Professional Documents

Culture Documents

3a. Monorail

3a. Monorail

Uploaded by

Lagnajit DasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3a. Monorail

3a. Monorail

Uploaded by

Lagnajit DasCopyright:

Available Formats

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. : DATE:

Execution of 2 Nos Individual Rural Piped Water Supply

PROJECT: Projectspertaining to Jharsuguda District including five years LE190742-C-WS-WT-DC-3036 31/03/2024

Operation & Maintenanc under package-I

DESIGNED : CHECKED : SHEET :

Design Calculation of Chlorination Buliding & chlorine

TITLE: NSP KPV

tonner with neutralization

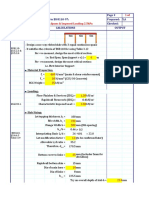

Design of Monorail - 3 Ton

Maximum span, l = 4.275 m

Loads:

Monorail capacity = 3T

Monorail capacity = 30 kN

weight of pulley + bucket (hoist) = 7.5 kN

Impact factor (Electrically Operated) = 1.25

Total load, P (30 x 1.25 + 7.5) = 45 kN

self weight of beam = 0.514 kN/m

a) Design of monorail in straight portion:

Additional loads :

Axial load on the beam = 10% of 30 kN 3 kN

Lateral load on the beam = 10% of 30 kN 3 kN

45

0.514

A 4.275 B

Reaction , RAy = RBy = (0.514x4.275 + 45) / 2 = 23.599 kN

Reaction , RAz = RBz = 1.5 kN

Maximum BM, My= 3x4.275 /4 = 3.206 kN-m

Maximum BM, Mz= 0.514x4.275x4.275/8 + 45x4.275 /4 = 49.268 kN-m

Axial Force on the beam = 3 kN

Design Forces:

Factored Shear force about major axis = Vy = 35.3985 kN

Factored Shear force about minor axis= Vz = 2.25 kN

Factored Bending Moment about minor axis = My = 4.809 kN-m

Factored Bending Moment about major axis = Mz = 73.902 kN-m

Factored Axial Force = N= 4.5 kN

For choosing trial section:

From Table 5, pg 30, IS 800:2007

Partial safety factor, gm0 = 1.1

000000Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. : DATE:

Execution of 2 Nos Individual Rural Piped Water Supply

PROJECT: Projectspertaining to Jharsuguda District including five years LE190742-C-WS-WT-DC-3036 31/03/2024

Operation & Maintenanc under package-I

DESIGNED : CHECKED : SHEET :

Design Calculation of Chlorination Buliding & chlorine

TITLE: NSP KPV

tonner with neutralization

Yield stress of the steel, fy = 250 N/mm2

According to Clause 8.2.2, pg 54, IS 800:2007

Considering plastic section, bb = 1

Plastic section modulus of trial section, Zpz,req = MZ gm0 / bb fy = 325168.8 mm3

Considering Laterally Unsupported beam, try section ISMB 350

Sectional Properties of ISMB 350:

Sectional Area, A = 6671 mm2

Depth of Section, h = 350 mm

Width of Flange, bf = 140 mm

Thickness of Flange, tf = 14.2 mm

Thickness of Web, tw = 8.1 mm

Depth of Web, (For Welded Section) d = 293.6 mm

Moments of Inertia, IZZ = 136303000 mm4

Iyy = 5377000 mm4

Radii of Gyration, rzz = 142.9 mm

ryy = 28.4 mm

Rasius at Root, r1 = 14 mm

Elastic Section Modulus, Zez = 779000 mm3

Zey = 76800 mm3

Plastic Section Modulus, Zpz = 889570 mm3

Zpy = 128256 mm3

Modulus of Elasticity, E = 200000 N/mm2

Classification of section:

According to Table 2, pg 18, IS 800;2007,

Flange Section: (Rolled - I)

b/tf = 4.93

Limit for Class 1 Plastic section, 9.4 e = 9.4

Limit for Class 2 Compact section, 10.5 e = 10.5

Limit for Class 3 Semi-compact section, 15.7 e = 15.7

Flange is a Plastic Section

Web Section: (Neutral Axis at Mid-depth)

Depth of web, d = 293.6 mm

d/tw = 36.247

Limit for Class 1 Plastic section, 84 e = 84

000000Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. : DATE:

Execution of 2 Nos Individual Rural Piped Water Supply

PROJECT: Projectspertaining to Jharsuguda District including five years LE190742-C-WS-WT-DC-3036 31/03/2024

Operation & Maintenanc under package-I

DESIGNED : CHECKED : SHEET :

Design Calculation of Chlorination Buliding & chlorine

TITLE: NSP KPV

tonner with neutralization

Limit for Class 2 Compact section, 105 e = 105

Limit for Class 3 Semi-compact section, 126 e = 126

Web is a Plastic Section

Considered section is classified as Plastic Section

Design bending strength of laterally unsupported beam:

According to Clause 8.2.2, pg 54, IS 800:2007

bb = 1

Imperfection parameter, aLT = (Rolled - I) 0.21

Effective Length, KL = 4.275 m

KL/r = 150.528

h/tf = 24.648

From Table 14, pg 57, IS 800:2007

Critical Stress, fcr,b = 162.687 N/mm2

Elastic Critical Moment, Mcr = 144.721 kN-m

Non-dimensional slenderness ratio, lLT =

bb Zpz fy / Mcr = 1.24 ≤ 1.2 Zez fy /Mcr = 1.271 OK

Since, Non-dimensional slenderness ratio = 1.24 > 0.4, effect of lateral torsional buckling

has to be considered

fLT = 0.5 [1 + aLT (lLT - 0.2) + lLT^2] = 1.378

cLT = 1 0.505 ≤ 1, OK

fLT + (fLT^2 - lLT^2)^0.5

Design bending compressive stress, fbd = cLT fy / gm0 = 114.773 N/mm2

Design bending strength, Mdz = bb Zpz fbd = 102.099 kN-m

Safe

Design bending strength, Mdy =

bb Zpy fy / gm0 = 29.149 > 1.2 Zey fy / gm0 = 20.945 kN-m

Design bending strength, Mdy = 20.945 kN-m

Safe

Check for sectional strength subjected to combined axial force and bending moment:

Design strength, Nd = Ag fy / gm0 = 1516.136 kN

n= N / Nd = 0.003

5n = 0.015

a= (A - 2btf) /A = 0.404

Therefore, Design reduced flexural strength under combined axial force and

the respective uniaxial moment acting alone is as follows:

000000Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. : DATE:

Execution of 2 Nos Individual Rural Piped Water Supply

PROJECT: Projectspertaining to Jharsuguda District including five years LE190742-C-WS-WT-DC-3036 31/03/2024

Operation & Maintenanc under package-I

DESIGNED : CHECKED : SHEET :

Design Calculation of Chlorination Buliding & chlorine

TITLE: NSP KPV

tonner with neutralization

According to Clause 9.3.1.2, pg 70, IS 800:2007

Mndz = (Rolled - I) 102.099 kN-m

Mndy = (Rolled - I) 20.945 kN-m

From Table 17, pg 71, IS 800:2007

a1 = 1

a2 = 2

According to Clause 9.3.1.1, pg 70, IS 800:2007

(My / Mndy)a1 + (Mz / Mndz)a2 = 0.754 ≤ 1, OK

(N / Nd) + (My / Mdy) + (Mz / Mdz) = 0.956 ≤ 1, OK

Check for compression capacity:

Effective Length, KLz = 4275 mm

Effective Length, KLy = 4275 mm

Effective slenderness ratio = (about z-z axis) KLz/rzz = 29.916

(about y-y axis) KLy/ryy = 150.528

Euler Buckling stress, fcc,z = p^2E/(KLz/rzz)^2 = 2205.579 N/mm2

fcc,y = p^2E/(KLy/ryy)^2 = 87.115 N/mm2

Non-dimensional effective slenderness ratio, = lz = 0.337

ly = 1.694

h/bf = 2.5

tf = 14.2 mm

From Table 10, pg 44, IS 800:2007

For section = (Rolled - I)

Buckling Class = (about z-z axis) a

(about y-y axis) b

From Table 7, pg 35, IS 800:2007

az = 0.21

ay = 0.34

fz = 0.5 [1 + az (lz - 0.2) + lz^2] = 0.571

fy = 0.5 [1 + ay (ly - 0.2) + ly^2] = 2.189

Stress reduction factor, cz = 1.276

cy = 0.243

Design compressive strength, fcd,z = 290 N/mm2

fcd,y = 55.227 N/mm2

fy / gm0 = 227.273 N/mm2

Design Compressive strength of the section, Pdz = 1516.138 kN

Pdy = 368.419 kN

Check for overall member strength subjected to bending and axial compression:

000000Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. : DATE:

Execution of 2 Nos Individual Rural Piped Water Supply

PROJECT: Projectspertaining to Jharsuguda District including five years LE190742-C-WS-WT-DC-3036 31/03/2024

Operation & Maintenanc under package-I

DESIGNED : CHECKED : SHEET :

Design Calculation of Chlorination Buliding & chlorine

TITLE: NSP KPV

tonner with neutralization

According to Clause 9.3.2.2, pg 71, IS 800:2007

nz = N / Pdz = 0.003

ny = N / Pdy = 0.012

1 + (lz - 0.2)nz = 1

1 + 0.8nz = 1.002

Kz = 1

1 + (ly - 0.2)ny = 1.018

1 + 0.8ny = 1.01

Ky = 1.01

From Table 18, pg 72, IS 800:2007

y= 1

Equivalent uniform moment factors, Cmz = 0.9

Cmy = 0.9

CmLT = 1

1 - [(0.1 lLT ny) / (CmLT - 0.25)] = 0.998

1 - [(0.1 ny) / (CmLT - 0.25)] = 0.9984

KLT = 0.9984

Interaction relationships:

0.944 ≤ 1, OK

P/P_dy + K_y (C_my M_y)/M_dy +K_LT M_z/M_dz =

0.78 ≤ 1, OK

P/P_dz + 〖 0.6K 〗 _y (C_my M_y)/M_dy +K_z (C_mz M_z)/M_dz =

Check for shear capactiy:

According to Clause 8.4, pg 59, IS 800:2007

Partial safety factor against shear failure, gm0 = 1.1

Shear area, Avz = (For Rolled I section - Major axis bending) 2835 mm2

Shear area, Avy = (For Rolled I section - Minor axis bending) 3976 mm2

Yield Strength of web, fyw = 250 N/mm2

Plastic shear resistance, Vpz = Avz fyw / 3 = 409.197 kN

Plastic shear resistance, Vpy = Avy fyw / 3 = 573.886 kN

Nominal shear strength, Vnz = Vpz = 409.197 kN

Nominal shear strength, Vny = Vpy = 573.886 kN

Design shear strength, Vdz = Vnz / gm0 = 371.997 kN

Safe

Design shear strength, Vdy = Vny / gm0 = 521.715 kN

Safe

Check for high or low shear:

000000Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. : DATE:

Execution of 2 Nos Individual Rural Piped Water Supply

PROJECT: Projectspertaining to Jharsuguda District including five years LE190742-C-WS-WT-DC-3036 31/03/2024

Operation & Maintenanc under package-I

DESIGNED : CHECKED : SHEET :

Design Calculation of Chlorination Buliding & chlorine

TITLE: NSP KPV

tonner with neutralization

0.6Vdz = 223.198 kN

0.6Vdy = 313.029 kN

The case is of low shear since V ≤ 0.6Vd

Thus, design bending strength Md is equal to the bending strength

calculated above

Check for web buckling:

According to Clause 8.4.2.1, pg 59, IS 800:2007

d/tw = 36.247

67e = 67

Safe and shear strength is governed by plastic shear strength (Vp)

Check for deflection:

d1 = 5wl4 = 0.082 mm

384EI

d2 = Pl3 = 2.687 mm

48EI

Total deflection = d1 + d2 = 2.769 mm

From Table 6, pg 31, IS 800:2007

For Crane Load (Electric Operation up to 50 T)

Limiting deflection = Span / 750 = 5.7 mm

Safe

b) Design of monorail in curved portion:

Radius of curvature, R = 2058 mm

Maximum allowable length along beam curvature, L =

(span between supports) 1078 mm

L

R

Subtended angle, f = 30.012 0

Semi-subtended angle, y = 15.006 0

Size of extra plate at top, width = b1 = 0 mm

thickness = d1 = 0 mm

000000Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. : DATE:

Execution of 2 Nos Individual Rural Piped Water Supply

PROJECT: Projectspertaining to Jharsuguda District including five years LE190742-C-WS-WT-DC-3036 31/03/2024

Operation & Maintenanc under package-I

DESIGNED : CHECKED : SHEET :

Design Calculation of Chlorination Buliding & chlorine

TITLE: NSP KPV

tonner with neutralization

Size of extra plate at bottom, width = b2 = 0 mm

thickness = d2 = 0 mm

Sectional Properties of built-up section:

Sectional Area, A = 6671 mm2

Depth of Section, h = 350 mm

Width of Flange, bf = 140 mm

Max. thickness of Flange, tf,max = 14.2 mm

Thickness of Web, tw = 8.1 mm

Depth of Web, (For Welded Section) d = 293.6 mm

C.G. from top, ytop = 175 mm

ybottom = 175 mm

Moments of Inertia, IZZ = 136303000 mm4

Iyy = 5377000 mm4

Radii of Gyration, rzz = 142.941 mm

ryy = 28.391 mm

Rasius at Root, r1 = 14 mm

Elastic Section Modulus, Zez,top = 778874.286 mm3

Zez,bottom = 778874.286 mm3

Zey = 76814.286 mm3

Plastic Section Modulus, Zpz = 889570 mm3

Zpy = 128256 mm3

Modulus of Elasticity, E = 200000 N/mm2

According to Clause 8.2.2.1, pg 54, IS 800:2007

Torsional constant, It = S (biti3/3) = 306230.05776 mm4

ψ (degrees) D1 D2 D3 D4 D5

5 0.1254 1.1254 0.066 0.0019 0.1235

10 0.1279 1.1279 0.1313 0.0077 0.1202

15 0.1317 1.1317 0.1998 0.0176 0.114

20 0.1371 1.1371 0.2702 0.0321 0.105

25 0.1447 1.1447 0.3439 0.0517 0.093

30 0.1547 1.1547 0.4226 0.0774 0.0774

35 0.1677 1.1677 0.5078 0.1104 0.0574

40 0.1848 1.1847 0.6016 0.1527 0.0321

45 0.2071 1.2071 0.7071 0.2071 0

000000Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. : DATE:

Execution of 2 Nos Individual Rural Piped Water Supply

PROJECT: Projectspertaining to Jharsuguda District including five years LE190742-C-WS-WT-DC-3036 31/03/2024

Operation & Maintenanc under package-I

DESIGNED : CHECKED : SHEET :

Design Calculation of Chlorination Buliding & chlorine

TITLE: NSP KPV

tonner with neutralization

50 0.2367 1.2367 0.829 0.2778 -0.0411

55 0.277 1.277 0.9744 0.3717 -0.0947

60 0.3333 1.333 1.1547 0.5 -0.1667

From interpolation

for y (degrees) D1 D2 D3 D4 D5

30.012 0.1317 1.1317 0.1999 0.0176 0.114

Sectorial area of the chord at top = 0.5 x bmax x ytop = 12250 mm2

Sectorial area of the chord at bottom = 0.5 x bmax x ybottom = 12250 mm2

Sectorial Moment of Inertia, Iw =

((14.2x140�/12+0x0�/12) x (14.2x140�/12+0x0�/12)

x (350-0-0)�)/5377000 = 240203019784 mm6

Torsional stiffness characteristics, x = R x (0.4 It/Iw)= 1.47

xy = 0.385 rad

2xy = 0.77 rad

3xy = 1.155 rad

cosh(xy) = 1.075 sinh(xy) = 0.395

cosh(2xy) = 1.311 sinh(2xy) = 0.848

cosh(3xy) = 1.745 sinh(3xy) = 1.429

Maximum factored bending moment, Mmax = D3 x R x P/2 = 13884554.25 N-mm

Maximum factored Bi-moment (Torsional), Bmax =

= P∗R2

[ sinh(3 xψ )−D3 x cosh(3 xψ )−D2 sinh(2 xψ )]

2∗x ( x 2 +1 ) cosh ( 3 xψ )

45000 x 2058� x (1.429 - (0.1999 x 1.47 x 1.745) - (1.1317 x 0.848))

2 x 1.47 x (1.47� +1) x 1.745

= -510728790 N-mm

Section Classification:

Considered section is classified as Plastic Section

Check for strength in bottom flange against major axis overall bending & torsional moment:

Mmax/Z + Bmax x w/Iw ≤ fy/gm0

(13884554.25/889570) + (510728790.347 x 12250/240203019783.853)

≤ (250/1.1)

41.655 ≤ 227.273 Hence Satisfactory

000000Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. : DATE:

Execution of 2 Nos Individual Rural Piped Water Supply

PROJECT: Projectspertaining to Jharsuguda District including five years LE190742-C-WS-WT-DC-3036 31/03/2024

Operation & Maintenanc under package-I

DESIGNED : CHECKED : SHEET :

Design Calculation of Chlorination Buliding & chlorine

TITLE: NSP KPV

tonner with neutralization

Check for strength against direct shear:

According to Clause 8.4, pg 59, IS 800:2007

Shear force, V = 33.75 kN

Assuming direct shear is completely resisted by the web portion

Shear area, Av = d x tw = 2378.16 mm2

Plastic shear resistance, Vp = Av fyw / 3 = 343.258 kN

Nominal shear strength, Vn = Vp = 343.258 kN

Design shear strength, Vd = Vn / gm0 = 312.053 kN

Hence Satisfactory

Check for strength against torsional shear:

Eccentricity due to curvature, e = R-Rcos(f/2) = 70.18 mm

Torsional moment, Tm = Pe/2 = 2.369 kN-m

Maximum torsional shear stress in the flange, zt,f = Tm x tf/It = 109.851 N/mm2

Direct shear stress = 14.192 N/mm2

Total shear stress = 124.043 N/mm2

Permissible shear stress = 131.216 N/mm2

Hence Satisfactory

Check for deflection:

k= (For continuous girder) 0.9

Span, L = 1.078 m

Overall depth of beam, H = 35 cm

Stress due to vert. loads excluding load factor and dynamic coef., smax =

0.386 t/cm2

Actual vertical deflection, d = ksmaxL /H 2

0.115 mm

Limiting deflection = Span / 750 = 1.437 mm

Safe

Laods to be applied in STAAD model:

For Dead Load Case

For straight portion of the beam

Dead load due to self-weight of monorail beam on end beams = 1.099 kN

Dead load due to self-weight of monorail beam on other beams = 2.198 kN

For curved portion of the beam

Dead load due to self-weight of monorail beam on end beams = 0.277 kN

Dead load due to self-weight of monorail beam on other beams = 0.554 kN

Dead load due to self-wt at intesection of crvd and strght portion = 1.376 kN

Dead load due to hoist load = 7.5 kN

000000Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent Treatment IC

DOCUMENT NO. : DATE:

Execution of 2 Nos Individual Rural Piped Water Supply

PROJECT: Projectspertaining to Jharsuguda District including five years LE190742-C-WS-WT-DC-3036 31/03/2024

Operation & Maintenanc under package-I

DESIGNED : CHECKED : SHEET :

Design Calculation of Chlorination Buliding & chlorine

TITLE: NSP KPV

tonner with neutralization

For Live Load Case

Live load due to hoist load = 37.5 kN

For Earthquake Load Case

According to Clause 7.3.3 (b), pg 20, IS 1893 (Part 1):2016

For straight portion of the beam

Dead load due to self-weight of monorail beam on end beams = 1.099 kN

Dead load due to self-weight of monorail beam on other beams = 2.198 kN

For curved portion of the beam

Dead load due to self-weight of monorail beam on end beams = 0.277 kN

Dead load due to self-weight of monorail beam on other beams = 0.554 kN

Dead load due to self-wt at intesection of crvd and strght portion = 1.376 kN

Dead load due to hoist load = 7.5 kN

000000Sensitivity: LNT Construction Internal Use

#

Sectional Depth of Width of Thickness Thickness

wt per m

Area Section Flange of Flange of Web

Designation

w a h b tf tw

kg N cm2 mm mm mm mm

lSMB 100 11.5 112.8 14.6 100 75 7.2 4

ISMB 125 13 127.5 16.6 125 75 7.6 4.4

lSMB 150 14.9 146.2 19 150 80 7.6 4.8

ISMB 175 19.3 189.3 24.62 175 90 8.6 5.5

ISMB 200 25.4 249.2 32.33 200 100 10.8 5.7

ISMB 225 31.2 306.1 39.72 225 110 11.8 6.5

ISMB 250 37.3 365.9 47.55 250 125 12.5 6.9

ISMB 300 44.2 433.6 56.26 300 140 12.4 7.5

ISMB 350 52.4 514 66.71 350 140 14.2 8.1

ISMB 400 61.6 604.3 78.46 400 140 16 8.9

ISMB 450 72.4 710.2 92.27 450 150 17.4 9.4

ISMB 500 86.9 852.5 110.74 500 180 17.2 10.2

Table 14, Critical Stress, fcr,b:

h/tf

KL/r

8 10 12 14 16 18 20 25

20 6220.5 5947.9 5794.5 5700 5637.8 5594.7 5563.8 5515.8

30 3149.3 2905.9 2764.6 2676 2616.7 2575.3 2545.3 2498.5

40 2036.1 1821.2 1693 1610.8 1555.1 1515.8 1487 1441.7

50 1492.9 1303.2 1187,3 1111.8 1059.9 1022.7 995.3 951.7

60 1178 1009.5 905 835.6 787.4 752.4 726.4 684.6

70 973.9 823.2 728.5 664.8 620.1 587.4 562.9 522.9

80 831.3 695.4 609.2 550.7 509.1 478.4 455.3 417.2

90 725.9 602.6 523.6 469.5 430.9 402.2 380.4 344.2

100 644.7 532 459.3 409,3 373.2 346.4 325.8 291.4

110 580.4 476.6 409.3 362.9 329.2 303.9 284.5 251.8

120 527.9 431.9 369.5 326 294.5 270.7 252.3 221.2

130 484.3 395 336.8 296.1 266.5 244.1 226.7 197.1

140 447.6 364.2 309.5 271.5 243.4 222.3 205.8 177.5

150 416 337.8 286.6 250.6 224.2 204.2 188.4 161.5

160 388.7 315.2 266.8 232.8 207.8 188.8 173.9 148.2

170 364.9 295.4 249.6 217.5 193.7 175.6 161.4 136.7

180 343.9 278 234.6 204.1 181.5 164.2 150.6 127.1

190 325.2 262.6 221.3 192.3 170.7 154.2 141.2 118.6

200 308.3 248.8 209.6 181.7 161.2 145.4 133 111.3

210 293.3 236.5 198.9 172.4 152.7 137.6 125.7 104.8

220 279.5 225.3 189.3 163.9 145.1 130.6 119.1 99

230 267.1 215.2 180.7 156.3 138.2 124.3 113.3 93.9

240 255.8 205.8 172.8 149.4 132 118.6 108 89.3

250 245.3 197.3 165.6 143 126.3 113.4 103.2 85.1

260 235.7 189.5 159 137.3 121.1 108.7 98.8 81.3

270 226.8 182.3 152.8 131.9 116.3 104.3 94.7 77.9

280 218.6 175.7 147.2 126.9 111.9 100.2 91.1 74.7

000000Sensitivity: LNT Construction Internal Use

#

290 210.9 169.4 141.9 122.3 107.8 96.6 87.7 71.8

300 203.8 163.7 137.1 118.1 104.1 93.2 84.5 69.1

000000Sensitivity: LNT Construction Internal Use

#

Elastic Elastic Plastic Plastic

Rasius at

Moments of Inertia Radii of Gyration Section Section Section Section

Root

Modulus Modulus Modulus Modulus

Ixx Iyy rxx ryy r1 Zez Zey Zpz Zpy

cm4 cm4 cm cm mm cm3 cm3 cm3 cm3

257.5 40.8 4.2 1.67 9 36.6 10.9 41.68 18.203

449 43.7 5.2 1.62 9 71.8 11.7 81.85 19.539

726.4 52.6 6.18 1.66 9 96.9 13.1 110.48 21.877

1272 85 7.19 1.86 10 145.4 18.9 166.08 31.563

2235.4 150 8.32 2.15 11 223.5 30 253.86 50.1

3441.8 218.3 9.31 2.34 12 305.9 39.7 348.27 66.299

5131.6 334.5 10.39 2.65 13 410.5 53.5 465.71 89.345

8603.6 453.9 12.37 2.84 14 573.6 64.8 651.74 108.216

13630.3 537.7 14.29 2.84 14 779 76.8 889.57 128.256

20458.4 622.1 16.15 2.82 14 1020 88.9 1176.18 148.463

30390.8 834 18.15 3.01 15 1350.7 111.2 1533.36 185.704

45218.3 1369.8 20.21 3.52 17 1808.7 152.2 2074.67 254.174

h/tf

30 35 40 50 60 80 100

5489.7 5473.8 5463.5 5451.4 5444.8 5438.2 5435.1

2472.8 2457.1 2447 2434.9 2428.3 2421.7 2418.6

1416.5 1401.1 1391 1379 1372.5 1365.9 1362.8

927.1 912 902 890.2 883.7 877.1 874.2

660.9 646.1 636.4 624.7 618.2 611.7 608.7

500 485.5 476 464.4 458 451.7 448.7

395.1 381.2 371.8 360.5 354.1 347.7 344.7

322.9 309.3 300.2 289.1 282.8 276.5 273,5

270.9 257.7 248.8 237.9 231.8 225.5 222.5

232.1 219.3 210.8 200.1 194 187.8 184,8

202.4 190.1 181.6 171.2 165.2 159.I 156.2

179 167.1 158.8 148.6 142.8 136.7 133.9

160.2 148.7 140.7 130.8 125 119 116.2

144.8 133.7 126 116.3 110.6 104.7 101.9

132 121.3 113.9 104.3 98.8 93 90.1

121.3 111 103.6 94.4 89 83.2 80.4

112.2 102.2 95.2 86 80.7 75 72.3

104.3 94.6 87.8 79 73.7 68.1 65.3

97.5 88.1 81.4 72.8 67.8 62.2 59.5

91.5 82.4 75.9 67.5 62.6 57.1 54.5

86.2 77.4 71.2 62.9 58.1 52.7 50.1

81.5 72.9 66.9 58.9 54.1 48.8 46.2

77.2 69 63.1 55.3 50.6 45.4 42.8

73.5 65.5 59.7 52.1 47.5 42.4 39.8

70.1 62.3 56.7 49.3 44.8 39.7 37.2

67 59.4 53.9 46.8 42.2 37.3 34.8

64.1 56.8 51.5 44.4 40 35.2 32.7

000000Sensitivity: LNT Construction Internal Use

#

61.5 54.3 49.2 42.2 38.1 33.2 30.8

59.1 52.1 47.1 40.4 36.2 31.5 29

000000Sensitivity: LNT Construction Internal Use

#

Designation

lSMB 100

ISMB 125

lSMB 150

ISMB 175

ISMB 200

ISMB 225

ISMB 250

ISMB 300

ISMB 350

ISMB 400

ISMB 450

ISMB 500

000000Sensitivity: LNT Construction Internal Use

#

You might also like

- Honda - CBR - 125R - Maintenance - and - Service - Manual PDFDocument20 pagesHonda - CBR - 125R - Maintenance - and - Service - Manual PDFMar0% (1)

- FULL Download Ebook PDF Introduction To Business Third 3rd Edition by Julian e Gaspar PDF EbookDocument41 pagesFULL Download Ebook PDF Introduction To Business Third 3rd Edition by Julian e Gaspar PDF Ebookchristina.davis595100% (41)

- Ebook PDF Transnational Management Text and Cases in Cross Border Management 8th Edition PDFDocument41 pagesEbook PDF Transnational Management Text and Cases in Cross Border Management 8th Edition PDFernest.kirschenbaum650100% (40)

- Lifting Hook For Precast SegmentDocument1 pageLifting Hook For Precast Segmenteric bargas100% (5)

- 21 Lifting Lugs - CalculatorDocument3 pages21 Lifting Lugs - CalculatorMbalekelwa Mpembe100% (1)

- ASTON Kartika GrogolDocument2 pagesASTON Kartika GrogolAngga Ciro Bams100% (1)

- References Calculations Bridge Abutment Curtain Wall Analysis and Design (Bs 5400)Document10 pagesReferences Calculations Bridge Abutment Curtain Wall Analysis and Design (Bs 5400)WycliffeNo ratings yet

- Pedestal Design 3, 4,5 & 6Document2 pagesPedestal Design 3, 4,5 & 6munishant10% (1)

- Monorail Beam DesignDocument6 pagesMonorail Beam DesignAnand.5No ratings yet

- Monorail 5TDocument12 pagesMonorail 5Tmrprabhu16No ratings yet

- Medicinal PlantsDocument10 pagesMedicinal PlantsAnurag GoelNo ratings yet

- CV Ahnaf Tahmid PDFDocument4 pagesCV Ahnaf Tahmid PDFishmamNo ratings yet

- Good Documentation PracticesDocument34 pagesGood Documentation PracticesSophia100% (8)

- 29 - Monorail 800 2007Document7 pages29 - Monorail 800 2007Powerhouse ShaftNo ratings yet

- SLAB at 1.5Document29 pagesSLAB at 1.5Brian Byrne MilayNo ratings yet

- S1 CalcDocument5 pagesS1 Calcranser27gamingNo ratings yet

- Purlin and RunnerDocument8 pagesPurlin and RunnerBabu Sundararaman0% (1)

- 3rdF SLAB Design CalculationsDocument35 pages3rdF SLAB Design CalculationsLon OdiNo ratings yet

- Setting PageDocument28 pagesSetting Pagevishnumani3011No ratings yet

- Slab Design Calculations: Definitions of TermsDocument18 pagesSlab Design Calculations: Definitions of TermsmarkeesNo ratings yet

- Gantry CraneDocument20 pagesGantry Cranekushaljp8989No ratings yet

- Busugan Part 2 Design BSDSDocument257 pagesBusugan Part 2 Design BSDSmarco miguelNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument10 pagesLarsen & Toubro Limited: ECC Division - EDRCJohnclaude ChamandiNo ratings yet

- 2F Floor (S4)Document6 pages2F Floor (S4)Zulkiflee TaugNo ratings yet

- Design of Pile and Pile Cap BeamDocument4 pagesDesign of Pile and Pile Cap Beamshivendra kumarNo ratings yet

- Purlin Design PDFDocument3 pagesPurlin Design PDFUday Udmale100% (1)

- Slab Design CalculationDocument4 pagesSlab Design CalculationjayNo ratings yet

- Gantry CraneDocument31 pagesGantry Cranekushaljp8989No ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- Ribbed Slab DesignDocument4 pagesRibbed Slab Designyusuf abdinasir100% (1)

- Rail Extension CalculationDocument9 pagesRail Extension CalculationDeepti DeepuNo ratings yet

- Slab CalculationDocument18 pagesSlab CalculationREC ALFONSO CINCONo ratings yet

- Parapet Wall Upto 3.45 M CushionDocument5 pagesParapet Wall Upto 3.45 M Cushionsrikanth2vangaraNo ratings yet

- Martinez Structural ReportDocument52 pagesMartinez Structural Reportfrancis sebastian lagamayoNo ratings yet

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- 21a Lifting Lugs - Calculator For Standard Lifting LugsDocument4 pages21a Lifting Lugs - Calculator For Standard Lifting LugsMbalekelwa MpembeNo ratings yet

- Slab Design CalculationsDocument21 pagesSlab Design CalculationsLucas Construction SolutionsNo ratings yet

- Slab Design CalculationsDocument33 pagesSlab Design CalculationsMark Christian EsguerraNo ratings yet

- Design of Tie Beam (TB)Document3 pagesDesign of Tie Beam (TB)Khael Angelo Zheus JaclaNo ratings yet

- Typical Beam Column Design ElectricalDocument4 pagesTypical Beam Column Design ElectricalPrabhumk07No ratings yet

- Apartment Structural DesignDocument29 pagesApartment Structural DesignpolarisNo ratings yet

- Steel Composite 1 VERY GOOD MahfuzDocument5 pagesSteel Composite 1 VERY GOOD MahfuzEdson NhabetseNo ratings yet

- RCC 7m C.F Re WallDocument30 pagesRCC 7m C.F Re WallArun RawatNo ratings yet

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDocument1 pageChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNo ratings yet

- Calculation Sheet: Title: Structure Design Location: Rev.: BDocument1 pageCalculation Sheet: Title: Structure Design Location: Rev.: Biwanguna71No ratings yet

- V.A.S Design & Infra Consultants Pvt. LTDDocument13 pagesV.A.S Design & Infra Consultants Pvt. LTDPankaj SherwalNo ratings yet

- Beam Design TemplateDocument9 pagesBeam Design TemplateWinston AdvinculaNo ratings yet

- Diaphragms For Gravity Loads (AASHTO)Document14 pagesDiaphragms For Gravity Loads (AASHTO)FAIZAN AHMEDNo ratings yet

- BS code-Base-Plate-DesignDocument38 pagesBS code-Base-Plate-Designrajasekhar.cheruvu8635No ratings yet

- Base Plate DesignDocument38 pagesBase Plate DesignRitwick MishraNo ratings yet

- Monorail Crane Girder CalculationDocument4 pagesMonorail Crane Girder Calculationrony100% (1)

- Slab Design Calculations: Definitions of TermsDocument28 pagesSlab Design Calculations: Definitions of TermsAlbasir Tiang Sedik REENo ratings yet

- Sumitomo Corporation: Checked by of Area: Turbine Build. Rev Dept StructuralDocument18 pagesSumitomo Corporation: Checked by of Area: Turbine Build. Rev Dept Structuralabhi aroteNo ratings yet

- 05 Erection ChecklistDocument8 pages05 Erection ChecklistAnonymous cG5MyHMNo ratings yet

- Composite BeamDocument2 pagesComposite BeamJustin MusopoleNo ratings yet

- Two Way Slab Design.Document9 pagesTwo Way Slab Design.tuansteelsNo ratings yet

- One-Way Ribbed Slab Design As Per BS8110Document5 pagesOne-Way Ribbed Slab Design As Per BS8110yusuf abdinasir100% (5)

- 4.3 Design Values of Bending Moments and Shear ForcesDocument7 pages4.3 Design Values of Bending Moments and Shear Forcesmn4webNo ratings yet

- Crane Gurder Model Desidn 10.0 M Span and 90 T CapacityDocument25 pagesCrane Gurder Model Desidn 10.0 M Span and 90 T Capacitymayankjain333No ratings yet

- 3 Slab Design CalculationsDocument4 pages3 Slab Design CalculationsNapoleon Carino100% (1)

- Open Foundation With Eccentric Loading and Moments-FinalDocument6 pagesOpen Foundation With Eccentric Loading and Moments-FinalMahadev Sastry100% (1)

- Combined Footing For TwoDocument15 pagesCombined Footing For Twoer.praveenraj30No ratings yet

- Calculation 132kV PI STRDocument30 pagesCalculation 132kV PI STRAbdullah Al MamunNo ratings yet

- Sa 4Document3 pagesSa 4Khael Angelo Zheus JaclaNo ratings yet

- 2.design of Gantry Girder - 50TDocument23 pages2.design of Gantry Girder - 50TLagnajit DasNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- 9) FootingDocument33 pages9) FootingLagnajit DasNo ratings yet

- 4.2 Wall 2 300Document5 pages4.2 Wall 2 300Lagnajit DasNo ratings yet

- Design ReportDocument83 pagesDesign ReportLagnajit DasNo ratings yet

- 4.1 Wall 1 400counterDocument10 pages4.1 Wall 1 400counterLagnajit DasNo ratings yet

- 0.3 Deck SlabDocument5 pages0.3 Deck SlabLagnajit DasNo ratings yet

- Staad Short Cut KeysDocument1 pageStaad Short Cut KeysLagnajit DasNo ratings yet

- 8.wind Load CalculationDocument6 pages8.wind Load CalculationLagnajit DasNo ratings yet

- SLABDocument6 pagesSLABLagnajit DasNo ratings yet

- Windload CalculationDocument3 pagesWindload CalculationLagnajit DasNo ratings yet

- Staire Case DesignDocument4 pagesStaire Case DesignLagnajit DasNo ratings yet

- Header Pipe EncasementDocument49 pagesHeader Pipe EncasementLagnajit DasNo ratings yet

- ! TitleDocument4 pages! TitleLagnajit DasNo ratings yet

- 6a) Walkway - On Filter BedDocument9 pages6a) Walkway - On Filter BedLagnajit DasNo ratings yet

- Design of Rigid PavementDocument7 pagesDesign of Rigid PavementLagnajit DasNo ratings yet

- 6) Roof Slab DesignDocument9 pages6) Roof Slab DesignLagnajit DasNo ratings yet

- FootingDocument57 pagesFootingLagnajit DasNo ratings yet

- SEISMIC VB CALCULATIONDocument10 pagesSEISMIC VB CALCULATIONLagnajit DasNo ratings yet

- Wse Ibps CV DD 2Document146 pagesWse Ibps CV DD 2Lagnajit DasNo ratings yet

- Observation 5 MEGH 3 ESRsDocument1 pageObservation 5 MEGH 3 ESRsLagnajit DasNo ratings yet

- 1438 The Development of Sociology As A DisciplineDocument3 pages1438 The Development of Sociology As A Disciplinejeneille belfonNo ratings yet

- Integrated Units A Planning Guide For Teachers: What Is An Integrated Unit?Document18 pagesIntegrated Units A Planning Guide For Teachers: What Is An Integrated Unit?Kim BuiNo ratings yet

- 0 chtp6 03 IMDocument40 pages0 chtp6 03 IMking100% (1)

- Crain Etal2017Document30 pagesCrain Etal2017Antonio CodinaNo ratings yet

- IPURSE-2015 Proceedings Presented PapersDocument459 pagesIPURSE-2015 Proceedings Presented PapersWithanage WithanageNo ratings yet

- 32-Bit Power Architecture MCU For Automotive General Purpose Applications - Chorus FamilyDocument139 pages32-Bit Power Architecture MCU For Automotive General Purpose Applications - Chorus FamilyEcus ElectronicsNo ratings yet

- History of 3D Animation Brief ExplanationDocument2 pagesHistory of 3D Animation Brief ExplanationAvery VillaNo ratings yet

- Viscometer Manual PDFDocument47 pagesViscometer Manual PDFBalqis yasinNo ratings yet

- Introduction To EconomicsDocument26 pagesIntroduction To EconomicsReyasat AliNo ratings yet

- (Main) : Computer Based Test (CBT)Document12 pages(Main) : Computer Based Test (CBT)Resonance Eduventures100% (1)

- Microsoft Access 2016 - Stewart MelartDocument74 pagesMicrosoft Access 2016 - Stewart Melartmaidanez_ro324133% (3)

- ADIS - COURSE Information SheetDocument1 pageADIS - COURSE Information SheetPriteshJangamNo ratings yet

- The Transmission-Line Modeling (TLM) Method in ElectromagneticsDocument132 pagesThe Transmission-Line Modeling (TLM) Method in ElectromagneticsFabio Hugo Souza MatosNo ratings yet

- Vacancy IndiaRepresentativeDocument8 pagesVacancy IndiaRepresentativeGen SocialNo ratings yet

- BSBPM505A Skills KitDocument49 pagesBSBPM505A Skills KitLili Pabuena VillarrealNo ratings yet

- Discriminant PPT Alg2Document16 pagesDiscriminant PPT Alg2Roger KhanNo ratings yet

- Sona 2 Mineral Oil System - 2021Document3 pagesSona 2 Mineral Oil System - 2021faizNo ratings yet

- FR - ACS800 - 0,55 A 132 KWDocument132 pagesFR - ACS800 - 0,55 A 132 KWMohammed Amine KenedNo ratings yet

- LM PerDev-Q2Document82 pagesLM PerDev-Q2Kem KemNo ratings yet

- MathDocument5 pagesMathJanice Villarmino100% (1)

- Curriculum Map: Mapeh DepartmentDocument9 pagesCurriculum Map: Mapeh DepartmentArvenParafinaNo ratings yet

- PRIME HRM Action Plan TemplateDocument3 pagesPRIME HRM Action Plan Templateeve100% (1)

- NepalQR Standardization Framework and GuidelinesDocument26 pagesNepalQR Standardization Framework and GuidelinesRüpësh ẞhäñdårîNo ratings yet