Professional Documents

Culture Documents

27.04.2023 - Eni Congo - Promar BD - Foukanda - Serenity

27.04.2023 - Eni Congo - Promar BD - Foukanda - Serenity

Uploaded by

BitsindouCopyright:

Available Formats

You might also like

- Cultural Organization Salient PointsDocument5 pagesCultural Organization Salient PointsJenshan WriteNo ratings yet

- Case StudyDocument2 pagesCase StudyJuztine Raboy100% (1)

- JSA For Life Line InstolationDocument17 pagesJSA For Life Line InstolationShekh BabulNo ratings yet

- Form Grouting & Concrete InspectionDocument3 pagesForm Grouting & Concrete Inspectionyuwantoni0% (1)

- Table of LegitimesDocument2 pagesTable of Legitimesangeliangeliangeli100% (2)

- Demanding For Child Support and CollectionDocument3 pagesDemanding For Child Support and CollectionElly Paul Andres Tomas100% (1)

- July 31 - 2023ENI CONGO - PROMAR Bridging KITINADocument54 pagesJuly 31 - 2023ENI CONGO - PROMAR Bridging KITINABitsindouNo ratings yet

- 2021-10-19-ENI CONGO - TIDEWATER Bridging DocumentDocument30 pages2021-10-19-ENI CONGO - TIDEWATER Bridging DocumentBitsindouNo ratings yet

- Ekoee Ccs Exs Mes WPR LBM t1 206 01Document39 pagesEkoee Ccs Exs Mes WPR LBM t1 206 01Olatunji Olawale JamesNo ratings yet

- Certificate of ClassificationDocument2 pagesCertificate of ClassificationVirtual ExtrovertNo ratings yet

- Civ-S-006 - USB SheetDocument2 pagesCiv-S-006 - USB SheetmadeirastelioNo ratings yet

- Civ-S-006 - USB SheetDocument2 pagesCiv-S-006 - USB SheetmadeirastelioNo ratings yet

- Civ S 007 Brick ForceDocument2 pagesCiv S 007 Brick ForcemadeirastelioNo ratings yet

- Civ-S-007 - Brick ForceDocument2 pagesCiv-S-007 - Brick ForcemadeirastelioNo ratings yet

- Weekly H & Safety Report From 13 To 19 June 2023Document20 pagesWeekly H & Safety Report From 13 To 19 June 2023mico fredNo ratings yet

- Ship FopDocument7 pagesShip FopAndriy IshchenkoNo ratings yet

- Civ-S-008 - Roof Truss ConnectorsDocument2 pagesCiv-S-008 - Roof Truss ConnectorsmadeirastelioNo ratings yet

- Conspro Management Services: Contents of ReportDocument5 pagesConspro Management Services: Contents of ReportGirishNo ratings yet

- Ship FopDocument8 pagesShip FopArt HouseNo ratings yet

- Request For Generator Fuel 3032024Document2 pagesRequest For Generator Fuel 3032024KamanziNo ratings yet

- S Mir 012Document1 pageS Mir 012PRAVEENNo ratings yet

- AB KIMO JoiningDocumentsDocument19 pagesAB KIMO JoiningDocumentsdhamodarNo ratings yet

- 02 2024 Minimum PPE RequirementDocument1 page02 2024 Minimum PPE RequirementFelix DemolaNo ratings yet

- MUM315115Document1 pageMUM315115bb6tspv2ydNo ratings yet

- 40 - Anchor Handling Procedure - 230705 - 171155Document44 pages40 - Anchor Handling Procedure - 230705 - 171155Tao HienNo ratings yet

- Alignment Meeting Minutes 2Document3 pagesAlignment Meeting Minutes 2Ifebhor AlexanderNo ratings yet

- JSA For WIndow Opening and Finishing WorkDocument17 pagesJSA For WIndow Opening and Finishing WorkShekh BabulNo ratings yet

- JSA For Scaffoding Erection and DismentlingDocument17 pagesJSA For Scaffoding Erection and DismentlingShekh BabulNo ratings yet

- JSA For SRP Instolation and DismentlingDocument17 pagesJSA For SRP Instolation and DismentlingShekh BabulNo ratings yet

- JSa For Glass FixingDocument17 pagesJSa For Glass FixingShekh BabulNo ratings yet

- Waterproofing InspectionDocument1 pageWaterproofing InspectionDyg Nur FarrahinNo ratings yet

- Civ S 005 Anti TermiteDocument2 pagesCiv S 005 Anti TermitemadeirastelioNo ratings yet

- K017-T12-0003 - 0 Method Statement For Extension Work of Temporary JettyDocument16 pagesK017-T12-0003 - 0 Method Statement For Extension Work of Temporary JettyBayu PutraNo ratings yet

- ENI CONGO - Bambini Spa Bridging DocumentDocument45 pagesENI CONGO - Bambini Spa Bridging DocumentBitsindouNo ratings yet

- MS For Concrete Block Mesonry WorkDocument10 pagesMS For Concrete Block Mesonry WorkPandiaraj VNo ratings yet

- Civ S 005 Anti TermiteDocument2 pagesCiv S 005 Anti TermitemadeirastelioNo ratings yet

- Internal QSHE Audit Plan For Year 2023 Rev03Document1 pageInternal QSHE Audit Plan For Year 2023 Rev03Syerifaizal Hj. MustaphaNo ratings yet

- Private Car Liability Only Policy - Zone B Motor Insurance Certificate Cum Policy ScheduleDocument2 pagesPrivate Car Liability Only Policy - Zone B Motor Insurance Certificate Cum Policy Scheduledd889wycpwNo ratings yet

- 4239 Mom TCM BBT 0007Document2 pages4239 Mom TCM BBT 0007Daniel NjokuNo ratings yet

- Curriculum Vitae: Personal DetailsDocument14 pagesCurriculum Vitae: Personal Detailsskylinkcyber3No ratings yet

- Bahari Mitra Ancora DesignDocument2 pagesBahari Mitra Ancora Designputri ajeng fernandaNo ratings yet

- Observation Report OctDocument2 pagesObservation Report OctVikknes KaliappanNo ratings yet

- S Mir 011Document1 pageS Mir 011PRAVEENNo ratings yet

- Ejb-2023!22!401-R3 Ravi Kiran Hull MtoDocument12 pagesEjb-2023!22!401-R3 Ravi Kiran Hull MtoDesh DeepakNo ratings yet

- ENGY-EnG3-MOS-20210603-002 - Method of Statement For Concrete Pavement WorksDocument21 pagesENGY-EnG3-MOS-20210603-002 - Method of Statement For Concrete Pavement WorksTemur LomidzeNo ratings yet

- WEEKLY H SAFETY REPORT FROM 30 May TO 05 June 2023Document21 pagesWEEKLY H SAFETY REPORT FROM 30 May TO 05 June 2023mico fredNo ratings yet

- 6.0 MS For Block WorkDocument4 pages6.0 MS For Block WorkVijendra SharmaNo ratings yet

- Material Inspection Request - CIVIL - QF - R-MIR-C-Q-281 (23 - 10 - 2023)Document4 pagesMaterial Inspection Request - CIVIL - QF - R-MIR-C-Q-281 (23 - 10 - 2023)krishanNo ratings yet

- 16mm TMX-UNBS. March23Document3 pages16mm TMX-UNBS. March23Okello StevenNo ratings yet

- Tugas AsesmentDocument28 pagesTugas AsesmentlisaNo ratings yet

- Dokumen Desain TeknisDocument17 pagesDokumen Desain Teknistedykrisnaarimukti25No ratings yet

- Crew ApplicationDocument2 pagesCrew ApplicationRoger VenturaNo ratings yet

- Home - OffshoreDocument5 pagesHome - OffshoreSeudonim SatoshiNo ratings yet

- Method Statement For Installaation of Hydronic Piping With SpecialitiesDocument37 pagesMethod Statement For Installaation of Hydronic Piping With SpecialitiesanwarNo ratings yet

- Cover Site FabricationsDocument2 pagesCover Site FabricationsSoegiantoro SoegiantoroNo ratings yet

- PR2300609 For Irrigation WorkDocument1 pagePR2300609 For Irrigation WorkashwinNo ratings yet

- Equasis - Ship Folder MSC TaniaDocument8 pagesEquasis - Ship Folder MSC TaniaKub Hasta Karya JombangNo ratings yet

- $R3MGCJ1Document4 pages$R3MGCJ1Lily Gonzales FernandezNo ratings yet

- Policy - Document - 451102 31 2025 1190Document3 pagesPolicy - Document - 451102 31 2025 1190rsakthimba08No ratings yet

- SM Marikina Work PermitDocument2 pagesSM Marikina Work Permitgtfcopy centerNo ratings yet

- ODS Drilling Crew Well Control CertificationsDocument10 pagesODS Drilling Crew Well Control CertificationsFahmi AbdullahNo ratings yet

- Monthly Report SG Removal Plant (Priode II Bulan Juni 2019)Document128 pagesMonthly Report SG Removal Plant (Priode II Bulan Juni 2019)rizkiNo ratings yet

- ASMS2 CertificatesDocument1 pageASMS2 CertificatesOzzy FenerciNo ratings yet

- Robust Design Methodology for Reliability: Exploring the Effects of Variation and UncertaintyFrom EverandRobust Design Methodology for Reliability: Exploring the Effects of Variation and UncertaintyBo BergmanNo ratings yet

- 2021-10-19-ENI CONGO - TIDEWATER Bridging DocumentDocument30 pages2021-10-19-ENI CONGO - TIDEWATER Bridging DocumentBitsindouNo ratings yet

- HSE Program Plan DAILYDocument4 pagesHSE Program Plan DAILYBitsindouNo ratings yet

- Safe Operating Procedure SOPDocument11 pagesSafe Operating Procedure SOPBitsindouNo ratings yet

- Risk Management Risk Assessment Risk Mitigation Risk MonitoringDocument9 pagesRisk Management Risk Assessment Risk Mitigation Risk MonitoringBitsindouNo ratings yet

- JSA ExampleQualityAssessmentoToolDocument2 pagesJSA ExampleQualityAssessmentoToolBitsindouNo ratings yet

- PRD-11-001-ver.03-Emergency & ContingencyDocument10 pagesPRD-11-001-ver.03-Emergency & ContingencyBitsindouNo ratings yet

- ENI CONGO - Bambini Spa Bridging DocumentDocument45 pagesENI CONGO - Bambini Spa Bridging DocumentBitsindouNo ratings yet

- HSE in DrillingDocument50 pagesHSE in DrillingBitsindouNo ratings yet

- My ResumeDocument3 pagesMy ResumeBitsindouNo ratings yet

- Heart of Dakness, PowerDocument4 pagesHeart of Dakness, PowerKhansa IrfanNo ratings yet

- Avoiding Ethical DisasterDocument13 pagesAvoiding Ethical DisasterShubham SenNo ratings yet

- Corporate Ethics and GovernanceDocument16 pagesCorporate Ethics and GovernancePhilipNo ratings yet

- Expectations:: Good Manners and Right Conduct (GMRC)Document2 pagesExpectations:: Good Manners and Right Conduct (GMRC)Jae Mae Moral Buban100% (3)

- Notes in Decision MakingDocument3 pagesNotes in Decision MakingJay GrijaldoNo ratings yet

- How To Be A Female Player (Butta Fly Jones)Document17 pagesHow To Be A Female Player (Butta Fly Jones)franklin ChikuwaNo ratings yet

- Progress Project RubricsDocument4 pagesProgress Project RubricsNurhuda HayatiNo ratings yet

- Chapter 3 Grooming and Etiquette in HospitalityDocument23 pagesChapter 3 Grooming and Etiquette in Hospitalitymaria tampocoNo ratings yet

- Sideshow #1Document39 pagesSideshow #1Jeydrew TVNo ratings yet

- MoU PADANG-HILDESHEIM ENGDocument4 pagesMoU PADANG-HILDESHEIM ENGRizki FitrayansyahNo ratings yet

- Punjabi University, Patiala Admissions M.A. Public AdministrationDocument2 pagesPunjabi University, Patiala Admissions M.A. Public AdministrationHardyNo ratings yet

- Filipino Values. EnglishDocument26 pagesFilipino Values. EnglishVee GalanoNo ratings yet

- 'S Case Was Trespassing: Started Chasing It?Document55 pages'S Case Was Trespassing: Started Chasing It?lamadridrafaelNo ratings yet

- How Do People Influence The Behaviour of Other PeopleDocument8 pagesHow Do People Influence The Behaviour of Other PeopleRhouzen VillanuevaNo ratings yet

- Challenges of Moral Education in The New UzbekistanDocument4 pagesChallenges of Moral Education in The New UzbekistanCentral Asian StudiesNo ratings yet

- Ethics Topic 11Document57 pagesEthics Topic 11Hikaru Akiyama100% (1)

- Research Literature IIDocument29 pagesResearch Literature IIDaragangMagayonNo ratings yet

- Sanha Tasmiyah IssueDocument6 pagesSanha Tasmiyah IssueConstant HopeNo ratings yet

- Leadership by Milkyas SolomonDocument17 pagesLeadership by Milkyas SolomonVerity SplendourNo ratings yet

- Reaction Paper Strategic ManagementDocument24 pagesReaction Paper Strategic Managementgusiongaming25No ratings yet

- Philosophy Module 2Document3 pagesPhilosophy Module 2Reina AprilNo ratings yet

- 09 Task Performance Group 4Document5 pages09 Task Performance Group 4Elisea Judel SerranoNo ratings yet

- Powell V MC Farlane (1979) 38 P &CR 452Document4 pagesPowell V MC Farlane (1979) 38 P &CR 452Sudarshani SumanasenaNo ratings yet

- Counter-Affidavit With AttachmentsDocument9 pagesCounter-Affidavit With AttachmentsManz Edam C. JoverNo ratings yet

- Grade VIII French Textbook PDFDocument86 pagesGrade VIII French Textbook PDFRadhika KulkarniNo ratings yet

- Hostel Admission Form SUIIT For B. TECH RegularDocument2 pagesHostel Admission Form SUIIT For B. TECH RegularjayNo ratings yet

27.04.2023 - Eni Congo - Promar BD - Foukanda - Serenity

27.04.2023 - Eni Congo - Promar BD - Foukanda - Serenity

Uploaded by

BitsindouOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

27.04.2023 - Eni Congo - Promar BD - Foukanda - Serenity

27.04.2023 - Eni Congo - Promar BD - Foukanda - Serenity

Uploaded by

BitsindouCopyright:

Available Formats

~.

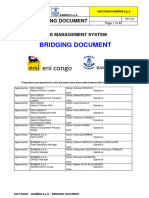

ent eni congo PRO MAR IENI CONGO-PROMAR

HSE BRIDGING [)QCUMENT

Avril 27, 2023 1 REV:10

Page 1 of 50

FOUKANDA FIELD

BARGE HOTEL FOR WORKOVER ACTIVITIES ON FOUKANDA

BRIDGING DOCUIME~NT

!!i ni congo & ~ PROMAlR

Preparation and agreement to th lu document have been made between ENI Congo & PROMAR

Approved by ENI CONGO Name: Davide Calarusso

Head of Division of Logistic !) ignature:

Date: 27/04/2023

Approved by ENI CONGO Name: Michele Piemontese

Head of Division Drilling Bignature:

Date: 27/04/2023

Approved by ENI CONGO Name: Marco CIANFANELL.I

Head of Division HSE Big nature:

Date: 27/04/2023

Approved by ENI CONGO Name: Pierre MATOLA

Deputy Head of Division HSE Bignatu re:

Date: 27/04/2023

Approved by ENI CONGO R Name: Carmine ZOTII

Head of Department ~)ignatu ·e:

Occupational Safetv Date: 27/04/2023

Approved by ENI CONGO Name: Andrea CASARIN

Head of Department Process mgnatu ·e:

Safety Date: 27/04/2023

Approved by ENI CONGO Name: Andre OYANDZA

Head of Service of Emergencies Signature:

Date: 27/04/2023

Approved by ENI CONGO: Name: Valence OSSETE

SIMOPS and Drilling Support Signature:

Date: 27/04/2023

Approved by PROMAR:

CEO

Name: Bertrand Prezioso

Date: 27/04/2023

Signatur~~- J .

Approved by PROMAR Name: Abdelkrim El Hart ri-:.-:~::,!~~

Fleet Operations manager Signature:CI harf Abdelkrlm :-::. , :::::.::" _

-DPA-CSO Date: 27/04/2023 ·- 1... :.. ..... . . .

Approved by PROMAR: Name: Arthur Leboucher ,.. 2023.05.08

Country Manager ~ ignature: k 08:28:52 +01'00'

Date: 27/0412023

Approved by PROMAR: Name: Diego SANZ 7 •

QHSES StlpetViset'-

\V\AIJ 1\ t, t: n.. Date: 27/04/2023

Signatum:

'\ ..

Approved by PROMAR: Name: Faye Thibaut NGOLI

QHSES Officer Congo Signatum:

Date: 27/0412023 2023.05.0

,~~ .. 5 09:20:24

+01 '00'

ENI CONGO- PRO MAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 2 of 50

DISTRIBUTION LIST

ENI CONGO

Michele PIEMONTESE Head of Division Drilling

Davide CALARUSSO Head of Division of Logistic

Marco CIANFANELLI Head of Division HSE

Pierre MATOLA Deputy Head of Division HSE

Carmine ZOTTI Head of Department Occupational Safety

Andrea CASARIN Head of Department Process Safety

Andre OYANDZA Head of Department Managing Emergencies

Anny Madeleine BENAZO NZOUMBA Head of Department Environment

Head of Service SIMOPS Drilling SUPPORT

Valence OSSETE

& PROJECTS

PROMAR

Bertrand PREZIOSO CEO

Abdelkrim El Harf Fleet Operations manager-DPA-CSO

Diego SANZ QHSES Supervisor

Arthur LEBOUCHER Country Manager

FAYE-THIBAUT NGOLI QHSES Officer

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 3 of 50

CONTENTS

DISTRIBUTION LIST ........................................................................................................................ 2

CONTENTS ...................................................................................................................................... 3

1 INTRODUCTION AND ABBREVIATIONS ................................................................................. 5

1.1 INTRODUCTION ........................................................................................................................................ 5

1.2 ABBREVIATIONS ...................................................................................................................................... 6

1.3 DEFINITIONS ........................................................................................................................................... 7

1.4 DOCUMENTS DE REFERENCE ................................................................................................................... 7

2 RESPONSABILITIES OF MANAGEMENT .............................................................................. 10

2.1 HSE RESPONSIBILITIES ......................................................................................................................... 10

2.2 ORGANIZATION SYSTEM ......................................................................................................................... 11

2.3 ORGANIZATION CHARTS ......................................................................................................................... 11

2.4 COMMUNICATION SYSTEMS .................................................................................................................... 11

2.5 VESSEL CONTACTS ............................................................................................................................... 12

2.6 PROMAR CONTACTS POINTE NOIRE ..................................................................................................... 12

2.7 ENI CONTACTS POINTE NOIRE ............................................................................................................... 12

2.8 ENI CONTACTS SITE .............................................................................................................................. 13

2.9 KEY PERSONNEL RESPONSIBILITIES ....................................................................................................... 15

3 MEETING AND PERSONNEL MOVEMENT............................................................................ 16

3.1 CREW CHANGE AND PERSONNEL MOVEMENT .......................................................................................... 16

3.2 INDUCTION SESSIONS ............................................................................................................................ 16

3.3 HSE MEETINGS ..................................................................................................................................... 16

4 OPERATING PROCEDURES .................................................................................................. 16

4.1 PERMIT TO WORK (PTW) ...................................................................................................................... 16

4.2 JOB SAFETY ANALYSIS (JSA) REQUIREMENTS ........................................................................................ 17

4.3 AUTHORITY TO STOP WORK .................................................................................................................. 18

4.4 LIFTING & HANDLING ............................................................................................................................. 19

4.5 PERSONNEL TRANSFER AT SEA .............................................................................................................. 20

5 RISK ASSESSMENT AND MANAGEMENT............................................................................ 21

5.1 QUICK RELEASE PROCEDURE FOR MOVING WINCHES ............................................................................... 22

5.2 PROCEDURE TO QUICK DISCONNECT MAMOLA SERENETY VESSEL. .......................................................... 22

5.3 SAFETY PLAN........................................................................................................................................ 23

6 WASTE, CHEMICAL AND OPERATIONAL DISCHARGES MANAGEMENT PLAN .............. 23

6.1 WASTE MANAGEMENT PLAN .................................................................................................................. 23

6.2 OPERATIONAL DISCHARGES................................................................................................................... 23

7 SAFEGUARDING OF HEALTH ............................................................................................... 24

7.1 GENERAL OCCUPATIONAL HEALTH .......................................................................................................... 24

7.2 PERSONAL PROTECTIVE EQUIPMENT (PPE) ........................................................................................... 24

7.3 HAZARDOUS SUBSTANCE, PRODUCT OR MATERIAL .................................................................................. 24

7.4 PREVENTION OF ASBESTOS HAZARDS ..................................................................................................... 25

8 COMPETENCE AND TRAINING OF PERSONNEL ................................................................ 25

8.1 MEDICAL FIT TO WORK .......................................................................................................................... 25

9 CLASSIFICATION OF EMERGENCY LEVELS, DRILL POLICY AND EMERGENCY PLANS 26

9.1 CLASSIFICATION OF EMERGENCY LEVELS IN ENI CONGO HSE MANAGEMENT SYSTEM.............................. 26

9.2 MUSTER POINT: .................................................................................................................................... 26

9.3 DRILL POLICY ........................................................................................................................................ 26

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 4 of 50

9.4 WEEKLY SAFETY AND ENVIRONMENTAL MEETING ..................................................................................... 27

9.5 PRINCIPLES OF MANAGING EMERGENCIES .............................................................................................. 27

9.6 OIL SPILLS ............................................................................................................................................ 28

THE VESSEL CAN BE USED BY ENI CONGO IN OIL SPILL RESPONSE AS NECESSARY. ............................................... 28

9.7 EMERGENCIES (OTHER THAN OIL SPILL) ................................................................................................. 28

9.8 MEDIA RESPONSE.................................................................................................................................. 30

9.9 LIAISON WITH LOCAL AUTHORITIES ......................................................................................................... 30

9.10 MEDICAL SUPPORT ................................................................................................................................ 30

9.11 MEDEVAC ............................................................................................................................................. 30

ENI CONGO FLUX INFORMATIF D'INFORMATION .................................................................................... 32

10 ACCIDENT, INCIDENT AND UNSAFE SITUATIONS REPORTING AND ANALYSIS ........ 35

11 MAINTENANCE, INSPECTIONS AND AUDITS ON SITE ................................................... 37

11.1 MAINTENANCE....................................................................................................................................... 37

11.2 INSPECTIONS ........................................................................................................................................ 37

11.3 AUDITS ................................................................................................................................................. 37

12 MONITORING OF MARITIME AREA ENI CONGO OILFIELD - STAND-BY SHIP –

SURVEILLANCE MISSION ............................................................................................................ 37

12.1 RESTRICTED AREA............................................................................................................................... 38

12.2 MONITORING OF MARITIME AREA ENI CONGO ...................................................................................... 39

12.3 SURVEILLANCE MISSION OF THE STAND-BY SHIP ...................................................................................... 39

12.4 PRINCIPLE OF ALERT REPORTING BETWEEN ENI CONGO AND MARINE CONTRACTOR ON SECURITY

OFFSHORE ........................................................................................................................................................ 40

13 APPENDICES.......................................................................................................................... 41

APPENDIX 1: .................................................................................................................................................. 41

APPENDIX 2: PROMAR TRAINING MATRIX ................................................................................................. 42

APPENDIX 3: ENI CONGO DEL HSE-INT 001 INTEGRATED POLICY HSE ................................................ 43

APPENDIX 4: PROMAR SAFETY COMMITMENT ......................................................................................... 44

APPENDIX 5: ENI CONGO ALCOHOL AND DRUG POLICY......................................................................... 45

APPENDIX 6: PROMAR DRUG AND ALCOHOL POLICY ............................................................................. 46

APPENDIX 7: ENI CONGO DEL HSE-SAL 002 ANTI TOBACCO POLICY .................................................... 47

APPENDIX 8: PROMAR NON SMOKING POLICY ........................................................................................ 48

APPENDIX 9: MAMOLA SERENITY FIRE CONTROL PLAN ........................................................................ 49

APPENDIX 10: GANGWAY CERTIFICATION........................................................................................................ 50

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 5 of 50

1 INTRODUCTION AND ABBREVIATIONS

1.1 Introduction

This document bridges the ENI CONGO Integrated HSE MS and PROMAR Integrated Management

System(PIMS). This Bridging Document is a gap analysis which identifies the main discrepancies that

may exist between the two HSE management systems. It clarifies which rules and procedures will be

enforced for safe operations.

PROMAR provides an onboard vessel safety management system that complies with the International

Safety Management (ISM) Code.

The goal of this Bridging document is to:

• Ensure that the roles and responsibilities of all persons in charge on the vessel(s) chartered

from PROMAR, for the duration of activities, are clearly defined, communicated and under-

stood.

• Ensure that all key personnel are aware of the work tasks to be undertaken in a safe manner.

• Ensure that all health and safety hazards, the risks associated with the operations on the char-

tered vessel(s) are assessed, controlled and communicated to all personnel that work on

board.

• Ensure that all personnel are competent for the work tasks that are to be undertaken.

• Ensure that all key personnel involved in the operations are aware of the appropriate channels

of information and communication means.

• Ensure that the ENI CONGO and PROMAR’s emergency procedures are properly integrated

for the duration of the contract.

The operations covered by this document are carried out by vessel(s) chartered from PROMAR, such

as (non-exhaustive):

• Cargo transfers from shore to ENI CONGO Oilfields.

• Bulk transfers (liquid and dry) in Pointe Noire, on ENI CONGO Oilfields.

• Pax transfers from Pointe Noire to ENI CONGO Oilfields, back and between offshore sites.

• Safety stand by alongside drilling rig or platform.

• Fire-fighting.

• Search and Rescue operation.

• Oil Spill response

• Ship to ship operation.

• Towing (if applicable).

• Any other operation (covered by the vessel’s chartering contract) requested by ENI CONGO.

NB: The maximum allowable POB is 126 including 16 crew and 13 catering personnel on MAMOLA

SERENITY. The maximum persons expected on FOUKANDA during SIMOPS is 50.

For some short duration operation organized on board the chartered vessel(s), it may involve person-

nel contracted by ENI CONGO, along with Service Companies.

Because Service Companies have generally their own HSE-MS’s, and their personnel are working

under the responsibility of ENI CONGO and/or of PROMAR, they are required to adhere to the HSE

rules and procedures defined in this document. Should any doubt arise; a gap analysis between both

HSE-MS would be performed.

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 6 of 50

All personnel working or visiting the vessel(s) chartered from PROMAR on ENI CONGO behalf shall

comply with the vessel(s)’s Management System and follow all HSE Rules and Procedures contained

within it.

Induction in the required aspect of the safety management system shall be carried out when the need

is identified (e.g. on arrival safety briefing, Permit to Work system).

ISPS (International Ship and Security Code) is mandatory on vessel(s) chartered from PROMAR &

ENI, and requires to be applied in accordance with international marine legislation.

PROMAR shall ensure, with the support of ENI CONGO that security controls are performed for cargo

and passengers towards ENI CONGO offshore assets, in line with ENI CONGO RG-SUR-02 " Con-

trôle d’acces et surveillance des sites et installations" (see Appendix 01), provided that this does not

conflict with chartered vessel(s)’s Ship Security Plan. Should any conflict arise as a result of security

matters, this shall be addressed to the respective persons as designated in the ISPS Code.

1.2 Abbreviations

ACP Advance Command Post

AERP Affiliate Emergency Response Plan

AR Anomaly Report

CMS ENI CONGO Medical Center in Pointe Noire

CMT Crisis Management Team - ENI CONGO Office –

LOCATION OF THE BASE

CMU Crisis Management Unit - ENI CONGO Office –

LOCATION OF THE BASE

CPLO Competent Person for Lifting Operation

CR (ENI CONGO) Company Rule

DHSE HSE Division – ENI CONGO

DROPS Dropped Objects Prevention Schemes

ED Environmental Damage

ER Event Report

FAC First Aid Case

GS (ENI CONGO) General Specification

HIRA Hazard Identification and Risk Assessment

HPI High Potential Incident

HSE Health, Safety and Environment

HSE-MS HSE- Management System

KPI Key Performance Indicator

IP Injured Person / Illness Person

IMDG International Maritime Dangerous Goods code

ISM International Safety Management

ISPS International Ship and Port Security code

JSA Job Safety Analysis

LTI Lost Time Incident

LTIF Lost Time Incident Frequency rate

MARPOL Marine Pollution

MOB Man Over Board

MOC Management Of Change

MOM Marine Offshore Manager

MTC Medical Treatment Case

MTISC Maritime Trade Information Sharing

NM Nautical Mile (1NM=1852m)

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 7 of 50

NMI Near Miss Incident

PIMS PROMAR Integrated Management System

NRA Navigational Restricted Area

ODMP Operations Discharge Management Plan

POB Personnel On Board

PPE Personal Protective Equipment

PTW Permit To Work system

RA Risk Assessment

REX Return of Experience

RSES Responsible for Safety and Environment on Site

RWDC Restricted Work Day Case

SFN Safety Feed-back Notice

SOLAS Safety Of Life At Sea

SIMOPS Simultaneous operations

STCW 95 Convention on Standards of Training, Certification and

Watch keeping for seafarers

SWL Safe Working Load

TCO Traffic Control Operator

ENI CONGO ENI CONGO

TRIR Total Recordable Injury Rate

WMP Waste Management Plan

1.3 Definitions

COMPANY ENI CONGO

CONTRACTOR PROMAR

1.4 Documents de reference

ENI CONGO :

• Del HSE-INT 001 Eni Congo Politique Intégrée HSE

• Del HSE-INT 002 Politique disciplinaire des travaux sous contrat

• Del HSE-SAL 001 Politique anti alcool et drogue

• Del HSE-SAL 002 Politique Anti tabac

• Del HSE-SIC 001 Politique de conduite des véhicules

• Man HSE-INT 001 Manuel du Système de Management Intégré HSE d'Eni Congo

• Man-HSE-SIC 001 Manuel de gestion de la sécurité routière

• MAN-HSE-SIC 002 Operation and lifting Equipment management

• pro HSE-AMB 001 Gestion, évaluation et identification des aspects environnementaux

• Pro HSE-AMB 003 Gestion des déchets

• Pro HSE-AMB 011 Dépollution et remise en état du sous-sol

• pro HSE-INT 001 Gestion des prescriptions légales

• Pro HSE-INT 002 Formation sensibilisation et compétences HSE

• Pro HSE-INT 004 Gestion des relevés et actions correctives

• pro HSE-INT 006 Gestion des audits HSE

• PRO HSE-INT 008 Communications HSE

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 8 of 50

• Pro HSE-INT 010 Gestion des modifications

• pro HSE-INT 011 Gestion des risques HSE et Reporting

• pro HSE-INT 014 Exigences HSE pour les contrats

• pro HSE-INT Signalisation et gestion des anomalies

• pro HSE-INT 017 Gestion exercices d'urgence

• pro HSE-INT 020 Contrôle opérationnel

• pro HSE-INT 024 Système de gestion sécurité des procédé

• Pro HSE-INT-023 Gestion des produits chimiques

• pro-HSE-INT 019 Système de surveillance des comportements à risque dans le domaine

HSE

• Pro HSE-SAL 002 Aptitude au Travail

• Pro HSE-SAL 005 Standards d'Hygiène pour le Catering

• Pro HSE-SAL 008 Guide de la santé au travail

• Pro HSE-SAL 009 Plan de gestion de l'ergonomie dans les bureaux

• Pro HSE-SIC 010 eni Congo rev02 Operations simultanées.

• Pro HSE-SIC 008 Transport marchandises dangereuses

• Opi HSE-AMB 006 Identification et gestion des déchets

• Opi HSE-AMB 007 Gestion et traitement des effluentes et déblais de forage

• Opi HSE-INT 002 Réunions HSE

• Opi HSE-INT 013 Stratégie de suivi sanitaire des agents exposés aux produits chimiques

• Opi HSE-INT 015 Conditions d'obtention du badge eni Congo

• Opi HSE-INT 021 Les règles d'or

• Opi HSE-SAL-017 Gestion des déchets d'activités de soins

• Opi HSE-SIC 001 Modalité de gestion des Permis de Travail

• Opi HSE-SIC 002 Modalités opérationnelle pour chariots élévateurs à fourche et élingage

des charges

• Opi HSE-SIC 003 Accidents et Near miss

• Opi HSE-SIC 008 Normes de sécurité de travail pour la gestion des isolements énergétiques

• Opi HSE-SIC 014 Contrôle de conformité relative au travail des sous-traitants

• Opi HSE-SIC 020 Normes de sécurité de travail pour la gestion des travaux dans les es-

paces confinés

• Opi HSE-SIC 027 Contrôle des équipements mobiles et portatifs

• Opi HSE-SIC 029 Gestion des tubings-tiges en provenance des chantiers de Workover, Fo-

rage et Site de production

• Opi HSE-SIC 031 Transport, stockage et utilisation

• Opi HSE-SIC 033 Exigences minimales de sécurité pour le transport et stockage des explo-

sifs

• Opi HSE-SIC-034 Gestion des équipements de protection individuelle (EPI)

• opi-HSE-SIC 004 Norme de sécurité pour les travaux en hauteur et l'utilisation des échafau-

dages

• Rap HSE-INT 01 KITINA Risk Register

• Pro HSE-SIC 001 Plan d'urgence général

• Pro HSE-SIC 016 eni Congo Plan d’urgence KITINA

• Pro HSE-SIC 028 eni Congo Plan d’urgence FOUKANDA

• Pro HSE-AMB 007 Onshore Oil Spill Contingency Plan

• Pro HSE SAL-001 Plan de réponses aux urgences médicales MERP

• Offshore Blowout Emergency response plan

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 9 of 50

• Normes de comportement pour les activités avec utilisation de moyens navals (Opi HSE-SIC

011)

• PRO HSE-SAL 011 Eni Congo S.A. R02 PROCEDURE OPERATIONNELLE POUR LA

LUTTE CONTRE LE COVID-19

PROMAR Reference Documents :

PRD-09-

Procedure Drug and Alcohol Testing

001

PRD-09-

Procedure Personal Protective Equipment

002

PRD-09-

Procedure

003 Risk Assessment

PRD-09-

Procedure Permit To Work

004

PRD-09-

Procedure Health

005

PRD-09-

Procedure Hygiene

006

PRD-09-

Procedure Hazardous Materials

007

PRD-08-

Procedure Incident Reporting and Investigation

001

PRD-07-

Procedure Management Of Change

001

PRD-11-

Procedure Emergency & Contingency

001

SPC-11-

Specification Emergency Contact List Congo

002

POL-01-

Policy Safety and Environmental Protection

001

POL-01-

Policy Ethics

002

POL-01-

Policy Quality

003

POL-01-

Policy Drugs and Alcohol

004

POL-01-

Policy Personnel Policy

005

POL-01-

Policy Non-Smoking Policy

008

POL-01-

Policy Stop the Job

011

POL-01-

Policy Clear Deck Policy

014

SPC-01-

Specification Promar Safety Commitment - Global EN.

009

International Standards :

International management system (IMS)

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 10 of 50

International standardization organization (ISO 9001, 45001 and 14001)

1.5 Declaration of the Liaison:

The contractor agrees to comply with all the requirements included in the Eni Integrated Man-

agement System and those highlighted in this HSE Bridging document.

2 RESPONSABILITIES OF MANAGEMENT

2.1 HSE responsibilities

As per international maritime legislation, any and all decision(s) made, or to be taken, with respect to

safety, security and pollution prevention by any person or contracting party shall be subject to the

Master’s overriding authority and responsibility when the Master deems it may affect the vessel.

HSE Responsibility must be defined in relation with vessel’s position on operation. 2 cases have to be

addressed:

• The vessel is within the 500 meters zone of ENI CONGO offshore assets (drilling rig, accom-

modation barge, platform): the Master refers to the ENI CONGO offshore asset Representa-

tive for any decision taken in regards of HSE. These operations must also align to PROMAR

Operating Manual. Where any anomalies are identified during operations, they are to

highlighted to both ENI and PROMAR . Stop Work Obligation must be used where nec-

essary.

• The vessel in out of any 500 m zone of ENI CONGO offshore assets: Master is in charge.

It is reminded that within 500 m zone, the following activities on board the chartered vessel(s) are not

allowed:

• Maintenance of any equipment, neither in the engine room nor at the bridge.

• Test of any equipment.

• Safety/emergency drills/Liaise with ENI Drill Planning if initiated by them.

• Smoking outside vessel’s accommodation.

• Hot Works

In the situation where the chartered vessel(s) is within a 500 m zone of a ENI CONGO offshore site,

and she must conduct a test or maintenance, the Master shall issue a Work Permit. This Work Permit

must be VALIDATED BY ENI Representative concerned, before the start of maintenance or test.

The Contractor Representative on the vessel(s) chartered from PROMAR is the Master:

• The Master is the ultimate authority on the vessel. He is PROMAR’s and vessels direct repre-

sentative and is recognised as such in international law. When in command he may not dele-

gate his ultimate authority and responsibility.

• He has the overriding authority to take whatever steps he may consider necessary to safeguard

the life of personnel in case of emergency on the vessel he is in command of.

• He is responsible for the health, safety and welfare of all personnel on the vessel he is in

command of including Company’s personnel and Service Companies personnel.

The chartered vessel(s)’s Chief Officer, also the designated Safety Officer, reports directly to the

Master. His main functions are:

• Advises and assists the Master in management of application of the HSE policy & in the ef-

fective execution of the designed work programs, in particular in risks prevention management;

emergencies preparedness; training and drills. He is the leader of all HSE actions that have to

be carried-out on the vessel.

• Takes an active role in the process improvement methodology.

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 11 of 50

• He assists the Master and chief engineer in organizing all inspections.

• Contribute to diffuse HSE philosophy and training of the vessel’s crew.

• Acts as the Master’s delegate when reporting events using the vessel’s reporting system.

The Doctor on Foukanda is available and will evaluate and confirm the need of MEDEVAC for all the

personnel on Foukanda and on the Mamola Serenity. For Mamola Serenity personnel he will inform

the Master of the vessel immediately if MEDEVAC is required.

2.2 Organization system

The organization between the different parties is as follow:

• The appointed Master is the leader of the day to day vessel activities.

• The logistic support is provided by ENI CONGO. Personnel transfers (including MEDEVAC) or

Rescue Operations are provided and arranged by ENI CONGO marine vessels.

• Upon request, ENI CONGO can give assistance with asset’s medical organization.

2.3 Organization charts

PROMAR ORGANISATIONAL CHART

Reference – section 01 PIMS- The Country Manager is part of the Operations Department which is

supported as below-

2.4 Communication systems

The main means to contact the vessel(s) chartered from PROMAR are as follows:

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 12 of 50

• Directly using the Satellite Phone, Mobile phone (in Pointe-Noire), VHF radio, email.

• By contacting the PROMAR Operations (Contract Management) or Safety Management Staff

via email or phone.

2.5 Vessel Contacts

VESSELS

EMAIL ADDRESS CONTACT NUMBERS

NAME

VSAT TEL. +47 23 679 087

MAMOLA FBB 1: +870 77 315 69 48

mamoserecap@promar-offshore.com

SERENITY SHIP'S PHONE +242 06 413 82 36

VHF Radio: Channel 10 or 06 or 16

2.6 PROMAR contacts Pointe Noire

Name Title Contacts details

Arthur Leboucher Country Manager Office: +242 05 204 87 58

Mobile : +242 06 407 38 89

E-mail:a.leboucher@promar-shipping.com

Faye-Thibaut NGOLI QHSES Officer Office: (+242) 05 620 32 71

Mobile: (+242) 06 940 31 98

E-mail: qhse.congo@promar-shipping.com

Abdelkrim El Harf DPA & CSO Office: +212 652 711 850

Mobile: +212 652 711 850

E-mail: a.elharf@promar-shipping.com

PROMAR Postal address PROMAR MARINE SERVICES

Première Zone du Port Autonome (zone BOLLORE)

P.O. Box: 571 - Pointe-Noire. Congo

2.7 ENI contacts Pointe Noire

Onshore Eni Congo Contacts

Name Position Telephone Email

Colarusso Davide Chef de Division 065961820

Davide.Colarusso@eni.com

Logistique

Salvatore Rossitto / Pietro Chiaia Base Marine Coordinator 242 050304242 mob Salvatore.rossitto@external.eni.com

+242 058001404 fix Pietro.chiaia@external.eni.com

Felix MOUKOKO/BONAZEBI felix.moukoko@external.eni.com.

Georges /EPOUKOUSSOU Anicet/ Expert Marin (+242)05 530 17 93 Georges.Bonazebi@external.eni.com

MOUKANI Richi anicet.epoukoussou@external.eni.com

Paolo Riccardi Marine coordinator +242 053170201 Paolo.riccardi@external.eni.com

Igor Mraovic DILO Marine adviser +242 040144277 igor.mraovic@eni.com

Marco Cianfanelli Chef Division HSE +242 055772088 marco.cianfanelli@eni.com

Pierre Matola Chef Vision Adjoint +242 055538224 pierre.matola@eni.com

Andrea CASARIN Chef departement Process

:+242 05 527 22 45 Andrea.Casarin@eni.com

Safety

Anny Benazo Chef departement

+242 057700479 Anny.Benazo-Nzoumba@eni.com

Environnment

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 13 of 50

Andre Oyandza Chef Service Suivi

+242 055301707 andre.oyandza@eni.com

Urgences

Chef Division resourse hu- antonio.maglio@eni.com

+242 055274381

Antonio Maglio maine Responsable surete

Chef De Departement Sys-

Prince Armel Loufouandi teme De Management In- +242 055476313 prince-armel.loufouandi@eni.com

teg

Chef De Departement Se-

Carmine Zotti +242 057752010 carmine.zotti@eni.com

curite Au Travail

Michele Piemontese Chef de Division Forage +242 05 6287295 michele.piemontese@eni.com

Chef de Departement Com-

Daniele Ferrara +242 05 510 00 02 daniele.ferrara@eni.com

pletion Workover

Chef de Service Support

Valence Ossete +242 05 510 00 02 valence.ossete@eni.com

Forage et Projets

2.8 Eni contacts Site

Name Title Contacts details

KITINA

Day Shift : : 05 800 9216

Thierry Christian

MEGOULA / Lys- Day Night shift :

ias Philippe Joa-

chim MFINA SOA : Thierry.Megoula@eni.com

: Lysias.Mfina@eni.com

Judelvie Ngondo HSE SOA :

Eric FOUTOU : Judelvy.Ngondo@external.eni.com

:

NANITELAMIO MEDIC : 058009356

Makiza/NSEMI

KITINA

SAT : 00 882 16 50 30 11 88

Brocchi Marco : 05 800 9600

Field Manager

Ben Arous Nizar : Marco.Brocchi@eni.com

: Nizar.BenArous@eni.com

Jacques MATONGO-

: 05 800 9712

KIMANGOU / Marvel Superintendant

: Makoumbou Jos Christinin

Freesny /VIVI- HSE

: Marvel.Vivi-Moukouanga@eni.com

MOUKOUANGA

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 14 of 50

Cote Plateforme :

Docteur Fouka-Bento : 05 800 9715

Cardini / Docteur Miti- : cardini.fouka.bentoo@external.eni.com

foumou Milandou :christsidney.mitifoumou@external.eni.com

MEDIC

Christ : 05 800 94 46

Cote Mamola : raymond.ngapela@external.eni.com

Docteur Ngapela Ray-

mond

Sama Armel/ Superintendant

: 05 800 97 20

Foundou Clavit, Production

: armel.sama@eni.com

Mayinguilas Des-

: clavit.foundou@eni.com

tin SVP

Superintendant : 05 800 9730

Balou Cyr /

Maintenance : cyr.Balou@eni.com

Yvon Miambi

: yvon.miambi@eni.com

Ngouayoulou Adnel, Control Room : 05 800 9710 /058009711

Mabiala Franchel, Awa : adnel.ngouayoulou@eni.com

Pembelet Privin, Biban- : franchel.Mabiala@eni.com

zoulou Arsene ; Ma- : Privin.pembelet@external.eni.com

houngou Andre Dieu- :arsene.bibanzoulou@eni.com

donné :Andre.mahoungou@external.eni.com

Company man

Day Shift Company man

Sema Aniamabo

: 05 800 97 55

Claude Taty

:U122.companyman@eni.com

Night Shift

Barrie Myers

Gordon Gourlay

BOATS BOATS BOATS

Surfers :

:

AMBROSUS FIFI VESSEL :

TIDE :

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 15 of 50

2.9 Key Personnel Responsibilities

Position Organisation Project Responsibilities

Overall responsibility for safety, execution and progress of the

project.

Manage day to day running of the project, monitor progress off-

Country shore and report accordingly.

Promar Ensure that HSE reporting (including accident and incident) is

Manager

progressed and is compatible with requirements.

Focal point for client operational and contractual matters.

Management and administration of all subcontracted activities.

Control of work scope and work programme

Provide ruling for Client Offshore representative on any contractual

issues during the offshore phase.

Verify training and competency of Client offshore representatives

Project Manager Eni

and approve their appointment.

Ensure that HSE reporting (including accident and incident) is pro-

gressed and is compatible with requirements.

Provide assurance to Client project manager that offshore activity is

conducted in accordance with the safety management system and

contract.

Offshore Repre-

Eni Report any incidents or near misses to Client project manager.

sentative

Provide assurance to Client project manager that client’s objectives

for the project (cost, time quality) are met.

Arranging client’s PTW as required.

Responsibility for safe execution of the agreed elements of the pro-

ject.

Planning of project activities.

Management of Change.

Offshore Lead member of on-board Management Team.

Promar

Representative Chair weekly safety committee meetings.

Liaison with client’s Offshore Representative.

Reporting (client and Project Team onshore) and investigation of all

marine and project related incidents.

Attain PTW from Offshore Representative.

Overall responsibility for marine operations and for safety, health

and welfare of personnel.

Vessel safety / maintenance.

Master of Vessel Vessel Compliance with all marine legislation.

Manage and report any emergency response situation in the field in

accordance with the requirements in this document.

Reporting all marine and vessel incidents to the Project Manager.

Field Manager will refer to the Operations Manager (DITE), and will

Field Manager be in charge of at least the following responsibilities (non -exhaus-

Eni

(SOA) tive list):

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 16 of 50

Good coordination and management of HSE aspects of simultaneous

activities and priority setting in order to minimize time;

Compliance and enforcement of HSE conditions by all personnel on

the rig site including Eni Congo personnel and the staff of the Service

companies;

Approval of Work Permits in accordance with the Eni Congo HSE-

Management System;

Ensure that the works are carried out in accordance with the laws

and regulations of Eni Congo and that they are in line with safety

systems;.

Ensures that all personnel are verified and assembled in an emer-

gency at the designated assembly point.

It is responsible for ensuring compliance with the requirements of

the SIMOPS Operational Plan.

3 MEETING AND PERSONNEL MOVEMENT

3.1 Crew change and personnel movement

PROMAR is primarily responsible for the crew changes and manning requirements of the chartered

vessel(s), and will ensure crew-changes are arranged as appropriate.

ENI CONGO will assist and facilitate crew changes to the best of their ability, as is reasonably practi-

cable.

Key Personnel (Master, Chief Officer, Chief Engineer, 2nd engineer, Electrician Officer) application

shall be submitted to ENI CONGO.

3.2 Induction sessions

The chartered vessel(s)’s document relative to HSE Induction describes the procedure in force for

the induction of all personnel arriving on the said vessel(s) for the first time and upon subsequent

returns.

• PROMAR carries out inductions on board as per the vessel(s)’s PIMS procedures & require-

ments only for the Seafarers. A familiarization form is signed and filed on the Bridge. These

aforementioned procedures are described in the PIMS. Halliburton HSE Officer is in Charge

of the Induction with video assistance for the remaining Technicians and sea-workers.

3.3 HSE meetings

PROMAR recognizes communication as one of the foundations on which to build a robust HSE culture

and to assist in this; regular meetings are held, namely:

• Weekly Safety and Environmental meetings on board chartered vessel(s).

• Meetings as required by the vessel’s PIMS.

• PROMAR shall assist to HSE meetings organized by ENI CONGO onshore.

4 OPERATING PROCEDURES

4.1 Permit To Work (PTW)

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 17 of 50

In order to manage the risks associated to the different activities carried-out on the chartered vessel(s),

PROMAR has the Permit to Work, referring to the vessel’s PIMS.

Permits to work shall be issued in accordance with the instructions contained within the PIMS. Where

indicated on the Permit to Work form the applicable check list should be used.

Only one permit system shall be used on the vessel at any time, this is especially important during

docking or major repair where the yard may have their own PTW system. Agreement should be

reached on which system is to be used.

The following activities require a permit to work:

• Confined space entry.

• Working on electrical systems.

• Working on pressurized systems.

• Work with fall hazards – heights greater than 1,5 m or over the water.

• Hot work.

• Where it is identified during the RA/JSA.

• Cold Work: Some painting and chemical works

The following activities require a hot work permit:

• All welding, cutting and grinding activities.

• Work on energized electrical equipment greater than 24 volts.

The permit is to be completed by the Master or competent ships officer (the responsible person) who

is required to confirm that all the required checks have been carried out and that the person carrying

out the work is competent before signing the permit.

All permits issued on the vessel must be issued by one person, (the permit controller) in order that

conflicting permits are not issued. In the event of a change of watch or crew change taking place while

a permit is opened the permit must be formally handed over by the off-going permit controller to his

relief who should countersign the permit to show acceptance.

Where required by local regulations, the port authority or ENI CONGO facility /jetty(see 2.1 HSE Re-

sponsibilities), they must be informed before hot work starts and after it has been completed.

Upon completion of the work, the Master (or his delegate) must:

• Perform a final inspection of the work site,

• Ensure that the work site is free of hazards resulting from the work activity,

• Sign the permit to verify completion of the work.

Note – The permit to work register is to be maintained and reviewed each watch change

4.2 Job Safety Analysis (JSA) requirements

The RA/JSA has been provided as a tool to be used to identify hazards involved when carrying out

various work activities. Once the hazards are identified, the risk factor can be calculated. A risk can

be defined as the likelihood of a hazard causing harm or damage. Controls are put into place to reduce

or eliminate the hazard. Although, the risk of the hazard causing the harm can be reduced, often it

cannot be eliminated completely. Persons involved in various work activities shall carry out a RA/JSA

prior to commencing any work activity.

The basic steps to complete a RA are:

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 18 of 50

• Identify the work activity, persons involved and location

• Identify the hazards.

• Calculate the initial risk.

• Insert the control measures.

• Calculate the final risk factor.

• Decide if the risk is acceptable.

• Communicate the findings to all persons involved in the task via a tool box talk.

• Record the tool box talk.

When going through this process, pay particular attention to hazards such as slips/trips/falls, pinch

points, line of fire, communications, bending, lifting, thermal, chemical, and electric, adding all hazards

that could be present.

Once the RA has been done, all persons involved should agree on the procedure(s) to control, or

reduce the risk of hazard unless changes need to be made. In such case, the work activity should not

start until all persons involved agree that the work activity can be accomplished, with the risk of hazard

appropriately mitigated.

The basic steps for completing a JSA are;

• Identify the work activity, the persons involved and location.

• Split the task down into steps: preparation, setting up equipment; carrying out the task; breaking

down equipment; clearing up; making the site safe.

For each of these component parts, carry out the RA process above, i.e.

• Identify the hazards.

• Calculate the initial risk.

• Insert the control measures.

• Calculate the final risk factor.

• Decide if the risk is acceptable.

Once all steps have been assessed you then:

• Communicate the findings to all persons involved in the task via a tool box talk.

• Record the tool box talk.

In general terms, a RA can be used for routine and uncomplicated tasks (such as painting or setting

the gangway) where a JSA would be used for non-routine or more complex tasks such as changing

out of an engine, a heavy lift or complicated cargo operation.

Caution: While carrying out a work activity, if conditions change or an additional hazard is identified,

all work should cease. If there is any concern, use RA/JSA, re-assess the controls and, if necessary,

re-plan and re-assess the task.

On completion of the tasks, it is important to identify any lessons learned and record improvements.

RA/JSA should be reviewed periodically to ensure that they remain suitable for managing the task.

RA/JSA’s are available in electronic form, to make amendments easier.

Note PROMAR ’s PTW system will not permit a RA to be re-used without review

4.3 Authority To Stop Work

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 19 of 50

All personnel have the authority and responsibility to halt any part or all of an operation they deem to

present an unacceptable risk or where they consider hazard management to be inadequate. The use

of ENI CONGO or PROMAR “Stop Work Policy” card is applicable.

The vessel’s SMS systems refers to this.

‘Stop Work Policy’ is the process whereby all employees must stop work when they see something

that is not quite right, or when they do not understand the work scope. Stop Work Obligation must be

practiced at all times when it does not appear that a work activity can be accomplished safely; all

employees have an obligation to themselves, their fellow crewmembers and to PROMAR to work

safely.

“Stop Work Policy” is a chance to talk about what is unsafe. It is an opportunity to look at the job and

to find a safer way of getting it done. It is important that everyone understands when a “Stop Work

Policy” command has been given. Be very clear when using “Stop Work Policy” - if your intention is to

stop a job, make it readily apparent to everyone involved. Once “Stop Work Policy” has been used all

parties should discuss the reasons why the job was stopped and jointly seek a safer alternative

method. Where applicable, the RA/JSA should be reviewed or a further tool box talk held. Work should

not resume until everyone has agreed that it is safe to do so.

Using “Stop Work Policy” is easy. “Stop Work Policy” is accomplished by just stopping the job by giving

a signal, a radio call, or moving away from an unsafe situation.

Examples justifying “Stop Work Policy” includes:

• Something unsafe is noticed or occurring.

• Something is not understood and could lead to an unsafe condition, act or omission.

• There has been a change from the original plan which could or has led to an unsafe condition

or situation.

• Something can be done to make the job safer.

“Stop Work Policy” is an opportunity to ensure that everyone involved in the operation is safe and that

the job is performed safely, every time.

4.4 Lifting & Handling

In general the vessel’s lifting and handling procedures will apply on the vessel during lifting and han-

dling operations. However, wherever reasonably practicable during interfacing operations, the most

stringent of the following rules will be used based on a joint agreement between the vessel(s) and the

other party or parties. In any case no lifting & handling operations will be done by the vessel or its

crew using a standard lower than that required by the vessel’s PIMS. A clear deck policy will be main-

tained and respected by all parties during any lifting & handling operations being performed on, or by,

a vessel chartered from PROMAR.

During SIMOPS operation

Refer to the vessel’s requirements as follows:

Reference:

• PIMS PROMAR Integrated Manual

o PRD-OSV-06-006-Cargo Operations

o PRD-OSV-06-001-Mechanical Handling

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 20 of 50

Lifting operations Color code of ENI CONGO to be in place.

NB- Colour code being used in the second Semester of 2022 is WHITE subject to change every 6

(six) months.

PERIOD COLOR CODE

Fr. 07/01/2021 to 12/31/2022 White

Fr. 01/01/2023 to 06/30/2023 Orange

All lifts to and from Eni platforms using the vessel will be done respecting the Eni Congo lifting opera-

tions manual (MAN-HSE-SIC 002) and respect the Eni Congo HSE Management System.

ENI CONGO/LOG/OPS

4.5 Personnel Transfer at sea

Refer to MNL-OSV-06-006-ver.02- Personal transfer which define the conditions and methods for the

transfer of personnel between ships and/or fixed offshore structures, and to specify the minimum re-

quirements for the ships access. It covers the design, preparation, performance, limit and procedure

of the transfer system during marine operations.

Personnel transfer will generally follow this approach: From Fast Crew Boat to Mamola Serenity

through the boat landing and from Mamola Serenity to the AWA platform through the gangway.

All these transfers involve the use of appropriate resource for example, boat landing , cranes, etc…).

All equipment as applicable must carry certification appropriate to its use and must have been de-

signed in accordance with to MNL-OSV-06-006-ver.02- Personal transfer.

The specific transfer system should be:

• Boat-landing

PROMAR Boatlanding Officer will be at the boarding area to regulate the Transfer. He has the duty

to control passengers PPE for compliance with PROMAR PPE Matrix. It is mandatory to follow his

instructions. On duty for a period of 12 hours as specified by the MLC Convention.

ENI LOG is in charge of the Booking and T-CARD Procedure.

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 21 of 50

• Via Gangway

Halliburton Deck Hand Officer is in charge of all the traffic.

Gangway is the second means of evacuation of personnel in case of emergency on the platform. It

also allows the transfer of personnel between Mamola Serenity Vessel and Platform, during normal

operations.

Lifeboat onboard the platform is a primary evacuation means.

Note : Halliburton personnel (Gangway on platform and Sentinel on Serenity) will be in charge of the

personnel transfer to/from Platform to/from Serenity. The Sentinel will ensure proper PPE is on before

crossing and also T-card is put in the right place. The sentinel also gives signal to the Gangway oper-

ator to move (up/down) the gangway. Gangway operator is in charge of the gangway during personnel

transfer. He will operate the winch (up and down) to allow personnel transfer and assure the imple-

mentation of T-card system on the platform.

The gangway is installed between platform and the vessel to allow movement of the crew from the

platform to the vessel, vice versa. The gangway is installed and secured from the platform side, there-

fore in case of vessel disconnect, the gangway remains attached to the platform. Below steps de-

scribed duties of gangway operator (on platform side) and sentinel (on vessel side) in case of vessel

disconnect : • The sentinel and gangway operator to ensure no one will use the gangway during or in

case of vessel disconnection • The sentinel shall stay at gangway in order to coordinate for evacuation

of platform personnel through gangway • The gangway operator to ensure that gangway is well se-

cured (from platform) with barrier tape and in high position as per the below picture in the annex10

They will work for 12hrs shift.

The personel on site should follow the instructions given by the two HALLIBURTON operators.

NB: In case adjustment is needed for the Gangway, Halliburton can communicate with the MASTER

and Master will manoeuvre accordingly to help adjust.

• Billy Pugh (The use of the FROG type personnel basket is recommended, the Bill-Pugh

type of personnel basket should be avoided, as far as practically possible

A risk assessment must take place prior to a transfer by personnel basket and the operation shall be

approved by the ENI Representative, Captain of the sending and receiving marine support as appro-

priate.

NOTA: The transfer of personnel by personnel basket or Frog is a voluntary operation.

Transfer of personnel using a fast crew boat or personnel transfer basket during the hours of darkness

or any other condition similarly restricting visibility is forbidden, except for emergency situation after

site’s ENI SOA approval. In case of transfer at night, the personnel involved in the transfer shall con-

duct a RA.

Masters should be aware of charterer’s procedures/instructions with regard to personnel basket trans-

fers.

5 RISK ASSESSMENT AND MANAGEMENT

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 22 of 50

All operations conducted on board the chartered vessel(s) will be covered by procedures for Risks

Assessments and hazards identifications, described in vessel’s PIMS as follows:

Ref PIMS Section 09

Changes in worksite conditions should be monitored continuously. If necessary, a review of the Risk

Assessment should be performed and the Risk Assessment updated as required.

5.1 Quick release procedure for moving winches

The quick release mooring wires help to ensure safe operations as well as asset protection in the

event of any incident.

The quick release test must be done prior all mooring operation.

Benefits of quick release mooring hooks:

• Protects personnel and infrastructure

• Provides safe mooring line release

• Simple local and remote release options

• Wide range of movement

• Inform engine room to start main engines

• If possible, disconnect the connections between the ship and the platform

• Inform the client that the emergency quick release will be activated in order to proceed to

safe distance from the platform

• Ship’s crew ready to cut wire in case of quick release failure system

• From the 8 PM mooring system console activate the quick release buttons

• Advance the ship to a safe distance

5.2 Procedure to quick disconnect Mamola Serenety vessel.

• Hold safety meeting with all personnel involved in the operation. Establish roles and responsi-

bilities before the start of the activities and repeat every 2 weeks during the activities.

• During the quick disconnect, the sentinel will remain in position to coordinate with gangway

operator ready in case personnel transfer through the gangway before/during disconnect.

• Quick disconnect can be only activated from Mamola Serenity

• Ensure radio communication is maintained all the time. Confirm channel to all involved and

make checking to ensure communication is clear.

• The captain contacts the SOA to organize the personnel transfer by gangway and emergency

disconnection.

• Captain to inform engine room to start main engine and alert ship’s crew to take position for

disconnect

• Captain to inform SOA the need or requirement to move Serenity Vessel at safe zone • SOA

to inform Halliburton Svc leader to be ready for vessel disconnection

• Halliburton Service leader (Halliburton representative on Foukanda) to inform his crew (super-

visor, pump operator and bosco) to prepare for vessel disconnection

• Close Air and Diesel valves • Crane EC-65 ready to lift the 4in hose and secure at platform

side

• In case of any 4in hose connected to feed platform with water from Serenity Vessel, close RIA

valve. Remove pins and open camlock ready to launch 4in hose

• Disconnect all umbilicals (Diesel, Air, Power cable) from the stern of the vessel.

• Pick up using EC-65 crane to secure from Platform

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 23 of 50

• In case of any H2S alarm in the platform, the team involved on the vessel disconnection must

be protected with a breathing apparatus to intervene

• Quick Disconnect (move main valve in open position from control panel, ensure hydraulic pres-

sure is at 3,000psi and dump valve is closed as per the below picture) the 2in HP hose and

drop on the sea

• Bosco to confirm to Svc leader when all connections are removed from the vessel prior to start

moving the vessel

• Mamola Serenity Vessel can now move toward using anchors winches and stay at 50m (safe

zone to be confirmed by Serenity captain)

• The captain of Mamola Serenity remains in contact with the SOA and awaits further instructions

from ENI

• PROMAR crew to monitor weather conditions

5.3 Safety Plan.

• The Mamola Serenety is already at the location and it is a FIFI’s class vessel

As per Safety Plan, it will be permanently assigned to once SIMOPS will start. (Ref Plan HSE

pour le Re-démarrage des activités sur AWA)

6 WASTE, CHEMICAL AND OPERATIONAL DISCHARGES MANAGEMENT PLAN

6.1 Waste Management Plan

On-board, the waste has to be managed as per International Maritime Organization standards &

PROMAR Wastes Management Plan.

Since waste treatment is done by ENI CONGO the waste segregation shall follow the ENI CONGO

regulation.

Vessel Master will be responsible for the proper disposal inside the skips of the waste generated by

PROMAR on the vessel.

PROMAR will be responsible for the proper disposal inside the skips of the waste they have generated

on the deck.

On-board, the waste has to be managed as per PROMAR’s Garbage Management Plan compliant

with MARPOL convention as per PROMAR Integrated Manual, section 10 PRD-10-001-Environmental

Management

Tracking of the waste will be ensured by PROMAR logistics according to their Waste management

Plan.

6.2 Operational Discharges

Biodegradable food waste has to be collected separately, grinded to meet a particle size less than

25mm (respective of Convention MARPOL of OMI) and can be discharged overboard.

Bilge water from machinery room is to be treated and monitored for oil content before discharge.

The limit of oil content in the bilge water discharge is 15 ppm (MARPOL rule).

A record showing quantity and oil content for every discharge has to be kept on chartered vessel(s),

and presented to ENI CONGO whenever required. This will be achieved by means of the vessel’s Oil

Record Book as required by MARPOL regulations.

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 24 of 50

Periodic Audits will be conducted, as described in paragraph 11.3 (Audits) of this document.

7 SAFEGUARDING OF HEALTH

7.1 General occupational health

The following summary is distributed widely, and is posted in offices and vessel’s bulletin boards

PROMAR-wide.

• People are the most important consideration in any undertaking.

• Provide a safe, hazard free, working environment.

• Protect employee health and company property.

• Prevent pollution by adherence to applicable laws and standards.

• Promote safe and efficient operations.

References:

Procedures can be found in PIMS:

• PIMS Chap 1- Policies and procedures

Reference to the following PIMS sections should be made at all times when undertaking any task.

• Refer to ENI CONGO Industrial Hygiene referential appendix 07 (GENERAL

OCCUPATIONNAL HEALTH)

7.2 Personal Protective Equipment (PPE)

The Personnel Protective Equipment to be used, as a minimum requirement on chartered vessel(s),

is referenced in the vessel’s PIMS PROMAR Integrated Manual, Section 09-SPC-OSV-09-002-ver.01-

OSV PPE Matrix & PRD-09-002-ver.01-Personal Protective Equipment

Note: Jewelry (such as earrings, necklaces, bracelets, rings) of any type and metal watch straps

are strongly discouraged during working hours as per PROMAR/ENI CONGO recommendation.

7.3 Hazardous substance, product or material

ENI CONGO will be responsible to provide all necessary documentation and declarations of hazard-

ous substance(s), product(s) or material(s), required to transport on a vessel chartered from

PROMAR, prior to be loaded and shipped.

The Master must ensure that all hazardous chemicals are controlled: deck crew check the MSDS,

and apply the adequate segregation rule, depending of the nature of the hazardous product (flamma-

ble, corrosive, explosive, etc.).

Each chemical/hazardous product supplied should come with a Material Safety Data Sheet (MSDS).

These must be retained on board and filed in the COSHH (Control of Substances Hazardous to Health)

/ HazMat / MSDS folder.

These MSDS contain important information that may be needed in the event of an accident or emer-

gency situation. It is important the location of the COSHH file is known by all on board and easily

available.

ENI CONGO – PROMAR - BRIDGING DOCUMENT

ENI CONGO-PROMAR

eni congo

Avril 27, 2023 REV:10

HSE BRIDGING DOCUMENT Page 25 of 50

Moreover, vessel may need and use Chemical/hazardous products for her operation. The loading, the

storage and the use of such products is under the responsibility of the Captain. Management of them

is described in vessel’s SMS PROMAR Integrated Manual and Operations Process. It may be prudent

to have additional copies of the MSDS at the point of use but this is not a requirement. In general

IMDG code should be followed.

7.4 Prevention of asbestos hazards

The vessel’s SMS does not explicitly deal with asbestos but refers to codes such at the Code of Safe

Working Practices (COSWP) for such matters. International maritime legislation will be referenced

when dealing with asbestos and asbestos related matters pertaining to vessel(s) chartered from

PROMAR.

8 COMPETENCE AND TRAINING OF PERSONNEL

The personnel procedures are as described in the vessel’s SMS PROMAR integrated manual and

regional documentation (titled: PERSONNEL PROCEDURES or Local content Procedure)

The competency of the personnel on board vessel(s) chartered from PROMAR is assured by the im-

plementation of appropriate recruitment and selection procedures already in place.

Every vessel shall have sufficient crew on-board to satisfy the requirements of the vessel’s safe

manning certificate. Additionally, a risk assessment shall be carried out to assess the correct level of

manning required for the intended vessel’s operation. The vessel shall be manned according to the

requirements of the risk assessment, even if this is in excess of the Minimum Safe Manning Certifi-

cate.