Professional Documents

Culture Documents

Ohs Audit Check List

Ohs Audit Check List

Uploaded by

Venkata SattiRaju0 ratings0% found this document useful (0 votes)

3 views4 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

3 views4 pagesOhs Audit Check List

Ohs Audit Check List

Uploaded by

Venkata SattiRajuCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

OHSAS AUDIT CHECK LIST

S.NO Audit question Observation/Objective evidence C/NC

1. Whether OHS Policy

documented/appropriate/displayed

2. Whether OHS Organizational set up exist

3a. Whether competence criteria for OHSAS

defined

3b. Education& Training on OHS in place?

Whether induction training in place?What

are the topics covered?Whether training

effectiveness assessed?Whether training

conducted in local language?

3c. Whether contractors are provided

training?

3d. Whether any visits to safety institutions

organized?

4. Whether employee participation in

place/how are they selected

5. Whether applicable Legal&Other

requirements documented/complied

6. Whether equipment safety check lists in

place

7. Whether incident/accident

reporting,investigation,implementation of

recommendation in place?Whether

statistics in place for reportable/non

reportable for the last 3 years?Any analysis

made?

7a. What is the method of emergency

communication with local bodies

8. Whether HIRA made?What is the criteria

followed?What is meant by acceptable

risk,unacceptable risk?Any

objectives,targets,programs set?

8a. Whether hazards list updated with new

developments(activities,products,services)?

9. Whether safety inspection in place

10 Whether Occupational health diseases

identified

10a. Whether employee health examination in

place/whether health improvement

recommendations implemented?

11. Whether first aid in place

12. Whether PPE in use?

13. Whether good housekeeping in place ?

What is method to deal with spills?

Whether sufficient bins in place suitably

located?Whether walkways clearly

marked?Whether floor is slippery?

13a. Whether scrubbing systems in place

14. Whether machines guarded

15. Whether material handling eqpt in

place(trolleys,fork lifters hoists etc)

15a. Whether alternate power source in place.

16. Whether ventilation, illumination, noise

monitored/records if industrial

hygiene surveys

16a Whether any system of periodic cleaning

and replacing the light fittings?

17. Whether safe operating procedures in

place? Whether they reflect consequence

of failure/mitigation measure?

17a. Whether instructions to contractors

including supply chain (transporter

compliance monitoring)in place

18. Whether work permit systems in place

19. Whether fire prevention, protection and

fighting systems in place/testing records in

place

19a. Whether any safety interlocks, alarms and

trip systems in place and tested

periodically?

20. Whether on site emergency plan in place

21. Whether Hazardous waste transport

/disposal in place

22. Whether safety in warehousing ensured?

23. Whether contractor safety ensured?

24. Whether visitor safety ensured?

25. Whether material safety data sheets in

place

26. Whether potential emergencies identified

27. Whether mock drills conducted?

28. What is the periodicity of safety committee

meeting? Whether MOM of safety

committee available?What are the

recommendations?how they are

implemented?Whether minutes circulated?

Whether minutes sent to DOF?

29. Whether OHS measuring eqpt in

place/calibrated?

30. Whether safety budget in place? Whether

it is reflected in annual report?

31. What is strength of safety department?

32. Whether there is internal training within

safety dept?

33. What are the authorities of safety Head

34. Whether safety contests organized?

35. Whether safety publications made

available to the employees

36. Whether safety day celebrated?

37. Whether OHS Center in place? Whether

emergency drugs in place? Whether

doctor/compounder available round the

clock? Whether any tie up in place with

nearby hospital?

38. Whether plant lay out available indicating

fire exits, fire extinguishers etc

39. Whether fire fighting system approved,

tested and maintained as per relevant

standard?

40. Whether inspection and maintenance

schedule available for fire fighting eqpt in

place?

41. Whether colour coding of pipe lines for

hazardous chemicals?

42. Whether electrical installations undergo

periodic inspections? Whether flame proof

fittings in place wherever required?

43. Whether static electricity points

identified/earthed/antistatic charge

devices fitted

44. Whether earth pits maintained?

45. Whether pressure vessels& lifting tackles

tested periodically by a competent person?

46. Whether drivers training in place?

47. Whether adequate number of warning

signals/signs available in the plant area?

48. Whether all drain covers in good condition?

49. Whether chemical storage areas identified?

Bunded/dyked/bonded/earthed/vessels

provided with emergency vent,relief

valve,bursting disc,level indicator,pressure

guage,overflow line/ ultrasonically tested?

50. Whether stand by empty tanks provided?

51. Whether cylinders stored properly/possess

license?

52. Whether licensed vehicles used for haz.

Material transportation?

53. Whether corrosion protection ensured for

all the steel structures?

54. Whether external communication

maintained with regulators/any

complaints, concerns? What are the details

of interested parties visits?

55. What is OHSAS Documentation in place

56. How do you control the documents?

57. What are external documents identified?

58. How do you control OHSAS records?

59. What are details of internal audit?

(Periodicity, audit schedule)

60. How many trained internal auditors

61. What are the details of Management

review? Whether all the agenda points

Addressed?

62. What do you mean by OHSAS

Performance?

You might also like

- Hazards ChecklistDocument7 pagesHazards ChecklistRemeras TartagalNo ratings yet

- Is 14489 2018Document21 pagesIs 14489 2018Rohit100% (3)

- Site Visit (SIV) ChecklistDocument21 pagesSite Visit (SIV) ChecklistVictor BiacoloNo ratings yet

- Audit Checklist For The Engineering and MaintenanceDocument2 pagesAudit Checklist For The Engineering and MaintenanceMohanad Alashkar100% (4)

- Product Quality Risk AssessmentDocument8 pagesProduct Quality Risk AssessmentApoloTrevino100% (1)

- Inspection Checklists - Sample Checklist For Manufacturing Facilities - OSH AnswersDocument6 pagesInspection Checklists - Sample Checklist For Manufacturing Facilities - OSH Answersshahira100% (1)

- Discourse Analysis in Education - ProposalDocument2 pagesDiscourse Analysis in Education - ProposalsherrymiNo ratings yet

- Ems AuditDocument3 pagesEms AuditVenkata SattiRajuNo ratings yet

- HSE Audit Detailed ChecklistDocument15 pagesHSE Audit Detailed ChecklistVinod KumarNo ratings yet

- Is 14489 Check ListDocument18 pagesIs 14489 Check Listvramadorai100% (5)

- Is 14489 2018 Audit Check ListDocument34 pagesIs 14489 2018 Audit Check ListRajesh Dhake100% (2)

- Checklist For Laboratory Quality Standards: (According To WHO Publication Lab Quality Standards and Their Implementation)Document11 pagesChecklist For Laboratory Quality Standards: (According To WHO Publication Lab Quality Standards and Their Implementation)Nazaqat FarooqNo ratings yet

- Safety Audit As Per IS 14489Document6 pagesSafety Audit As Per IS 14489alautomatesNo ratings yet

- Safety Checklists: A I, A & RDocument37 pagesSafety Checklists: A I, A & Rmd sarfaraz khanNo ratings yet

- Checklist For CLIA ComplianceDocument10 pagesChecklist For CLIA ComplianceMichael HallNo ratings yet

- Checklist For Audit in Quality Control - Pharmaceutical GuidelinesDocument2 pagesChecklist For Audit in Quality Control - Pharmaceutical GuidelinesOussama BELHADJ-RABAHNo ratings yet

- Are The Pipelines Fitted With Safety Equipment Such As Leak Detectors, Automatic Shut-Off Valves, Etc.?Document2 pagesAre The Pipelines Fitted With Safety Equipment Such As Leak Detectors, Automatic Shut-Off Valves, Etc.?Henry Bastian CNo ratings yet

- Safety Checklists: Accident Investigation, Analysis & ReportingDocument48 pagesSafety Checklists: Accident Investigation, Analysis & ReportingnatasNo ratings yet

- GMP Audit Check ListDocument1 pageGMP Audit Check ListDharmesh PatelNo ratings yet

- Health and Safety Self Audit Checklist GeneralDocument8 pagesHealth and Safety Self Audit Checklist Generalوأكثرهم كارهونNo ratings yet

- Subcontractors EHS Audit TemplateDocument7 pagesSubcontractors EHS Audit TemplateDeepakNo ratings yet

- SIMSA Fire Safety Audit ChecklistDocument8 pagesSIMSA Fire Safety Audit ChecklistAshish MendirattaNo ratings yet

- Supplier Qualification Form C-67194Document11 pagesSupplier Qualification Form C-67194MinJeong Cuteemo Kim0% (1)

- OISD ChecklistDocument3 pagesOISD ChecklistLoganathan DharmarNo ratings yet

- FD Self AssessmentDocument7 pagesFD Self Assessmentapi-277257927No ratings yet

- Is 14489 - 1998 Safety Audit QuestionnaireDocument23 pagesIs 14489 - 1998 Safety Audit Questionnairekirandevi1981100% (1)

- HSE TEAM TOUR CHECKLIST Maintenance Block Utilties AreaDocument2 pagesHSE TEAM TOUR CHECKLIST Maintenance Block Utilties Areaf.BNo ratings yet

- Safety Inspection Checklist and Observation ReportDocument14 pagesSafety Inspection Checklist and Observation Reportpartha100% (1)

- Health and Safety PolicyDocument16 pagesHealth and Safety PolicySuzma Dhakal100% (1)

- IS 14489 Check ListDocument17 pagesIS 14489 Check Listsathish_iyengarNo ratings yet

- Hse Team Tour Checklist Workshop Welding AreaDocument2 pagesHse Team Tour Checklist Workshop Welding Areaf.B100% (3)

- HSE Audit Checklist: Emergency Equipment Safety Inspection Checklist ItemDocument3 pagesHSE Audit Checklist: Emergency Equipment Safety Inspection Checklist Itemramod100% (2)

- Construction Safety Audit ChecklistDocument7 pagesConstruction Safety Audit Checklistamit sikkaNo ratings yet

- Checklist Orchid FarmDocument13 pagesChecklist Orchid FarmAmporn IceNo ratings yet

- Construction Safety InspectionDocument12 pagesConstruction Safety InspectionAhmet SenlerNo ratings yet

- Screenshot 2023-11-05 at 11.26.43 AMDocument2 pagesScreenshot 2023-11-05 at 11.26.43 AMFarhanah masrinNo ratings yet

- SHES QuestionsDocument33 pagesSHES QuestionsPaulo Edrian Dela PenaNo ratings yet

- All Safety Inspection ChecklistsDocument30 pagesAll Safety Inspection ChecklistsSagar Sharma67% (3)

- Safety AuditDocument22 pagesSafety AuditRavi MishraNo ratings yet

- Questions: C-1 Oh & S Management C-1.1 OH & S PolicyDocument46 pagesQuestions: C-1 Oh & S Management C-1.1 OH & S PolicyPratik KatholeNo ratings yet

- SMETA Checklist (Working Conditions, Child Labour)Document13 pagesSMETA Checklist (Working Conditions, Child Labour)Arbab qasimNo ratings yet

- Club Safety Checklist - AuditDocument103 pagesClub Safety Checklist - AuditFajar IslamNo ratings yet

- Risk MGMTDocument2 pagesRisk MGMTmuradpanditNo ratings yet

- Construction Site Inspection Checklist For Safety RepresentativesDocument2 pagesConstruction Site Inspection Checklist For Safety RepresentativesMORRIS MWONGELANo ratings yet

- MHI - Safety Audit Inspection ChecklistDocument4 pagesMHI - Safety Audit Inspection ChecklistDominic John Armada0% (1)

- Alat AnalisaDocument29 pagesAlat AnalisaAntoni PardedeNo ratings yet

- General Workplace Inspection ChecklistDocument2 pagesGeneral Workplace Inspection ChecklistrajkumarNo ratings yet

- 22 Safety ChecklistsDocument30 pages22 Safety ChecklistsIrvys G. Juarez Dordi100% (2)

- Final - Hazard - Identification - Checklist - Gas & Oil - Mysha - 0419022037 - M.SC PDFDocument5 pagesFinal - Hazard - Identification - Checklist - Gas & Oil - Mysha - 0419022037 - M.SC PDFMysha Momtaz100% (1)

- Construction Site Management ChecklistDocument6 pagesConstruction Site Management ChecklistAbdulaziz IbrahimNo ratings yet

- Construction Industry Inspection Checklist (Long Version)Document6 pagesConstruction Industry Inspection Checklist (Long Version)Usman ShahidNo ratings yet

- General Inspection Checklist For Safety RepresentativesDocument2 pagesGeneral Inspection Checklist For Safety RepresentativesDoaa GamalNo ratings yet

- 22-SAFETY Inspection Checklists: Hsseworld Com Health, Safety, Security and EnvironmentDocument30 pages22-SAFETY Inspection Checklists: Hsseworld Com Health, Safety, Security and EnvironmentMohammed Hasnain Saleem/KSA/EMD100% (1)

- Safety Audit TipsDocument3 pagesSafety Audit TipsvipulNo ratings yet

- Coshh StoreDocument1 pageCoshh StoreNijo JosephNo ratings yet

- Product Defense Guidance IFS HPC V2Document9 pagesProduct Defense Guidance IFS HPC V2Jordi BesoraNo ratings yet

- Safety Checklist 05092019Document7 pagesSafety Checklist 05092019Eranda SDNo ratings yet

- CSP Health and Safety Inspection Checklist 2016 74255Document15 pagesCSP Health and Safety Inspection Checklist 2016 74255Nicole QuimpoNo ratings yet

- Protocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesFrom EverandProtocall 934 Hazardous Materials Technician: Ten Fingers and Ten ToesNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

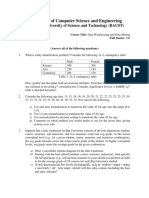

- Department of Computer Science and EngineeringDocument3 pagesDepartment of Computer Science and EngineeringMd.Ashiqur RahmanNo ratings yet

- Ritesh SIPDocument67 pagesRitesh SIPManojNo ratings yet

- Seminar Report FinalDocument14 pagesSeminar Report FinalAnimesh Kumar TilakNo ratings yet

- Brochure PDFDocument4 pagesBrochure PDFAmel Ben YahiaNo ratings yet

- Raspberry Pi CNC MachineDocument7 pagesRaspberry Pi CNC MachineMatias FernandezNo ratings yet

- Belden GRS105 24TX6SFP 2HV 2ADocument2 pagesBelden GRS105 24TX6SFP 2HV 2AMelyssa Motta da SilvaNo ratings yet

- 2 Year MTechDocument75 pages2 Year MTecharafat mohmmedNo ratings yet

- F4ge9684a Motor GuaresiDocument57 pagesF4ge9684a Motor GuaresiGiovanni PreussNo ratings yet

- Gate Valves Options: Two-Piece Stem Housing Single Stem ExtensionsDocument2 pagesGate Valves Options: Two-Piece Stem Housing Single Stem Extensionsmykel_dpNo ratings yet

- Electrical Symbol Legend Abbreviations (Cont.) : Fire Alarm/Detection System Basic Materials Voice and Data Raceway SystemDocument4 pagesElectrical Symbol Legend Abbreviations (Cont.) : Fire Alarm/Detection System Basic Materials Voice and Data Raceway SystemRaul RaulNo ratings yet

- Email Marketing ManagerDocument2 pagesEmail Marketing Managerjugal bariNo ratings yet

- Digital Engineering Standard Part 1 Concepts and Principles v4.1Document57 pagesDigital Engineering Standard Part 1 Concepts and Principles v4.1디노패밀리DINO MOM DINONo ratings yet

- 5760 - 248 HSLDocument36 pages5760 - 248 HSLSokjo0ker17No ratings yet

- FDA Approval For ABSolu Ultrasound PlatformDocument2 pagesFDA Approval For ABSolu Ultrasound Platformoskr.bstNo ratings yet

- Distributed Denial of ServiceDocument2 pagesDistributed Denial of ServiceneelakshijollyNo ratings yet

- Thomson Tg580Document3 pagesThomson Tg580Solosoy ElmismoNo ratings yet

- Rangkuman Dan RefleksiDocument3 pagesRangkuman Dan Refleksiaidilarkam2828No ratings yet

- MeitY - Cyber Security - 13 Feb - FinalDocument16 pagesMeitY - Cyber Security - 13 Feb - FinalBrijesh SinghNo ratings yet

- Job Objective:: Resume of Abdullah Ahmed Alghamdi Kingdom of Saudi Arabia Jeddah Mobile:0560206028Document3 pagesJob Objective:: Resume of Abdullah Ahmed Alghamdi Kingdom of Saudi Arabia Jeddah Mobile:0560206028raghacivilNo ratings yet

- WigginsDocument2 pagesWigginsmirbek mairykovNo ratings yet

- LETO (Torrejon) : General InfoDocument39 pagesLETO (Torrejon) : General InfoMiguel Angel MartinNo ratings yet

- ETC3550 Applied Forecasting For Business and Economics: Ch12. Some Practical Forecasting IssuesDocument22 pagesETC3550 Applied Forecasting For Business and Economics: Ch12. Some Practical Forecasting IssuesjuanivazquezNo ratings yet

- Computer System ArchitectureDocument25 pagesComputer System ArchitecturethelodieNo ratings yet

- Just Squeeze Me FullDocument11 pagesJust Squeeze Me FullPeeter NormanNo ratings yet

- A Creator's Guide To Building An Email ListDocument14 pagesA Creator's Guide To Building An Email Listsujit44No ratings yet

- Distance Learning MatrixDocument1 pageDistance Learning MatrixRuth PetrosNo ratings yet

- Nokia BB5 de BrandingDocument16 pagesNokia BB5 de BrandingGutz Teo ManuelNo ratings yet

- Job DescriptionDocument3 pagesJob DescriptionMann SalviNo ratings yet

- Requirement Gathering For IT Infrastructure - 1Document11 pagesRequirement Gathering For IT Infrastructure - 1ASN PrasadNo ratings yet