Professional Documents

Culture Documents

MS - Fabrication Work

MS - Fabrication Work

Uploaded by

rajubiswashseCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS - Fabrication Work

MS - Fabrication Work

Uploaded by

rajubiswashseCopyright:

Available Formats

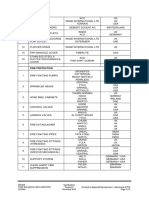

APPENDIX - 8

Method Statement

Job/ Activity/Task: Fabrication Work Ref:

Codes/Standards applicable:

TCPL Green Energy Solutions Private Limited

Job Location: TGESPL

Risk assessment reference: (Attach RA document to this Method

Statement)

Prepared by: Reviewed by:

Signature: Approved by:

Date: Valid till:

Contract details and Responsibility: (The Supplier executing the work is responsible for carrying

out a particular action. The Supplier’s On-site Coordinator is responsible to ensure that the Supplier is

competent and satisfied with the procedures listed. The Supplier’s On-site Coordinator is required to

provide supervision, to the extent necessary, to make sure the Method Statement is being followed

and to take immediate corrective action if it is not).

Scope of work: (Provide description of the work)

Item Job Step Identified Hazard and Controls

(Break the job down Assessment (What you are going to do to make this

into steps) (What can cause a step as safe as possible, include

high degree of harm?) equipment to be used where appropriate)

1 Material preparation Cutting and Provide proper machine guarding,

Shearing including barriers, interlocks, and

Machines emergency stops.

Chemical Hazards Ensure operators are trained in safe

hearing damage operating procedures and use

musculoskeletal appropriate personal protective

disorders equipment (PPE) such as gloves and

Fire and safety glasses.

Explosion Use less hazardous alternatives

Heat and whenever possible. Provide adequate

Radiation ventilation and personal protective

electrocution equipment (PPE) such as gloves,

goggles, and respirators.

Implement proper storage and

handling procedures, including labeling

and spill containment.

Use engineering controls like noise

barriers and acoustic enclosures to

reduce noise levels.

Implement a hearing conservation

program, including regular noise level

monitoring and the provision of

hearing protection devices (HPDs) such

as earplugs or earmuffs.

Provide mechanical aids such as lifting

equipment or conveyors to reduce

manual handling.

Design workstations and workflows to

minimize awkward postures.

Train workers in proper lifting

techniques and encourage frequent

breaks and stretching exercises.

Store flammable materials in

designated areas with proper

ventilation and fire suppression

systems.

Use spark-resistant tools and

equipment where applicable.

Implement strict housekeeping

procedures to minimize the

accumulation of flammable dust or

debris.

Provide appropriate PPE such as

welding helmets, gloves, and

protective clothing.

Implement engineering controls like

welding screens or curtains to shield

nearby workers from radiation.

Ensure adequate ventilation to remove

welding fumes and gases from the

work area.

Ensure electrical equipment is properly

installed, grounded, and maintained.

Provide electrical safety training for

workers, including procedures for

lockout/tag out (LOTO) when servicing

equipment.

Inspect and test electrical systems

regularly to identify and address any

hazards.

2 Assembly processes musculoskeletal Provide mechanical lifting aids such as

injuries hoists, cranes, or forklifts to reduce

crush or manual handling.

entanglement Train workers in proper lifting

Fall techniques and encourage team lifting

Adhesives and for heavier objects.

Solvents Design workstations to minimize

Electrocution reaching and bending.

Heat and Fire Implement machine guarding,

hearing damage including barriers, interlocks, and

presence-sensing devices, to prevent

access to hazardous areas.

Conduct regular maintenance and

inspections to ensure equipment is in

safe working condition.

Use guardrails, toe boards, and

personal fall protection equipment

such as harnesses and lanyards when

working at heights.

Ensure platforms and scaffolds are

properly constructed, inspected, and

maintained.

Use less hazardous alternatives

whenever possible.

Provide adequate ventilation and

personal protective equipment (PPE)

such as gloves, goggles, and

respirators.

Implement proper storage and

handling procedures, including labeling

and spill containment.

Ensure electrical equipment is properly

maintained, grounded, and used in

accordance with safety guidelines.

Provide electrical safety training for

workers and implement lockout/tag

out (LOTO) procedures when servicing

equipment.

Use fire-resistant materials and

equipment when possible.

Provide appropriate personal

protective equipment (PPE) such as

welding helmets, gloves, and aprons.

Maintain a clean work area free from

combustible materials and implement

fire prevention measures such as fire

extinguishers and fire blankets.

Use engineering controls like noise

barriers and acoustic enclosures to

reduce noise levels.

Implement a hearing conservation

program, including regular noise level

monitoring and the provision of

hearing protection devices (HPDs) such

as earplugs or earmuffs.

3 Forming and Shaping crush or Implement machine guarding,

entanglement including barriers, interlocks, and

Heat and Burns presence-sensing devices, to prevent

Ejection of Parts access to hazardous areas.

or Material Conduct regular maintenance and

Chemical Agents inspections to ensure equipment is in

hearing damage safe working condition.

Repetitive Motion Provide thermal insulation for hot

Fall surfaces and equipment.

Ensure workers wear appropriate

personal protective equipment (PPE)

such as heat-resistant gloves, aprons,

and clothing.

Implement procedures for safe

handling of hot materials and tools.

Implement barriers or shields to

contain ejected material.

Ensure workers maintain a safe

distance from machinery during

operation.

Provide training on safe work practices

and the use of personal protective

equipment (PPE) such as safety glasses

and face shields.

Use less hazardous alternatives

whenever possible.

Provide adequate ventilation and

personal protective equipment (PPE)

such as gloves, goggles, and

respirators.

Implement proper storage and

handling procedures, including labeling

and spill containment.

Use engineering controls like noise

barriers and acoustic enclosures to

reduce noise levels.

Implement a hearing conservation

program, including regular noise level

monitoring and the provision of

hearing protection devices (HPDs) such

as earplugs or earmuffs.

Design workstations and workflows to

minimize repetitive motions and

awkward postures.

Provide ergonomic tools and

equipment to reduce strain on

workers.

Implement job rotation and breaks to

allow for rest and recovery.

Use guardrails, toe boards, and

personal fall protection equipment

such as harnesses and lanyards when

working at heights.

Ensure platforms and scaffolds are

properly constructed, inspected, and

maintained.

Accepted by:____________________

What should a good Method Statement contain?

(General not exclusive)

1. Details of contract:

The name and local address of the persons to whom you are contracted (including the site

address if different).

The names, job titles, and telephone numbers of all relevant contacts, including the site

supervisor, manager or director responsible for the site.

The number of employees on the job at any time and names.

When the work is going to take place i.e. dates and times (nights, week end work, etc), the

dates for set up, removal and clearance.

The names of the principal Supplier, the planning supervisor and CDM client, if CDM applies.

The name(s) of any license holders involved.

2. Scope of work and risk assessment:

Provide a description of the work.

Provide details of any access and fire risk and precautions to be taken.

Include details of how safe places of work will be provided and maintained.

Provide details of any other risks and precautions.

3. Control measures:

State the expected exposure to hazards using the controls specified.

Describe the steps taken to reduce exposure as low as reasonably practicable and to control

any release into the environment.

Provide sketch(es) showing:

o • size of work area;

o • location

o • waste routes;

o • and skips etc.

Describe how control measures are to be maintained on site and what checks.

4. Method of work:

State any additional precautions to reduce exposure to hazards.

Provide detailed site information and a site specific description of the working method to be

used with reasons.

State what tools and other equipment are to be used.

5. Other site-specific information relating to:

Entry and exit procedures.

Waste disposal.

Emergency procedures

Written details, photograph or diagram

You might also like

- Rebar Installation: Job Safety AnalysisDocument1 pageRebar Installation: Job Safety AnalysisRetselisitsoe100% (3)

- NWC Corporate Projects Risk Assessment Forms: Confined SpaceDocument4 pagesNWC Corporate Projects Risk Assessment Forms: Confined SpaceNowfal Habeeb50% (2)

- 332CDocument2 pages332CLo Siento de VerdadNo ratings yet

- MS - Plumbing JobDocument13 pagesMS - Plumbing JobrajubiswashseNo ratings yet

- MS - Anti TermiteDocument4 pagesMS - Anti TermiterajubiswashseNo ratings yet

- PPE Match ActivityDocument2 pagesPPE Match ActivityNicolas Andrés VargasNo ratings yet

- Hazard Identification Checklist: Issues/Areas To ConsiderDocument3 pagesHazard Identification Checklist: Issues/Areas To ConsiderAaquil RaziNo ratings yet

- JSA On Torqueing BoltsDocument5 pagesJSA On Torqueing Boltssyed baqarNo ratings yet

- Trade Area: Construction Industry-PaintingDocument3 pagesTrade Area: Construction Industry-PaintingRam-tech Jackolito FernandezNo ratings yet

- Workshop One NotesDocument43 pagesWorkshop One NotesMos AlvoNo ratings yet

- BSEE 3B-BOSH JOB HAZARD ANALYSIS EXAM (Regaspi, Alvin B.)Document5 pagesBSEE 3B-BOSH JOB HAZARD ANALYSIS EXAM (Regaspi, Alvin B.)Allen Kyle PrielaNo ratings yet

- Home Based Learning INPDocument8 pagesHome Based Learning INPjanna mae patriarcaNo ratings yet

- Day 4 WorkshopDocument1 pageDay 4 WorkshopJOHN CARLO ROSELLONo ratings yet

- Day 4 Workshop 2Document1 pageDay 4 Workshop 2JOHN CARLO ROSELLONo ratings yet

- Workplace Hazards in ConstructionDocument2 pagesWorkplace Hazards in ConstructionDWi Uwee DejHeNo ratings yet

- AHA Painting WorkDocument3 pagesAHA Painting Workanilkumaranoop74No ratings yet

- JSA DrillingDocument12 pagesJSA DrillingAbdus SamadNo ratings yet

- LO2 - PolicyDocument4 pagesLO2 - Policy4t8k88fcfkNo ratings yet

- Presentazione Standard SERGIODocument25 pagesPresentazione Standard SERGIOsergioNo ratings yet

- ENVIRONMENT & SUSTAINABILITY (Safety)Document16 pagesENVIRONMENT & SUSTAINABILITY (Safety)nurul izzanyNo ratings yet

- Activity Hazard Analysis For Backfilling and CompactionDocument2 pagesActivity Hazard Analysis For Backfilling and Compactionanoopanil16No ratings yet

- Report FDP - Safety Health and EnvironmentDocument26 pagesReport FDP - Safety Health and EnvironmentJss Aircond & ElectricalNo ratings yet

- Report FDP - Safety Health and EnvironmentDocument26 pagesReport FDP - Safety Health and EnvironmentJss Aircond & ElectricalNo ratings yet

- Hazard Analysis Office EnvironmentDocument1 pageHazard Analysis Office Environmentjaglansunil100% (1)

- WKS 6 Noise in ManufacturingDocument3 pagesWKS 6 Noise in ManufacturingVelpandian ManiNo ratings yet

- Risk Assessment: 1 Hazard Identification 1.1 Hazardous MaterialsDocument29 pagesRisk Assessment: 1 Hazard Identification 1.1 Hazardous MaterialsjohnNo ratings yet

- Standard Blasting ProceduresDocument8 pagesStandard Blasting Proceduresshirlyvertudazo25No ratings yet

- JESA - Welding Grinding & Cutting WorksDocument7 pagesJESA - Welding Grinding & Cutting WorksLeo PascualNo ratings yet

- Melab 2 Final ReportDocument5 pagesMelab 2 Final ReportVierzon TiamzonNo ratings yet

- Job Safety Analysis Installation (JSA)Document4 pagesJob Safety Analysis Installation (JSA)Aser Batoy Jr.No ratings yet

- Fall Protection - Toolbox Talk - EnglishDocument1 pageFall Protection - Toolbox Talk - EnglishJomy JohnyNo ratings yet

- Accident Prevention: Health & Safety Management For QuarriesDocument19 pagesAccident Prevention: Health & Safety Management For QuarriesSanjana Ganesh100% (1)

- Fitness Centres, Gyms and PoolsDocument1 pageFitness Centres, Gyms and PoolsVasile NodisNo ratings yet

- AU General Risk Assessment: Brief Description of Activity: Assessor/s: DateDocument3 pagesAU General Risk Assessment: Brief Description of Activity: Assessor/s: DateElsad HuseynovNo ratings yet

- Hazard Analysis AutomotiveDocument1 pageHazard Analysis AutomotivejaglansunilNo ratings yet

- Job Safety Analysis - N2 PurgingDocument3 pagesJob Safety Analysis - N2 Purgingbenjamin alingNo ratings yet

- Controlling HazardsDocument14 pagesControlling HazardsAwetahegn HagosNo ratings yet

- JsaDocument13 pagesJsaArnold Roy Coballes Manalo100% (1)

- Guia 9 Elementos de ProteccionDocument7 pagesGuia 9 Elementos de Protecciondiego sierra florezNo ratings yet

- Job Hazard Analysis PermitDocument1 pageJob Hazard Analysis PermitKhorchnoi Abaja CalimlimNo ratings yet

- Conditions To Prevent AccidentDocument21 pagesConditions To Prevent Accidentczds6594No ratings yet

- ILS Guidebook Health SafetyDocument20 pagesILS Guidebook Health SafetyFran PizarroNo ratings yet

- Mine SafetyDocument3 pagesMine SafetyShahad BalaoroNo ratings yet

- 15 ConstructionDocument2 pages15 ConstructionBob StevenNo ratings yet

- Safety and HealthDocument54 pagesSafety and Healthkhairuddin shamsudinNo ratings yet

- 01 General Safety PDF PDFDocument1 page01 General Safety PDF PDFrichNo ratings yet

- PROMFG INTER ENG 2019 DarmonDocument6 pagesPROMFG INTER ENG 2019 DarmonAda DarmonNo ratings yet

- InsaragDocument29 pagesInsaragdeki afriansyahNo ratings yet

- JSA PlumberDocument2 pagesJSA PlumberNaresh KumarNo ratings yet

- Confined Space ChecklistDocument1 pageConfined Space ChecklistIbrahim EsmatNo ratings yet

- Cleaning: Risk Assessment For: Establishment: Assessment By: DateDocument4 pagesCleaning: Risk Assessment For: Establishment: Assessment By: DateEzzati AzizNo ratings yet

- JSA 02-Rev.01 - Blinding & DeblindingDocument1 pageJSA 02-Rev.01 - Blinding & DeblindinggolusinghdataNo ratings yet

- Hydrogen Safety ChecklistDocument3 pagesHydrogen Safety ChecklistPradeepNo ratings yet

- JHA Example - CHC ScenarioDocument2 pagesJHA Example - CHC ScenarioBNCHNo ratings yet

- Assignment HazardsDocument11 pagesAssignment HazardsCh TälhåNo ratings yet

- Module 20 - Job Hazard Analysis (JHA)Document8 pagesModule 20 - Job Hazard Analysis (JHA)Aviects Avie JaroNo ratings yet

- PPE Manual A5 en 2Document9 pagesPPE Manual A5 en 2ANSARNo ratings yet

- Pera Air CompressorDocument6 pagesPera Air CompressorJigar VekariyaNo ratings yet

- Demolition XXXDocument13 pagesDemolition XXXSawLaiBoyanNo ratings yet

- Pattern AssociationDocument36 pagesPattern AssociationRoots999No ratings yet

- RTWP - 2Document62 pagesRTWP - 2AsmaeNo ratings yet

- Chapter 2 JFET AC AnalysisDocument47 pagesChapter 2 JFET AC AnalysisRazman RamedanNo ratings yet

- Estimation of Welding Cost: by K.R.Prasanna Venkatesan WE0663Document41 pagesEstimation of Welding Cost: by K.R.Prasanna Venkatesan WE0663Anonymous 7yN43wjl100% (1)

- HaraprasadShastri NepalDurbarV-2 1915 TextDocument348 pagesHaraprasadShastri NepalDurbarV-2 1915 TextSIva85kami100% (1)

- Formulas Physics B CH 11, 12, 22, 23, 24, 25 WavesDocument6 pagesFormulas Physics B CH 11, 12, 22, 23, 24, 25 WavesEpic WinNo ratings yet

- Chapter 1 - IntroductionDocument4 pagesChapter 1 - IntroductionJessela MarieNo ratings yet

- GNPF Practical Manual FinalDocument46 pagesGNPF Practical Manual FinalMonalisa SahooNo ratings yet

- GeographyDocument13 pagesGeographyRao RaasNo ratings yet

- HFX Manual ENDocument40 pagesHFX Manual ENmohammad AshrafNo ratings yet

- Vendor ListDocument1 pageVendor ListbhimaNo ratings yet

- Drago Cmuk: Technical ManagerDocument3 pagesDrago Cmuk: Technical ManagerDrago CmukNo ratings yet

- Image Processing and Pattern Recoginition Lab ManualDocument38 pagesImage Processing and Pattern Recoginition Lab ManualDeepa SNo ratings yet

- Unit 4Document53 pagesUnit 4Ashish JoshiNo ratings yet

- Presentation - Slum Department 21st Sept 2010Document42 pagesPresentation - Slum Department 21st Sept 2010Nupur Bhadra100% (1)

- Gidaa Alamry: AbstractDocument15 pagesGidaa Alamry: AbstractJann Ernest R. FesalbonNo ratings yet

- TND381 DDocument63 pagesTND381 DteomondoNo ratings yet

- Bravo500 enDocument12 pagesBravo500 encretzuuu90No ratings yet

- Ore) Fe: GL Ikeerch AcDocument492 pagesOre) Fe: GL Ikeerch Accomputergator2014No ratings yet

- LeafDocument39 pagesLeafDomagoj Butumović100% (1)

- Taxonomy Unit Test AccommodatedDocument2 pagesTaxonomy Unit Test Accommodatedapi-242217113100% (2)

- Water Hammer - : Can It Happen in My Plant?Document45 pagesWater Hammer - : Can It Happen in My Plant?limin zhang75% (4)

- Combined Footing:-: Principles of Proportioning Combined FootingsDocument2 pagesCombined Footing:-: Principles of Proportioning Combined FootingsUno CasprowichNo ratings yet

- Some Basic Concepts of Chemistry: Corporate Office: Aakash Tower, 8, Pusa Road, New Delhi-110005 Ph.011-47623456Document137 pagesSome Basic Concepts of Chemistry: Corporate Office: Aakash Tower, 8, Pusa Road, New Delhi-110005 Ph.011-47623456parv goyalNo ratings yet

- British Universal Columns and BeamsDocument4 pagesBritish Universal Columns and BeamsblaqhaqarNo ratings yet

- Q-PANEL Standard Substrate Applications GuideDocument2 pagesQ-PANEL Standard Substrate Applications GuideGhulam HussainNo ratings yet

- نسخة 12- Lecture Hematological DisordersDocument12 pagesنسخة 12- Lecture Hematological DisordersRoxe BroNo ratings yet

- SJ 46np46n49np49nDocument8 pagesSJ 46np46n49np49nSiti Khadijah Ab RahmanNo ratings yet

- Lecture 20Document24 pagesLecture 20Trix CCNo ratings yet