Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsTDS Dynoadd F-1 15092022

TDS Dynoadd F-1 15092022

Uploaded by

vikram.iitkgpCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Piles in Permafrost Conditions PDFDocument45 pagesPiles in Permafrost Conditions PDFAurimas MiškinisNo ratings yet

- AEROSIL® 200: Description Typical ApplicationsDocument1 pageAEROSIL® 200: Description Typical ApplicationsAPEX SONNo ratings yet

- Yd-011 TdsDocument4 pagesYd-011 TdsOswaldo Manuel Ramirez Marin100% (2)

- TI Acronal 5522 PDFDocument1 pageTI Acronal 5522 PDFWahid KarolNo ratings yet

- Angus Zoldine Xl-29se Crosslinker TdsDocument9 pagesAngus Zoldine Xl-29se Crosslinker TdsAnkit MaheshwariNo ratings yet

- DYNOL 607 - G - Surfactant 0717 EN OIDocument2 pagesDYNOL 607 - G - Surfactant 0717 EN OIJian WenNo ratings yet

- Rheofinish 225D: Water Based Chemical Release AgentDocument2 pagesRheofinish 225D: Water Based Chemical Release Agentsarahsewell9No ratings yet

- LF200 TDSDocument3 pagesLF200 TDSRobert SkibaNo ratings yet

- Evonik-Surfynol DF-37 Dewebbing (Defoamer) Latex GlovesDocument2 pagesEvonik-Surfynol DF-37 Dewebbing (Defoamer) Latex GlovesherryNo ratings yet

- AEROSIL R 972 TDS EN EN TDS PV 52043842 en GB WORLDDocument1 pageAEROSIL R 972 TDS EN EN TDS PV 52043842 en GB WORLDeliteindustries.pkNo ratings yet

- Desmodur VP LS 2394 - en - 05573580 17844557 19844485Document4 pagesDesmodur VP LS 2394 - en - 05573580 17844557 19844485gUiLhErMe fAnTiNiNo ratings yet

- Joncryl-9532 TDSDocument2 pagesJoncryl-9532 TDSMohamed HalemNo ratings yet

- Dispersing Agent For Water-Based Systems Ionic Homopolymer DispersantDocument1 pageDispersing Agent For Water-Based Systems Ionic Homopolymer Dispersantumar buttNo ratings yet

- ADDITOL XL 123 N - EN - LetterDocument2 pagesADDITOL XL 123 N - EN - LetterFabio Enrique Gomez RamirezNo ratings yet

- Neorez 600Document1 pageNeorez 600Abhineet ShrivastavaNo ratings yet

- 901 104 01 Robond L Waterborne Laminating Adhesives North American Product GuideDocument4 pages901 104 01 Robond L Waterborne Laminating Adhesives North American Product GuidebrighterNo ratings yet

- A New APEO-free Surfactant Solution For The Paint - SolvayDocument24 pagesA New APEO-free Surfactant Solution For The Paint - Solvayichsan hakimNo ratings yet

- Tds Acronaleco702ap enDocument3 pagesTds Acronaleco702ap enShreyashi MukhopadhayNo ratings yet

- TDS - CRAYVALLAC® LA-150 - en - WWDocument1 pageTDS - CRAYVALLAC® LA-150 - en - WWrndsb.aopNo ratings yet

- Covestro PoliuretanoDocument24 pagesCovestro PoliuretanoRAFAEL MIERES100% (1)

- Tds Uniqflow 372s enDocument1 pageTds Uniqflow 372s enm daneshpourNo ratings yet

- Tds Uniqflow 372s enDocument1 pageTds Uniqflow 372s enm daneshpourNo ratings yet

- Dowsil US CF 2403Document2 pagesDowsil US CF 2403ShambhatiaNo ratings yet

- Acronal ECO 702 AP TI EDA Nov 07Document3 pagesAcronal ECO 702 AP TI EDA Nov 07nanoNo ratings yet

- Flexisperse™ 133N: Technical Data SheetDocument2 pagesFlexisperse™ 133N: Technical Data SheetalejandroNo ratings yet

- Architectural CoatingDocument28 pagesArchitectural CoatingDuc Nguyen100% (3)

- High Performance Substrate Wetting Agents Brand Superwetter FamilyDocument29 pagesHigh Performance Substrate Wetting Agents Brand Superwetter FamilyDương Minh MẫnNo ratings yet

- 0901 B 803808 EbffdDocument7 pages0901 B 803808 EbffdForeverNo ratings yet

- MAINCOTE HG-56 Acrylic Resin A Binder For Maintenance CoatingsDocument8 pagesMAINCOTE HG-56 Acrylic Resin A Binder For Maintenance CoatingsLong An ĐỗNo ratings yet

- DOW CORNING 3362N-Insulating Glass SealantDocument3 pagesDOW CORNING 3362N-Insulating Glass SealantTran The AnhNo ratings yet

- Nivapol Polem A 1170Document1 pageNivapol Polem A 1170sastra_anugrahaNo ratings yet

- PRIMAL™ HG-1000 Binder: Technical Data SheetDocument9 pagesPRIMAL™ HG-1000 Binder: Technical Data SheetLong An DoNo ratings yet

- Fosroc Nukote BGIIDocument4 pagesFosroc Nukote BGIIm.elsanee.cubicNo ratings yet

- LSR LC-50-2004Document3 pagesLSR LC-50-2004tarot.insights4uNo ratings yet

- ADDITOL-dry-CF100 EN A4Document2 pagesADDITOL-dry-CF100 EN A4Monserrat PérezNo ratings yet

- 24 391 01 Coatings and Inks Additive Selection GuideDocument16 pages24 391 01 Coatings and Inks Additive Selection GuideLong An DoNo ratings yet

- Acematt Ok 412Document1 pageAcematt Ok 412optimus_1404No ratings yet

- TDS-EN-Conflex PS - Rev 016-Aug21Document2 pagesTDS-EN-Conflex PS - Rev 016-Aug21LONG LASTNo ratings yet

- Genapol PF 20Document2 pagesGenapol PF 20Mohamed HalemNo ratings yet

- Coatings and Inks Additive: Selection GuideDocument16 pagesCoatings and Inks Additive: Selection GuideherryNo ratings yet

- Brochure EpotecDocument18 pagesBrochure Epotectrường phạmNo ratings yet

- Lapox ARF 11Document2 pagesLapox ARF 11Osama GabrNo ratings yet

- 2015 BASF Flexible-Packaging-Inks Landscape EL PDFDocument12 pages2015 BASF Flexible-Packaging-Inks Landscape EL PDFAgres KrismantonaNo ratings yet

- Data Sheet Dowcorning 111Document2 pagesData Sheet Dowcorning 111Nyoman RakaNo ratings yet

- Lanco PP 1362 DDocument2 pagesLanco PP 1362 DAkhtar aliNo ratings yet

- DYNOL™ 360: Description Technical DataDocument1 pageDYNOL™ 360: Description Technical DatatopguitarNo ratings yet

- Zinc Rich 1p pc102Document2 pagesZinc Rich 1p pc102livefreakNo ratings yet

- Desmodur N 3200Document4 pagesDesmodur N 3200محمد مقلدNo ratings yet

- Dodicor 2725 NFDocument3 pagesDodicor 2725 NFVenkatesha Perumal RamasamyNo ratings yet

- Desmodur Z 4470 BA: Type Form Supplied UsesDocument4 pagesDesmodur Z 4470 BA: Type Form Supplied Usessriatul2006No ratings yet

- Desmophen A 160 SN: Type Characterization Form Supplied UsesDocument2 pagesDesmophen A 160 SN: Type Characterization Form Supplied UsesFadi MagdyNo ratings yet

- Fosroc Renderoc LA55: Single Component Free Flowing Low Alkali Micro Concrete Uses PropertiesDocument2 pagesFosroc Renderoc LA55: Single Component Free Flowing Low Alkali Micro Concrete Uses PropertiesVincent JavateNo ratings yet

- Albafix FRDDocument7 pagesAlbafix FRDsaskoNo ratings yet

- 843 02170 01 Acrysol dr180 Rheology Modifier TdsDocument3 pages843 02170 01 Acrysol dr180 Rheology Modifier TdsAhmed ElgendyNo ratings yet

- Water-Based Single Component High Gloss Acrylic For DTM and Topcoat ApplicationsDocument6 pagesWater-Based Single Component High Gloss Acrylic For DTM and Topcoat ApplicationsamitNo ratings yet

- Carboguard 703Document2 pagesCarboguard 703Achraf BoudayaNo ratings yet

- Neusilin TDS US2Document1 pageNeusilin TDS US2Rohit RanjanNo ratings yet

- 高溫油脂MOLYKOTE D-321 R Anti-Friction 71-0219G-01Document2 pages高溫油脂MOLYKOTE D-321 R Anti-Friction 71-0219G-01If ChenNo ratings yet

- Acronal Ds 6262 TdsDocument1 pageAcronal Ds 6262 TdsLong An DoNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (7)

- Maharashtra HSC Chemistry Paper 2-Target PublicationDocument45 pagesMaharashtra HSC Chemistry Paper 2-Target PublicationKhanAbdullah100% (1)

- Template Uji Umur Simpan Kadar Air KritisDocument14 pagesTemplate Uji Umur Simpan Kadar Air KritisSusi Nur KusumawatiNo ratings yet

- Lab 10Document15 pagesLab 10Tanzeela KhalidNo ratings yet

- EarthQuake Design As Per Is-1893-2014 and Wind Load Calculation of 325 KL OHtDocument14 pagesEarthQuake Design As Per Is-1893-2014 and Wind Load Calculation of 325 KL OHtsanju middya100% (1)

- Derra J Phys D38 2995 UHP Proj ReviewDocument17 pagesDerra J Phys D38 2995 UHP Proj ReviewSINGGIH KSNo ratings yet

- Pipeline Corrosion Management CapabilityDocument2 pagesPipeline Corrosion Management CapabilityMajdi Abdulrahman Mohamed RahamaNo ratings yet

- Photosynthesis and The Carbon Cycle: Lower Secondary Checkpoint Year 8Document20 pagesPhotosynthesis and The Carbon Cycle: Lower Secondary Checkpoint Year 8Youssef MohamedNo ratings yet

- Of ONSC (Sem. 6/ Elex./MSBTE) 1-2: Fiber OpticDocument22 pagesOf ONSC (Sem. 6/ Elex./MSBTE) 1-2: Fiber Optic1 Nikhil TambeNo ratings yet

- CetexamnoticeDocument22 pagesCetexamnoticevandanakodan6No ratings yet

- 12je (A) - Major Test - 23092023Document13 pages12je (A) - Major Test - 23092023Sohan KrishnaNo ratings yet

- Personal - ATARNotes+ - ATAR Notes VCE Chemistry 3&4 Notes (2024-2025)Document122 pagesPersonal - ATARNotes+ - ATAR Notes VCE Chemistry 3&4 Notes (2024-2025)playstationus465No ratings yet

- HGVNBDocument14 pagesHGVNBiexNo ratings yet

- Apex Entrance Exam Test PaperDocument12 pagesApex Entrance Exam Test PaperApex Institute100% (1)

- 1 MagnetismDocument4 pages1 MagnetismBelly MenesesNo ratings yet

- Dynamics of Floating BodiesDocument5 pagesDynamics of Floating BodiesAnu ParameswaranNo ratings yet

- Top Student Chemistry PredictionsDocument153 pagesTop Student Chemistry Predictionsangelinenyaboke6No ratings yet

- Fre. Gravity A Geometrical Course PDFDocument465 pagesFre. Gravity A Geometrical Course PDFDavid Prieto100% (1)

- United States Patent: Kim-Habermehl Et Al. (10) Patent N0.: (45) Date of PatentDocument9 pagesUnited States Patent: Kim-Habermehl Et Al. (10) Patent N0.: (45) Date of PatentJoseph ChenNo ratings yet

- Lab 9 NaBH4 ReductionDocument4 pagesLab 9 NaBH4 ReductionAlison NguyenNo ratings yet

- UNIT III Oils and FatsDocument36 pagesUNIT III Oils and FatsShubham WarseNo ratings yet

- Lecture Note Electrical Machine Thermal DesignDocument32 pagesLecture Note Electrical Machine Thermal DesignchaucibaiNo ratings yet

- Solutions Set 5 AtkinsDocument18 pagesSolutions Set 5 AtkinsSakinah Himav RezeikaNo ratings yet

- Ce8353 SomDocument2 pagesCe8353 Somsrinithims78No ratings yet

- LASERDocument27 pagesLASERPavan KumarNo ratings yet

- Mettler Toledo CruciblesDocument28 pagesMettler Toledo CruciblesАлександра КондаковаNo ratings yet

- User Manual NeoDen IN12 Reflow OvenDocument24 pagesUser Manual NeoDen IN12 Reflow OvenAllan FerrariNo ratings yet

- GeographyDocument173 pagesGeographysadgh gyuhj100% (2)

- Bs5467 2016 Electriccables Thermosetting Insulated Armoured Cable Sofrated VoltagesDocument48 pagesBs5467 2016 Electriccables Thermosetting Insulated Armoured Cable Sofrated VoltagesAfiqul IslamNo ratings yet

- Shake PDFDocument15 pagesShake PDFGabriel EvanNo ratings yet

TDS Dynoadd F-1 15092022

TDS Dynoadd F-1 15092022

Uploaded by

vikram.iitkgp0 ratings0% found this document useful (0 votes)

1 views1 pageOriginal Title

TDS Dynoadd F-1 15092022 (3)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views1 pageTDS Dynoadd F-1 15092022

TDS Dynoadd F-1 15092022

Uploaded by

vikram.iitkgpCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

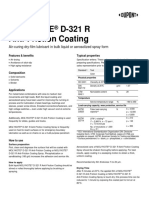

Dynoadd F-1

Anti-crater and flow additive

Excellent flow and levelling Typical applications and dosage

Improves substrate wetting Industrial coatings 0.1% - 1.0%

Coil coatings 0.1% - 1.0%

Eliminates craters and pinholes Automotive OEM 0.02% - 0.3%

Silicone-free Printing Inks 0.1% - 2.0%

Wood coatings 0.1% - 1.0%

Properties Dynoadd F-1 is compatible with most solvent-

Dynoadd F-1 is a polymeric, silicone-free general- borne and non-solvent coating systems

purpose flow and anti-crater additive for solvent- independently of lacquer chemistry.

borne coatings. It lowers surface tension in coating

formulations, thus improving substrate wetting. Technical Data

Surface defects like craters, cissing, and pinholes are Liquid polymer (100%).

eliminated. Dynoadd F-1 has balanced compatibility

with most backbone resins and has defoaming Typical

properties in a large number of formulations. Parameter Method

value

Dynoadd F-1 is an excellent choice in multiple-layer Clear

Appearance Subjective

coatings. liquid

Viscosity

5600 DIN 53019

mPa.s. 23°C

Specific

Strong gravity 1,060 ISO 15212-1

effect 25/4°C

Soluble in aromatic hydrocarbons, glycol ethers,

esters and alcohols.

Partially soluble in aliphatic hydrocarbons.

Insoluble in water.

Weak

effect

Flow / Wetting Foam Slip

Levelling control

Regulatory Status

EU-REACH- compliant.

A regulatory status of this product and MSDS can be

Method of addition obtained upon request at www.dynoadd.com

Addition is usually in the let-down stage. Dividing the

addition of Dynoadd F-1 between the pigment Storage Stability

dispersion and in the let-down can improve pigment Storage stability is three years from the date of

wetting and hiding power. production when stored at temperatures below

25 °C in closed containers.

REVISION 15/09/2022 WWW.DYNOADD.COM DYNOADD@DYNEA.COM

You might also like

- Piles in Permafrost Conditions PDFDocument45 pagesPiles in Permafrost Conditions PDFAurimas MiškinisNo ratings yet

- AEROSIL® 200: Description Typical ApplicationsDocument1 pageAEROSIL® 200: Description Typical ApplicationsAPEX SONNo ratings yet

- Yd-011 TdsDocument4 pagesYd-011 TdsOswaldo Manuel Ramirez Marin100% (2)

- TI Acronal 5522 PDFDocument1 pageTI Acronal 5522 PDFWahid KarolNo ratings yet

- Angus Zoldine Xl-29se Crosslinker TdsDocument9 pagesAngus Zoldine Xl-29se Crosslinker TdsAnkit MaheshwariNo ratings yet

- DYNOL 607 - G - Surfactant 0717 EN OIDocument2 pagesDYNOL 607 - G - Surfactant 0717 EN OIJian WenNo ratings yet

- Rheofinish 225D: Water Based Chemical Release AgentDocument2 pagesRheofinish 225D: Water Based Chemical Release Agentsarahsewell9No ratings yet

- LF200 TDSDocument3 pagesLF200 TDSRobert SkibaNo ratings yet

- Evonik-Surfynol DF-37 Dewebbing (Defoamer) Latex GlovesDocument2 pagesEvonik-Surfynol DF-37 Dewebbing (Defoamer) Latex GlovesherryNo ratings yet

- AEROSIL R 972 TDS EN EN TDS PV 52043842 en GB WORLDDocument1 pageAEROSIL R 972 TDS EN EN TDS PV 52043842 en GB WORLDeliteindustries.pkNo ratings yet

- Desmodur VP LS 2394 - en - 05573580 17844557 19844485Document4 pagesDesmodur VP LS 2394 - en - 05573580 17844557 19844485gUiLhErMe fAnTiNiNo ratings yet

- Joncryl-9532 TDSDocument2 pagesJoncryl-9532 TDSMohamed HalemNo ratings yet

- Dispersing Agent For Water-Based Systems Ionic Homopolymer DispersantDocument1 pageDispersing Agent For Water-Based Systems Ionic Homopolymer Dispersantumar buttNo ratings yet

- ADDITOL XL 123 N - EN - LetterDocument2 pagesADDITOL XL 123 N - EN - LetterFabio Enrique Gomez RamirezNo ratings yet

- Neorez 600Document1 pageNeorez 600Abhineet ShrivastavaNo ratings yet

- 901 104 01 Robond L Waterborne Laminating Adhesives North American Product GuideDocument4 pages901 104 01 Robond L Waterborne Laminating Adhesives North American Product GuidebrighterNo ratings yet

- A New APEO-free Surfactant Solution For The Paint - SolvayDocument24 pagesA New APEO-free Surfactant Solution For The Paint - Solvayichsan hakimNo ratings yet

- Tds Acronaleco702ap enDocument3 pagesTds Acronaleco702ap enShreyashi MukhopadhayNo ratings yet

- TDS - CRAYVALLAC® LA-150 - en - WWDocument1 pageTDS - CRAYVALLAC® LA-150 - en - WWrndsb.aopNo ratings yet

- Covestro PoliuretanoDocument24 pagesCovestro PoliuretanoRAFAEL MIERES100% (1)

- Tds Uniqflow 372s enDocument1 pageTds Uniqflow 372s enm daneshpourNo ratings yet

- Tds Uniqflow 372s enDocument1 pageTds Uniqflow 372s enm daneshpourNo ratings yet

- Dowsil US CF 2403Document2 pagesDowsil US CF 2403ShambhatiaNo ratings yet

- Acronal ECO 702 AP TI EDA Nov 07Document3 pagesAcronal ECO 702 AP TI EDA Nov 07nanoNo ratings yet

- Flexisperse™ 133N: Technical Data SheetDocument2 pagesFlexisperse™ 133N: Technical Data SheetalejandroNo ratings yet

- Architectural CoatingDocument28 pagesArchitectural CoatingDuc Nguyen100% (3)

- High Performance Substrate Wetting Agents Brand Superwetter FamilyDocument29 pagesHigh Performance Substrate Wetting Agents Brand Superwetter FamilyDương Minh MẫnNo ratings yet

- 0901 B 803808 EbffdDocument7 pages0901 B 803808 EbffdForeverNo ratings yet

- MAINCOTE HG-56 Acrylic Resin A Binder For Maintenance CoatingsDocument8 pagesMAINCOTE HG-56 Acrylic Resin A Binder For Maintenance CoatingsLong An ĐỗNo ratings yet

- DOW CORNING 3362N-Insulating Glass SealantDocument3 pagesDOW CORNING 3362N-Insulating Glass SealantTran The AnhNo ratings yet

- Nivapol Polem A 1170Document1 pageNivapol Polem A 1170sastra_anugrahaNo ratings yet

- PRIMAL™ HG-1000 Binder: Technical Data SheetDocument9 pagesPRIMAL™ HG-1000 Binder: Technical Data SheetLong An DoNo ratings yet

- Fosroc Nukote BGIIDocument4 pagesFosroc Nukote BGIIm.elsanee.cubicNo ratings yet

- LSR LC-50-2004Document3 pagesLSR LC-50-2004tarot.insights4uNo ratings yet

- ADDITOL-dry-CF100 EN A4Document2 pagesADDITOL-dry-CF100 EN A4Monserrat PérezNo ratings yet

- 24 391 01 Coatings and Inks Additive Selection GuideDocument16 pages24 391 01 Coatings and Inks Additive Selection GuideLong An DoNo ratings yet

- Acematt Ok 412Document1 pageAcematt Ok 412optimus_1404No ratings yet

- TDS-EN-Conflex PS - Rev 016-Aug21Document2 pagesTDS-EN-Conflex PS - Rev 016-Aug21LONG LASTNo ratings yet

- Genapol PF 20Document2 pagesGenapol PF 20Mohamed HalemNo ratings yet

- Coatings and Inks Additive: Selection GuideDocument16 pagesCoatings and Inks Additive: Selection GuideherryNo ratings yet

- Brochure EpotecDocument18 pagesBrochure Epotectrường phạmNo ratings yet

- Lapox ARF 11Document2 pagesLapox ARF 11Osama GabrNo ratings yet

- 2015 BASF Flexible-Packaging-Inks Landscape EL PDFDocument12 pages2015 BASF Flexible-Packaging-Inks Landscape EL PDFAgres KrismantonaNo ratings yet

- Data Sheet Dowcorning 111Document2 pagesData Sheet Dowcorning 111Nyoman RakaNo ratings yet

- Lanco PP 1362 DDocument2 pagesLanco PP 1362 DAkhtar aliNo ratings yet

- DYNOL™ 360: Description Technical DataDocument1 pageDYNOL™ 360: Description Technical DatatopguitarNo ratings yet

- Zinc Rich 1p pc102Document2 pagesZinc Rich 1p pc102livefreakNo ratings yet

- Desmodur N 3200Document4 pagesDesmodur N 3200محمد مقلدNo ratings yet

- Dodicor 2725 NFDocument3 pagesDodicor 2725 NFVenkatesha Perumal RamasamyNo ratings yet

- Desmodur Z 4470 BA: Type Form Supplied UsesDocument4 pagesDesmodur Z 4470 BA: Type Form Supplied Usessriatul2006No ratings yet

- Desmophen A 160 SN: Type Characterization Form Supplied UsesDocument2 pagesDesmophen A 160 SN: Type Characterization Form Supplied UsesFadi MagdyNo ratings yet

- Fosroc Renderoc LA55: Single Component Free Flowing Low Alkali Micro Concrete Uses PropertiesDocument2 pagesFosroc Renderoc LA55: Single Component Free Flowing Low Alkali Micro Concrete Uses PropertiesVincent JavateNo ratings yet

- Albafix FRDDocument7 pagesAlbafix FRDsaskoNo ratings yet

- 843 02170 01 Acrysol dr180 Rheology Modifier TdsDocument3 pages843 02170 01 Acrysol dr180 Rheology Modifier TdsAhmed ElgendyNo ratings yet

- Water-Based Single Component High Gloss Acrylic For DTM and Topcoat ApplicationsDocument6 pagesWater-Based Single Component High Gloss Acrylic For DTM and Topcoat ApplicationsamitNo ratings yet

- Carboguard 703Document2 pagesCarboguard 703Achraf BoudayaNo ratings yet

- Neusilin TDS US2Document1 pageNeusilin TDS US2Rohit RanjanNo ratings yet

- 高溫油脂MOLYKOTE D-321 R Anti-Friction 71-0219G-01Document2 pages高溫油脂MOLYKOTE D-321 R Anti-Friction 71-0219G-01If ChenNo ratings yet

- Acronal Ds 6262 TdsDocument1 pageAcronal Ds 6262 TdsLong An DoNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (7)

- Maharashtra HSC Chemistry Paper 2-Target PublicationDocument45 pagesMaharashtra HSC Chemistry Paper 2-Target PublicationKhanAbdullah100% (1)

- Template Uji Umur Simpan Kadar Air KritisDocument14 pagesTemplate Uji Umur Simpan Kadar Air KritisSusi Nur KusumawatiNo ratings yet

- Lab 10Document15 pagesLab 10Tanzeela KhalidNo ratings yet

- EarthQuake Design As Per Is-1893-2014 and Wind Load Calculation of 325 KL OHtDocument14 pagesEarthQuake Design As Per Is-1893-2014 and Wind Load Calculation of 325 KL OHtsanju middya100% (1)

- Derra J Phys D38 2995 UHP Proj ReviewDocument17 pagesDerra J Phys D38 2995 UHP Proj ReviewSINGGIH KSNo ratings yet

- Pipeline Corrosion Management CapabilityDocument2 pagesPipeline Corrosion Management CapabilityMajdi Abdulrahman Mohamed RahamaNo ratings yet

- Photosynthesis and The Carbon Cycle: Lower Secondary Checkpoint Year 8Document20 pagesPhotosynthesis and The Carbon Cycle: Lower Secondary Checkpoint Year 8Youssef MohamedNo ratings yet

- Of ONSC (Sem. 6/ Elex./MSBTE) 1-2: Fiber OpticDocument22 pagesOf ONSC (Sem. 6/ Elex./MSBTE) 1-2: Fiber Optic1 Nikhil TambeNo ratings yet

- CetexamnoticeDocument22 pagesCetexamnoticevandanakodan6No ratings yet

- 12je (A) - Major Test - 23092023Document13 pages12je (A) - Major Test - 23092023Sohan KrishnaNo ratings yet

- Personal - ATARNotes+ - ATAR Notes VCE Chemistry 3&4 Notes (2024-2025)Document122 pagesPersonal - ATARNotes+ - ATAR Notes VCE Chemistry 3&4 Notes (2024-2025)playstationus465No ratings yet

- HGVNBDocument14 pagesHGVNBiexNo ratings yet

- Apex Entrance Exam Test PaperDocument12 pagesApex Entrance Exam Test PaperApex Institute100% (1)

- 1 MagnetismDocument4 pages1 MagnetismBelly MenesesNo ratings yet

- Dynamics of Floating BodiesDocument5 pagesDynamics of Floating BodiesAnu ParameswaranNo ratings yet

- Top Student Chemistry PredictionsDocument153 pagesTop Student Chemistry Predictionsangelinenyaboke6No ratings yet

- Fre. Gravity A Geometrical Course PDFDocument465 pagesFre. Gravity A Geometrical Course PDFDavid Prieto100% (1)

- United States Patent: Kim-Habermehl Et Al. (10) Patent N0.: (45) Date of PatentDocument9 pagesUnited States Patent: Kim-Habermehl Et Al. (10) Patent N0.: (45) Date of PatentJoseph ChenNo ratings yet

- Lab 9 NaBH4 ReductionDocument4 pagesLab 9 NaBH4 ReductionAlison NguyenNo ratings yet

- UNIT III Oils and FatsDocument36 pagesUNIT III Oils and FatsShubham WarseNo ratings yet

- Lecture Note Electrical Machine Thermal DesignDocument32 pagesLecture Note Electrical Machine Thermal DesignchaucibaiNo ratings yet

- Solutions Set 5 AtkinsDocument18 pagesSolutions Set 5 AtkinsSakinah Himav RezeikaNo ratings yet

- Ce8353 SomDocument2 pagesCe8353 Somsrinithims78No ratings yet

- LASERDocument27 pagesLASERPavan KumarNo ratings yet

- Mettler Toledo CruciblesDocument28 pagesMettler Toledo CruciblesАлександра КондаковаNo ratings yet

- User Manual NeoDen IN12 Reflow OvenDocument24 pagesUser Manual NeoDen IN12 Reflow OvenAllan FerrariNo ratings yet

- GeographyDocument173 pagesGeographysadgh gyuhj100% (2)

- Bs5467 2016 Electriccables Thermosetting Insulated Armoured Cable Sofrated VoltagesDocument48 pagesBs5467 2016 Electriccables Thermosetting Insulated Armoured Cable Sofrated VoltagesAfiqul IslamNo ratings yet

- Shake PDFDocument15 pagesShake PDFGabriel EvanNo ratings yet