Professional Documents

Culture Documents

Loading Omu-03 29-03-2024

Loading Omu-03 29-03-2024

Uploaded by

adzianpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Loading Omu-03 29-03-2024

Loading Omu-03 29-03-2024

Uploaded by

adzianpCopyright:

Available Formats

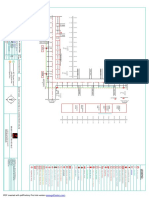

OCEANLINK SERVICES PTE LTD FORM NO: SMM-008-D

REVISION DATE: 03.01.2024

CARGO LOADING PLAN ISSUE STATUS: 5

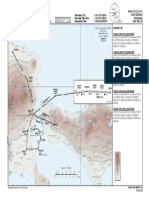

Ship' Name: FLAGSHIP Loading Vessel (or) Terminal: JPUT Alongside Date/Time: 29.03.2024/ 1012 Anchorage (or) Berth No. : Jetty-03

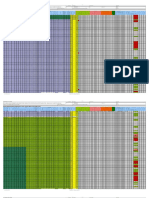

Grade Name Density @15° C : Load Temp °C : VCF WCF Vol (m3) Qty (MT) Grade Name Density @15° C Disch Temp °C : VCF WCF Vol (m3) Qty (MT)

HSFO 380 CST 0.9897 42 0.9814 0.9886 4462.77 4329.83 0.00

Cargo Grades and Cargo Grades and

0.00 0.00

Nomination Nomination

0.00 0.00

0.00 0.00

Initial 300 MT

Emergency Stop VERBAL: STOP,STOP,STOP

Emergency ONE LONG BLAST WITH WHISLE SHIP Communication Channel VHF CH. 06 Loading Rate 600 MT

Signal Max Rate

Topping 300MT

COT 1 (P) COT 1 (S) COT 2 (P) COT 2 (S) COT 3 (P) COT 3 (S) COT 4 (P) COT 4 (S) COT 5 (P) COT 5 (S) COT 6 (P) COT 6 (S) SLOP (P /S) Loading De-Ballast Draft (m)

Sounding (m)

Sounding (m)

Sounding (m)

Sounding (m)

Sounding (m)

Sounding (m)

Sounding (m)

Sounding (m)

Sounding (m)

Sounding (m)

Sounding (m)

Sounding (m)

Sounding (m)

Loading

SWB Tk No.

Trim (m)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Vol ( m3)

Seqs :

FWD

AFT

Initial 0.5 27.5 0.4 20.6 0.5 45.3 0.6 49.8 7.1 493.5 7.1 494.7 1.3 92.8 1.3 94.9 3.4 223.0 2.4 220.2 1.3 92.2 1.3 92.6 1947.08 0.0 3.00 4.00 1.00

SEQ 1 7.10 531.4 7.10 531.5 875.10 FPT(P) 3.50 4.70 1.20

SEQ 2 7.1 563.2 7.1 564.8 943.21 FPT(S) 2.70 6.30 3.60

SEQ 3 7.1 679.7 7.1 678.3 1262.97 WBT1P 4.30 6.50 2.20

SEQ 4 7.1 679.7 7.1 680.4 916.90 WBT1S 5.60 6.80 1.20

SEQ 5 3.9 256.3 3.9 256.4 464.58 WBT2W 6.00 6.80 0.80

SEQ 6 0.00 WBT3P 0.00

SEQ 7 0.00 WBT3S 0.00

SEQ 8 0.00 WBT4P 0.00

SEQ 9 0.00 WBT4S 0.00

SEQ 10 0.00 WBT7P 0.00

Topping 0.00 WBT7S 0.00

Total

228.80 235.78 634.47 628.51 0.00 0.00 438.52 436.58 456.69 460.22 471.01 472.20 0.00 4462.77 0.0 -

Load:

Final

(Dep): 256.3 256.4 679.7 678.3 493.5 494.7 531.4 531.5 679.7 680.4 563.2 564.8 0.0 6409.85 0.0 6.00 6.80 0.80

*Remarks*

Ch Off (1) Ch Off (2) Approved by Master

Insert Manually

Name: ARMANSYAPUTRA .P Name: DIDIN DESARTO Name: MICHAEL

No Require to Fill Up

Singanture: Singanture: Singanture:

Not Applicable

`

CHIEF OFFICER STANDING INSTRUCTION

Before commence of cargo operation, All Duty Officers have to read, understand and brief to all cargo duty crew and give clear instruction. Any doubt should be clarified immediately.

This standing instruction is to be used along with the cargo load / discharge plan.

1. Tool Box Meeting & Safety check list 11. M.S.D.S

. A tool box meeting to be conducted before the barge tied alongside receiving vessel or berthing at loading terminal. . The cargo MSDS will be posted at the common mess room

. All Officer and crew involve in the cargo operation are to attend the tool box meeting.

. Safety check list for loading / discharging to be completed before commencement of cargo operation. 12. Safe Access

. The repetitive checks for "R" items to be carried out as per agreed periods. · When ship gangway or portable gangway is being used for safe access to shore berth, gang way net

must be rigged and spread underneath the gangway.

2. Cargo stowage · When alongside receiving vessel, if the free board of the receiving vessel is 9.0m or more or

. Cargo information such as cargo grade, quantity, density and temperature to be loaded / discharge height that hampered to our crew from access, crew not allow to board the receiving vessel.

are written in the cargo stowage plan. Please refer to cargo stowage plan. · Monkey ladder / Jacob ladder is not allowed to be used except gangway or pilot ladder.

· No crew is allowed to walk at Terminal jetty.

3. Cargo line setting & Overfill alarm

. Bosun will set the cargo line setting and pump to use. Once setting has completed, Chief Officer will verify. 13. Emergency – Pollution Prevention

. The cargo tank high and over-filled alarm must be tested before loading / discharging operation. . All scupper plugs must be liquid tight and properly plugged. During rainy weather, when draining rain water,

crew to be stationed whenever the scupper plug are removed temporary.

4. Load / Discharge rate & manifold pressure . The spill recovery equipment (SOPEP) must be placed near the cargo manifold and stand-by for immediate use.

· Maximum acceptable loading rate has been posted in the cargo control room and common mess room. . The portable wilden pump must be tested before vessel enter the terminal. The discharge hose

. Chief Officer will inform crew once the agreed loading rate after the safety meeting to be inserted into the slop tank.

with the loading terminal representative.

· Discharge rate will be informed to all crew, after the safety meeting with the receiving vessel. 14. Fire Fighting Equipment

· Crew to monitor the manifold pressure and inform Chief Officer regularly. . All F.F.E are maintained in good condition and must be readily available in case of Emergency

. The foam turret to be aim at the cargo manifold (if applicable).

5. Loading – Cargo topping off & stop sounding level.

. The sounding level for topping off and final stop sounding will be informed to the crew and 15. STOP WORK authority

posted near the cargo tank sounding pipe. . Crew is empowered to stop work:

. At regular intervals throughout the watch period he should check that valves remain correctly positioned. · If there is any lightning activity within the area or strong wind (Sumatra Squall), inform Chief Officer immediatelly

. On completion of all cargo, (and after any required waiting period for static accumulator cargo), · Do not hesitate to stop cargo operation if safety is breached.

all tank sounding are to be checked. · If you feel unwell, please inform the Chief Officer.

· If the cargo tank high level alarm sounded or visual light is activated, STOP CARGO OPERATION IMMEDIATELY, and

6. Cargo Venting and Closed loading report to Chief Officer

. Cargo venting will be thru the vent breather valve and thru the PV valve or simlar approved venting system.

. No opening of cargo tank hatch is allowed. 16. Mooring

. if sighting port are available on the tank hatch, flame screen must be in placed. . Mooring must be tend to especially during the rise and low tide and also whenever large vessel passing by.

7. Discharging – Cargo stripping. 17. Cargo Pump Room

. The cargo tank discharge sequence are as per cargo stowage plan. . The cargo pump room fan must run throughout the vessel stay at loading terminal and tied to the receiving vessel.

. Chief Officer will be present for cargo tank stripping.

18. Personal Protective Equipments (PPE)

8. Hose blowing after discharge . Appropriate PPE is to be worn when crew is on duty. Portable radio battery must be charged when in used.

. After discharge each cargo grade, crew to follow Chief Officer’s instruction for air blow of cargo hose.

19. Handing / Taking Over Watch

9. Ballast . Handing and Taking over watch to be carried out on deck.

. Ballast requirement are written in the cargo plan. For ballast or de-ballast, Chief Officer will instruct Bosun

which ballast tank to ballast or de-ballast. 20. Emergency Contact Numbers.

. The emergency call numbers are posted in the cargo control room. Additionally, herewith is the emergency

10. Draft and trim contact number as per table below.

. Estimate draft at various stages of the loading / discharging operation are to be stated

- Loading – to achieve even keel draft Oceanlink Services Pte Ltd Contact

- Discharging – Stern trim not more than 2.50m – 3.50m 1 United Maritime Emergency Hot Line 6538 1109

2 United Maritime Main Line 6538 9789

3 Capt. Nizam (DPA) 8822 1427

You might also like

- Lift SchindlerDocument1 pageLift SchindlerRudi ElfendesNo ratings yet

- Test Report Form: Candidate DetailsDocument1 pageTest Report Form: Candidate DetailsPranav BabbarNo ratings yet

- Elm04 10solutions - Doc 0Document13 pagesElm04 10solutions - Doc 0venkatvarsha100% (2)

- Brosur TC PDFDocument2 pagesBrosur TC PDFHelmi Zuhdi MuliaNo ratings yet

- 2305-31 Removing Gear Box at Dai Phong Wind Farm ProjectDocument1 page2305-31 Removing Gear Box at Dai Phong Wind Farm ProjectDat TienNo ratings yet

- M5N Civ SHP 125 601 BD 4424 - R1Document1 pageM5N Civ SHP 125 601 BD 4424 - R1tarekNo ratings yet

- No (S) - V - BRACING - VB13 2: 1/B-B' VB13 +110.715 EL.+ 2/B-B' VB13 +110.715 EL.+Document1 pageNo (S) - V - BRACING - VB13 2: 1/B-B' VB13 +110.715 EL.+ 2/B-B' VB13 +110.715 EL.+M. Azharuddin TamboliNo ratings yet

- For Construction: 2 No Beam Required As Drawn MKD ' L0R0011Be109PDocument1 pageFor Construction: 2 No Beam Required As Drawn MKD ' L0R0011Be109PrajendraNo ratings yet

- Mcore Lab Private Limited: Test Report of Rock CoresDocument1 pageMcore Lab Private Limited: Test Report of Rock Coressivananda reddyNo ratings yet

- 402-G2-JVC-300-D-101-B - Phases 3B & 3C - All Viaducts Inside Stations - Transverse Joint Closure - Plan View, Sections & Details - VFCDocument10 pages402-G2-JVC-300-D-101-B - Phases 3B & 3C - All Viaducts Inside Stations - Transverse Joint Closure - Plan View, Sections & Details - VFCahmedmido14No ratings yet

- Detail A: Shuqaiq 3 Independent Water ProjectDocument1 pageDetail A: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Electrical Load Calculations: - x000D - x000DDocument4 pagesElectrical Load Calculations: - x000D - x000DChay NagNo ratings yet

- List Gambar Penerimaan Klas Rev2Document14 pagesList Gambar Penerimaan Klas Rev2Dolok Joko KenconoNo ratings yet

- Oman-1800x2100-Center Opening Auto Door-b+g+m+5-Sheet No - 01 of 05Document5 pagesOman-1800x2100-Center Opening Auto Door-b+g+m+5-Sheet No - 01 of 05Lakhwinder SainiNo ratings yet

- Master List WelderDocument2 pagesMaster List WelderMoch_adiganjarNo ratings yet

- 2306-02 Replace DriveTrain at Dai Phong Wind FarmDocument3 pages2306-02 Replace DriveTrain at Dai Phong Wind FarmDat TienNo ratings yet

- Method Statement For Installation Anchor BoltsDocument7 pagesMethod Statement For Installation Anchor BoltsSyed AtherNo ratings yet

- Method Statment FOR BILINDING WORKDocument6 pagesMethod Statment FOR BILINDING WORKSyed AtherNo ratings yet

- Mir For Aluminium LadderDocument13 pagesMir For Aluminium LadderRoshan George PhilipNo ratings yet

- Construction Specs For Hvac Building WorksDocument77 pagesConstruction Specs For Hvac Building WorksSkylink Estimation TeamNo ratings yet

- 1242 B2 ISMB200: No (S) - BEAM - B2 1Document1 page1242 B2 ISMB200: No (S) - BEAM - B2 1M. Azharuddin TamboliNo ratings yet

- Eep 000097 0102148005 3 ST Det 0669 R02Document1 pageEep 000097 0102148005 3 ST Det 0669 R02Vikram DalalNo ratings yet

- Method Statement For Installation of Cable Tray: STC Admin Car Park Building ProjectDocument12 pagesMethod Statement For Installation of Cable Tray: STC Admin Car Park Building ProjectSyed AtherNo ratings yet

- Company Welder & Welding Operator Register Based On Aws D1.5 2015Document1 pageCompany Welder & Welding Operator Register Based On Aws D1.5 2015REZKINo ratings yet

- 0080 D141 00001 - Rev.3 - C1Document2 pages0080 D141 00001 - Rev.3 - C1nuntaricherdchaiNo ratings yet

- 100136C-051-DD-1841-1013 - 1 (Shop Drawing) - 008-008Document1 page100136C-051-DD-1841-1013 - 1 (Shop Drawing) - 008-008Tamil Arasu SNo ratings yet

- No (S) - V - BRACING - VB10 1: 1/A-B VB10 +104.615 EL.+Document1 pageNo (S) - V - BRACING - VB10 1: 1/A-B VB10 +104.615 EL.+M. Azharuddin TamboliNo ratings yet

- Welding Notes: Bill of Materials For Assembly MK'D: Ama3-5: Assy Qty: 1Document1 pageWelding Notes: Bill of Materials For Assembly MK'D: Ama3-5: Assy Qty: 1Seena NaikNo ratings yet

- GRP 86A PipelineDocument1 pageGRP 86A PipelineAli RaheemNo ratings yet

- STC800 SanyDocument3 pagesSTC800 SanySwarup DasNo ratings yet

- Sapar-Veraval Route Inpath PDFDocument3 pagesSapar-Veraval Route Inpath PDFvaghasiyagunjanNo ratings yet

- Layout and Profile of Tunnel Alignment (BD) - V2Document7 pagesLayout and Profile of Tunnel Alignment (BD) - V2know netNo ratings yet

- PipelineDocument9 pagesPipelineRhoteram VikkuNo ratings yet

- DAF SDS CombinedDocument11 pagesDAF SDS CombinedJhonnel PunzalanNo ratings yet

- Mid 5-XDocument10 pagesMid 5-XDavisTranNo ratings yet

- AQsthFER - DE.00002.R00.implFLOOR PLANDocument1 pageAQsthFER - DE.00002.R00.implFLOOR PLANpauloagarayNo ratings yet

- Siemens Sa: Corredor Logístico Integrado de Nacala, S.A. Company / CostumerDocument24 pagesSiemens Sa: Corredor Logístico Integrado de Nacala, S.A. Company / CostumerAdelino UacateNo ratings yet

- SATR-W-2008 Rev 8 FD-1Document6 pagesSATR-W-2008 Rev 8 FD-1asiqna100% (1)

- MCG - Engineer DrawingsDocument8 pagesMCG - Engineer DrawingsharisNo ratings yet

- Siemens Sa: Corredor Logístico Integrado de Nacala, S.A. Company / CostumerDocument25 pagesSiemens Sa: Corredor Logístico Integrado de Nacala, S.A. Company / CostumerAdelino UacateNo ratings yet

- LMCPL-P2023-02-COS-08 - Working Platform - Lighting Gantry A5 & A6Document8 pagesLMCPL-P2023-02-COS-08 - Working Platform - Lighting Gantry A5 & A6Ali md YounusNo ratings yet

- 4020-001A-VE-002 Rev 0 GENERAL ARRANGEMENT AMX9000 MIXER - Rev.0 Code2Document1 page4020-001A-VE-002 Rev 0 GENERAL ARRANGEMENT AMX9000 MIXER - Rev.0 Code2thoriq ikhwanNo ratings yet

- Performance FLM Movistar CooperadorDocument1 pagePerformance FLM Movistar CooperadorDeyvis CarvajalNo ratings yet

- No (S) - V - BRACING - VB14 1: 1/B-B' VB14 +104.415 EL.+Document1 pageNo (S) - V - BRACING - VB14 1: 1/B-B' VB14 +104.415 EL.+M. Azharuddin TamboliNo ratings yet

- Skirt Board Assembly 2400Mm D9 Apron Feeder Skirt Board AssemblyDocument4 pagesSkirt Board Assembly 2400Mm D9 Apron Feeder Skirt Board AssemblyMohammad AdilNo ratings yet

- Truss Engineering ReportDocument1 pageTruss Engineering ReportMuhammad AdnanNo ratings yet

- Mass Balance Calculation (Ratio)Document1 pageMass Balance Calculation (Ratio)maizanazaNo ratings yet

- M5N Civ SHP 125 601 BD 4308 2 - R0Document1 pageM5N Civ SHP 125 601 BD 4308 2 - R0Tarek AbulailNo ratings yet

- Ael ST DRW 0307 001Document1 pageAel ST DRW 0307 001slimNo ratings yet

- Colt MK12 MOD1 FIX Stock (DX)Document1 pageColt MK12 MOD1 FIX Stock (DX)throw awayNo ratings yet

- Top Reinforcement Section A - A: (Each)Document1 pageTop Reinforcement Section A - A: (Each)Tarek AbulailNo ratings yet

- Wady 7a1-132-23Document1 pageWady 7a1-132-23BluesCreeper OfficialNo ratings yet

- Master Table: General Energy Conservation Special NotesDocument1 pageMaster Table: General Energy Conservation Special NotesSiyad p salamNo ratings yet

- 30 Hex 1018 MTCDocument1 page30 Hex 1018 MTCParvendar ratheeNo ratings yet

- R1 Yankb-10Document2 pagesR1 Yankb-10UPTD ARJASARINo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- 154D3502AA D: Elementary DiagramDocument1 page154D3502AA D: Elementary DiagramYas AlbNo ratings yet

- Method of Statment CONCRETEDocument7 pagesMethod of Statment CONCRETESyed AtherNo ratings yet

- Moog MF-101 LPF SchematicsDocument5 pagesMoog MF-101 LPF SchematicscrackintheshatNo ratings yet

- LMCPL-P2023-02-COS-06 - Working Platform - Lighting Gantry A1 & A7Document8 pagesLMCPL-P2023-02-COS-06 - Working Platform - Lighting Gantry A1 & A7Ali md YounusNo ratings yet

- Siemens Sa: Corredor Logístico Integrado de Nacala, S.A. Company / CostumerDocument26 pagesSiemens Sa: Corredor Logístico Integrado de Nacala, S.A. Company / CostumerAdelino UacateNo ratings yet

- Azure Labs v4.4Document63 pagesAzure Labs v4.4Anand Vishwanathan100% (2)

- Machine Spindle Noses: 6 Bison - Bial S. ADocument2 pagesMachine Spindle Noses: 6 Bison - Bial S. AshanehatfieldNo ratings yet

- Manuel Resume 17Document2 pagesManuel Resume 17api-286125655No ratings yet

- 2018-04-12 St. Mary's County TimesDocument32 pages2018-04-12 St. Mary's County TimesSouthern Maryland OnlineNo ratings yet

- Lifting Lug Design Calculation Report: Page 1 of 6Document6 pagesLifting Lug Design Calculation Report: Page 1 of 6maniaxpdfNo ratings yet

- Department of Education: Republic of The PhilippinesDocument2 pagesDepartment of Education: Republic of The PhilippinesArgie Joy Marie AmpolNo ratings yet

- Chapter-1 Introduction of The Study: A Study On Financial Performance by Ratio AnalysisDocument47 pagesChapter-1 Introduction of The Study: A Study On Financial Performance by Ratio Analysisjayan panangadanNo ratings yet

- Week 1: Learning Activity 1 Short Quiz 1Document39 pagesWeek 1: Learning Activity 1 Short Quiz 1yagami100% (1)

- Analyzing IoT Data in Python Chapter1Document27 pagesAnalyzing IoT Data in Python Chapter1FgpeqwNo ratings yet

- Parts of The House and FurnitureDocument1 pageParts of The House and FurnitureJOSE MARIA ARIGUZNAGA ORDUÑANo ratings yet

- Praise Be To Allah: Mymona HendricksDocument37 pagesPraise Be To Allah: Mymona HendricksRulytta MimiNo ratings yet

- Module 3 - AmcmlDocument3 pagesModule 3 - AmcmlAmotsik GolezNo ratings yet

- Emma's Daily Routine - ReadingDocument2 pagesEmma's Daily Routine - ReadingEl Brayan'TVNo ratings yet

- Short Notes For Heat Transfer - Docx 97.docx 93Document18 pagesShort Notes For Heat Transfer - Docx 97.docx 93kumarsumit1942No ratings yet

- Training Day-1 V5Document85 pagesTraining Day-1 V5Wazabi MooNo ratings yet

- Variasi Dan Manfaat Teh Herbalife Nutrition: David Heber, M.D., PH.D., FACP, FASN Chairman Herbalife Nutrition InstituteDocument24 pagesVariasi Dan Manfaat Teh Herbalife Nutrition: David Heber, M.D., PH.D., FACP, FASN Chairman Herbalife Nutrition InstituteNimadefebyNo ratings yet

- Bentley Software Installation and ActivationDocument2 pagesBentley Software Installation and ActivationSaifur RahmanNo ratings yet

- RS232Document29 pagesRS232Pravish Sainath100% (1)

- Operating Instructions Dixie Cerradora de LatasDocument22 pagesOperating Instructions Dixie Cerradora de LatasMario Amieva BalsecaNo ratings yet

- CAEG Question Bank With SolutionsDocument24 pagesCAEG Question Bank With Solutionssksnjgaming100% (1)

- Key Notes For Fire and Gas MappingDocument4 pagesKey Notes For Fire and Gas MappingAhmad MuzammilNo ratings yet

- Semi-Detailed Lesson Plan: Teacher: Blessie Jean A. YbañezDocument3 pagesSemi-Detailed Lesson Plan: Teacher: Blessie Jean A. YbañezJENNIFER YBAÑEZNo ratings yet

- TFM 3Document9 pagesTFM 3Miguel de VivarNo ratings yet

- 9 African Islamic Banking & Takaful Summit: Organized byDocument11 pages9 African Islamic Banking & Takaful Summit: Organized byMansoor InvoicemateNo ratings yet

- Adib - Haghighatjoo - Orchestration Project - Prelude - 4Document8 pagesAdib - Haghighatjoo - Orchestration Project - Prelude - 4Adib HaghighatjooNo ratings yet

- Challan 900 (08-03-2018)Document1 pageChallan 900 (08-03-2018)Shankey JAlanNo ratings yet

- S4-4 Damping Paper TakedaDocument26 pagesS4-4 Damping Paper TakedaRonald Omar García RojasNo ratings yet

- 211-Article Text-399-1-10-20180522 PDFDocument42 pages211-Article Text-399-1-10-20180522 PDFAlex KanathNo ratings yet