Professional Documents

Culture Documents

None

None

Uploaded by

Donny EmanuelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

None

None

Uploaded by

Donny EmanuelCopyright:

Available Formats

Question:

✍ None

You can view the question in original Chegg URL page.

Expert answer: 0 0

✍ None

Step: 1

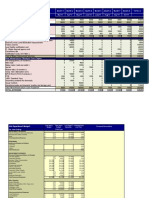

The Flow Schedule For Production At Different Level Of Inspection Is Given Below: -

Flow Of Production Inspection Inspection Inspection

At 15% At 40% At 100%

Work In Process, Beginning (20%) 14000 14000 14000

Started During March 120000 120000 120000

To Account For 134000 134000 134000

Good Units Completed And Transferred Out 113000 113000 113000

Normal Spoilage 6600 7440 6780

Abnormal Spoilage 3400 2560 3220

Work In Process, Ending 11000 11000 11000

Accounted For 134000 134000 134000

Explanation

Normal Spoilage At 15% Inspection = (120,000 - 10,000) * 6% = 6,600 Units

Explanation

Normal Spoilage At 40% Inspection = (134,000 - 10,000) * 6% = 7,440 Units

Explanation

Normal Spoilage At 100% Inspection = 113,000 * 6% = 6,780 Units

Explanation

Abnormal Spoilage = 10,000 Units - Normal Spoilage (It Applies For All The Inspection Levels)

Workings:

`Good Units Completed And Transfered Out = Work In Process, Beginning + Started During March - Normal Spoilage - Work In Process, Ending

14000 + 120000 - 10000 - 11000 = 113,000`

Final Answer

Hence, The Final Answer Is As Follows: -

Flow Of Production Inspection Inspection Inspection

At 15% At 40% At 100%

Work In Process, Beginning 14000 14000 14000

Started During March 120000 120000 120000

To Account For 134000 134000 134000

Good Units Completed And Transferred Out 113000 113000 113000

Normal Spoilage 6600 7440 6780

Abnormal Spoilage 3400 2560 3220

Work In Process, Ending 11000 11000 11000

Accounted For 134000 134000 134000

None

You might also like

- Blue Notes - Commercial LawDocument202 pagesBlue Notes - Commercial LawAlyssa Torio100% (3)

- Due Date: 09/28/2019 Service For: Your Account Summary: Questions About Your Bill?Document6 pagesDue Date: 09/28/2019 Service For: Your Account Summary: Questions About Your Bill?dianaNo ratings yet

- ACT202 Project Master Budgeting 1Document24 pagesACT202 Project Master Budgeting 1Asrafia Mim 1813026630No ratings yet

- Complaint For Unlawful Detainer - FINALDocument5 pagesComplaint For Unlawful Detainer - FINALAldrinmarkquintana100% (4)

- GunturDwiRamaA AnalisisRantaiPasok MSExcell 3241795 4ID03Document2 pagesGunturDwiRamaA AnalisisRantaiPasok MSExcell 3241795 4ID03guntur dwiNo ratings yet

- Warden CoDocument2 pagesWarden CoADITHYA KOVILINo ratings yet

- CapitalBudgeting AbhishekKumarDocument2 pagesCapitalBudgeting AbhishekKumarabhi1231122No ratings yet

- Post Graduate Session 2 OperationsDocument129 pagesPost Graduate Session 2 Operationssujithgec1No ratings yet

- Mutual Fund Class NotesDocument29 pagesMutual Fund Class Notessantoshamrute0711No ratings yet

- Cost of UnproductivityDocument6 pagesCost of Unproductivitysan_yadav76No ratings yet

- Weller Company Cash FlowDocument3 pagesWeller Company Cash FlowMd. Omar Sakib HossainNo ratings yet

- Weller Company Cash FlowDocument3 pagesWeller Company Cash Flowsuske.uchiha2000No ratings yet

- Sap FiDocument23 pagesSap FiMohamed Fahmy SalahNo ratings yet

- HO and Branches Combined StatmentDocument5 pagesHO and Branches Combined Statmentmmh771984No ratings yet

- PRACTICE PROBLEM (Optional) : Units To Account ForDocument1 pagePRACTICE PROBLEM (Optional) : Units To Account ForlalalalaNo ratings yet

- Worksheet 1 FinalDocument1 pageWorksheet 1 FinalLovely MafiNo ratings yet

- Cost Sheet Problem 1Document18 pagesCost Sheet Problem 1Vaidehi MirajkarNo ratings yet

- Ot and 10 ColumnDocument6 pagesOt and 10 ColumnumeshNo ratings yet

- Extra Credit - Project SelectionDocument2 pagesExtra Credit - Project SelectionOreoluwa AdediwuraNo ratings yet

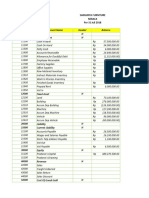

- Account No. Account Name Account TypeDocument2 pagesAccount No. Account Name Account Typesc9296No ratings yet

- Beginning WIP BeginningDocument2 pagesBeginning WIP BeginningTintin N. XiaoNo ratings yet

- Meli Training (Merged)Document8 pagesMeli Training (Merged)destaweldetnsaeNo ratings yet

- AdithDocument26 pagesAdithADITHYA KOVILINo ratings yet

- Balance General: Código Cuenta Sumas Saldos Transferen CIA Inventario Listado de ResultadoDocument2 pagesBalance General: Código Cuenta Sumas Saldos Transferen CIA Inventario Listado de Resultadoedinsonbrayan20No ratings yet

- Extra Credit - Project SelectionDocument2 pagesExtra Credit - Project SelectionOreoluwa AdediwuraNo ratings yet

- 2016 PPDocument13 pages2016 PPumeshNo ratings yet

- ISO14001 Certification Budget: Monthly WorksheetDocument6 pagesISO14001 Certification Budget: Monthly WorksheetManjunathNo ratings yet

- Comp4 1Document3 pagesComp4 1Kavya GopakumarNo ratings yet

- 2 TM C Finance-Task-CalcDocument3 pages2 TM C Finance-Task-Calcvlad vladNo ratings yet

- Home NetDocument2 pagesHome Netsandhu248No ratings yet

- Conversion of Firm To Company QuesDocument28 pagesConversion of Firm To Company QuesSakshi KoolwalNo ratings yet

- Financial Statement 1st PaperDocument24 pagesFinancial Statement 1st PaperMtNo ratings yet

- Process CostingDocument2 pagesProcess Costingmrsjeon0501No ratings yet

- OEE Januari 2021Document292 pagesOEE Januari 2021bimaNo ratings yet

- Chase Levl MixedDocument6 pagesChase Levl Mixedasbak22No ratings yet

- Prob 5 UnsolvedDocument3 pagesProb 5 UnsolvedBhushan ShirsathNo ratings yet

- Harian Okta Dan Stephen 21Document5 pagesHarian Okta Dan Stephen 21Imam RzkNo ratings yet

- Campeciño Masanting RamirezDocument3 pagesCampeciño Masanting RamirezJulius Mercons MasantingNo ratings yet

- 1 Year ProjectionDocument1 page1 Year ProjectionDamion CampbellNo ratings yet

- Chart of AccountDocument1 pageChart of Accountalirazawriter95No ratings yet

- Assignment 1 Zaid Ehab 19100551Document6 pagesAssignment 1 Zaid Ehab 19100551mohamed abushanabNo ratings yet

- Options Open Interest Analysis SimplifiedDocument15 pagesOptions Open Interest Analysis SimplifiedNaveenNo ratings yet

- Kapoor Software LTDDocument5 pagesKapoor Software LTDluniapNo ratings yet

- Assest of My PlanDocument2 pagesAssest of My PlanSharooq ShameenNo ratings yet

- Annual Dinner 2016: Items Total Amount Paid Amount Balance AmountDocument1 pageAnnual Dinner 2016: Items Total Amount Paid Amount Balance AmountAymen ArifNo ratings yet

- Session-8 Capital BudgetingDocument11 pagesSession-8 Capital BudgetingKishan TCNo ratings yet

- Account Number Account Name Header Balance 10000 Asset H 11000 Current Asset HDocument4 pagesAccount Number Account Name Header Balance 10000 Asset H 11000 Current Asset Hm. calvin KelvinNo ratings yet

- Solution: Computation of The FollowingDocument1 pageSolution: Computation of The FollowingherrajohnNo ratings yet

- CostingDocument46 pagesCostingRaghav KhakholiaNo ratings yet

- Chapter 2 Ca AnswersDocument9 pagesChapter 2 Ca Answersfaaltu accountNo ratings yet

- Manufacturing Account Income Statement 20200827Document1 pageManufacturing Account Income Statement 20200827Haewon KookNo ratings yet

- Advancetech Engineering PVT LTD: Pay Slip (With Reimbrusement) For The Month of May, 2019Document1 pageAdvancetech Engineering PVT LTD: Pay Slip (With Reimbrusement) For The Month of May, 2019Aman SikarwarNo ratings yet

- Stars Produces Stars For Elementary Teachers To Reward Their StudentsDocument14 pagesStars Produces Stars For Elementary Teachers To Reward Their StudentsJalaj GuptaNo ratings yet

- 22D-Activity Resource AssignmentsDocument7 pages22D-Activity Resource AssignmentsAhmed FahmyNo ratings yet

- Jurnal: 2. Pengakuan Realisasi Home Office Branch OfficeDocument2 pagesJurnal: 2. Pengakuan Realisasi Home Office Branch OfficefaldyNo ratings yet

- Summer Camp 2019 Costing: Indirect CostDocument3 pagesSummer Camp 2019 Costing: Indirect CostRabiya AsifNo ratings yet

- Ujian 3-Operating Cash InflowDocument3 pagesUjian 3-Operating Cash InflowNovianty KasegerNo ratings yet

- FM PracticalDocument18 pagesFM Practicalarpit200314No ratings yet

- Phoenix ModelDocument9 pagesPhoenix ModelShrivats SinghNo ratings yet

- تاجايتحلاا دراوملا Les besoins Les ressources تايمستلا غلابملا تايمستلا غلابملاDocument23 pagesتاجايتحلاا دراوملا Les besoins Les ressources تايمستلا غلابملا تايمستلا غلابملاESOK80No ratings yet

- FM PracDocument15 pagesFM Pracanushkas0701No ratings yet

- Neraca Saldo Klinik Drg. Laksmita Dewi & PartnerDocument1 pageNeraca Saldo Klinik Drg. Laksmita Dewi & PartnerBarjp PakNo ratings yet

- Expert AnswerDocument3 pagesExpert AnswerDonny EmanuelNo ratings yet

- 35179798Document1 page35179798Donny EmanuelNo ratings yet

- DownloadDocument15 pagesDownloadDonny EmanuelNo ratings yet

- NoneDocument1 pageNoneDonny EmanuelNo ratings yet

- NoneDocument1 pageNoneDonny EmanuelNo ratings yet

- NoneDocument1 pageNoneDonny EmanuelNo ratings yet

- DownloadDocument3 pagesDownloadDonny EmanuelNo ratings yet

- X Tan BX X V E: NoneDocument1 pageX Tan BX X V E: NoneDonny EmanuelNo ratings yet

- Readytoprint Chrome - Com 202428293729Document1 pageReadytoprint Chrome - Com 202428293729Donny EmanuelNo ratings yet

- NoneDocument1 pageNoneDonny EmanuelNo ratings yet

- Screenshot - 2024 03 04 13 40 34 329 - Com - Android.chrome EditDocument12 pagesScreenshot - 2024 03 04 13 40 34 329 - Com - Android.chrome EditDonny EmanuelNo ratings yet

- ZDIHUXCDODocument13 pagesZDIHUXCDODonny EmanuelNo ratings yet

- Chrome - Screenshot - Feb 29, 2024 8 - 57 - 06 PM GMT+07 - 00Document1 pageChrome - Screenshot - Feb 29, 2024 8 - 57 - 06 PM GMT+07 - 00Donny EmanuelNo ratings yet

- Q2 MODULE 5 - AssessmentDocument3 pagesQ2 MODULE 5 - Assessmentleo markNo ratings yet

- Carnaval Owners ManualDocument17 pagesCarnaval Owners Manualmike_net8903No ratings yet

- POETSPoster Aircraft 3Document2 pagesPOETSPoster Aircraft 3Khương Lê DuyNo ratings yet

- Buyers Guide 19 127065Document149 pagesBuyers Guide 19 127065p.viala.kNo ratings yet

- Last Minute Revision Practice Edexcel GCSE Mathematics (Foundation)Document9 pagesLast Minute Revision Practice Edexcel GCSE Mathematics (Foundation)bonyantunNo ratings yet

- YOLO-LITE: A Real-Time Object Detection Algorithm Optimized For Non-GPU ComputersDocument8 pagesYOLO-LITE: A Real-Time Object Detection Algorithm Optimized For Non-GPU ComputersDeepak Kumar SinghNo ratings yet

- Informatica Mapping ScenariosDocument81 pagesInformatica Mapping ScenariosSri Kanth SriNo ratings yet

- Upper TrainingDocument7 pagesUpper TrainingManav SharmaNo ratings yet

- ACCOUNTING FOR CORPORATIONS-Basic ConsiderationsDocument41 pagesACCOUNTING FOR CORPORATIONS-Basic ConsiderationsMarriel Fate Cullano100% (2)

- Class XII Phase Test I - SubDocument2 pagesClass XII Phase Test I - SubFariha KhanNo ratings yet

- Planning AND Materiali TY: Subject: Basic Audit Lecturers: Nguyen Thi Mai HuongDocument53 pagesPlanning AND Materiali TY: Subject: Basic Audit Lecturers: Nguyen Thi Mai HuongMạnh hưng Lê100% (1)

- Analysis of Research On Amazon AWS Cloud Computing Seller Data SecuritDocument6 pagesAnalysis of Research On Amazon AWS Cloud Computing Seller Data SecuritIjrei JournalNo ratings yet

- Chapter-6-Electromagnetic InductionDocument9 pagesChapter-6-Electromagnetic Inductioncharitham112No ratings yet

- WEG Regulador Automatico de Tension Wrga 02 10001284080 Manual EspanolDocument97 pagesWEG Regulador Automatico de Tension Wrga 02 10001284080 Manual EspanolEstalin Ochoa100% (1)

- DRUG FREE WORKPLACE Private - Public With ChartDocument26 pagesDRUG FREE WORKPLACE Private - Public With ChartKristi Lou TamingNo ratings yet

- TSI's Motion For Judgment Nov As FiledDocument93 pagesTSI's Motion For Judgment Nov As FiledEd PatruNo ratings yet

- Exercise 13 - Hand and Power ToolsDocument3 pagesExercise 13 - Hand and Power ToolsDzenrhe ParanNo ratings yet

- Proclimb Procross Torsional Conversion KitDocument8 pagesProclimb Procross Torsional Conversion KitcpcracingNo ratings yet

- Oracle ERP Data SheetDocument2 pagesOracle ERP Data Sheetvinoth4iNo ratings yet

- 1 Report WritingDocument32 pages1 Report WritingAyesha Tahir100% (1)

- Assignment/ Tugasan - Biostatistic/ BiostatistikDocument6 pagesAssignment/ Tugasan - Biostatistic/ Biostatistikfirdaus che daudNo ratings yet

- External Assessment:: A Framework For Organizational StrategizingDocument31 pagesExternal Assessment:: A Framework For Organizational StrategizingMelai NfmbjNo ratings yet

- Shahid Bhagat Singh Goregaon Creek ETH - 7000013070 - VolumeIDocument302 pagesShahid Bhagat Singh Goregaon Creek ETH - 7000013070 - VolumeImahesh sherkhaneNo ratings yet

- Case Study: Distributed Scrum Project For Dutch RailwaysDocument7 pagesCase Study: Distributed Scrum Project For Dutch RailwaysDark LordNo ratings yet

- # 1 Apex MiningDocument5 pages# 1 Apex MiningAnonymous ibNWfYB2No ratings yet

- Step by Step GuideDocument5 pagesStep by Step GuideSourav SahaNo ratings yet

- Chapter 6 PowerpointDocument32 pagesChapter 6 Powerpointsabin katwalNo ratings yet