Professional Documents

Culture Documents

Topology Optimization of Motorcycle Swin

Topology Optimization of Motorcycle Swin

Uploaded by

Bhawesh SthaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Topology Optimization of Motorcycle Swin

Topology Optimization of Motorcycle Swin

Uploaded by

Bhawesh SthaCopyright:

Available Formats

IJSART - Volume 3 Issue 5 – MAY 2017 ISSN [ONLINE]: 2395-1052

Topology Optimization of Motorcycle Swing Arm

Trupti Rankhambe1 , Gajendra Kumar Nhaichaniya 2

Department of Mechanical Engineering

1, 2

Pimpari Chinchwad College Of Engineering, SPPU, Pune-47.

Abstract-This article is based on weight reduction of a III. LITERATURE REVIEW

motorcycle swing arm by Topology optimization. The

development of optimized model is based on design space Fei Niu, Shengli Xu, Gengdong Cheng[1] from the

which takes into account overall dimensions, topological National Natural Science Foundation of China . To find the

optimization and validation using finite element analysis. The stiffest design of structure, minimum structural compliance

weight is known to be one of the most important factor that has been a very popular formulation in structural topology

impact the performance and the cost and for this reason its optimization. The structure being optimized in this

reduction often becomes the main objective to achieve. The formulation is subjected to given external forces and fixed

goal of the experiment is to reduce the mass of the component structural support, i.e., the second type boundary condition in

without compromising the other relevant factors. For analysis continuum mechanics. Low compliance is equivalent to small

and study, a well reputed general class 150 cc motorcycle’s displacement and high stiffness, i.e. a minimum compliance

swing arm was selected. design implies a stiffest design.

Keywords-Swing-arm, topological modification and validation Hrishikesh Joshi, Ashish Powar, Sanket Khuley and

D.P.Yesane[2] (2016) from Mechanical Engineering,

I. INTRODUCTION Marathwada Mitra Mandal’s Institute of Technology, FEA

analysis is performed on both the original and modified

The Indian two wheeler segment contributes the components. Two basic designs exist, namely single-sided and

largest volumes amongst all the segments in automobile double-sided swing arms. The aim is to maximize the vertical

industry. India was the sixth largest motor vehicle/car stiffness and ensure it is considerably higher than the rear

manufacturer in the world in 2013 (Wikipedia). India is the suspension spring stiffness.

second largest motorcycle (6.54 m produced in 2007-08) and

the fourth largest commercial vehicle manufacturer in the Marco Cavazzuti, Andrea Baldini, Enrico Bertocchi,

world. India is the third largest producer of two wheelers in Dario Costi, Enrico Torricelli, Patrizio Moruzzi (January

the world it come just next to Japan and China. In last few 2011)[6],In particular, topology & size optimizations are

years the Indian two-wheelers industry has got spectacular coupled with fem analyses and adopted in cascade for

growth. This shows that motorcycles are major contributors to reaching an optimum chassis configuration. The objective of

the overall vehicles. They share a large part of total daily fuel the optimization process is the chassis weight reduction, yet in

consumption of our country. An average human weighs about fulfillment of structural performance constraints as required by

65-75 kg. The combined weight of motorcycle and rider Ferrari standards.

would be near about 200-220 kg. Hence we can say that about

70 % of fuel is consumed by the motorcycle itself. Book of Anton Olason, Daniel Tidman[7], the focus of

this work is to develop a practical method when using

II. NOMENCLATURE topology optimization in the design process. Topology is an

area of mathematics that studies properties of geometric

Ls static load per side beam objects that depend on the shape, but not size, distances or

Mt total mass on vehicle angles; properties that are independent of any continuous

M average mass of person deformation.

L vertical load on side beam

L horizontal load on side beam IV. SWING ARM

F horizontal load on inner horizontal side

F horizontal load on outer horizontal side A motorcycle's suspension serves a dual role,

Ɵ spring damper inclination providing the rider with control of steering and braking while

also absorbing the road conditions to give a more comfortable

ride. The suspension components consist of fork tubes on the

Page | 413 www.ijsart.com

IJSART - Volume 3 Issue 5 – MAY 2017 ISSN [ONLINE]: 2395-1052

front of the bike and a swing arm in the rear. The swing arm is V. MATERIAL PROPERTIES

the main component of the rear suspension and also provides a

base for the rear axle to be mounted.There are two types of Sr. Property A206

swing arms found on most bikes. Typically, most bikes have No.

what is referred to as a monoshock regular swing arm. In this 1 Ultimate Tensile Strength 436 MPA

design, a coil over shock is joined to a linkage that is 2 Yield Tensile Strength 350 MPA

connected to the bike frame and the H-shaped swing arm 3 Young’s Modulus 70 GPA

itself. A newer version is the single-sided swing arm. This 4 Density 2.8*103 Kg/m3

type is similar to the H-shaped swing arm in function and 5 Poisson’s Ratio 0.3

design, except that one side has been removed so a tire can be 6 BHN 120

easily changed. Many types of suspension were tried,

including Indians leaf spring suspended swing arm, and VI. BOUNDARY CONDITIONS AND WEIGHT

Matchless cantilevered coiled-spring swing arm. The swing

arm has also been used for the front suspension of Scooter. In The swing arm, you will note, is joined to the bike

this case it aids in simplifying maintenance. The function of frame via a pivot which is higher than the hub of the wheel.

swing arm is joined to the motorcycle at a higher pivot point Wherever the swing arm attaches to the frame, it is behind the

than where the rear axle is connected. This works to prevent bike's Centre of Gravity.The rear suspension system connects

squat in the tail of the bike when you accelerate and helps to the frame of the bike to the rear wheel by attaching one end of

provide adequate spacing for the shocks to function. When the shocks to the swing arm. The horizontal force at the swing

rear brakes are applied, the swing arm is pulled level with the arm pivot goes to accelerate mass of machine but it also

road. This lowers the pivot point where the swing arm joins creates the moment or torque about COG tending to rotate the

the bike frame and lengthens the wheelbase at the same time, bike backword, cause squat in other words. On the other hand

making the bike more stable and easier to control. A design (Fv), the vertical force tends to lift the machine relieving

space is the initial part from which material is removed until a suspension spring load but also create torque about COG

final shape is reached during optimization. Creating design tending to rotate bike forword is antisquat effect. In this case

space by using the modeling tools in CATIAV5. Any part that where the forces passes through COG squat and antisquat

is a design space will be reshaped during optimization, while moments balanced each other out and remaining vertical force

any part that is not a design space will remain as it is. A design just tend to lift sprung part of machine without any pitch

space can have any shape or topology as long as it is a single moment. During static running condition, the dampers exert

solid volume. A part that is used as a design space should not forces due to the dead weight of bike and people on the swing

be very detailed. Using the simplest design spaces ensures the arm, which acts on the rear side of the motorcycle. Also

most freedom to generate a shape. By giving more fine details during maximum acceleration, the chain exerts torque on the

in the design space, it will take longer time to run the sprocket. This load acts as pressure on the swing arm on rear

optimization. A shape generated by optimization is contained lateral faces where the wheel hub is mounted. Considering

entirely within the volume of the original design space, since these two conditions, one critical condition could be the

material is only removed and not added.Fig.1.shows design simultaneous application of these two loads. This condition

space for swing arm. needs to be analyzed.

Loads Calculations:- The weight of the motorcycle is 134 kg.

Considering average weight of person as 75 kg, total dead

weight is 209 kg. In most two-wheelers, the distribution of

weight on rear axle is 58% to 65%. For the model selected, the

weight distribution is taken to be 60 % on rear axle. Also 30%

of weight is reduced due to tires and wheels and other

unsprung masses. Thus net load on swing arm can be

calculated as,

Ls = [ms + 2mp] ×0.6(1) = 170.04 kg.

This 170.04 kg which will be distributed equally on

the two side beams in case when the motorcycle is running

straight. The load will be acting at an angle of about 530 at

Fig.1 3D Modeling of initial swing arm

Page | 414 www.ijsart.com

IJSART - Volume 3 Issue 5 – MAY 2017 ISSN [ONLINE]: 2395-1052

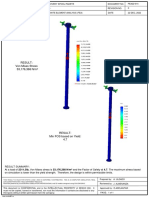

which the damper is mounted. Thus, the loads are separated Maximum Stress = 2.759 MPA

into vertical and horizontal components.

-Vertical load Lvs = Ls Sin θs = 170.04*(sin53) = 1335.01N Minimum Stress = 3.803*10-3MPA

-Horizontal load Lvh= Ls Cos θs = 170.04*(cos 53) =

1003.88N. In analysis by applying resultant of these forces

further results are obtained.

Fig.3 Analysis of initial swing arm

Fig.2 Boundary conditions on swing arm

IX. STIFFNESS MAXIMIZATION OF VEHICLE

STRUCTURE

VII. CORNERING CONDITION

The structural body of a vehicle is required to provide

Cornering is one of the important criteria in design on

stiffness in bending and torsional direction beyond some lower

motorcycle components. During cornering, different

limits prescribed by design team based on previous experience

components are subjected to variation in loads in magnitude as

or competitive vehicle. Maximization of stiffness equal to

well as direction. In case of swing arm, high lateral forces act

minimization of mean compliance of structure under load.

in unbalanced state. The magnitude of variation depends upon

Stress level in any part of structure can be determined by

the angle of inclination and the vehicle speed.

conducting finite element analysis. A reliable indicator of

inefficient use of material is low value of stress in some part

Boundary Conditions: - It is assumed that 20% more load are

of structure. Ideally stress in every part of structure should be

transferred to the inner side during cornering. Thus, the inner

close to the same, safe level. This concept leads to rejection

side beam will have 70% of the total weight and remaining

criterion based on local stress level, where low stress material

30% on the outer side beam. If we consider a maximum

assumed to be under utilize, therefore removed subsequently.

cornering angle of 400, and divide the forces into vertical and

The removal of material can be conveniently undertaken by

horizontal components, there will be torsional and lateral

deleting element from finite element model. The stress level at

imbalance on the middle part.

each element is determined by comparing, for e.g. von mises

70% of weight,

stress of element σevm with maximum von mises stress of

Fmax = 0.7×209×9.81 = 1435.203 N and remaining 30% =

whole structure σmaxvm. After each finite element analysis,

Fmin = 615.087 N.

element which satisfy following condition are deleted from

The maximum values i.e. the inner side swing arm and the

model.

middle part is analyzed. The inner side Swing arm will

(σevm/ σmaxvm) < RRi ……...where RRi = Current

experience more force than outer one. The imbalance will be

rejection ratioSuch a cycle of finite element analysis and

acting on the middle part.

element removal is repeated using the same value of RRi until

a steady state is reached, which means that there are no

VIII. ANALYSIS AND TOPOLOGY OPTIMIZATION

elements being deleted using current rejection ratio. At this

stage evolutionary rate, ER is added to rejection ratio, i.e.

To get precise result design domain is divided into

RRi+1 = RRi+ER.

25501 first order tetra elements. In design space (initial swing

arm design) by applying above boundary conditions

With the increased rejection ratio the iteration takes place

following displacement and stresses generated as shown in fig.

again until a new steady state is reached.

below:-

Maximum Displacement = 6.745*10-2mm

Page | 415 www.ijsart.com

IJSART - Volume 3 Issue 5 – MAY 2017 ISSN [ONLINE]: 2395-1052

have to redesign according to manufacturability with sense of

optimization.

Fig.4 Isometric view of Optimized swing Arm

Fig.8 Imported optimized model of Swing Arm in CATIA

By importing model in different CAD software it can

be redesign as above conditions. Here CATIA software is used

to redesign such component as shown in below fig.

Fig.5 Bottom View of optimized Swing Arm

Fig.6 Top View of optimized Swing Arm

Fig.9 Different views of final model of optimized Swing Arm

X. CONCLUSION

The Topology Optimization method starts from the

full design space and removes inefficient material from

structure according to stress level of elements. The resulting

Fig.7 Developed stress before and after Optimization design provides a clear definition of Topology (‘without grey

area’). Element removal can be done by simply assigning

Topology Optimization suggest Optimized design of material property number of rejected elements to zero and

swing Arm as shown in fig. below, which is very difficult to ignoring those elements when the global stiffness matrix is

manufacturing or may have high cost to manufacturing. So for assembled in subsequent finite element analysis. Weight of

efficient manufacturing process with low cost, component design space is about 11.2 Kg, it reduces by Topology

Page | 416 www.ijsart.com

IJSART - Volume 3 Issue 5 – MAY 2017 ISSN [ONLINE]: 2395-1052

Optimization up to 5.8 Kg. which is notable. Reduction in

weight achieved 50%.

ACKNOWLEDGEMENT

This work is supported by the PIMPARI

CHINCHWAD COLLEGE ENGINEERING, PUNE. The

supports are gratefully acknowledged. We thank Mr. Sanjay

Matekar sir for the stimulating and invaluable discussions,

REFERENCES

[1] Fei Niu, Shengli Xu, Gengdong Cheng (2011), ‘A general

formulation of structural topology optimization for

maximizing structural stiffness’, Published online: 3

November 2010_c Springer-Verlag 2010

[2] Hrishikesh Joshi, Ashish Powar, Sanket Khuley and

D.P.Yesane, ‘Analysis and Topological Optimization of

Motorcycle Swing-Arm’, International Journal of Current

Engineering and Technology, (2016)

[3] Roberto Saponeli, Massimo Damasio, ‘Topology

Optimization Of Motorcycle Swing Arm under service

load using Abaqus And Tosca’,(2015)

[4] Hrishikesh Joshi, Ashish Powar, Sanket Khuley and

D.P.Yesane, ‘Analysis and Topological Optimization of

Motorcycle Front Wheel’, International Journal of

Current Engineering and Technology, (2016)

[5] Vidyadhar Sudarshan Dixit, Shailesh S Pimpale(2016),

‘Vibration Response and Optimization of Swing ARM’,

2016 IJESC

[6] Marco Cavazzuti, Andrea Baldini, Enrico Bertocchi,

Dario Costi, Enrico Torricelli, Patrizio Moruzzi, ‘High

performance automotive chassis design: a topology

optimization based approach’, (January 2011)

Reference Books

[7] Book of ‘Methodology for Topology and Shape

Optimization in the Design Process’ by ANTON

OLASON, DANIEL TIDMAN (Master’s Thesis 2010:11)

Internet

[8] www.wikipedia.co.in

Page | 417 www.ijsart.com

You might also like

- Intermediate Tubesheet Calculation PDFDocument18 pagesIntermediate Tubesheet Calculation PDFhbsheenNo ratings yet

- Rudder SizingDocument6 pagesRudder SizingNeo ZaoNo ratings yet

- Considerations Upon A New Tripod Joint SolutionDocument9 pagesConsiderations Upon A New Tripod Joint Solutionbee140676No ratings yet

- Swing Arm Calculation and Analysis JournalDocument5 pagesSwing Arm Calculation and Analysis JournalBálají Sèlvakümár100% (1)

- Design and Optimization of Bicycle Frame For The Cyclist's ComfortDocument5 pagesDesign and Optimization of Bicycle Frame For The Cyclist's ComfortEditor IJRITCCNo ratings yet

- Parameters Optimization of Motorcycle FrameDocument16 pagesParameters Optimization of Motorcycle FrameVani AdigaNo ratings yet

- Whelhub DesignDocument10 pagesWhelhub DesignamoyaNo ratings yet

- Presentation On Car Design With SpoilerDocument25 pagesPresentation On Car Design With SpoilerPrashant KumarNo ratings yet

- Design & Fabrication of Front Wheel Upright Assembly For An ATVDocument5 pagesDesign & Fabrication of Front Wheel Upright Assembly For An ATVumeshNo ratings yet

- Design & Fabrication of Rear Outboard Wheel Assembly For An ATVDocument5 pagesDesign & Fabrication of Rear Outboard Wheel Assembly For An ATVumeshNo ratings yet

- Modified Suspension of Motorcycle - A ReviewDocument4 pagesModified Suspension of Motorcycle - A ReviewMULYADINo ratings yet

- Optimization of Key Parts of Front Suspension System of Three WheelerDocument6 pagesOptimization of Key Parts of Front Suspension System of Three WheelerDarmanNo ratings yet

- Vibrational Analysis of Bicycle ChassisDocument13 pagesVibrational Analysis of Bicycle ChassisIJIRSTNo ratings yet

- Modal and Stress Analysis of Lower Wishbone Arm Along With TopologyDocument7 pagesModal and Stress Analysis of Lower Wishbone Arm Along With TopologyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Palanivendhan 2020 IOP Conf. Ser.: Mater. Sci. Eng. 993 012129Document8 pagesPalanivendhan 2020 IOP Conf. Ser.: Mater. Sci. Eng. 993 012129faizNo ratings yet

- Article 1609934781Document46 pagesArticle 1609934781AakashRanjanNo ratings yet

- A Review of Vibration Analysis of Scooter ChassisDocument5 pagesA Review of Vibration Analysis of Scooter ChassisIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- Design and Optimization of Front Axle of Heavy TruckDocument10 pagesDesign and Optimization of Front Axle of Heavy TruckBurak TuncerNo ratings yet

- Design of Double Wishbone Suspension System of BAJA VehicleDocument8 pagesDesign of Double Wishbone Suspension System of BAJA VehicleSai Krishna SKNo ratings yet

- Design and Optimization of Front Axle of Heavy Truck: August 2019Document10 pagesDesign and Optimization of Front Axle of Heavy Truck: August 2019Mr ZekeNo ratings yet

- Structural Analysis of Double-Wishbone Suspension SystemDocument7 pagesStructural Analysis of Double-Wishbone Suspension SystemIJRASETPublicationsNo ratings yet

- Suspension Assembly of BAJA ATVDocument4 pagesSuspension Assembly of BAJA ATVInfogain publicationNo ratings yet

- DESIGN AND ANALYSIS OF AL 7075 Steering Knuckle PDFDocument7 pagesDESIGN AND ANALYSIS OF AL 7075 Steering Knuckle PDFsanjeev105No ratings yet

- DesignofEfficycle PSFDocument10 pagesDesignofEfficycle PSFAbhijeet sinhaNo ratings yet

- Design of Efficycle: November 2016Document10 pagesDesign of Efficycle: November 2016Shivank SharmaNo ratings yet

- Static Analysis of Wheel Rim Using Catia and Ansys16.0: August 2016Document7 pagesStatic Analysis of Wheel Rim Using Catia and Ansys16.0: August 2016Immanuel ANo ratings yet

- Design and Analysis of Steering Knuckle PDFDocument7 pagesDesign and Analysis of Steering Knuckle PDFSai Krishna SKNo ratings yet

- 1 5024108Document7 pages1 5024108GamerNo ratings yet

- Analysis of Steering Knuckle of All Terrain Vehicl PDFDocument10 pagesAnalysis of Steering Knuckle of All Terrain Vehicl PDFpranavNo ratings yet

- Fatigue Analysis of Front Axle For Automobile Heavy Motor VehicleDocument13 pagesFatigue Analysis of Front Axle For Automobile Heavy Motor VehicleIJRASETPublicationsNo ratings yet

- Research Paper SuspensionDocument7 pagesResearch Paper SuspensionAnirudh GuptaNo ratings yet

- Bicycle Crank AnalysisDocument7 pagesBicycle Crank AnalysisrisirarocksNo ratings yet

- Irjet V5i6554 PDFDocument3 pagesIrjet V5i6554 PDFAloaa AlaaNo ratings yet

- Apostila - Veiculos NicolazziDocument10 pagesApostila - Veiculos NicolazziRenan SartoriNo ratings yet

- DesignofEfficycle PSFDocument10 pagesDesignofEfficycle PSFKumar PrakharNo ratings yet

- Design Optimization of Bicycle Crank Using (FEA)Document6 pagesDesign Optimization of Bicycle Crank Using (FEA)abhishek dmaleNo ratings yet

- Design Integration For Semi-Floating Axle Wheel Bearing: Mr. Bhushan C. Chinchore Mr. Sanjay B. MatekarDocument5 pagesDesign Integration For Semi-Floating Axle Wheel Bearing: Mr. Bhushan C. Chinchore Mr. Sanjay B. MatekarLợi Lê ĐìnhNo ratings yet

- 575 2.modeling and Structural Analysis of Knuckle Steering Using Fem With Different MaterialsDocument8 pages575 2.modeling and Structural Analysis of Knuckle Steering Using Fem With Different Materials2be0care1No ratings yet

- Analysis & Topological Optimization Off Motorcycle Front WheelDocument6 pagesAnalysis & Topological Optimization Off Motorcycle Front WheelHrishikesh JoshiNo ratings yet

- Shape Optimization of A Steering Knuckle Using SOLIDWORKSDocument9 pagesShape Optimization of A Steering Knuckle Using SOLIDWORKSprashantNo ratings yet

- All Terrain VehicleDocument9 pagesAll Terrain VehicleAnirudh PanickerNo ratings yet

- Design and Optimization of Hub and Knuckle For Formula SAE CarDocument5 pagesDesign and Optimization of Hub and Knuckle For Formula SAE CarTalles OliveiraNo ratings yet

- MEC 540 Final ProjectDocument18 pagesMEC 540 Final ProjectPlinio GuzmanNo ratings yet

- JETIR1906Y23Document5 pagesJETIR1906Y23Team LegendsNo ratings yet

- Av 03402790283Document5 pagesAv 03402790283International Journal of computational Engineering research (IJCER)No ratings yet

- JETIR2009041Document7 pagesJETIR2009041Glorius CarmenNo ratings yet

- Optimization of Double Wishbone Suspension System by Replacing Its Upper Arm by Single Member in Atv IJERTV6IS110006 PDFDocument6 pagesOptimization of Double Wishbone Suspension System by Replacing Its Upper Arm by Single Member in Atv IJERTV6IS110006 PDFMahesh BorateNo ratings yet

- Design and Development of Steering Knuckle With Spindle and Its Optimization A Review IJERTV5IS030068Document3 pagesDesign and Development of Steering Knuckle With Spindle and Its Optimization A Review IJERTV5IS030068Anirudh CRNo ratings yet

- Structural Performance Analysis of Formula Sae Car: Jurnal Mekanikal December 2010, No. 31, 46 - 61Document16 pagesStructural Performance Analysis of Formula Sae Car: Jurnal Mekanikal December 2010, No. 31, 46 - 61Piyush SoodNo ratings yet

- Design of Racing Motorcycle Swingarm With Shape OptimisationDocument6 pagesDesign of Racing Motorcycle Swingarm With Shape OptimisationChi ZhangNo ratings yet

- Baja VehicleDocument6 pagesBaja VehicleSai Krishna SKNo ratings yet

- Chainless Cbicy Project Templet 96 .1Document19 pagesChainless Cbicy Project Templet 96 .1Anuka VarshaNo ratings yet

- All Terrain Vehicle Project SynopsisDocument14 pagesAll Terrain Vehicle Project SynopsisTARUN DHUNNA100% (5)

- Y4592 PDFDocument4 pagesY4592 PDFPrathamesh PatikNo ratings yet

- Modeling and Static Analysis of Shock Absorber Using Different MaterialsDocument8 pagesModeling and Static Analysis of Shock Absorber Using Different MaterialsManjunath ReddyNo ratings yet

- Steering KnuckleDocument6 pagesSteering Knucklesubash100% (1)

- Design, Analysis and Optimization of Leaf SpringDocument9 pagesDesign, Analysis and Optimization of Leaf SpringTeuku Andy0% (1)

- Structural and Fatigue Analysis of Two Wheeler Lighter Weight Alloy WheelDocument12 pagesStructural and Fatigue Analysis of Two Wheeler Lighter Weight Alloy WheelRahul GautamNo ratings yet

- Static Analysis of Wheel Rim Using Catia and Ansys16.0: August 2016Document7 pagesStatic Analysis of Wheel Rim Using Catia and Ansys16.0: August 2016Anonymous 9xvU1FNo ratings yet

- Journalsresaim Ijresm v3 I7 66Document6 pagesJournalsresaim Ijresm v3 I7 66Rodrigo bolaNo ratings yet

- Design of Accurate Steering Gear MechanismDocument12 pagesDesign of Accurate Steering Gear Mechanism1DA17ME055 Harshit MDNo ratings yet

- Paper 115Document12 pagesPaper 115Vignesan MechNo ratings yet

- f1swf 2024 Technical RegulationsDocument58 pagesf1swf 2024 Technical RegulationsBhawesh SthaNo ratings yet

- TCAE CFDSUPPORT Axial Fan Design and SimulationDocument20 pagesTCAE CFDSUPPORT Axial Fan Design and SimulationBhawesh SthaNo ratings yet

- Installation of Gussets To Reduce Stress On The JuDocument7 pagesInstallation of Gussets To Reduce Stress On The JuBhawesh SthaNo ratings yet

- Cam 15 PDocument128 pagesCam 15 PBhawesh SthaNo ratings yet

- Reference ValuesDocument3 pagesReference ValuesBhawesh SthaNo ratings yet

- TCFD POINTWISE Potsdam Propeller BenchmarkDocument6 pagesTCFD POINTWISE Potsdam Propeller BenchmarkBhawesh SthaNo ratings yet

- Coupled CFD FE Analysis For The Exhaust Manifold To Reduce Stress of A Direct Injection-Diesel EngineDocument7 pagesCoupled CFD FE Analysis For The Exhaust Manifold To Reduce Stress of A Direct Injection-Diesel EngineBhawesh SthaNo ratings yet

- Properties of AWS ER70S-6Document6 pagesProperties of AWS ER70S-6Bhawesh SthaNo ratings yet

- 1264 DatasheetDocument9 pages1264 DatasheetBhawesh SthaNo ratings yet

- Project Appraisal and Project Formulation (8 Hours)Document33 pagesProject Appraisal and Project Formulation (8 Hours)Bhawesh SthaNo ratings yet

- 1.project EngineeringDocument40 pages1.project EngineeringBhawesh SthaNo ratings yet

- 2020res STR Hierarchy AMDocument13 pages2020res STR Hierarchy AMBhawesh SthaNo ratings yet

- Finance: 6.introduction To Project Financing (5 HRS)Document25 pagesFinance: 6.introduction To Project Financing (5 HRS)Bhawesh SthaNo ratings yet

- Problems For Finite Element Method PDFDocument48 pagesProblems For Finite Element Method PDFBhawesh SthaNo ratings yet

- Project Planning and SchedulingDocument101 pagesProject Planning and SchedulingBhawesh Stha0% (1)

- Proj Risk AnalysisDocument31 pagesProj Risk AnalysisBhawesh SthaNo ratings yet

- Proj Implementation - ControllingDocument72 pagesProj Implementation - ControllingBhawesh SthaNo ratings yet

- Under Carriage of Construction EquipmentDocument19 pagesUnder Carriage of Construction EquipmentBhawesh SthaNo ratings yet

- Equipment ProcurementDocument18 pagesEquipment ProcurementBhawesh Stha100% (1)

- Equipment ProcurementDocument18 pagesEquipment ProcurementBhawesh Stha100% (1)

- Grinding Damage Prediction For Ceramics Via CDM Model: Bi ZhangDocument8 pagesGrinding Damage Prediction For Ceramics Via CDM Model: Bi ZhangDakhlaouiNo ratings yet

- Chapter Three The Yield CriteriaDocument9 pagesChapter Three The Yield CriteriaAbdalmalek ShamsanNo ratings yet

- journalsresaim,+IJRESM V4 I2 11Document6 pagesjournalsresaim,+IJRESM V4 I2 11chem jobsNo ratings yet

- Yielding of Brass Case Walls in The ChamberDocument25 pagesYielding of Brass Case Walls in The Chamberblowmeasshole1911100% (1)

- Design of A Flexible Automated Bottle Filling Machine: February 2017Document16 pagesDesign of A Flexible Automated Bottle Filling Machine: February 2017M E B QasqasNo ratings yet

- A Simplified Procedure To Determine Post-Necking True Stress-Strain Curve From Uniaxial Tensile Test of Round Metallic Specimen Using DICDocument7 pagesA Simplified Procedure To Determine Post-Necking True Stress-Strain Curve From Uniaxial Tensile Test of Round Metallic Specimen Using DICSunil GoyalNo ratings yet

- 4 Dey2020Document16 pages4 Dey2020Haider AddewanyNo ratings yet

- Plasticity LectureDocument17 pagesPlasticity LectureOptimMart InternationaleNo ratings yet

- Plasticity PresentationDocument52 pagesPlasticity PresentationriganNo ratings yet

- Unit - IDocument116 pagesUnit - IJagadeesan ManogaranNo ratings yet

- Fea22-014-R0 - Recovery Spool PadeyeDocument3 pagesFea22-014-R0 - Recovery Spool PadeyeMc Dowell CampangNo ratings yet

- 079180285X PipeStressEngineeringDocument5 pages079180285X PipeStressEngineeringJAVIER RICARDONo ratings yet

- CODE DIV - 2 Review of The ASME Code Section VIII Division 2 - 2007 PDFDocument12 pagesCODE DIV - 2 Review of The ASME Code Section VIII Division 2 - 2007 PDFManish542100% (1)

- PDF 5Document17 pagesPDF 5James BundNo ratings yet

- MSC Nastran Useful Resources - An Overview of SOL 106 - Nonlinear Static AnalysisDocument8 pagesMSC Nastran Useful Resources - An Overview of SOL 106 - Nonlinear Static AnalysisAnonymous MMKF5TRXCNo ratings yet

- Vessel Design RefDocument56 pagesVessel Design Refrogel_gana80% (10)

- Modeling of Single-Fillet Lap Joint in Solidworks SimulationDocument8 pagesModeling of Single-Fillet Lap Joint in Solidworks SimulationpeshoaNo ratings yet

- MCQ DomDocument179 pagesMCQ DomArputha RajNo ratings yet

- Objective GATE QuestionsDocument24 pagesObjective GATE QuestionsAshwani GoelNo ratings yet

- Multiple Riser Configurations Top-Tensioned Risers Hybrid Riser SystemDocument103 pagesMultiple Riser Configurations Top-Tensioned Risers Hybrid Riser Systemsaeed ghafoori100% (4)

- Ch7 Post Processing v2019 28jan 2019Document35 pagesCh7 Post Processing v2019 28jan 2019Dio YoshitakaNo ratings yet

- Structural Safety Assessmentofa Floating Dockduring Docking OperationDocument9 pagesStructural Safety Assessmentofa Floating Dockduring Docking OperationevanNo ratings yet

- Crack Cause Analysis of Pulverizing Wheel in Fan Mill of 600 MWDocument14 pagesCrack Cause Analysis of Pulverizing Wheel in Fan Mill of 600 MWPhoenix RomeoNo ratings yet

- Design of Machine ElementsDocument56 pagesDesign of Machine ElementsSrirama DaasanNo ratings yet

- 1998 - Study of Stress Development in Axi-Symmetric Products Processed by Radial Forging Using A 3-D Non-Linear Finite-Element MethodDocument9 pages1998 - Study of Stress Development in Axi-Symmetric Products Processed by Radial Forging Using A 3-D Non-Linear Finite-Element MethodNguyen Hoang DungNo ratings yet

- Normality CriterionDocument10 pagesNormality Criteriong401992No ratings yet