Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

4 viewsAction Plan

Action Plan

Uploaded by

esayasCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Statement: February 2023Document7 pagesStatement: February 2023MUSA ABDULSALAM ALARONo ratings yet

- 5M CHANGE ProcedureDocument8 pages5M CHANGE ProcedurePk Nimiwal100% (1)

- IQA IATF ChecksheetDocument37 pagesIQA IATF ChecksheetSumeet Rathee100% (6)

- APQP ProcedureDocument9 pagesAPQP ProcedurePk Nimiwal100% (5)

- NPD Check SheetDocument6 pagesNPD Check Sheets.charlie50% (2)

- Benefits of FMEADocument9 pagesBenefits of FMEAbaranirajsalem100% (2)

- Blake EletronicsDocument10 pagesBlake EletronicsParkbyun HanaNo ratings yet

- QSP-D&D-02 APQP ProcedureDocument6 pagesQSP-D&D-02 APQP ProcedureDeepak Kumar100% (1)

- DSM-200520-SP-10 Recommended Implementation Plan For Basic DataDocument7 pagesDSM-200520-SP-10 Recommended Implementation Plan For Basic DataAllif TukiranNo ratings yet

- QSP-05 Maintenance of Infrastructure TPM R2Document10 pagesQSP-05 Maintenance of Infrastructure TPM R2DhinakaranNo ratings yet

- QM 7 - Section 7.Document13 pagesQM 7 - Section 7.cghodake1No ratings yet

- Special Ops NanosDocument16 pagesSpecial Ops NanosBryan396100% (2)

- ALM - CBRE Agile TFS Project Process Guidance v8Document74 pagesALM - CBRE Agile TFS Project Process Guidance v8vittoria1No ratings yet

- Business Process Audit Cycle: AuditorDocument2 pagesBusiness Process Audit Cycle: AuditorRavi javaliNo ratings yet

- Week 9 Continuous Improvement Quality ToolsDocument39 pagesWeek 9 Continuous Improvement Quality ToolskomuNo ratings yet

- ERP Project Management Primer: Quick Reference Guide To Best Practice Templates and Tips To Jumpstart Your ERP ProjectsDocument60 pagesERP Project Management Primer: Quick Reference Guide To Best Practice Templates and Tips To Jumpstart Your ERP ProjectsMahendra SinghNo ratings yet

- R&D Procedure - Control of Drawing Engg Specification P1Document1 pageR&D Procedure - Control of Drawing Engg Specification P1sumanNo ratings yet

- Process For Process Failure Mode & Effect Analysis (PFMEA)Document11 pagesProcess For Process Failure Mode & Effect Analysis (PFMEA)Gourav SainiNo ratings yet

- 02 PM - Step1 - EN - r4Document23 pages02 PM - Step1 - EN - r4dadytresnaNo ratings yet

- QualitysystemsDocument8 pagesQualitysystemsádfa caNo ratings yet

- As Is Vendor TPMDocument3 pagesAs Is Vendor TPMabhijitgharatNo ratings yet

- 961 Annex B Form 6b Me Strategy TemplateDocument2 pages961 Annex B Form 6b Me Strategy TemplateJeffrey Han Sy VanbelgicaNo ratings yet

- Park Managment System: Research + DiscoveryDocument1 pagePark Managment System: Research + DiscoveryabuzarNo ratings yet

- TMT Procedure - Analysis of Data & Continuous Improvement P2Document1 pageTMT Procedure - Analysis of Data & Continuous Improvement P2sumanNo ratings yet

- Turtle Diagram (Process Mapping) - ContohDocument3 pagesTurtle Diagram (Process Mapping) - Contohjefry sitorusNo ratings yet

- EPMDocument176 pagesEPMdhruva.verma100% (1)

- ISO 22000-2018 Clause Vs DeptDocument8 pagesISO 22000-2018 Clause Vs Deptangelaychen100% (1)

- Investment ProgrammingDocument14 pagesInvestment ProgrammingDILG NagaNo ratings yet

- Report On Maintenance Programme Recommendations and DisseminationDocument13 pagesReport On Maintenance Programme Recommendations and DisseminationKunal ShahNo ratings yet

- R&D Procedure - Control of Drawing Engg Specification P2Document1 pageR&D Procedure - Control of Drawing Engg Specification P2sumanNo ratings yet

- Maintenance Service SummaryDocument5 pagesMaintenance Service SummaryChenny RenNo ratings yet

- Drystar - 5302 5.0 - tcm220-21666Document47 pagesDrystar - 5302 5.0 - tcm220-21666Otniel KathonNo ratings yet

- Community Banking: Branch Operations Support & ServicesDocument28 pagesCommunity Banking: Branch Operations Support & ServicesFaizal potNo ratings yet

- 12 Chemistry Notes Ch01 The Solid StateDocument22 pages12 Chemistry Notes Ch01 The Solid StateVitesh TyagiNo ratings yet

- GM 1927 16 Process Control Plan Audit PCPADocument7 pagesGM 1927 16 Process Control Plan Audit PCPAMostafa Abd ElalemNo ratings yet

- 12 - P - Maintenance & Spare PartsDocument12 pages12 - P - Maintenance & Spare Partsrc2834338No ratings yet

- QAP Format PDFDocument7 pagesQAP Format PDFSree VBroNo ratings yet

- Smed PDFDocument72 pagesSmed PDFNaveen MalikNo ratings yet

- APQP Final ProcedureDocument9 pagesAPQP Final ProcedurePk NimiwalNo ratings yet

- Department: CNC SHOP Auditee: AuditorDocument33 pagesDepartment: CNC SHOP Auditee: AuditormuthuselvanNo ratings yet

- PEAR PresentationDocument38 pagesPEAR PresentationMiguel Ramos100% (2)

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDocument9 pagesGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikNo ratings yet

- 03 PM - Step2 - EN - r1Document22 pages03 PM - Step2 - EN - r1dadytresnaNo ratings yet

- SDT 6.0.3 Installation ManualDocument15 pagesSDT 6.0.3 Installation ManualMauricio MuñozNo ratings yet

- FMEA Master PresentationDocument63 pagesFMEA Master Presentationnigeldouch100% (1)

- Step 7 - Investment ProgrammingDocument14 pagesStep 7 - Investment ProgrammingTherese Mae AumanNo ratings yet

- Department: HOT SHOP Auditee: AuditorDocument52 pagesDepartment: HOT SHOP Auditee: AuditorSead ZejnilovicNo ratings yet

- Objectives Targets and ProgramsDocument5 pagesObjectives Targets and ProgramsKoshalNo ratings yet

- ISO ChecklistDocument36 pagesISO ChecklistDhinakaran100% (1)

- FLCQA-2004. Finish Goods DeliveryDocument6 pagesFLCQA-2004. Finish Goods Deliveryhuutam.ha93No ratings yet

- Intelligent Use of FMEA Presented By: Quality Associates InternationalDocument66 pagesIntelligent Use of FMEA Presented By: Quality Associates Internationalpradeep100% (1)

- Wrap Up TrainingDocument5 pagesWrap Up TrainingBUBUS BAHRUSSALAMNo ratings yet

- Propuesta WebsiteDocument7 pagesPropuesta WebsiteSujetoSujetoNo ratings yet

- Document No: Request For Quotation (RFQ Handling)Document4 pagesDocument No: Request For Quotation (RFQ Handling)jayNo ratings yet

- FMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFDocument10 pagesFMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFBonny BonitoNo ratings yet

- TCM F Ims 014 NCR Pama PC Cleaning MeiDocument2 pagesTCM F Ims 014 NCR Pama PC Cleaning Meiwahyu nurcahyoNo ratings yet

- Perfomance Review FormDocument2 pagesPerfomance Review Formndayiragije JMVNo ratings yet

- Timesheet GuidelineDocument8 pagesTimesheet GuidelinerohiniNo ratings yet

- Module 38. Analyze TollgateDocument36 pagesModule 38. Analyze Tollgatetaghavi1347No ratings yet

- BCEC-IT-CP-006-Rev.2-Staff Laptop Requisition, Issuance, Maintenance and UsageDocument15 pagesBCEC-IT-CP-006-Rev.2-Staff Laptop Requisition, Issuance, Maintenance and UsageCarwell AbatayoNo ratings yet

- Produksi Bersih (Cleaner Production: Methodology Audit CP (Unido)Document10 pagesProduksi Bersih (Cleaner Production: Methodology Audit CP (Unido)Dewi MasriNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Supply and Demand TogetherDocument6 pagesSupply and Demand TogetherQuang ĐạiNo ratings yet

- International Marketing Handout 2022-P1Document47 pagesInternational Marketing Handout 2022-P1Nguyễn Xuân HoaNo ratings yet

- Question 1: Read The Following Case and Attempt The Questions BelowDocument4 pagesQuestion 1: Read The Following Case and Attempt The Questions BelowShubham Aggarwal0% (1)

- Business & Corporate Law (BCL) : Prof. Parul GuptaDocument39 pagesBusiness & Corporate Law (BCL) : Prof. Parul GuptaManav SinghNo ratings yet

- Livelihood Loan Application Form For Deped - 1Document3 pagesLivelihood Loan Application Form For Deped - 1LyzelNo ratings yet

- Material ReservationDocument2 pagesMaterial ReservationRestuNo ratings yet

- SBD RCIP II PMGSY2 Sep17 ADBDocument125 pagesSBD RCIP II PMGSY2 Sep17 ADBRajendra KumrawatNo ratings yet

- Aisc-420-10 10 SSPC-QP 3Document16 pagesAisc-420-10 10 SSPC-QP 3Pacco HmNo ratings yet

- Attendance 2.0 Present 2.1 Absent With ApologyDocument3 pagesAttendance 2.0 Present 2.1 Absent With ApologyPaul NumbeNo ratings yet

- The Influence of Recruitment and Selection On Organizational Performance PDFDocument63 pagesThe Influence of Recruitment and Selection On Organizational Performance PDFAngelNo ratings yet

- Zoho CRM FlexDocument4 pagesZoho CRM Flexnishith.fddiNo ratings yet

- Domino's Pizza: The Global Leader in Pizza DeliveryDocument11 pagesDomino's Pizza: The Global Leader in Pizza DeliveryIva YarmovaNo ratings yet

- KYC CIS American Chinese Trading & Consulting INCDocument4 pagesKYC CIS American Chinese Trading & Consulting INCfranviNo ratings yet

- Public Private PartnershipsDocument22 pagesPublic Private PartnershipsPeter MutuiNo ratings yet

- Error Spotting Asked in Previous Year Prelim Exams: Get High Standard Mock Test Series For All Bank ExamsDocument12 pagesError Spotting Asked in Previous Year Prelim Exams: Get High Standard Mock Test Series For All Bank ExamsTechshalaNo ratings yet

- Assignment No. 3: Finance (BAT661) / 2 March2020Document9 pagesAssignment No. 3: Finance (BAT661) / 2 March2020Ashok SinghNo ratings yet

- BINTDocument2 pagesBINTJericho SumagueNo ratings yet

- Emdqp Ins 215Document16 pagesEmdqp Ins 215EduardNo ratings yet

- SAP Certification: Click HereDocument12 pagesSAP Certification: Click HereAbhishek MishraNo ratings yet

- Test Bank For Nutrition Essentials A Personal Approach 3rd Edition Wendy SchiffDocument24 pagesTest Bank For Nutrition Essentials A Personal Approach 3rd Edition Wendy Schiffcurlerbedye7dlv100% (41)

- Eureka ForbesDocument40 pagesEureka ForbesSrinath chinnaNo ratings yet

- Company Law and Corporate Governance - Cia 3Document12 pagesCompany Law and Corporate Governance - Cia 3harjas singhNo ratings yet

- Cc9222 Integrated Manufacturing Systems r9Document2 pagesCc9222 Integrated Manufacturing Systems r9SUBRAMANIAN PMNo ratings yet

- Outline Reviewer On Labor RelationsDocument6 pagesOutline Reviewer On Labor RelationsAlvy Faith Pel-ey100% (1)

- New Research File Complete PDFDocument42 pagesNew Research File Complete PDFTesslene Claire SantosNo ratings yet

- Indian Railways Catering and Tourism Corporation.: NAME: Rinal Vekaria SRN: 2019030070 Class: Sybms MarketingDocument10 pagesIndian Railways Catering and Tourism Corporation.: NAME: Rinal Vekaria SRN: 2019030070 Class: Sybms MarketingRinky VekariaNo ratings yet

- Hema Nagpal: Vice President Human ResourcesDocument3 pagesHema Nagpal: Vice President Human ResourcesKushal SainNo ratings yet

- Inventory Management System (3) - 2Document4 pagesInventory Management System (3) - 2iraoui jamal (Ebay)No ratings yet

Action Plan

Action Plan

Uploaded by

esayas0 ratings0% found this document useful (0 votes)

4 views3 pagesOriginal Title

Action plan

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

4 views3 pagesAction Plan

Action Plan

Uploaded by

esayasCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

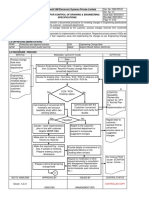

ACTIVITY PLAN

PDCA WHAT WHEN WHO WHERE HOW WHY

February March April May June July

Introduction CFT Production/ Flow map To know the

members Maintenance production

process

Theme Selection CFT Production/ Check Theme

members Maintenance sheet selection

Current Situation CFT Production/ Pareto Knowing the

Analysis members Maintenance diagram/ current

PLAN Histogram situation of the

machines

Target setting & CFT Production/ Graph/ For the

Preparation of members Maintenance 5W2H comprehension

action plan of the result

Cause Analysis CFT Production/ Fishbone Identifying

members Maintenance diagram/ root cause

Scatter

DO diagram

Identify CFT Production/ 5W2H To eliminate

countermeasures members Maintenance the root cause

& of the problem

Implementation

Check and CFT Production/ Graph/ Compared to

CHECK measure the result members Maintenance Pareto the target

diagram

Standardize the CFT Production/ Control Eliminating the

ACT result members Maintenance chart problem

Progress Notes/Comments

Steps Action Items Responsible Planned Planned

party Start date Finished date

1 Assessment and Baseline 01/07/2016 E.C 07/07/2016 E.C

Measurement

1.1 Identify target machines for CFT members

improvement

1.2 Conduct initial OEE CFT members

assessment

1.3 Establish baseline OEE CFT members

metrics

1.4 Document current CFT members

production processes

2 Root Cause Analysis 01/07/2016 E.C 01/07/2016 E.C

2.1 Identify factors affecting CFT members

OEE

2.2 Conduct root cause analysis CFT members

2.3 Prioritize root causes CFT members

2.4 Validate root causes with CFT members

the OEE team

3 Develop Improvement 15/07/2016 E.C 21/07/2016 E.C

Strategies

3.1 Brainstorm potential CFT members

solutions

3.2 Evaluate and select CFT members

improvement strategies

3.3 Develop detailed action CFT members

plans for each strategy

3.4 Obtain necessary resources CFT members

for implementation

4 Implementation of 01/08/2016 E.C O5/08/2016 E.C

Improvement Plans

4.1 Execute improvement plans CFT members

4.2 Monitor progress against CFT members

milestones

4.3 Address any issues or CFT members

roadblocks

5 Continuous Monitoring and 15/09/2016 E.C 30/09/2016 E.C

Adjustment

5.1 Implement real-time CFT members

monitoring systems

5.2 Regularly review OEE CFT members

metrics

5.3 Adjust strategies based on CFT members

performance feedback

6 Documentation and Training 06/10/2016 E.C 30/10/2016 E.C

6.1 Document updated CFT members

processes and best practices

6.2 Provide training for the CFT members

production team

7 Review and Continuous 01/11/2016 E.C 30/11/2016 E.C

Improvement

7.1 Conduct post- CFT members

implementation review

7.2 Identify lessons learned and CFT members

areas for further

improvement

7.3 Update OEE improvement CFT members

plan for ongoing

optimization

You might also like

- Statement: February 2023Document7 pagesStatement: February 2023MUSA ABDULSALAM ALARONo ratings yet

- 5M CHANGE ProcedureDocument8 pages5M CHANGE ProcedurePk Nimiwal100% (1)

- IQA IATF ChecksheetDocument37 pagesIQA IATF ChecksheetSumeet Rathee100% (6)

- APQP ProcedureDocument9 pagesAPQP ProcedurePk Nimiwal100% (5)

- NPD Check SheetDocument6 pagesNPD Check Sheets.charlie50% (2)

- Benefits of FMEADocument9 pagesBenefits of FMEAbaranirajsalem100% (2)

- Blake EletronicsDocument10 pagesBlake EletronicsParkbyun HanaNo ratings yet

- QSP-D&D-02 APQP ProcedureDocument6 pagesQSP-D&D-02 APQP ProcedureDeepak Kumar100% (1)

- DSM-200520-SP-10 Recommended Implementation Plan For Basic DataDocument7 pagesDSM-200520-SP-10 Recommended Implementation Plan For Basic DataAllif TukiranNo ratings yet

- QSP-05 Maintenance of Infrastructure TPM R2Document10 pagesQSP-05 Maintenance of Infrastructure TPM R2DhinakaranNo ratings yet

- QM 7 - Section 7.Document13 pagesQM 7 - Section 7.cghodake1No ratings yet

- Special Ops NanosDocument16 pagesSpecial Ops NanosBryan396100% (2)

- ALM - CBRE Agile TFS Project Process Guidance v8Document74 pagesALM - CBRE Agile TFS Project Process Guidance v8vittoria1No ratings yet

- Business Process Audit Cycle: AuditorDocument2 pagesBusiness Process Audit Cycle: AuditorRavi javaliNo ratings yet

- Week 9 Continuous Improvement Quality ToolsDocument39 pagesWeek 9 Continuous Improvement Quality ToolskomuNo ratings yet

- ERP Project Management Primer: Quick Reference Guide To Best Practice Templates and Tips To Jumpstart Your ERP ProjectsDocument60 pagesERP Project Management Primer: Quick Reference Guide To Best Practice Templates and Tips To Jumpstart Your ERP ProjectsMahendra SinghNo ratings yet

- R&D Procedure - Control of Drawing Engg Specification P1Document1 pageR&D Procedure - Control of Drawing Engg Specification P1sumanNo ratings yet

- Process For Process Failure Mode & Effect Analysis (PFMEA)Document11 pagesProcess For Process Failure Mode & Effect Analysis (PFMEA)Gourav SainiNo ratings yet

- 02 PM - Step1 - EN - r4Document23 pages02 PM - Step1 - EN - r4dadytresnaNo ratings yet

- QualitysystemsDocument8 pagesQualitysystemsádfa caNo ratings yet

- As Is Vendor TPMDocument3 pagesAs Is Vendor TPMabhijitgharatNo ratings yet

- 961 Annex B Form 6b Me Strategy TemplateDocument2 pages961 Annex B Form 6b Me Strategy TemplateJeffrey Han Sy VanbelgicaNo ratings yet

- Park Managment System: Research + DiscoveryDocument1 pagePark Managment System: Research + DiscoveryabuzarNo ratings yet

- TMT Procedure - Analysis of Data & Continuous Improvement P2Document1 pageTMT Procedure - Analysis of Data & Continuous Improvement P2sumanNo ratings yet

- Turtle Diagram (Process Mapping) - ContohDocument3 pagesTurtle Diagram (Process Mapping) - Contohjefry sitorusNo ratings yet

- EPMDocument176 pagesEPMdhruva.verma100% (1)

- ISO 22000-2018 Clause Vs DeptDocument8 pagesISO 22000-2018 Clause Vs Deptangelaychen100% (1)

- Investment ProgrammingDocument14 pagesInvestment ProgrammingDILG NagaNo ratings yet

- Report On Maintenance Programme Recommendations and DisseminationDocument13 pagesReport On Maintenance Programme Recommendations and DisseminationKunal ShahNo ratings yet

- R&D Procedure - Control of Drawing Engg Specification P2Document1 pageR&D Procedure - Control of Drawing Engg Specification P2sumanNo ratings yet

- Maintenance Service SummaryDocument5 pagesMaintenance Service SummaryChenny RenNo ratings yet

- Drystar - 5302 5.0 - tcm220-21666Document47 pagesDrystar - 5302 5.0 - tcm220-21666Otniel KathonNo ratings yet

- Community Banking: Branch Operations Support & ServicesDocument28 pagesCommunity Banking: Branch Operations Support & ServicesFaizal potNo ratings yet

- 12 Chemistry Notes Ch01 The Solid StateDocument22 pages12 Chemistry Notes Ch01 The Solid StateVitesh TyagiNo ratings yet

- GM 1927 16 Process Control Plan Audit PCPADocument7 pagesGM 1927 16 Process Control Plan Audit PCPAMostafa Abd ElalemNo ratings yet

- 12 - P - Maintenance & Spare PartsDocument12 pages12 - P - Maintenance & Spare Partsrc2834338No ratings yet

- QAP Format PDFDocument7 pagesQAP Format PDFSree VBroNo ratings yet

- Smed PDFDocument72 pagesSmed PDFNaveen MalikNo ratings yet

- APQP Final ProcedureDocument9 pagesAPQP Final ProcedurePk NimiwalNo ratings yet

- Department: CNC SHOP Auditee: AuditorDocument33 pagesDepartment: CNC SHOP Auditee: AuditormuthuselvanNo ratings yet

- PEAR PresentationDocument38 pagesPEAR PresentationMiguel Ramos100% (2)

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDocument9 pagesGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikNo ratings yet

- 03 PM - Step2 - EN - r1Document22 pages03 PM - Step2 - EN - r1dadytresnaNo ratings yet

- SDT 6.0.3 Installation ManualDocument15 pagesSDT 6.0.3 Installation ManualMauricio MuñozNo ratings yet

- FMEA Master PresentationDocument63 pagesFMEA Master Presentationnigeldouch100% (1)

- Step 7 - Investment ProgrammingDocument14 pagesStep 7 - Investment ProgrammingTherese Mae AumanNo ratings yet

- Department: HOT SHOP Auditee: AuditorDocument52 pagesDepartment: HOT SHOP Auditee: AuditorSead ZejnilovicNo ratings yet

- Objectives Targets and ProgramsDocument5 pagesObjectives Targets and ProgramsKoshalNo ratings yet

- ISO ChecklistDocument36 pagesISO ChecklistDhinakaran100% (1)

- FLCQA-2004. Finish Goods DeliveryDocument6 pagesFLCQA-2004. Finish Goods Deliveryhuutam.ha93No ratings yet

- Intelligent Use of FMEA Presented By: Quality Associates InternationalDocument66 pagesIntelligent Use of FMEA Presented By: Quality Associates Internationalpradeep100% (1)

- Wrap Up TrainingDocument5 pagesWrap Up TrainingBUBUS BAHRUSSALAMNo ratings yet

- Propuesta WebsiteDocument7 pagesPropuesta WebsiteSujetoSujetoNo ratings yet

- Document No: Request For Quotation (RFQ Handling)Document4 pagesDocument No: Request For Quotation (RFQ Handling)jayNo ratings yet

- FMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFDocument10 pagesFMEA Errata Sheet ENG AIAG VDA FMEA Handbook 202000602 PDFBonny BonitoNo ratings yet

- TCM F Ims 014 NCR Pama PC Cleaning MeiDocument2 pagesTCM F Ims 014 NCR Pama PC Cleaning Meiwahyu nurcahyoNo ratings yet

- Perfomance Review FormDocument2 pagesPerfomance Review Formndayiragije JMVNo ratings yet

- Timesheet GuidelineDocument8 pagesTimesheet GuidelinerohiniNo ratings yet

- Module 38. Analyze TollgateDocument36 pagesModule 38. Analyze Tollgatetaghavi1347No ratings yet

- BCEC-IT-CP-006-Rev.2-Staff Laptop Requisition, Issuance, Maintenance and UsageDocument15 pagesBCEC-IT-CP-006-Rev.2-Staff Laptop Requisition, Issuance, Maintenance and UsageCarwell AbatayoNo ratings yet

- Produksi Bersih (Cleaner Production: Methodology Audit CP (Unido)Document10 pagesProduksi Bersih (Cleaner Production: Methodology Audit CP (Unido)Dewi MasriNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Supply and Demand TogetherDocument6 pagesSupply and Demand TogetherQuang ĐạiNo ratings yet

- International Marketing Handout 2022-P1Document47 pagesInternational Marketing Handout 2022-P1Nguyễn Xuân HoaNo ratings yet

- Question 1: Read The Following Case and Attempt The Questions BelowDocument4 pagesQuestion 1: Read The Following Case and Attempt The Questions BelowShubham Aggarwal0% (1)

- Business & Corporate Law (BCL) : Prof. Parul GuptaDocument39 pagesBusiness & Corporate Law (BCL) : Prof. Parul GuptaManav SinghNo ratings yet

- Livelihood Loan Application Form For Deped - 1Document3 pagesLivelihood Loan Application Form For Deped - 1LyzelNo ratings yet

- Material ReservationDocument2 pagesMaterial ReservationRestuNo ratings yet

- SBD RCIP II PMGSY2 Sep17 ADBDocument125 pagesSBD RCIP II PMGSY2 Sep17 ADBRajendra KumrawatNo ratings yet

- Aisc-420-10 10 SSPC-QP 3Document16 pagesAisc-420-10 10 SSPC-QP 3Pacco HmNo ratings yet

- Attendance 2.0 Present 2.1 Absent With ApologyDocument3 pagesAttendance 2.0 Present 2.1 Absent With ApologyPaul NumbeNo ratings yet

- The Influence of Recruitment and Selection On Organizational Performance PDFDocument63 pagesThe Influence of Recruitment and Selection On Organizational Performance PDFAngelNo ratings yet

- Zoho CRM FlexDocument4 pagesZoho CRM Flexnishith.fddiNo ratings yet

- Domino's Pizza: The Global Leader in Pizza DeliveryDocument11 pagesDomino's Pizza: The Global Leader in Pizza DeliveryIva YarmovaNo ratings yet

- KYC CIS American Chinese Trading & Consulting INCDocument4 pagesKYC CIS American Chinese Trading & Consulting INCfranviNo ratings yet

- Public Private PartnershipsDocument22 pagesPublic Private PartnershipsPeter MutuiNo ratings yet

- Error Spotting Asked in Previous Year Prelim Exams: Get High Standard Mock Test Series For All Bank ExamsDocument12 pagesError Spotting Asked in Previous Year Prelim Exams: Get High Standard Mock Test Series For All Bank ExamsTechshalaNo ratings yet

- Assignment No. 3: Finance (BAT661) / 2 March2020Document9 pagesAssignment No. 3: Finance (BAT661) / 2 March2020Ashok SinghNo ratings yet

- BINTDocument2 pagesBINTJericho SumagueNo ratings yet

- Emdqp Ins 215Document16 pagesEmdqp Ins 215EduardNo ratings yet

- SAP Certification: Click HereDocument12 pagesSAP Certification: Click HereAbhishek MishraNo ratings yet

- Test Bank For Nutrition Essentials A Personal Approach 3rd Edition Wendy SchiffDocument24 pagesTest Bank For Nutrition Essentials A Personal Approach 3rd Edition Wendy Schiffcurlerbedye7dlv100% (41)

- Eureka ForbesDocument40 pagesEureka ForbesSrinath chinnaNo ratings yet

- Company Law and Corporate Governance - Cia 3Document12 pagesCompany Law and Corporate Governance - Cia 3harjas singhNo ratings yet

- Cc9222 Integrated Manufacturing Systems r9Document2 pagesCc9222 Integrated Manufacturing Systems r9SUBRAMANIAN PMNo ratings yet

- Outline Reviewer On Labor RelationsDocument6 pagesOutline Reviewer On Labor RelationsAlvy Faith Pel-ey100% (1)

- New Research File Complete PDFDocument42 pagesNew Research File Complete PDFTesslene Claire SantosNo ratings yet

- Indian Railways Catering and Tourism Corporation.: NAME: Rinal Vekaria SRN: 2019030070 Class: Sybms MarketingDocument10 pagesIndian Railways Catering and Tourism Corporation.: NAME: Rinal Vekaria SRN: 2019030070 Class: Sybms MarketingRinky VekariaNo ratings yet

- Hema Nagpal: Vice President Human ResourcesDocument3 pagesHema Nagpal: Vice President Human ResourcesKushal SainNo ratings yet

- Inventory Management System (3) - 2Document4 pagesInventory Management System (3) - 2iraoui jamal (Ebay)No ratings yet