo V Ni Grain Size

C63775 0.41 0.90 0.25 0.008 0.011 1.02 0.22 0.005 0.22 7

Specn. Min. 0.38 0.75 0.15 - - 0.80 0.15 - - 6

Max. 0.43 1.00 0.35 0.025 0.025 1.10 0.25 0.30 1.00 -

HEAT TREATMENT

Procedure :- Q00025 Rev S

Heat Treatment Furnace :- Continous Type Furnace (CHTF) Temperature Monitoring Method:- Side Thermocouples in the Working Zone ( Method A)

HT Load No. of N :- CW-851 HT Batch No. of Q&T:- CW-853 Qty :- 88 Nos.

Test Piece Heat Treatment :- Along with job QTC location:- Sacrificial QTC Size- Actual Part

Hot Working Normalising Time Hardening Time Quench Quench Bath Temp. 1st Temper Time

Ratio Temp. Hrs. Temp. Hrs. Media Start End Temp. Hrs.

QTC 24.25 900⁰C 2.40 870⁰C 2.40 OIL 26°C 44°C 610°C 4 (Air Cool)

Forging 24.25 900⁰C 2.40 870⁰C 2.40 OIL 26°C 44°C 610°C 4 (Air Cool)

Specn. Min. 870⁰C 840⁰C --- --- 540⁰C

Max. 925⁰C 900⁰C --- 80⁰C 700⁰C

MECHANICAL PROPERTIES

QTC Test Specimen QTC Test UTS YS Elg RA Charpy Impact

Specimen Orientation Hardness Temp. 0.2 % Offset Test ( Charpy ) J

Location after H.T. ⁰C PSI PSI % % Temp. Requirement 1 2 3 Average

Refer annexure for testing details

Test Piece Orientation:- Longitudinal & Transverse Charpy 'V' notch

Test Piece Size :- 8.75 mm Dia, 35 mm Gauge Length 10 mm X 10 mm X 55 mm LG

Remarks : All the jobs have been visually examined and are free from bursts, laps, seams, cracks, porosity.

All the jobs have been 100% checked for MPI test and found satisfactory.

Enclosures: 1) Steel Mill TC 2) Hardness report 3) Dimensional Report 4) Testing Annexure

Note :- We hereby guarantee no weld repairs performed.

. We hereby certify that the above figures are correct as contained in the records of the company

For Heat Treatment batch traceability point, "CW-853" stamped near to Heat code.

Furnace calibration done as per AMS 2750F and meets the requirements.

Mr. Ajay Joshi (HEAD-MQC, HT & NDT)

Authorised Signatory

F-MQC-10 / Rev. 00 / 01-Apr-2016

Works & Registered Office Tel : +91-02137-679819

Gat No. 163, Hissa No.1, Pune-Nagar Road, Fax : +91-02137-679820

Sanaswadi, Tal. Shirur, Pune- 412208 (INDIA) customerservice@westernindiaforgings.com

www.westernindiaforgings.com CIN : U28910PN1981PTC024155

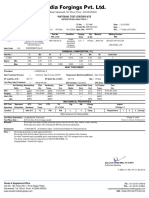

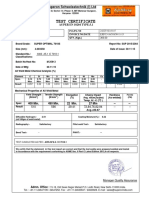

HARDNESS TEST REPORT

Customer:- TechnipFMC TC No: EC0176

P.O. No.:- 4500620576 Line Item: 0020 PO Date : 13.12.2021 Date : 22.05.2022

BODY FORGING, ULT PLUG VALVE 1 ULT150 F/3

Item : IN UNION ENDS AISI 4140 Material : AISI 4140

Part No.: 3257105 Rev K Heat No. : C63775

Drawing No.: DU500001271 Rev B Ambient Temp : 25°C

Die No.: 1299 Hardness Range:- 277 - 331 HBW

Qty.: 88 Nos. Test Method : Brinell Hardness Test

Vendor Sr.No.: - Equipment Used: Brinell Hardness Tester

HT Load No.: N: CW-851 QT: CW-853 Sr No.2017/09 & 09/2021-036

Reference Standard: ASTM E10 Machine Make: FSA & SAROJ

Load Applied: 3000 Kgs Calibration Agency: MM Engineers & MTMS

Cert. No.: MME/CAL/260/21-22 (FSA)

Type of Penetrator: Dia 10 mm Carbide Ball

Cert. No.: MATRIX/CAL/2021-2022/12/2040 (SAROJ)

Std Block Details: SH-249 (Hardness value - 287.4 HBW) Calibrated On: 14.08.2021(FSA) & 10.12.2021(SAROJ)

Entity Performing Test: WIF Sanaswadi Calibrated Due On:13.02.2022(FSA) & 09.12.2022(SAROJ)

Hardness

Q03006 Rev. AC / Q03009 Rev. X Date of Test :- 07.01.2022

Procedure :-

Precise Measuring Method of HBW Impression : Type B : Hand-Held Microscope with fixed measuring lines.

Qty. Hardness in HBW

88 Nos. 285-321 HBW

Test Performed By Reviewed By Approved By :

Atul Jedhe Satish Gadgil (Sr.Manager HT) Mr. Ajay Joshi (HEAD-MQC, HT & NDT)

F-HT-10 / Rev. 00 / 01-Apr-2016

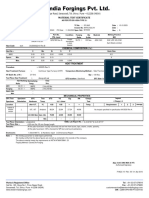

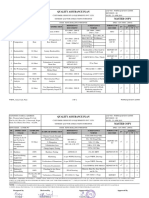

Mechanical Test Annexure

Die No.: 1299 Material Grade: AISI 4140

Heat No.: C63775 HT Lot No. : CW-853

Heat Code: LPC TC No. : EC0176

TENSILE TEST

QTC Test QTC Hardness after UTS YS Elg RA

Specimen Test Temp. NABL Lab Sample

Specimen H.T. 0.2 % Offset

Orientation (⁰C) Report No. No.

Location HBW KSI KSI % %

0.5" below HT

L 302, 311 Ambient J-22-848-P 1 155.65 137.081 20.06 61.81

Surface

277 - 331 Spec. Min. 120.00 100.00 16.00 35.00

IMPACT TEST

QTC Test

Specimen Requirement Test Temp. NABL Lab Sample

Specimen 1 2 3 Average

Orientation (⁰C) Report No. No.

Location

Avg. - 42 J Min

60 66 62 62.67

Single - 32 J Min

LE - 0.51 mm Min -29°C 0.77 0.83 0.79 0.80

%Shear - Report 50 55 55 53.33

L

Avg. - 27 J Min

48 58 60 55.33

Single - 20 J Min

LE - Report -40°C 0.63 0.75 0.77 0.72

%Shear - Report 40 50 50 46.67

0.5" below

Avg. - 28 J Min J-22-848-P 1

HT Surface 28 28 32 29.33

Single - 18.7 J Min

-29°C

LE - Report 0.38 0.39 0.43 0.40

%Shear - Report 20 20 20 20.00

T

Avg. - 20 J Min

24 20 24 22.67

Single - 14 J Min

LE - Report -40°C 0.34 0.30 0.35 0.33

%Shear - Report 15 10 15 13.33

Mr. Ajay Joshi (HEAD-MQC, HT & NDT)

Authorised Signatory

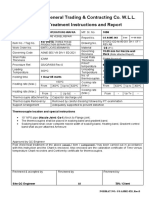

Certificate of Compliance

Customer : TechnipFMC TC No.: EC0176

Date: 22.05.2022

Die No. : 1299 Heat Code : LPC

PO No : 4500620576 Line Item No : 0020

Offer Qty. : 88 Nos.

Part No/ Rev : 3257105 Rev K Drg No / Rev : DU500001271 Rev B

BODY FORGING, ULT PLUG VALVE

Part Name : Serial No. : -

1 ULT150 F/3 IN UNION ENDS AISI

4140

I. Material

A. Material Type : AISI 4140

B. Material Spec/ Rev. : As per Spec no : M25070 Rev No. F (Date:16.07.2021)

C. Material Test Report No : Mill Heat No : C63775

II. Dimensional

A. AQL : AS PER QUALITY PLAN B. Sample Size : 13 Nos.

III. Secondary Process : Heat Treatment

A. Process Name : Normalised

Heat Lot No. : CW-851 Process Spec : Q00025 Rev S

B. Process Name : QT

Heat Lot No. : CW-853 Process Spec : Q00025 Rev S

IV. NDE

A. Process Name : MPI

Certificate No : NA Process Spec : NA

B. Process Name : UT

Certificate No : NA Process Spec : NA

This is certified that subjected material is manufactured from material mentioned above &

verified by us as per written sample size & found conforming to requirements.

For Heat Treatment batch traceability point, "CW-853" stamped near to Heat code.

Sign with Stamp

Mr. Ajay Joshi (HEAD-MQC, HT & NDT)

You might also like

- Hvac PM Service Checklist ContractorDocument1 pageHvac PM Service Checklist Contractorudupiganesh3069100% (2)

- Astm C 423Document12 pagesAstm C 423Abhinav AcharyaNo ratings yet

- Material TCDocument1 pageMaterial TCgmbakshiNo ratings yet

- Geriatric Consideration in NursingDocument31 pagesGeriatric Consideration in NursingBabita Dhruw100% (5)

- 694Document1 page694Mauricio Ramirez100% (1)

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5armin heidariNo ratings yet

- Pricing Your Work Corporate and Industrial PhotographyDocument15 pagesPricing Your Work Corporate and Industrial PhotographyManu Mnau MnauNo ratings yet

- 1299 - Ec0583Document5 pages1299 - Ec0583Deipak HoleNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- 1485 - Ec0251Document6 pages1485 - Ec0251Deepak HoleNo ratings yet

- 1300 EC2192 SignedDocument4 pages1300 EC2192 SignedDeepak HoleNo ratings yet

- 1299 EC2153 SignedDocument5 pages1299 EC2153 SignedDeepak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- 1300 - Ec0313Document5 pages1300 - Ec0313Deepak HoleNo ratings yet

- 1485 - Ec0208Document5 pages1485 - Ec0208Deepak HoleNo ratings yet

- 1591 EC2213 SignedDocument5 pages1591 EC2213 SignedDeepak HoleNo ratings yet

- 1590 EC2249 SignedDocument5 pages1590 EC2249 SignedDeepak HoleNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- 1300 EC1986 SignedDocument4 pages1300 EC1986 SignedDeepak HoleNo ratings yet

- 1900 - EC2157-signedDocument4 pages1900 - EC2157-signedDeepak HoleNo ratings yet

- 1426 Ec2262Document3 pages1426 Ec2262Deepak HoleNo ratings yet

- 4555 70 03 Ec2125 1111Document4 pages4555 70 03 Ec2125 1111Deepak HoleNo ratings yet

- 1426 Ec1942Document3 pages1426 Ec1942Deipak HoleNo ratings yet

- 1485 - EC2092-signedDocument4 pages1485 - EC2092-signedDeepak HoleNo ratings yet

- Material Test Certificate: M/s Alstom Projects India LimitedDocument1 pageMaterial Test Certificate: M/s Alstom Projects India LimitedDeepak HoleNo ratings yet

- 1485 - EC2172-signedDocument4 pages1485 - EC2172-signedDeepak HoleNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- Metallurgical Test Certificate: Doc. No. R-QC.11 Nov.12Document2 pagesMetallurgical Test Certificate: Doc. No. R-QC.11 Nov.12MacelNo ratings yet

- HT 003Document1 pageHT 003Sam RajaNo ratings yet

- HT 002Document1 pageHT 002Sam RajaNo ratings yet

- Test Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerDocument1 pageTest Certificate / Certificate of Conformity in Accordance With en 10204 3.1 CustomerMehulkumar PatelNo ratings yet

- Specification Main PartsDocument8 pagesSpecification Main PartsvalveNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romero100% (1)

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- MTC - A335 P22 Seamless PipeDocument1 pageMTC - A335 P22 Seamless PipeSri GangaNo ratings yet

- Material Test Report: Cert No: 697430Document1 pageMaterial Test Report: Cert No: 697430Abozar BilanNo ratings yet

- Gate Valve 3in 150 XMK1020754308-27Document5 pagesGate Valve 3in 150 XMK1020754308-27Mygame 1402No ratings yet

- Certificate of Analysis & Testing: P.O. No. P.O. DateDocument1 pageCertificate of Analysis & Testing: P.O. No. P.O. DateFundary ShopNo ratings yet

- M.E.Forge Tech: Customer:M/s L & T Valves LimitedDocument1 pageM.E.Forge Tech: Customer:M/s L & T Valves LimitedK.s. Raghavendra KumarNo ratings yet

- tc_amr (1)Document1 pagetc_amr (1)balaNo ratings yet

- XQT190001050101 HTHDocument10 pagesXQT190001050101 HTHvalveNo ratings yet

- 21app0808 MTR-14Document1 page21app0808 MTR-14gmendoza.logistica3No ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Astm A350 LF2Document1 pageAstm A350 LF2anjangandak2932100% (1)

- 7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913Document1 page7607 E7018 SUPER OPTIMAL 4.0mm - BNM25913魏利强No ratings yet

- Inspection Report - Motor+16701004051+KT - 12V1600G80SDocument1 pageInspection Report - Motor+16701004051+KT - 12V1600G80SChristopherNo ratings yet

- 0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611Document2 pages0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611JORGE BAENANo ratings yet

- 21-Thermometer Calibration CartificateDocument1 page21-Thermometer Calibration CartificateCustomer SupportNo ratings yet

- Specification Main PartsDocument8 pagesSpecification Main PartsvalveNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- Ab 2501 24 MTCDocument3 pagesAb 2501 24 MTCVISHNU KKNo ratings yet

- Ad 1005 WB1Document5 pagesAd 1005 WB1billylu06No ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Page 3 Tsi MTC Plate (MTC - 249)Document2 pagesPage 3 Tsi MTC Plate (MTC - 249)trayojam.rilNo ratings yet

- NE6188CZDocument9 pagesNE6188CZhobolghaniNo ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- Ningbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1Document2 pagesNingbo Dongxin High-Strength Nut Co.,Ltd: Test Certificate Conforming To Bs en 10204:2004 3.1GLORIA MONSALVE SALAZARNo ratings yet

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Cricri CriNo ratings yet

- Inspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5Document1 pageInspection Certificate According To EN 10204, Type 3.1.: EN ISO 17632-A: T464MM1H5abdulNo ratings yet

- NST 3.1 PDFDocument1 pageNST 3.1 PDFPankaj RaneNo ratings yet

- 1466 - Ec0044Document5 pages1466 - Ec0044Deipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- 1335 - Ec1904Document1 page1335 - Ec1904Deipak HoleNo ratings yet

- Material Test Certificate: TechnipfmcDocument4 pagesMaterial Test Certificate: TechnipfmcDeipak HoleNo ratings yet

- Wifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDocument3 pagesWifpl Qap 2019-20-015 Rev 00 Mdns 40ni6cr4mo3 SignedDeipak HoleNo ratings yet

- Quotation Yoke WIFL Sanaswadi 201718Document4 pagesQuotation Yoke WIFL Sanaswadi 201718Deipak HoleNo ratings yet

- StdReport10286 (7) 13.07.2019Document695 pagesStdReport10286 (7) 13.07.2019Deipak HoleNo ratings yet

- Cameron CompDocument14 pagesCameron CompDeipak HoleNo ratings yet

- MQC RM Approval ModuleDocument5 pagesMQC RM Approval ModuleDeipak HoleNo ratings yet

- Punching Slip: Prepared by Date: MQC SignDocument1 pagePunching Slip: Prepared by Date: MQC SignDeipak HoleNo ratings yet

- Customer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDocument1 pageCustomer: Probe Oil Tools Ltd. Product Type: All Product: All Grade: All Sales Rep: All Location: WIFPLDeipak HoleNo ratings yet

- Al 111 2377-00 Rev 20 28-5-18Document2 pagesAl 111 2377-00 Rev 20 28-5-18Deipak HoleNo ratings yet

- मतदाता सूचना/Voter InformationDocument1 pageमतदाता सूचना/Voter InformationDeipak HoleNo ratings yet

- Western India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDocument1 pageWestern India Forgings PVT LTD: ISO 9001, IATF 16949, ISO 14001, OHSAS 18001, PED AD 2000 Merkblatt WO CERTIFIED COMPANYDeipak HoleNo ratings yet

- Wifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDocument2 pagesWifpl-Qap-2019!20!008 Rev-00 Hindustan Equipment PVT Ltd-SignedDeipak HoleNo ratings yet

- Die No Product TP Req Cust Po No Line Item No Cust PO Date Andritz Hydro Private LimitedDocument6 pagesDie No Product TP Req Cust Po No Line Item No Cust PO Date Andritz Hydro Private LimitedDeipak HoleNo ratings yet

- WIF Laboratory Plan For 2019-2020Document30 pagesWIF Laboratory Plan For 2019-2020Deipak HoleNo ratings yet

- CGF FPC Palm Oil RoadmapDocument31 pagesCGF FPC Palm Oil RoadmapnamasayanazlyaNo ratings yet

- 4 Thematic Analysis TemplateDocument19 pages4 Thematic Analysis Templateapi-591189885No ratings yet

- Cognizant Test 1Document20 pagesCognizant Test 1Veeraragavan SubramaniamNo ratings yet

- Stable Fixed Points of Card Trick FunctionsDocument10 pagesStable Fixed Points of Card Trick FunctionsDerekNo ratings yet

- Types of ParentingDocument13 pagesTypes of ParentingViseshNo ratings yet

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument3 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- JTB Unitization Gas Project: Electrical Equipment/ Tools Inspection ChecklistDocument1 pageJTB Unitization Gas Project: Electrical Equipment/ Tools Inspection ChecklistAK MizanNo ratings yet

- Fs Tco Battery Diesel Delivery Trucks Jun2022Document3 pagesFs Tco Battery Diesel Delivery Trucks Jun2022The International Council on Clean TransportationNo ratings yet

- $50SAT - Eagle2 - Communications - Release Version V1 - 2Document25 pages$50SAT - Eagle2 - Communications - Release Version V1 - 2Usman ShehryarNo ratings yet

- Simulation and ModulationDocument89 pagesSimulation and ModulationGuruKPO67% (6)

- Capitalisation AssignmentDocument5 pagesCapitalisation AssignmentFayis FYSNo ratings yet

- Brother 1660e Service ManualDocument117 pagesBrother 1660e Service ManualtraminerNo ratings yet

- Ccc221coalpowerR MDocument58 pagesCcc221coalpowerR Mmfhaleem@pgesco.comNo ratings yet

- Statement of Purpose Name: Krishna Teja SwarnaDocument2 pagesStatement of Purpose Name: Krishna Teja SwarnaMohammadRahemanNo ratings yet

- Assignment 04 Solved (NAEEM HUSSAIN 18-CS-47)Document7 pagesAssignment 04 Solved (NAEEM HUSSAIN 18-CS-47)NAEEM HUSSAINNo ratings yet

- Current ElectricityDocument93 pagesCurrent ElectricitySurya SNo ratings yet

- MSFS Cessna Citation CJ4 Model 525C Operator's Guide (v1)Document92 pagesMSFS Cessna Citation CJ4 Model 525C Operator's Guide (v1)Matheus RochaNo ratings yet

- XXX (Topic) 好处影响1 相反好处 2. 你⾃自⼰己的观点,后⾯面会展开的Document3 pagesXXX (Topic) 好处影响1 相反好处 2. 你⾃自⼰己的观点,后⾯面会展开的Miyou KwanNo ratings yet

- Jon FosseDocument4 pagesJon FosseNoe CarNo ratings yet

- Biophilic Design: ARC407 DissertationDocument4 pagesBiophilic Design: ARC407 DissertationAaryan JainNo ratings yet

- Drug Dosage and IV Rates Calculations PDFDocument6 pagesDrug Dosage and IV Rates Calculations PDFvarmaNo ratings yet

- MAD Practical 6Document15 pagesMAD Practical 6DIVYESH PATELNo ratings yet

- Tle 7-1st Periodic TestDocument2 pagesTle 7-1st Periodic TestReymart TumanguilNo ratings yet

- SBT Sekolah Berprestasi Tinggi (HPS) High Performing SchoolsDocument14 pagesSBT Sekolah Berprestasi Tinggi (HPS) High Performing SchoolsAminNo ratings yet

- Final Simple Research (BS CRIM. 1-ALPHA)Document5 pagesFinal Simple Research (BS CRIM. 1-ALPHA)Julius VeluntaNo ratings yet

- Taylor Swift LyricsDocument2 pagesTaylor Swift LyricsElsie DomeNo ratings yet