Professional Documents

Culture Documents

Installation Process: TITLE: EQUIPMENT/FURNISHING - 751A3000200-200 - Sink Replacement

Installation Process: TITLE: EQUIPMENT/FURNISHING - 751A3000200-200 - Sink Replacement

Uploaded by

agungrizky.batCopyright:

Available Formats

You might also like

- Caterpillar Cat 303.5 D Mini Excavator (Prefix RHP) Service Repair Manual (RHP00001 and Up)Document23 pagesCaterpillar Cat 303.5 D Mini Excavator (Prefix RHP) Service Repair Manual (RHP00001 and Up)kfmuseddkNo ratings yet

- Caterpillar Cat M318D MH Wheeled Excavator (Prefix P9M) Service Repair Manual (P9M00001 and Up) PDFDocument21 pagesCaterpillar Cat M318D MH Wheeled Excavator (Prefix P9M) Service Repair Manual (P9M00001 and Up) PDFfkdmma100% (2)

- Caterpillar Cat 304CR Mini Hydraulic Excavator (Prefix NAD) Service Repair Manual (NAD00001 and Up)Document23 pagesCaterpillar Cat 304CR Mini Hydraulic Excavator (Prefix NAD) Service Repair Manual (NAD00001 and Up)kfmuseddk100% (2)

- Caterpillar Cat 304.5 Mini Hydraulic Excavator (Prefix ANR) Service Repair Manual (ANR00001 and Up)Document24 pagesCaterpillar Cat 304.5 Mini Hydraulic Excavator (Prefix ANR) Service Repair Manual (ANR00001 and Up)kfmuseddk100% (1)

- Caterpillar Cat 302.5C Mini Hydraulic Excavator (Prefix GBB) Service Repair Manual (GBB00001 and Up)Document20 pagesCaterpillar Cat 302.5C Mini Hydraulic Excavator (Prefix GBB) Service Repair Manual (GBB00001 and Up)kfmuseddk100% (1)

- Caterpillar Cat 303.5 Mini Hydraulic Excavator (Prefix DCH) Service Repair Manual (DCH00001 and Up) PDFDocument21 pagesCaterpillar Cat 303.5 Mini Hydraulic Excavator (Prefix DCH) Service Repair Manual (DCH00001 and Up) PDFfkdmma50% (4)

- Caterpillar Cat 315C EXCAVATOR (Prefix CFL) Service Repair Manual (CFL00001 and Up)Document27 pagesCaterpillar Cat 315C EXCAVATOR (Prefix CFL) Service Repair Manual (CFL00001 and Up)kfm8seuudu67% (3)

- Astm E3-11Document12 pagesAstm E3-11Alejandro OrtizNo ratings yet

- Caterpillar Cat 303.5 Mini Hydraulic Excavator (Prefix AFW) Service Repair Manual (AFW00001 and Up) PDFDocument23 pagesCaterpillar Cat 303.5 Mini Hydraulic Excavator (Prefix AFW) Service Repair Manual (AFW00001 and Up) PDFfkdmma100% (1)

- Cylinder Head Valves: EspecificacionesDocument9 pagesCylinder Head Valves: Especificacionesgalvis1020No ratings yet

- Caterpillar Cat M316F Wheeled Excavator (Prefix F6N) Service Repair Manual (F6N00001 and Up) PDFDocument20 pagesCaterpillar Cat M316F Wheeled Excavator (Prefix F6N) Service Repair Manual (F6N00001 and Up) PDFfkdmmaNo ratings yet

- Caterpillar Cat M316C WHEELED Excavator (Prefix BDX) Service Repair Manual (BDX02001 and Up) PDFDocument26 pagesCaterpillar Cat M316C WHEELED Excavator (Prefix BDX) Service Repair Manual (BDX02001 and Up) PDFfkdmmaNo ratings yet

- NE04 014revbDocument23 pagesNE04 014revbMarlene Yuriserll Ruiz MuñozNo ratings yet

- Offwing Alide InstallDocument16 pagesOffwing Alide InstallAndreea MăgureanuNo ratings yet

- Pisston Pump VibratoryDocument12 pagesPisston Pump VibratorySteven Y.MNo ratings yet

- Caterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix KB3) Service Repair Manual (KB300001 and Up)Document24 pagesCaterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix KB3) Service Repair Manual (KB300001 and Up)rpoy9396615No ratings yet

- Cylinder LinersDocument4 pagesCylinder Linersma.powersourceNo ratings yet

- Caterpillar Cat 304.5 Mini Hydraulic Excavator (Prefix WAK) Service Repair Manual (WAK00001 and Up)Document23 pagesCaterpillar Cat 304.5 Mini Hydraulic Excavator (Prefix WAK) Service Repair Manual (WAK00001 and Up)kfmuseddk100% (1)

- Caterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix TSL) Service Repair Manual (TSL00001 and Up)Document23 pagesCaterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix TSL) Service Repair Manual (TSL00001 and Up)rpoy9396615No ratings yet

- Caterpillar Cat 226 Skid Steer Loader (Prefix 5FZ) Service Repair Manual (5FZ00001-06699)Document24 pagesCaterpillar Cat 226 Skid Steer Loader (Prefix 5FZ) Service Repair Manual (5FZ00001-06699)rpoy9396615No ratings yet

- Transmission - Disassemble: Welcome: x350kxmDocument25 pagesTransmission - Disassemble: Welcome: x350kxmSIA Stats RENTNo ratings yet

- 313B and 313B CR Excavator: Service Repair ManualDocument27 pages313B and 313B CR Excavator: Service Repair Manualgoogle accountNo ratings yet

- c32 Cylinder HeadDocument5 pagesc32 Cylinder HeadHaidar SareeniNo ratings yet

- Caterpillar Cat 226B3 SKID STEER LOADER (Prefix AS2) Service Repair Manual (AS200001 and Up)Document23 pagesCaterpillar Cat 226B3 SKID STEER LOADER (Prefix AS2) Service Repair Manual (AS200001 and Up)rpoy9396615No ratings yet

- Caterpillar Cat 216B3 Skid Steer Loader (Prefix JXM) Service Repair Manual (JXM00001 and Up)Document22 pagesCaterpillar Cat 216B3 Skid Steer Loader (Prefix JXM) Service Repair Manual (JXM00001 and Up)rpoy9396615No ratings yet

- 777D A-Frame PreloadingDocument3 pages777D A-Frame PreloadingsatyaNo ratings yet

- Cylinder Liner ProjectionDocument4 pagesCylinder Liner ProjectionFernando Daniel Saez VillarrealNo ratings yet

- Unpacking and Installation Procedure For The Main Body and OptionsDocument11 pagesUnpacking and Installation Procedure For The Main Body and OptionsNistor SilviuNo ratings yet

- Caterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix ESL) Service Repair Manual (ESL00001 and Up)Document27 pagesCaterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix ESL) Service Repair Manual (ESL00001 and Up)rpoy9396615No ratings yet

- Alternator - Disassemble: Shutdown SIS Previous ScreenDocument11 pagesAlternator - Disassemble: Shutdown SIS Previous ScreennobodymagdesignNo ratings yet

- Caterpillar Cat 245 EXCAVATOR (Prefix 95V) Service Repair Manual (95V00471 and Up)Document26 pagesCaterpillar Cat 245 EXCAVATOR (Prefix 95V) Service Repair Manual (95V00471 and Up)rpoy9396615No ratings yet

- Vibracion en Los Tractores D285AxDocument6 pagesVibracion en Los Tractores D285AxJose A. Basanta H.No ratings yet

- Montagem e Desmontagem Da Camisa 3306Document3 pagesMontagem e Desmontagem Da Camisa 3306Lucas ApostoloNo ratings yet

- Dokumen - Tips - Caterpillar Cat 315c L Excavator Prefix CJC Service Repair Manual cjc00001 and Up 1622227837Document26 pagesDokumen - Tips - Caterpillar Cat 315c L Excavator Prefix CJC Service Repair Manual cjc00001 and Up 1622227837Luis Carlos Salazar DelgadoNo ratings yet

- Caterpillar Cat 226B3 SKID STEER LOADER (Prefix MWD) Service Repair Manual (MWD00001 and Up)Document23 pagesCaterpillar Cat 226B3 SKID STEER LOADER (Prefix MWD) Service Repair Manual (MWD00001 and Up)rpoy9396615No ratings yet

- Caterpillarcatcs 683evibratorycompactorprefixagrservicerepairmanualagr00001andup 230813075534 58291ec7Document33 pagesCaterpillarcatcs 683evibratorycompactorprefixagrservicerepairmanualagr00001andup 230813075534 58291ec7Manuel Martinez MoratoNo ratings yet

- Desarme MTR HidrostaticoDocument12 pagesDesarme MTR HidrostaticoIvan CastellanosNo ratings yet

- Caterpillar Cat M318C MH WHEELED EXCAVATOR (Prefix BEB) Service Repair Manual (BEB02001 and Up) PDFDocument26 pagesCaterpillar Cat M318C MH WHEELED EXCAVATOR (Prefix BEB) Service Repair Manual (BEB02001 and Up) PDFfkdmmaNo ratings yet

- Polea Del Cigüeñal - Quitar e Instalar (SENR5553)Document3 pagesPolea Del Cigüeñal - Quitar e Instalar (SENR5553)Grover Escobal MendezNo ratings yet

- Aftercooler - Remove Removal Procedure: Shutdown SIS Previous ScreenDocument3 pagesAftercooler - Remove Removal Procedure: Shutdown SIS Previous ScreenTASHKEELNo ratings yet

- Sebf 8269 Привод 3408Document16 pagesSebf 8269 Привод 3408mohamed hamedNo ratings yet

- 320c Excavadora Cat Desarmado y Armado Bombas HidraulicasDocument20 pages320c Excavadora Cat Desarmado y Armado Bombas HidraulicasJuan camilo Cárdenas garciaNo ratings yet

- Caterpillar Cat 236B SKID STEER LOADER (Prefix HEN) Service Repair Manual (HEN00001-06749)Document22 pagesCaterpillar Cat 236B SKID STEER LOADER (Prefix HEN) Service Repair Manual (HEN00001-06749)rpoy9396615No ratings yet

- Fuel Transfer Pump - Disassemble (SENR1126-36)Document4 pagesFuel Transfer Pump - Disassemble (SENR1126-36)redminote12pro.5garNo ratings yet

- Caterpillar Cat 301.8C Mini Hydraulic Excavator (Prefix JSB) Service Repair Manual (JSB00001 and Up) PDFDocument22 pagesCaterpillar Cat 301.8C Mini Hydraulic Excavator (Prefix JSB) Service Repair Manual (JSB00001 and Up) PDFfkdmmaNo ratings yet

- New Front Crankshaft Seals and New Rear Crankshaft Seals Are Now in Production (1160, 1161)Document6 pagesNew Front Crankshaft Seals and New Rear Crankshaft Seals Are Now in Production (1160, 1161)TASHKEEL100% (1)

- Cylinder Liner ProjectionDocument3 pagesCylinder Liner ProjectionSreepriodas RoyNo ratings yet

- Implement Pump - DisassembleDocument13 pagesImplement Pump - DisassembleLeo PerezNo ratings yet

- Arme y Desarme de Bomba Hidraulica 320CDocument10 pagesArme y Desarme de Bomba Hidraulica 320CIngemak UrbanoNo ratings yet

- Caterpillar Cat 329DL Excavator (Prefix TPM) Service Repair Manual (TPM00001 and Up) PDFDocument25 pagesCaterpillar Cat 329DL Excavator (Prefix TPM) Service Repair Manual (TPM00001 and Up) PDFfkdmmaNo ratings yet

- D342 Vehicular Engine 76V00001-00504 (MaDocument5 pagesD342 Vehicular Engine 76V00001-00504 (MaOmar SuazoNo ratings yet

- Caterpillar Cat M322D MH WHEELED EXCAVATOR (Prefix W2T) Service Repair Manual (W2T00001 and Up) PDFDocument20 pagesCaterpillar Cat M322D MH WHEELED EXCAVATOR (Prefix W2T) Service Repair Manual (W2T00001 and Up) PDFfkdmmaNo ratings yet

- Caterpillar Cat M315D2 Wheeled Excavator (Prefix CA4) Service Repair Manual (CA400001 and Up) PDFDocument27 pagesCaterpillar Cat M315D2 Wheeled Excavator (Prefix CA4) Service Repair Manual (CA400001 and Up) PDFfkdmma100% (1)

- Caterpillar Cat 329DL EXCAVATOR (Prefix RSK) Service Repair Manual (RSK00001 and Up) PDFDocument24 pagesCaterpillar Cat 329DL EXCAVATOR (Prefix RSK) Service Repair Manual (RSK00001 and Up) PDFfkdmmaNo ratings yet

- BM - 2000 Service Manual 2Document77 pagesBM - 2000 Service Manual 2yesprintsydneyNo ratings yet

- Caterpillar Cat 216B3 Skid Steer Loader (Prefix DSN) Service Repair Manual (DSN00001 and Up)Document27 pagesCaterpillar Cat 216B3 Skid Steer Loader (Prefix DSN) Service Repair Manual (DSN00001 and Up)rpoy9396615No ratings yet

- Auxiliary Water PumpDocument3 pagesAuxiliary Water PumpGolbert GolbiNo ratings yet

- Cabine RomoveDocument7 pagesCabine RomoveANo ratings yet

- Motor 60Z02152 - 02 (1) CAT 3306Document4 pagesMotor 60Z02152 - 02 (1) CAT 3306Ismael De Jesus Andrade50% (2)

- 08 Engine MechanicalDocument80 pages08 Engine MechanicalmadcostaNo ratings yet

- A Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsFrom EverandA Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsNo ratings yet

- MS51029 20 - Military Fasteners ComDocument2 pagesMS51029 20 - Military Fasteners Comagungrizky.batNo ratings yet

- Easa Sib 2016-20R1 1Document2 pagesEasa Sib 2016-20R1 1agungrizky.batNo ratings yet

- Easa Ad 2023-0209 1Document4 pagesEasa Ad 2023-0209 1agungrizky.batNo ratings yet

- Easa Ad 2024-0038 1Document10 pagesEasa Ad 2024-0038 1agungrizky.batNo ratings yet

- Title: Communications - Cids - Introduce Cids Version - 59B: Service Bulletin Revision Transmittal SheetDocument48 pagesTitle: Communications - Cids - Introduce Cids Version - 59B: Service Bulletin Revision Transmittal Sheetagungrizky.batNo ratings yet

- CE 512 Ce Laws, Ethics, Codes, and Standards Report No. 6 Standard Construction ProcessesDocument76 pagesCE 512 Ce Laws, Ethics, Codes, and Standards Report No. 6 Standard Construction ProcessesDM CINo ratings yet

- Overview Fusion Welding Standards PDFDocument1 pageOverview Fusion Welding Standards PDFHà Việt ĐứcNo ratings yet

- Pt. Wufu Steel Indonesia - Harga Besi Hollow Stainless SteelDocument5 pagesPt. Wufu Steel Indonesia - Harga Besi Hollow Stainless Steelcecep mahmudinNo ratings yet

- Spark DepoDocument5 pagesSpark Deporehan0747No ratings yet

- Instructions To Bidders: Arcenciel LebanonDocument23 pagesInstructions To Bidders: Arcenciel Lebanonfacebook securityNo ratings yet

- Coimisiún Na Scrúduithe Stáit State Examinations Commission: Leaving Certificate Examination, 2018Document12 pagesCoimisiún Na Scrúduithe Stáit State Examinations Commission: Leaving Certificate Examination, 2018Diaa SaberNo ratings yet

- Valvula de Tormenta PeroloDocument1 pageValvula de Tormenta Perololalo lopezNo ratings yet

- Wet Chemical Deep Fat FryerDocument64 pagesWet Chemical Deep Fat FryerSergei KurpishNo ratings yet

- Superalloys - A Primer and HistoryDocument4 pagesSuperalloys - A Primer and Historyhemakumars100% (1)

- Comparative Evaluation of Concrete Properties With Varying ProportionsDocument11 pagesComparative Evaluation of Concrete Properties With Varying ProportionsAbdulkadir AdamNo ratings yet

- Sleepers For Railway TrackDocument14 pagesSleepers For Railway TrackChukhu Aane DuiNo ratings yet

- Anchor Bolt DesignDocument8 pagesAnchor Bolt DesignNadir Khattak Jr.No ratings yet

- Why Utkarsh PVC Pipes Is PopularDocument11 pagesWhy Utkarsh PVC Pipes Is PopularUtkarsh India LTD.No ratings yet

- ROAD & PAVEMENT Draft ModelDocument1 pageROAD & PAVEMENT Draft ModelKannan MurugesanNo ratings yet

- Schlesinger Catalogue PDFDocument24 pagesSchlesinger Catalogue PDFcotecobein19No ratings yet

- Bridge Engineering - Definition, Types, Design and Construction of BridgesDocument6 pagesBridge Engineering - Definition, Types, Design and Construction of BridgesAshis MingalaNo ratings yet

- Product Catalogue 2012-2013Document220 pagesProduct Catalogue 2012-2013Ilija RunjajicNo ratings yet

- كتالوج خزانات الزامل الدفان 2Document24 pagesكتالوج خزانات الزامل الدفان 2Ahmed FathyNo ratings yet

- Docum PDFDocument8 pagesDocum PDFsivagaaneshNo ratings yet

- 09 Breakdown BOQ - Without PriceDocument8 pages09 Breakdown BOQ - Without PricesahilNo ratings yet

- Professional ElectiveDocument4 pagesProfessional ElectiveMayank ShrivastavaNo ratings yet

- Hertel Indexable InsertsDocument2 pagesHertel Indexable InsertsDamir MarijanovicNo ratings yet

- Mizan Tepi University: Collage of Engineering and TechnologyDocument18 pagesMizan Tepi University: Collage of Engineering and TechnologyANDLENATUNo ratings yet

- Experiment No: - 4 Shell Moulding Process AimDocument5 pagesExperiment No: - 4 Shell Moulding Process AimDhananjay Shimpi100% (1)

- Fire Stop InstallationDocument3 pagesFire Stop InstallationAristo OnanNo ratings yet

- Valtech - KR: Valve Inspection and Testing Inspection ValvesDocument11 pagesValtech - KR: Valve Inspection and Testing Inspection ValvesHARSHANo ratings yet

- X-Tile CTADocument2 pagesX-Tile CTABernardo GarciaNo ratings yet

- Welding Rod Calculation 2024Document4 pagesWelding Rod Calculation 2024jcabenian8No ratings yet

Installation Process: TITLE: EQUIPMENT/FURNISHING - 751A3000200-200 - Sink Replacement

Installation Process: TITLE: EQUIPMENT/FURNISHING - 751A3000200-200 - Sink Replacement

Uploaded by

agungrizky.batOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Process: TITLE: EQUIPMENT/FURNISHING - 751A3000200-200 - Sink Replacement

Installation Process: TITLE: EQUIPMENT/FURNISHING - 751A3000200-200 - Sink Replacement

Uploaded by

agungrizky.batCopyright:

Available Formats

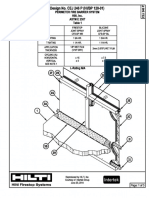

INSTALLATION PROCESS

TITLE : EQUIPMENT/FURNISHING – 751A3000200-200 –

SINK REPLACEMENT

1. PLANNING INFORMATION

A. EFFECTIVITY

This procedure is valid for Smart galleys P/N SIMAXXXHXXYYYZZ .

B. CONCURRENT REQUIREMENTS

None

C. REASON

This procedure describes the process to remove and replace galley sink P/N

751A3000200-200.

D. DESCRIPTION

This procedure gives instructions to :

- Remove installed sink

- Install new sink.

E. APPLICATION

On Smart Galleys SIMAXXXH11YYYZZ equipped with a sink.

INITIAL ISSUE : JAN 24/19 IP-751A3000200

REVISION No : 0 PAGE : 1 of 8

INSTALLATION PROCESS

2. INFORMATION ON MATERIAL

A. NECESSARY MATERIAL FOR EACH EQUIPMENT

ITEM PART NUMBER Qty DESCRIPTION

001 751A3000200-200 1 SINK

002 751A3000209-200 4 SPACER

003 RTV 108 AR ADHESIVE

004 CAF 4 AR SEALANT

005 CAF 33 AR SEALANT

006 RTV 796 AR SEALANT

007 11713 AR RAL 9007 SILICONE

B. TOOLING

- Standard tools.

- Sandpaper grain 80.

INITIAL ISSUE : JAN 24/19 IP-751A3000200

REVISION No : 0 PAGE : 2 of 8

INSTALLATION PROCESS

-

3. OPERATING INSTRUCTIONS

A. PRELIMINARY STEPS

The work can be done in aircraft or in a workshop.

Take CMM with IPL 25-36-01.

B. OPERATING PROCEDURE

(1) Sink removal

1 Open waste bin compartment door.

2 Remove waste bin from the waste bin compartment.

3 Unscrew and remove two screws (300) and two screws (310) CMM 25-36-

01 Figure 12 (sheet 3 of 3) / GRAPHIC 25-36-01-950-029-A01. Keep

screws for reinstallation.

4 Remove sheet metal (290) CMM 25-36-01 Figure 12 (sheet 3 of 3) /

GRAPHIC 25-36-01-950-029-A01. Keep sheet metal for reinstallation.

5 Unscrew and remove two screws (330) CMM 25-36-01 Figure 12 (sheet 3

of 3) / GRAPHIC 25-36-01-950-029-A01. Keep screws for reinstallation.

6 Remove sheet metal (320) CMM 25-36-01 Figure 12 (sheet 3 of 3) /

GRAPHIC 25-36-01-950-029-A01. Keep sheet metal for reinstallation.

7 Unscrew and remove one screw (200) and one nut (210) CMM 25-36-01

Figure 12 (sheet 2 of 3) / GRAPHIC 25-36-01-950-029-A01. Keep screw

and nut for reinstallation.

8 Lift away calking press (250) from the sink using a scrapper and pull and

remove assembly made of items (230), (240), (250) CMM 25-36-01 Figure

12 (sheet 2 of 3) / GRAPHIC 25-36-01-950-029-A01. Keep assembly for

reinstallation.

9 On siphon assy, unscrew nut (1) Figure 1 and pull backward axis (2)

Figure 1 so that plug (3) Figure 1 can be pulled out.

10 Pull out and remove plug (3) Figure 1. Keep plug (3) for reinstallation.

11 Grab the siphon body (4) Figure 1 and unscrew nut (5) Figure 1. Keep nut

(5) for reinstallation.

INITIAL ISSUE : JAN 24/19 IP-751A3000200

REVISION No : 0 PAGE : 3 of 8

INSTALLATION PROCESS

12 In the waste bin compartment, unscrew and remove four screws (160) and

four washers (170) CMM 25-36-01 Figure 12 (sheet 2 of 3) / GRAPHIC

25-36-01-950-029-A01

13 Using a scrapper, lift away and remove sink (150) equipped with spacers

(180). Discard sink equipped with spacers.

(3)

(5)

Above sink

Under sink

(1)

(4)

(2)

FIGURE 1

SIPHON ASSEMBLY

INITIAL ISSUE : JAN 24/19 IP-751A3000200

REVISION No : 0 PAGE : 4 of 8

INSTALLATION PROCESS

(2) Surface preparation for installation

1 Clean sink compartment panels of all trace of adhesive.

2 Clean removed nut (5) Figure 1 of all trace of adhesive.

3 Clean calking press (250) CMM 25-36-01 Figure 12 (sheet 2 of 3) /

GRAPHIC 25-36-01-950-029-A01 of all trace of sealant.

4 Clean waste bin compartment panels and sheet metal (340) and (360)

CMM 25-36-01 Figure 12 (sheet 3 of 3) / GRAPHIC 25-36-01-950-029-

A01 of all trace of sealant.

5 Sand sink (001) inner and lower areas according to Figure 2 with

sandpaper grain 80.

6 Sand four spacers (002) upper surface according to Figure 2 with

sandpaper grain 80.

SINK UPPER

SURFACE SINK LOWER

SURFACE

SPACERS

Sand yellow areas

FIGURE 2

SINK SANDED AREAS (YELLOW AREAS)

INITIAL ISSUE : JAN 24/19 IP-751A3000200

REVISION No : 0 PAGE : 5 of 8

INSTALLATION PROCESS

(3) Sink installation

1 Install new spacers (002) (four places) on the sink compartment horizontal

panel.

2 Install and tighten four removed screws (160) with washers (170) CMM

25-36-01 Figure 12 (sheet 2 of 3) / GRAPHIC 25-36-01-950-029-A01.

3 Degrease sink compartment horizontal panel, spacer sanded area and

sink lower surface sanded area with a clean lint-free cloth using

Trichloroethane.

4 Fill the sink lower surface sanded area with adhesive (003) with enough

thickness so that the adhesive is in contact with sink compartment

horizontal panel when the sink will be installed.

5 Install the sink in position on the sink compartment horizontal panel.

6 Protect the surface of the sink and apply an evenly pressure (with weights)

on sink during adhesive polymerization (2 hours).

7 Remove weights and protection from the sink.

8 Degrease lower surface of removed nut (5) Figure 1 (surface to be in

contact with the sink when installed) and the sanded area of the upper

surface of the sink with a clean lint-free cloth using Trichloroethane.

9 Apply evenly a thin coat of adhesive (003) on the lower surface of the

removed nut (5) Figure 1.

10 Grab the siphon body (4) Figure 1 and install and tighten nut (5) Figure 1.

11 Remove excess of adhesive (003) around nut (5) Figure 1.

12 Insert plug (3) Figure 1 in siphon plug hole. Take care of the position of

the hole in the plug so that axis (2) Figure 1 can be inserted in the plug (3)

Figure 1 hole.

13 Insert axis (2) Figure 1 in plug (3) Figure 1 hole.

14 Install and tighten nut (1) Figure 1 with sealant (003)

15 Degrease lower surface of calking press (250) CMM 25-36-01 Figure 12

(sheet 2 of 3) / GRAPHIC 25-36-01-950-029-A01 (surface to be in contact

with the sink when installed) and the corresponding area of the upper

surface of the sink with a clean lint-free cloth using Trichloroethane.

INITIAL ISSUE : JAN 24/19 IP-751A3000200

REVISION No : 0 PAGE : 6 of 8

INSTALLATION PROCESS

16 Apply evenly a thin coat of sealant (004) on the lower surface of the

calking press (250) CMM 25-36-01 Figure 12 (sheet 2 of 3) / GRAPHIC

25-36-01-950-029-A01.

17 Insert the removed assembly made of items (230), (240), (250) CMM 25-

36-01 Figure 12 (sheet 2 of 3) / GRAPHIC 25-36-01-950-029-A01 through

the sink hole. Take care of the position of the pin located inside the calking

press as shown in CMM 25-36-01 Figure 12 (sheet 2 of 3) / GRAPHIC 25-

36-01-950-029-A01.

18 Insert axis (240) in link spring (220) hole CMM 25-36-01 Figure 12 (sheet

2 of 3) / GRAPHIC 25-36-01-950-029-A01

19 Insert one removed screw (200) CMM 25-36-01 Figure 12 (sheet 2 of 3) /

GRAPHIC 25-36-01-950-029-A01 in spring lower hook.

20 Install and tighten one removed screw (200) with one removed nut (210)

on spring link (220) CMM 25-36-01 Figure 12 (sheet 2 of 3) / GRAPHIC

25-36-01-950-029-A01.

21 Push operating button (230) Figure 12 (sheet 2 of 3) / GRAPHIC 25-36-

01-950-029-A01 and check that the siphon plug opens and closes

properly. If needed, adjust the position of link spring (220) CMM 25-36-01

Figure 12 (sheet 2 of 3) / GRAPHIC 25-36-01-950-029-A01 for proper

operation.

22 Fill the sink with water until the draining cap is fully covered by water.

23 After one hour, check the water thighteness of the connection between

sink and siphon and that no leak can be found under the sink at any point

of the draining line.

24 Push the operating button (230) CMM 25-36-01 Figure 12 (sheet 2 of 3) /

GRAPHIC 25-36-01-950-029-A01 and drain the water.

25 Install removed sheet metal (320) CMM 25-36-01 Figure 12 (sheet 3 of 3)

/ GRAPHIC 25-36-01-950-029-A01.

26 Install and tighten two removed screws (330) CMM 25-36-01 Figure 12

(sheet 3 of 3) / GRAPHIC 25-36-01-950-029-A01.

27 Install removed sheet metal (290) CMM 25-36-01 Figure 12 (sheet 3 of 3)

/ GRAPHIC 25-36-01-950-029-A01.

28 Install and tighten two removed screws (300) and two removed screws

(310) CMM 25-36-01 Figure 12 (sheet 3 of 3) / GRAPHIC 25-36-01-950-

029-A01.

INITIAL ISSUE : JAN 24/19 IP-751A3000200

REVISION No : 0 PAGE : 7 of 8

INSTALLATION PROCESS

29 Apply a sealant (005) bead on the junction of the sheet metal plates and

the waste bin compartment panels according to figure 3.

30 Apply a sealant (006) bead all around the sink at the junction with panels

and edges of the sink compartment.

31 Apply a sealant (007) bead at the junction of the sink and the edges at the

front of the sink compartment.

32 Install waste bin in waste bin compartment.

33 Close waste bin compartment door.

Sealant bead according to

green line

FIGURE 3

SEALANT BEAD INSTALLATION

INITIAL ISSUE : JAN 24/19 IP-751A3000200

REVISION No : 0 PAGE : 8 of 8

You might also like

- Caterpillar Cat 303.5 D Mini Excavator (Prefix RHP) Service Repair Manual (RHP00001 and Up)Document23 pagesCaterpillar Cat 303.5 D Mini Excavator (Prefix RHP) Service Repair Manual (RHP00001 and Up)kfmuseddkNo ratings yet

- Caterpillar Cat M318D MH Wheeled Excavator (Prefix P9M) Service Repair Manual (P9M00001 and Up) PDFDocument21 pagesCaterpillar Cat M318D MH Wheeled Excavator (Prefix P9M) Service Repair Manual (P9M00001 and Up) PDFfkdmma100% (2)

- Caterpillar Cat 304CR Mini Hydraulic Excavator (Prefix NAD) Service Repair Manual (NAD00001 and Up)Document23 pagesCaterpillar Cat 304CR Mini Hydraulic Excavator (Prefix NAD) Service Repair Manual (NAD00001 and Up)kfmuseddk100% (2)

- Caterpillar Cat 304.5 Mini Hydraulic Excavator (Prefix ANR) Service Repair Manual (ANR00001 and Up)Document24 pagesCaterpillar Cat 304.5 Mini Hydraulic Excavator (Prefix ANR) Service Repair Manual (ANR00001 and Up)kfmuseddk100% (1)

- Caterpillar Cat 302.5C Mini Hydraulic Excavator (Prefix GBB) Service Repair Manual (GBB00001 and Up)Document20 pagesCaterpillar Cat 302.5C Mini Hydraulic Excavator (Prefix GBB) Service Repair Manual (GBB00001 and Up)kfmuseddk100% (1)

- Caterpillar Cat 303.5 Mini Hydraulic Excavator (Prefix DCH) Service Repair Manual (DCH00001 and Up) PDFDocument21 pagesCaterpillar Cat 303.5 Mini Hydraulic Excavator (Prefix DCH) Service Repair Manual (DCH00001 and Up) PDFfkdmma50% (4)

- Caterpillar Cat 315C EXCAVATOR (Prefix CFL) Service Repair Manual (CFL00001 and Up)Document27 pagesCaterpillar Cat 315C EXCAVATOR (Prefix CFL) Service Repair Manual (CFL00001 and Up)kfm8seuudu67% (3)

- Astm E3-11Document12 pagesAstm E3-11Alejandro OrtizNo ratings yet

- Caterpillar Cat 303.5 Mini Hydraulic Excavator (Prefix AFW) Service Repair Manual (AFW00001 and Up) PDFDocument23 pagesCaterpillar Cat 303.5 Mini Hydraulic Excavator (Prefix AFW) Service Repair Manual (AFW00001 and Up) PDFfkdmma100% (1)

- Cylinder Head Valves: EspecificacionesDocument9 pagesCylinder Head Valves: Especificacionesgalvis1020No ratings yet

- Caterpillar Cat M316F Wheeled Excavator (Prefix F6N) Service Repair Manual (F6N00001 and Up) PDFDocument20 pagesCaterpillar Cat M316F Wheeled Excavator (Prefix F6N) Service Repair Manual (F6N00001 and Up) PDFfkdmmaNo ratings yet

- Caterpillar Cat M316C WHEELED Excavator (Prefix BDX) Service Repair Manual (BDX02001 and Up) PDFDocument26 pagesCaterpillar Cat M316C WHEELED Excavator (Prefix BDX) Service Repair Manual (BDX02001 and Up) PDFfkdmmaNo ratings yet

- NE04 014revbDocument23 pagesNE04 014revbMarlene Yuriserll Ruiz MuñozNo ratings yet

- Offwing Alide InstallDocument16 pagesOffwing Alide InstallAndreea MăgureanuNo ratings yet

- Pisston Pump VibratoryDocument12 pagesPisston Pump VibratorySteven Y.MNo ratings yet

- Caterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix KB3) Service Repair Manual (KB300001 and Up)Document24 pagesCaterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix KB3) Service Repair Manual (KB300001 and Up)rpoy9396615No ratings yet

- Cylinder LinersDocument4 pagesCylinder Linersma.powersourceNo ratings yet

- Caterpillar Cat 304.5 Mini Hydraulic Excavator (Prefix WAK) Service Repair Manual (WAK00001 and Up)Document23 pagesCaterpillar Cat 304.5 Mini Hydraulic Excavator (Prefix WAK) Service Repair Manual (WAK00001 and Up)kfmuseddk100% (1)

- Caterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix TSL) Service Repair Manual (TSL00001 and Up)Document23 pagesCaterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix TSL) Service Repair Manual (TSL00001 and Up)rpoy9396615No ratings yet

- Caterpillar Cat 226 Skid Steer Loader (Prefix 5FZ) Service Repair Manual (5FZ00001-06699)Document24 pagesCaterpillar Cat 226 Skid Steer Loader (Prefix 5FZ) Service Repair Manual (5FZ00001-06699)rpoy9396615No ratings yet

- Transmission - Disassemble: Welcome: x350kxmDocument25 pagesTransmission - Disassemble: Welcome: x350kxmSIA Stats RENTNo ratings yet

- 313B and 313B CR Excavator: Service Repair ManualDocument27 pages313B and 313B CR Excavator: Service Repair Manualgoogle accountNo ratings yet

- c32 Cylinder HeadDocument5 pagesc32 Cylinder HeadHaidar SareeniNo ratings yet

- Caterpillar Cat 226B3 SKID STEER LOADER (Prefix AS2) Service Repair Manual (AS200001 and Up)Document23 pagesCaterpillar Cat 226B3 SKID STEER LOADER (Prefix AS2) Service Repair Manual (AS200001 and Up)rpoy9396615No ratings yet

- Caterpillar Cat 216B3 Skid Steer Loader (Prefix JXM) Service Repair Manual (JXM00001 and Up)Document22 pagesCaterpillar Cat 216B3 Skid Steer Loader (Prefix JXM) Service Repair Manual (JXM00001 and Up)rpoy9396615No ratings yet

- 777D A-Frame PreloadingDocument3 pages777D A-Frame PreloadingsatyaNo ratings yet

- Cylinder Liner ProjectionDocument4 pagesCylinder Liner ProjectionFernando Daniel Saez VillarrealNo ratings yet

- Unpacking and Installation Procedure For The Main Body and OptionsDocument11 pagesUnpacking and Installation Procedure For The Main Body and OptionsNistor SilviuNo ratings yet

- Caterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix ESL) Service Repair Manual (ESL00001 and Up)Document27 pagesCaterpillar Cat 247B3 MULTI TERRAIN LOADER (Prefix ESL) Service Repair Manual (ESL00001 and Up)rpoy9396615No ratings yet

- Alternator - Disassemble: Shutdown SIS Previous ScreenDocument11 pagesAlternator - Disassemble: Shutdown SIS Previous ScreennobodymagdesignNo ratings yet

- Caterpillar Cat 245 EXCAVATOR (Prefix 95V) Service Repair Manual (95V00471 and Up)Document26 pagesCaterpillar Cat 245 EXCAVATOR (Prefix 95V) Service Repair Manual (95V00471 and Up)rpoy9396615No ratings yet

- Vibracion en Los Tractores D285AxDocument6 pagesVibracion en Los Tractores D285AxJose A. Basanta H.No ratings yet

- Montagem e Desmontagem Da Camisa 3306Document3 pagesMontagem e Desmontagem Da Camisa 3306Lucas ApostoloNo ratings yet

- Dokumen - Tips - Caterpillar Cat 315c L Excavator Prefix CJC Service Repair Manual cjc00001 and Up 1622227837Document26 pagesDokumen - Tips - Caterpillar Cat 315c L Excavator Prefix CJC Service Repair Manual cjc00001 and Up 1622227837Luis Carlos Salazar DelgadoNo ratings yet

- Caterpillar Cat 226B3 SKID STEER LOADER (Prefix MWD) Service Repair Manual (MWD00001 and Up)Document23 pagesCaterpillar Cat 226B3 SKID STEER LOADER (Prefix MWD) Service Repair Manual (MWD00001 and Up)rpoy9396615No ratings yet

- Caterpillarcatcs 683evibratorycompactorprefixagrservicerepairmanualagr00001andup 230813075534 58291ec7Document33 pagesCaterpillarcatcs 683evibratorycompactorprefixagrservicerepairmanualagr00001andup 230813075534 58291ec7Manuel Martinez MoratoNo ratings yet

- Desarme MTR HidrostaticoDocument12 pagesDesarme MTR HidrostaticoIvan CastellanosNo ratings yet

- Caterpillar Cat M318C MH WHEELED EXCAVATOR (Prefix BEB) Service Repair Manual (BEB02001 and Up) PDFDocument26 pagesCaterpillar Cat M318C MH WHEELED EXCAVATOR (Prefix BEB) Service Repair Manual (BEB02001 and Up) PDFfkdmmaNo ratings yet

- Polea Del Cigüeñal - Quitar e Instalar (SENR5553)Document3 pagesPolea Del Cigüeñal - Quitar e Instalar (SENR5553)Grover Escobal MendezNo ratings yet

- Aftercooler - Remove Removal Procedure: Shutdown SIS Previous ScreenDocument3 pagesAftercooler - Remove Removal Procedure: Shutdown SIS Previous ScreenTASHKEELNo ratings yet

- Sebf 8269 Привод 3408Document16 pagesSebf 8269 Привод 3408mohamed hamedNo ratings yet

- 320c Excavadora Cat Desarmado y Armado Bombas HidraulicasDocument20 pages320c Excavadora Cat Desarmado y Armado Bombas HidraulicasJuan camilo Cárdenas garciaNo ratings yet

- Caterpillar Cat 236B SKID STEER LOADER (Prefix HEN) Service Repair Manual (HEN00001-06749)Document22 pagesCaterpillar Cat 236B SKID STEER LOADER (Prefix HEN) Service Repair Manual (HEN00001-06749)rpoy9396615No ratings yet

- Fuel Transfer Pump - Disassemble (SENR1126-36)Document4 pagesFuel Transfer Pump - Disassemble (SENR1126-36)redminote12pro.5garNo ratings yet

- Caterpillar Cat 301.8C Mini Hydraulic Excavator (Prefix JSB) Service Repair Manual (JSB00001 and Up) PDFDocument22 pagesCaterpillar Cat 301.8C Mini Hydraulic Excavator (Prefix JSB) Service Repair Manual (JSB00001 and Up) PDFfkdmmaNo ratings yet

- New Front Crankshaft Seals and New Rear Crankshaft Seals Are Now in Production (1160, 1161)Document6 pagesNew Front Crankshaft Seals and New Rear Crankshaft Seals Are Now in Production (1160, 1161)TASHKEEL100% (1)

- Cylinder Liner ProjectionDocument3 pagesCylinder Liner ProjectionSreepriodas RoyNo ratings yet

- Implement Pump - DisassembleDocument13 pagesImplement Pump - DisassembleLeo PerezNo ratings yet

- Arme y Desarme de Bomba Hidraulica 320CDocument10 pagesArme y Desarme de Bomba Hidraulica 320CIngemak UrbanoNo ratings yet

- Caterpillar Cat 329DL Excavator (Prefix TPM) Service Repair Manual (TPM00001 and Up) PDFDocument25 pagesCaterpillar Cat 329DL Excavator (Prefix TPM) Service Repair Manual (TPM00001 and Up) PDFfkdmmaNo ratings yet

- D342 Vehicular Engine 76V00001-00504 (MaDocument5 pagesD342 Vehicular Engine 76V00001-00504 (MaOmar SuazoNo ratings yet

- Caterpillar Cat M322D MH WHEELED EXCAVATOR (Prefix W2T) Service Repair Manual (W2T00001 and Up) PDFDocument20 pagesCaterpillar Cat M322D MH WHEELED EXCAVATOR (Prefix W2T) Service Repair Manual (W2T00001 and Up) PDFfkdmmaNo ratings yet

- Caterpillar Cat M315D2 Wheeled Excavator (Prefix CA4) Service Repair Manual (CA400001 and Up) PDFDocument27 pagesCaterpillar Cat M315D2 Wheeled Excavator (Prefix CA4) Service Repair Manual (CA400001 and Up) PDFfkdmma100% (1)

- Caterpillar Cat 329DL EXCAVATOR (Prefix RSK) Service Repair Manual (RSK00001 and Up) PDFDocument24 pagesCaterpillar Cat 329DL EXCAVATOR (Prefix RSK) Service Repair Manual (RSK00001 and Up) PDFfkdmmaNo ratings yet

- BM - 2000 Service Manual 2Document77 pagesBM - 2000 Service Manual 2yesprintsydneyNo ratings yet

- Caterpillar Cat 216B3 Skid Steer Loader (Prefix DSN) Service Repair Manual (DSN00001 and Up)Document27 pagesCaterpillar Cat 216B3 Skid Steer Loader (Prefix DSN) Service Repair Manual (DSN00001 and Up)rpoy9396615No ratings yet

- Auxiliary Water PumpDocument3 pagesAuxiliary Water PumpGolbert GolbiNo ratings yet

- Cabine RomoveDocument7 pagesCabine RomoveANo ratings yet

- Motor 60Z02152 - 02 (1) CAT 3306Document4 pagesMotor 60Z02152 - 02 (1) CAT 3306Ismael De Jesus Andrade50% (2)

- 08 Engine MechanicalDocument80 pages08 Engine MechanicalmadcostaNo ratings yet

- A Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsFrom EverandA Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsNo ratings yet

- MS51029 20 - Military Fasteners ComDocument2 pagesMS51029 20 - Military Fasteners Comagungrizky.batNo ratings yet

- Easa Sib 2016-20R1 1Document2 pagesEasa Sib 2016-20R1 1agungrizky.batNo ratings yet

- Easa Ad 2023-0209 1Document4 pagesEasa Ad 2023-0209 1agungrizky.batNo ratings yet

- Easa Ad 2024-0038 1Document10 pagesEasa Ad 2024-0038 1agungrizky.batNo ratings yet

- Title: Communications - Cids - Introduce Cids Version - 59B: Service Bulletin Revision Transmittal SheetDocument48 pagesTitle: Communications - Cids - Introduce Cids Version - 59B: Service Bulletin Revision Transmittal Sheetagungrizky.batNo ratings yet

- CE 512 Ce Laws, Ethics, Codes, and Standards Report No. 6 Standard Construction ProcessesDocument76 pagesCE 512 Ce Laws, Ethics, Codes, and Standards Report No. 6 Standard Construction ProcessesDM CINo ratings yet

- Overview Fusion Welding Standards PDFDocument1 pageOverview Fusion Welding Standards PDFHà Việt ĐứcNo ratings yet

- Pt. Wufu Steel Indonesia - Harga Besi Hollow Stainless SteelDocument5 pagesPt. Wufu Steel Indonesia - Harga Besi Hollow Stainless Steelcecep mahmudinNo ratings yet

- Spark DepoDocument5 pagesSpark Deporehan0747No ratings yet

- Instructions To Bidders: Arcenciel LebanonDocument23 pagesInstructions To Bidders: Arcenciel Lebanonfacebook securityNo ratings yet

- Coimisiún Na Scrúduithe Stáit State Examinations Commission: Leaving Certificate Examination, 2018Document12 pagesCoimisiún Na Scrúduithe Stáit State Examinations Commission: Leaving Certificate Examination, 2018Diaa SaberNo ratings yet

- Valvula de Tormenta PeroloDocument1 pageValvula de Tormenta Perololalo lopezNo ratings yet

- Wet Chemical Deep Fat FryerDocument64 pagesWet Chemical Deep Fat FryerSergei KurpishNo ratings yet

- Superalloys - A Primer and HistoryDocument4 pagesSuperalloys - A Primer and Historyhemakumars100% (1)

- Comparative Evaluation of Concrete Properties With Varying ProportionsDocument11 pagesComparative Evaluation of Concrete Properties With Varying ProportionsAbdulkadir AdamNo ratings yet

- Sleepers For Railway TrackDocument14 pagesSleepers For Railway TrackChukhu Aane DuiNo ratings yet

- Anchor Bolt DesignDocument8 pagesAnchor Bolt DesignNadir Khattak Jr.No ratings yet

- Why Utkarsh PVC Pipes Is PopularDocument11 pagesWhy Utkarsh PVC Pipes Is PopularUtkarsh India LTD.No ratings yet

- ROAD & PAVEMENT Draft ModelDocument1 pageROAD & PAVEMENT Draft ModelKannan MurugesanNo ratings yet

- Schlesinger Catalogue PDFDocument24 pagesSchlesinger Catalogue PDFcotecobein19No ratings yet

- Bridge Engineering - Definition, Types, Design and Construction of BridgesDocument6 pagesBridge Engineering - Definition, Types, Design and Construction of BridgesAshis MingalaNo ratings yet

- Product Catalogue 2012-2013Document220 pagesProduct Catalogue 2012-2013Ilija RunjajicNo ratings yet

- كتالوج خزانات الزامل الدفان 2Document24 pagesكتالوج خزانات الزامل الدفان 2Ahmed FathyNo ratings yet

- Docum PDFDocument8 pagesDocum PDFsivagaaneshNo ratings yet

- 09 Breakdown BOQ - Without PriceDocument8 pages09 Breakdown BOQ - Without PricesahilNo ratings yet

- Professional ElectiveDocument4 pagesProfessional ElectiveMayank ShrivastavaNo ratings yet

- Hertel Indexable InsertsDocument2 pagesHertel Indexable InsertsDamir MarijanovicNo ratings yet

- Mizan Tepi University: Collage of Engineering and TechnologyDocument18 pagesMizan Tepi University: Collage of Engineering and TechnologyANDLENATUNo ratings yet

- Experiment No: - 4 Shell Moulding Process AimDocument5 pagesExperiment No: - 4 Shell Moulding Process AimDhananjay Shimpi100% (1)

- Fire Stop InstallationDocument3 pagesFire Stop InstallationAristo OnanNo ratings yet

- Valtech - KR: Valve Inspection and Testing Inspection ValvesDocument11 pagesValtech - KR: Valve Inspection and Testing Inspection ValvesHARSHANo ratings yet

- X-Tile CTADocument2 pagesX-Tile CTABernardo GarciaNo ratings yet

- Welding Rod Calculation 2024Document4 pagesWelding Rod Calculation 2024jcabenian8No ratings yet