Professional Documents

Culture Documents

Technyl Safe C 116FC NC

Technyl Safe C 116FC NC

Uploaded by

kls.thorodinsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technyl Safe C 116FC NC

Technyl Safe C 116FC NC

Uploaded by

kls.thorodinsonCopyright:

Available Formats

caring is our formula

TECHNICAL DATA SHEET

TECHNYL SAFE C 116FC NC

(Previously DOMAMID 6LVFC NC)

TECHNYL SAFE C 116FC NC is a polyamide 6, unfilled, improved flowability, food contact approved for injection moulding. Designed to be

used for food contact in industrial consumer good as well as appliance applications.

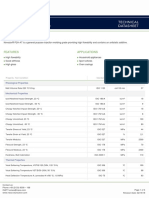

General

Feature Food contact approved Improved flowability

Polymer type PA6 (Polyamide 6)

Processing technology Injection molding

Certification Food contact EU Food contact FDA

RoHS

Applications Small appliance Consumer good application

Industrial Applications building / construction

large appliance

Colors available Natural

Forms Pellets

Product identification

ISO 1043 abbreviation PA6

ISO 16396 designation PA6,M1,S12-030

Condition Standard Unit Value

Physical properties

Density ISO 1183 g/cm³ 1.14

Molding shrinkage, parallel ISO 294-4, 2577 % 0.9 - 1.1

Molding shrinkage, normal ISO 294-4, 2577 % 1 - 1.2

Melt volume-flow rate, MVR, 5.0 kg 275°C, 5kg ISO 1133 cm³/10 min 225

Viscosity number 96% H2SO4 ISO 307 cm³/g 125

DOMO Engineering Plastics | Technical Service

TechnicalService@domo.org | www.domochemicals.com

Date of issue: 03/2024

Page 1

caring is our formula

TECHNICAL DATA SHEET TECHNYL SAFE C 116FC NC

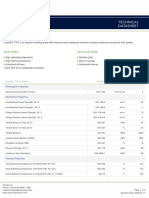

Condition Standard Unit Value

Mechanical properties dam / cond.*

Tensile modulus 1 mm/min ISO 527-1/-2 MPa 3100 / -

Strain at break 50 mm/min ISO 527-1/-2 % 50 / -

Yield stress 50 mm/min ISO 527-1/-2 MPa 80 / -

Flexural modulus, ISO 178 2 mm/min ISO 178 MPa 2700 / -

Flexural strength, ISO 178 2 mm/min ISO 178 MPa 100 / -

Charpy impact strength, +23°C +23°C ISO 179/1eU kJ/m² NB / -

Charpy notched impact strength, +23°C +23°C ISO 179/1eA kJ/m² 4/-

Izod impact strength, +23°C +23°C ISO 180/1U kJ/m² NB / -

Izod notched impact strength, +23°C +23°C ISO 180/1A kJ/m² 4/-

Rockwell hardness ISO 2039/2 ScaleR 120 / -

Thermal properties

Melting temperature, 10°C/min ISO 11357-1 °C 221

Temp. of deflection under load, 0.45 MPa 0.45 MPa ISO 75 °C 180

Temp. of deflection under load, 1.80 MPa 1.80 MPa ISO 75 °C 70

Vicat softening temperature 50°C/h - 50N ISO 306 °C 205

Electrical properties

Volume resistivity IEC 62631-3-1 ohm.m 1E+013

Surface resistivity IEC 62631-3-1 ohm 1E+013

Comparative tracking index Solution A IEC 60112 V 600

CTI performance level category Sol A PLC 0

Burning behaviour

Flammability, 0.75 mm 0.75 mm UL 94 V2

Flammability, 1.5 mm 1.5 mm UL 94 V2

Flammability, 3.0 mm 3.0 mm UL 94 V2

Glow-wire flammability index, GWFI 1-3 mm IEC 60695-2-12 °C 850

Glow-wire ignition temperature, GWIT 1-3 mm IEC 60695-2-13 °C 725

Burning rate, FMVSS, Thickness 1 mm FMVSS 302 < 100 mm/min

Test run at 23°C if not differently specified, DAM state (dry as moulded), valid for natural colored products.

*: conditioned according to ISO 1110

DOMO Engineering Plastics | Technical Service

TechnicalService@domo.org | www.domochemicals.com

Date of issue: 03/2024

Page 2

caring is our formula

TECHNICAL DATA SHEET TECHNYL SAFE C 116FC NC

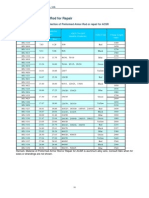

Processing conditions

Drying temperature/time 75-85°C / 2-4h (with dew point of dried air < -30 °C)

Recommended melt temperature 230 - 250 °C

Recommended mould temperature 40 - 80 °C

These parameters are typical of the product but should be related to the type of machinery used and to the type of moulded part.

Disclaimer

The information provided in this documentation corresponds to our technical knowledge at the date of its publication and do not

constitute a specification. This information may be subject to revision at our discretion. Domo cannot anticipate all conditions under which

this information and our products of other manufactures in combination with our products may be used. Domo accepts no responsibility

for results obtained by the application of this information or for the safety and suitability of our products alone or in combination with

other products. Users are advised to make their own tests to determine the safety and suitability of each product or product combination

for their own purposes. Unless otherwise agreed in writing, Domo sells the product without warranties. Buyers and users assume all

responsibility and liability for loss or damage arising from handling and use of our products, whether used alone or in combination with

other products. Unless specifically indicated, the grades mentioned are not suitable for applications in the pharmaceutical/medical

sector.

DOMO Engineering Plastics | Technical Service

TechnicalService@domo.org | www.domochemicals.com

Date of issue: 03/2024

Page 3

You might also like

- 0983-03 Method Statement For Installation & Testing of Fire Fighting PipesDocument4 pages0983-03 Method Statement For Installation & Testing of Fire Fighting Pipeshasan_67648961650% (2)

- F560Document3 pagesF560Gustavo SuarezNo ratings yet

- Ultramid A205fDocument3 pagesUltramid A205fSATHISH KUMAR SNo ratings yet

- Celanex 3300-2 PBTDocument3 pagesCelanex 3300-2 PBTDiegoTierradentroNo ratings yet

- Technyl Star S 218 V30 BK 31NDocument3 pagesTechnyl Star S 218 V30 BK 31Nratz23695No ratings yet

- Novodur P2H-ATDocument3 pagesNovodur P2H-ATavinashchauhan2695No ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfDocument4 pagesCAMPUS® Datasheet: Ultradur® B 4330 G6 HR - PBT-I-GF30 BasfAngererNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNo ratings yet

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNo ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- Campus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHDocument2 pagesCampus® Datasheet: Pocan® BF 4235 - Pbt-Gf30 FR Lanxess Deutschland GMBHAngererNo ratings yet

- CAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfDocument5 pagesCAMPUS® Datasheet: Ultradur® B 4406 G6 Q798 SW 15138 - PBT-GF30 FR BasfdivyarasinNo ratings yet

- Econamid FL 6B30Document2 pagesEconamid FL 6B30Jagadeesh WaranNo ratings yet

- R42000249GKF - Celanex 2003 - PBT - TDSDocument4 pagesR42000249GKF - Celanex 2003 - PBT - TDSCarlos AgianiNo ratings yet

- PocanB3235000000 GF30 1Document5 pagesPocanB3235000000 GF30 1rihabNo ratings yet

- CELCONM90Document5 pagesCELCONM90DiegoTierradentroNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- OKW ABS,+Guide+ValuesDocument1 pageOKW ABS,+Guide+ValuesDanielNo ratings yet

- Dupont Delrin 527UV BK701Document4 pagesDupont Delrin 527UV BK701Phung LucNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- 76 StyrolutionPS454NDocument5 pages76 StyrolutionPS454N59074No ratings yet

- Styrolution PS 147F: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 147F: General Purpose Polystyrene (GPPS)Ayaan Anowar100% (1)

- Styrolution PS 454N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 454N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Delrin® 100 NC010-enDocument14 pagesDelrin® 100 NC010-enshahin_723No ratings yet

- Asa Ineos Styrolution Europe GMBH: Luran® S 776seDocument6 pagesAsa Ineos Styrolution Europe GMBH: Luran® S 776sebobNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- Emerge™ Pc/Abs 7740: Technical InformationDocument3 pagesEmerge™ Pc/Abs 7740: Technical InformationbobNo ratings yet

- Bayer Makrolon 2407Document3 pagesBayer Makrolon 2407DiegoTierradentro100% (1)

- Kumho 750SWDocument1 pageKumho 750SWChu ChuNo ratings yet

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)Document1 pageABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ISO)DiegoTierradentroNo ratings yet

- Kynar Flex® 2800-20 ResinDocument5 pagesKynar Flex® 2800-20 ResinmohammedNo ratings yet

- PC1220R Infino LotteDocument1 pagePC1220R Infino LotteSCAR GONZALEzNo ratings yet

- Styrolution PS 476L: Technical DatasheetDocument3 pagesStyrolution PS 476L: Technical DatasheetTRUONGNo ratings yet

- RADILONAESL128100NTDocument4 pagesRADILONAESL128100NTRicardoNo ratings yet

- TerluranGP 22Document5 pagesTerluranGP 22Chu ChuNo ratings yet

- Zytel® 101 NC010-gbDocument11 pagesZytel® 101 NC010-gbalejandrocharlescollNo ratings yet

- Zytel® 45HSB NC010-gbDocument14 pagesZytel® 45HSB NC010-gbJuan Fernando CampuzanoNo ratings yet

- TECHNYL® A 216 Y10: DescriptionDocument2 pagesTECHNYL® A 216 Y10: DescriptionpaquienNo ratings yet

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoNo ratings yet

- PA6-30GF LANXESS Durethan BKV130P 702214 ISO ENDocument2 pagesPA6-30GF LANXESS Durethan BKV130P 702214 ISO ENKalipse FerreiraNo ratings yet

- StarexDocument1 pageStarexGuille FormosoNo ratings yet

- VESTAMID® L1670 - EvonikDocument5 pagesVESTAMID® L1670 - EvonikShikha MishraNo ratings yet

- CELANEX® 2000-K-EnDocument3 pagesCELANEX® 2000-K-EnCarlos AgianiNo ratings yet

- Tds Carbon enDocument1 pageTds Carbon engegacolucNo ratings yet

- Bakelite PF6507Document4 pagesBakelite PF6507dioguitomsolhaNo ratings yet

- CELCON® M90-EnDocument8 pagesCELCON® M90-EnJosue OrtizNo ratings yet

- Makrolon® 2805Document8 pagesMakrolon® 2805Dridi BadredineNo ratings yet

- PD Arnite t06 204 SN (En)Document2 pagesPD Arnite t06 204 SN (En)MuthuswamyNo ratings yet

- Radilon A Cp300K 333 BK: Product InformationDocument4 pagesRadilon A Cp300K 333 BK: Product InformationmuthuNo ratings yet

- Makrolon SF800 - en - 56979992 00009671 17283484Document3 pagesMakrolon SF800 - en - 56979992 00009671 17283484Shinichi SuzukiNo ratings yet

- Tarolox 10 g6 Standard 003 enDocument3 pagesTarolox 10 g6 Standard 003 enMohamed Ali MaâlaouiNo ratings yet

- SC-1100R DatasheetDocument2 pagesSC-1100R DatasheetAgus IrawanNo ratings yet

- Zytel® 101L NC010-gbDocument21 pagesZytel® 101L NC010-gbRamiro PredassiNo ratings yet

- HOSTAFORM® C 27021 - POM - Unfilled: DescriptionDocument5 pagesHOSTAFORM® C 27021 - POM - Unfilled: Descriptionrahul vermaNo ratings yet

- Role Impact in Knowledge Management of Automotive Component Firms in IndonesiaDocument4 pagesRole Impact in Knowledge Management of Automotive Component Firms in Indonesiakls.thorodinsonNo ratings yet

- PT - MAS Katalog Yellow 202308Document3 pagesPT - MAS Katalog Yellow 202308kls.thorodinsonNo ratings yet

- OnePager - Ultramid Extrusion - EN - K7 - AnsichtDocument1 pageOnePager - Ultramid Extrusion - EN - K7 - Ansichtkls.thorodinsonNo ratings yet

- SSESSMENTS Indonesia Import Price Index - PolycarbonateDocument1 pageSSESSMENTS Indonesia Import Price Index - Polycarbonatekls.thorodinsonNo ratings yet

- PC-1220U - UL (2015.03월)Document2 pagesPC-1220U - UL (2015.03월)kls.thorodinsonNo ratings yet

- HHI279Document3 pagesHHI279kls.thorodinsonNo ratings yet

- Desmopan Product Range ENDocument14 pagesDesmopan Product Range ENkls.thorodinsonNo ratings yet

- Scan 01222024113041Document6 pagesScan 01222024113041kls.thorodinsonNo ratings yet

- Nexeo Plastics Kingfa PBT RG151Document2 pagesNexeo Plastics Kingfa PBT RG151kls.thorodinsonNo ratings yet

- NORYL Resin - Chemical Resistance PropertiesDocument4 pagesNORYL Resin - Chemical Resistance Propertieskls.thorodinsonNo ratings yet

- Dumpdata A50Document224 pagesDumpdata A50KillburnNo ratings yet

- DSS Notes PDFDocument131 pagesDSS Notes PDFmaniram70% (1)

- Tatawade Fire Fighting Work BOQ WO No. 1356000008 Ms. Kraftech FireDocument8 pagesTatawade Fire Fighting Work BOQ WO No. 1356000008 Ms. Kraftech Fireharshadshivankar121No ratings yet

- Tutorial Week 3c - MECH3361 Workbench GuideDocument2 pagesTutorial Week 3c - MECH3361 Workbench GuideashokkumarNo ratings yet

- Public Toilet Elec-Pt-Type-1 (45 M2) GRNDDocument1 pagePublic Toilet Elec-Pt-Type-1 (45 M2) GRNDteddyNo ratings yet

- Pipe Friction Loss TableDocument5 pagesPipe Friction Loss TableGan Penton100% (1)

- Whitepaper MachineVariablesAffectingAdhesionDocument66 pagesWhitepaper MachineVariablesAffectingAdhesionHari Shanker MishraNo ratings yet

- Lecture1-215331Fuses and SwitchesDocument62 pagesLecture1-215331Fuses and SwitchesHarsh NegiNo ratings yet

- HX-HR Series Preformed Armor Rods For RepairDocument3 pagesHX-HR Series Preformed Armor Rods For RepairhcindustryNo ratings yet

- Is Code 1343 For Pre Stressed ConcreteDocument64 pagesIs Code 1343 For Pre Stressed ConcreteGuntiMuralidhar100% (9)

- Steel Grade: General InformationDocument2 pagesSteel Grade: General Informationabu asiyahNo ratings yet

- Cement Lecture Note - AAIDocument27 pagesCement Lecture Note - AAINafizNo ratings yet

- Building Repairs and MaintenanceDocument167 pagesBuilding Repairs and MaintenanceAnshul Soni100% (1)

- 03 09 Saw Waterproofing Membranes TunnelDocument3 pages03 09 Saw Waterproofing Membranes TunnelParashuram ChauhanNo ratings yet

- BS Bolt DesignDocument3 pagesBS Bolt Designbalamurali031No ratings yet

- Haura Risyad MandiriDocument10 pagesHaura Risyad MandiriWarsono LukitoNo ratings yet

- Molykote 1122 MailerDocument1 pageMolykote 1122 MailerProject Sales CorpNo ratings yet

- D&H Sécheron Electrodes Private Limited: Approximate Comparison WithDocument5 pagesD&H Sécheron Electrodes Private Limited: Approximate Comparison WithmahaveenNo ratings yet

- Research On Utilizing Recycled Plastic To Make Environment-Friendly PlywoodDocument2 pagesResearch On Utilizing Recycled Plastic To Make Environment-Friendly PlywoodAnela KimNo ratings yet

- V - Brochure SL CompoundDocument12 pagesV - Brochure SL CompoundThành SơnNo ratings yet

- P-205-05 Current Transformers For Special ApplicationDocument16 pagesP-205-05 Current Transformers For Special ApplicationSarmad HussainNo ratings yet

- (CIDECT DG1) - Design Guide For Circular Hollow Section (CHS) Joints Under Predominantly Static LoadingDocument142 pages(CIDECT DG1) - Design Guide For Circular Hollow Section (CHS) Joints Under Predominantly Static Loading_at_to_50% (2)

- Understanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDocument13 pagesUnderstanding Primary Secondary Pumping Part 6 - 5 Ways To Pump An HVAC SystemDavid O. AlmeidaNo ratings yet

- The Real Estate Digest MichiganDocument28 pagesThe Real Estate Digest MichiganbilbeypubNo ratings yet

- (Computational and Experimental Methods in Structures 6) Aliabadi, Mohammad H - Woven Composites (2015, Imperial College Press)Document248 pages(Computational and Experimental Methods in Structures 6) Aliabadi, Mohammad H - Woven Composites (2015, Imperial College Press)Andres CastilloNo ratings yet

- CSI Color Hardener: Technical Data Sheet 1.0509DSDocument2 pagesCSI Color Hardener: Technical Data Sheet 1.0509DSAyman MohamedNo ratings yet

- Typical Meter Center Set-Up For CT-Rated MeteringDocument1 pageTypical Meter Center Set-Up For CT-Rated Meteringmontgomery100% (2)

- Manufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Document2 pagesManufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Madduri HemantNo ratings yet