Professional Documents

Culture Documents

ASTM E18 (2019) - Part9

ASTM E18 (2019) - Part9

Uploaded by

david4231993Copyright:

Available Formats

You might also like

- Aws d1.1 Ut Inspection ProcedureDocument17 pagesAws d1.1 Ut Inspection ProcedureMohanadNo ratings yet

- Function, Structure, Operation of Engine Null (4JK1)Document36 pagesFunction, Structure, Operation of Engine Null (4JK1)jonathan100% (3)

- KASTO 016 (로크웰 경도 시험기) PDFDocument27 pagesKASTO 016 (로크웰 경도 시험기) PDFTJNo ratings yet

- 26.9 Seismic Qualification Testing of TransformerDocument3 pages26.9 Seismic Qualification Testing of Transformerkrmurali2000No ratings yet

- Calculation of Viscosity-Gravity Constant (VGC) of Petroleum OilsDocument3 pagesCalculation of Viscosity-Gravity Constant (VGC) of Petroleum Oilsebsilvaesther100% (1)

- SOP No. 10 Recommended Standard Operating Procedure For Calibration of Rigid RulesDocument9 pagesSOP No. 10 Recommended Standard Operating Procedure For Calibration of Rigid RuleslukasjoNo ratings yet

- ASTM E74 ExplainedDocument62 pagesASTM E74 ExplainedCharlo GordoNo ratings yet

- Rockwell Hardness of Graphite Materials: Standard Test Method ForDocument3 pagesRockwell Hardness of Graphite Materials: Standard Test Method ForMuhammad NaumanNo ratings yet

- ASTM E18 (2019) - Part8Document1 pageASTM E18 (2019) - Part8david4231993No ratings yet

- Nistspecialpublication960 5Document124 pagesNistspecialpublication960 5nehal3788090No ratings yet

- Rockwell Hardness of Graphite Materials: Standard Test Method ForDocument3 pagesRockwell Hardness of Graphite Materials: Standard Test Method ForLabeed ShamilNo ratings yet

- Curvas ROCDocument2 pagesCurvas ROCRodrigo VattuoneNo ratings yet

- Curvas ROCDocument2 pagesCurvas ROCRodrigo VattuoneNo ratings yet

- ASTM E18 (2019) - Part4Document1 pageASTM E18 (2019) - Part4david4231993No ratings yet

- A 255 - 99 Qti1ns05oqDocument21 pagesA 255 - 99 Qti1ns05oqfekihassanNo ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E18 (2019) - Part25Document1 pageASTM E18 (2019) - Part25david4231993No ratings yet

- 4 - St4nd4rd T3st M3th0d f0r Pull0ut Str3ngth of H4rd3n3d Co0ncr3teDocument1 page4 - St4nd4rd T3st M3th0d f0r Pull0ut Str3ngth of H4rd3n3d Co0ncr3teJOSE CANTERONo ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- Usbr1012 PDFDocument4 pagesUsbr1012 PDFYCNo ratings yet

- OrmatioDocument1 pageOrmatioMechanicalNo ratings yet

- Damaging Power: Oil-InsulatedDocument2 pagesDamaging Power: Oil-InsulatedDante FilhoNo ratings yet

- Akobeng 2007 Acta Paediatrica3Document4 pagesAkobeng 2007 Acta Paediatrica3STEPHANIE DANAE DAINE FRITZNo ratings yet

- C748-98 (2015) Standard Test Method For Rockwell Hardness of Graphite MaterialsDocument3 pagesC748-98 (2015) Standard Test Method For Rockwell Hardness of Graphite MaterialsDuc Nguyen VanNo ratings yet

- CON 700 ManualDocument24 pagesCON 700 ManualVijay YadavNo ratings yet

- Conductivity MeterDocument23 pagesConductivity MeterSachin VaisayNo ratings yet

- Determining Hardenability of Steel: Standard Test Methods ForDocument21 pagesDetermining Hardenability of Steel: Standard Test Methods ForWilliam Ruiz MartinezNo ratings yet

- Astm C748.10372Document3 pagesAstm C748.10372Luis Felipe Cam ChiangNo ratings yet

- SOP10 - 20141022 - ReglasDocument9 pagesSOP10 - 20141022 - ReglasDiego LincangoNo ratings yet

- Calibration of The Electron Binding-Energy Scale of An X-Ray Photoelectron SpectrometerDocument16 pagesCalibration of The Electron Binding-Energy Scale of An X-Ray Photoelectron Spectrometerbenjaminverduzco4No ratings yet

- Astm C748Document2 pagesAstm C748정호철No ratings yet

- Exercises: Lithium BatteriesDocument2 pagesExercises: Lithium BatteriesThanh NhiNo ratings yet

- Procedura Za Proveru VagaDocument4 pagesProcedura Za Proveru VagaDragan LazicNo ratings yet

- ISO 21501-4 Calibratio of Air Particle Counters From A Metrology Perpective PDFDocument8 pagesISO 21501-4 Calibratio of Air Particle Counters From A Metrology Perpective PDFManuel TorresNo ratings yet

- ASTM E18 (2019) - Part16Document1 pageASTM E18 (2019) - Part16david4231993No ratings yet

- Cait NormsDocument4 pagesCait NormsgenerjustnNo ratings yet

- ASTM Precision and Bias StatementsDocument1 pageASTM Precision and Bias StatementsAndrew PiNo ratings yet

- ISO 8217 - Test Methods Precision and InterpretationDocument4 pagesISO 8217 - Test Methods Precision and Interpretationhesigu14No ratings yet

- Lab Manual: Measurement and Quality Assurance WorkshopDocument57 pagesLab Manual: Measurement and Quality Assurance WorkshopBewabaNo ratings yet

- Conductividad NIST 1423 VigenteDocument34 pagesConductividad NIST 1423 Vigentetvhogar garciaNo ratings yet

- Astm E18Document39 pagesAstm E18Poedyaji MawardiNo ratings yet

- ISO 21501-4 Perspectiva MetrológicaDocument8 pagesISO 21501-4 Perspectiva MetrológicaNicolas VargasNo ratings yet

- Section 9: Standard Test ProceduresDocument2 pagesSection 9: Standard Test ProceduresYonh Yunior Ticona CallaNo ratings yet

- Astm D 562-01 Standard Test Method For Consistency of Paints Measuring Krebs Unit Viscosity Using A StormerDocument6 pagesAstm D 562-01 Standard Test Method For Consistency of Paints Measuring Krebs Unit Viscosity Using A StormerGianinaRoncalChávez33% (3)

- ASTM E18 (2019) - Part6Document1 pageASTM E18 (2019) - Part6david4231993No ratings yet

- Fusion of Poly (Vinyl Chloride) (PVC) Compounds Using A Torque RheometerDocument6 pagesFusion of Poly (Vinyl Chloride) (PVC) Compounds Using A Torque RheometerveintavoNo ratings yet

- Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using A Stormer-Type ViscometerDocument7 pagesConsistency of Paints Measuring Krebs Unit (KU) Viscosity Using A Stormer-Type ViscometerSoundara PandianNo ratings yet

- Astm D562 - 2010Document7 pagesAstm D562 - 2010Zahra Sadredini100% (1)

- ANai - 300 - 40030 - EN - Simultaneous Stage 1 Conductivity and TOC Lab Testing of Pharmaceutical WaterDocument3 pagesANai - 300 - 40030 - EN - Simultaneous Stage 1 Conductivity and TOC Lab Testing of Pharmaceutical WaterNguyen Minh NhutNo ratings yet

- Ancoragem em RochaDocument11 pagesAncoragem em RochaJ.GuerhardNo ratings yet

- Guidelines On Determination of Resistivity of Rock SpecimenDocument10 pagesGuidelines On Determination of Resistivity of Rock SpecimenCgpscAspirantNo ratings yet

- Norma Do BetuminosoDocument9 pagesNorma Do BetuminosoAna PinhoNo ratings yet

- Experiment 5 Physics 250 Wheatstone Bridge ApparatusDocument5 pagesExperiment 5 Physics 250 Wheatstone Bridge ApparatusJeff's SKiNo ratings yet

- E1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes TérmicasDocument3 pagesE1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes Térmicasfredy lopezNo ratings yet

- ASTM D2228 Rubber Prop-Abrasion Resistance TestingDocument9 pagesASTM D2228 Rubber Prop-Abrasion Resistance TestingJesse KrebsNo ratings yet

- A02 003A A Comparison of The Integrity Clarity Solubility Station IR Measurement ProbesDocument2 pagesA02 003A A Comparison of The Integrity Clarity Solubility Station IR Measurement ProbesCarol ChiaNo ratings yet

- A High-Voltage Reference Testbed For The Evaluation ofDocument2 pagesA High-Voltage Reference Testbed For The Evaluation ofYolandaIbáñezNo ratings yet

- Traceable High-Frequency Vibration Calibration of Accelerometers in The Temperature Range of - 60 CTO90 C Randy MendozaDocument16 pagesTraceable High-Frequency Vibration Calibration of Accelerometers in The Temperature Range of - 60 CTO90 C Randy MendozamaracaverikNo ratings yet

- Understanding ROC CurveDocument2 pagesUnderstanding ROC Curve古寒州No ratings yet

- Plastics Testing and Characterization: Industrial ApplicationsFrom EverandPlastics Testing and Characterization: Industrial ApplicationsNo ratings yet

- ASTM E384 (2022) - Part8Document1 pageASTM E384 (2022) - Part8david4231993No ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part39Document1 pageASTM E18 (2019) - Part39david4231993No ratings yet

- ASTM E18 (2019) - Part36Document1 pageASTM E18 (2019) - Part36david4231993No ratings yet

- ASTM E384 (2022) - Part1Document1 pageASTM E384 (2022) - Part1david4231993No ratings yet

- ASTM E18 (2019) - Part20Document1 pageASTM E18 (2019) - Part20david4231993No ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part33Document1 pageASTM E18 (2019) - Part33david4231993No ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part11Document1 pageASTM E18 (2019) - Part11david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- ASTM E18 (2019) - Part2Document1 pageASTM E18 (2019) - Part2david4231993No ratings yet

- Y5 Existing Endangered ExtinctDocument2 pagesY5 Existing Endangered Extinctsadviau3No ratings yet

- Smaw 12 Module 1Document7 pagesSmaw 12 Module 1Francis Rico Mutia RufonNo ratings yet

- Latent Autoimmune Diabetes in Adults (LADA)Document5 pagesLatent Autoimmune Diabetes in Adults (LADA)Fina Ahmad FitrianaNo ratings yet

- Stability Study of Cocoa Butter Body Scrub Formulated With Ground Cocoa Pod HuskDocument7 pagesStability Study of Cocoa Butter Body Scrub Formulated With Ground Cocoa Pod Huskudiwaluyo waluyoNo ratings yet

- D. Benos vs. LawilaoDocument7 pagesD. Benos vs. Lawilaochuck_0428No ratings yet

- Lumax LED-Presentation PDFDocument31 pagesLumax LED-Presentation PDFSalman HashmiNo ratings yet

- The Environment (Protection) Act, 1986Document38 pagesThe Environment (Protection) Act, 1986Anugya JhaNo ratings yet

- Prelims in NSTP-CWTS 1Document4 pagesPrelims in NSTP-CWTS 1Janes MalaluanNo ratings yet

- Nestle: Nestlé's Mission Statement (R1)Document11 pagesNestle: Nestlé's Mission Statement (R1)Abdul RehmanNo ratings yet

- TXXXXXXXX Zusatzinformation Entsorgung 0enDocument6 pagesTXXXXXXXX Zusatzinformation Entsorgung 0enBeltazor HellboyNo ratings yet

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document30 pagesTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkNo ratings yet

- Reviewer General Physics 1Document1 pageReviewer General Physics 1Asdf GhjNo ratings yet

- Science of Happiness PSYC 201 Syllabus Fall 2014Document7 pagesScience of Happiness PSYC 201 Syllabus Fall 2014gman61693No ratings yet

- FMCG SectorDocument65 pagesFMCG SectordmaxprasangaNo ratings yet

- CV Manat Ryan Hard NababanDocument1 pageCV Manat Ryan Hard NababanmanatNo ratings yet

- ACS Motion Control - Tech80 SB 1381 ManualDocument183 pagesACS Motion Control - Tech80 SB 1381 ManualPsaNo ratings yet

- Engl5 Problem Solution EssayDocument7 pagesEngl5 Problem Solution Essayapi-511280084No ratings yet

- Parle AgroDocument3 pagesParle AgroKumar GautamNo ratings yet

- CyberbullyingDocument8 pagesCyberbullyingQUINTILLA ALEXXA YNA MARINo ratings yet

- Gastroenterology Clinical Focus High Yield Gi and HepatologyDocument426 pagesGastroenterology Clinical Focus High Yield Gi and HepatologyAhana MukherjeeNo ratings yet

- EDGE CEOMrngBrief-22JulyDocument23 pagesEDGE CEOMrngBrief-22JulyApat PadiNo ratings yet

- B2+ Test Series (32) : Name: - Score: - /100Document4 pagesB2+ Test Series (32) : Name: - Score: - /100Ngân Nguyễn Bùi HoaNo ratings yet

- Unraveling PhobiaDocument19 pagesUnraveling PhobiaCounsel IndiaNo ratings yet

- Tape Mobil JVC.Document16 pagesTape Mobil JVC.EdisonNainggolanNo ratings yet

- KFUPM-ME Department ME 460 Thermal Desalination SystemsDocument2 pagesKFUPM-ME Department ME 460 Thermal Desalination SystemsMajid KhanNo ratings yet

- Ahbab Travels & Tours: UMRAH PACKAGE - 2019 - Per Person in 10 Pax GroupDocument3 pagesAhbab Travels & Tours: UMRAH PACKAGE - 2019 - Per Person in 10 Pax GroupWaqi WaqiNo ratings yet

- Water Kiosk DesignDocument1 pageWater Kiosk DesignAbdirahman Mohamed NurNo ratings yet

- MumhospitallistDocument132 pagesMumhospitallistSufiyan KhedekarNo ratings yet

- Total Supply Chain Management Cost Data CollectionDocument4 pagesTotal Supply Chain Management Cost Data CollectionSuhailNo ratings yet

ASTM E18 (2019) - Part9

ASTM E18 (2019) - Part9

Uploaded by

david4231993Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM E18 (2019) - Part9

ASTM E18 (2019) - Part9

Uploaded by

david4231993Copyright:

Available Formats

E18 − 19

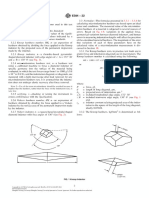

TABLE 4 Results of the Precision and Bias Study than the RPB value for that Rockwell scale is an indication that

Test Block

Average

Sr SR rPB RPB

the results may be equivalent.

Hardness

10.7 Any judgments based on 10.5 and 10.6 would have an

Data from 2000 study

62.8 HRA 62.50 0.164 0.538 0.459 1.506 approximately 95 % probability of being correct.

73.1 HRA 73.04 0.138 0.358 0.387 1.002 10.8 This precision and bias study was conducted on a

83.9 HRA 84.54 0.085 0.468 0.238 1.309

25.0 HRC 24.99 0.335 0.440 0.937 1.232 selected number of the most commonly used Rockwell scales.

45.0 HRC 45.35 0.156 0.259 0.438 0.725 For Rockwell scales not listed, the rPB and RPB values may be

65.0 HRC 65.78 0.153 0.389 0.427 1.089

estimated using the conversion tables of E140 to determine a

45.9 HR30N 46.75 0.299 2.489 0.837 6.969

64.0 HR30N 64.74 0.248 0.651 0.694 1.822 corresponding increment of hardness for the scale of interest at

81.9 HR30N 82.52 0.195 0.499 0.547 1.396 the hardness level of interest. The user is cautioned that

Data from 2006 study

40 HRBW 43.90 0.492 0.668 1.378 1.871

estimating the rPB and RPB values in this way, decreases the

60 HRBW 61.77 0.663 0.697 1.855 1.953 probability of them being correct.

95 HRBW 91.09 0.250 0.292 0.701 0.817

62 HREW 64.07 0.346 0.675 0.970 1.890

10.9 Although the precision values given in Table 4 provide

81 HREW 81.61 0.232 0.406 0.649 1.136 guidance on interpreting differences in Rockwell hardness

100 HREW 96.22 0.177 0.322 0.497 0.901 measurement results, a complete evaluation of measurement

22 HR30TW 18.33 0.702 0.901 1.965 2.522

56 HR30TW 58.0 0.476 0.517 1.333 1.447

uncertainty will provide a more definitive interpretation of the

79 HR30TW 81.0 0.610 0.851 1.709 2.382 results for the specific testing conditions.

10.10 The data generally indicated reasonable precision

except for the 45.9 HR30N scale. In that scale the SR and RPB

values are very high compared to all of the other scales. An

hardness tester on the same day. When comparing two test examination of the raw data reveled that one lab’s results were

results made under these conditions, a measurement difference much higher than the others, significantly affecting the overall

of less than the rPB value for that Rockwell scale is an results in that scale. The results from all of the other scales

indication that the results may be equivalent. seem to be reasonable.

10.6 The value of RPB indicates the typical amount of 10.11 Bias—There are no recognized standards by which to

variation that can be expected between test results obtained for fully estimate the bias of this test method.

the same material by different operators using different hard-

ness testers on different days. When comparing two test results 11. Keywords

made under these conditions, a measurement difference of less 11.1 hardness; mechanical test; metals; Rockwell

ANNEXES

(Mandatory Information)

A1. VERIFICATION OF ROCKWELL HARDNESS TESTING MACHINES

A1.1 Scope A1.2 General Requirements

A1.1.1 Annex A1 specifies three types of procedures for A1.2.1 The testing machine shall be verified at specific

verifying Rockwell hardness testing machines: direct instances and at periodic intervals as specified in Table A1.1,

verification, indirect verification, and daily verification. and when circumstances occur that may affect the performance

of the testing machine.

A1.1.2 Direct verification is a process for verifying that

critical components of the hardness testing machine are within A1.2.2 The temperature at the verification site shall be

allowable tolerances by directly measuring the test forces, measured with an instrument having an accuracy of at least

depth measuring system, machine hysteresis, and testing cycle. 62.0 °C or 63.6 °F. It is recommended that the temperature be

monitored throughout the verification period, and significant

A1.1.3 Indirect verification is a process for periodically

temperature variations be recorded and reported. The tempera-

verifying the performance of the testing machine by means of

ture at the verification site does not need to be measured for a

standardized test blocks and indenters.

daily verification or when qualifying additional user’s indent-

A1.1.4 The daily verification is a process for monitoring the ers in accordance with A1.4.10.

performance of the testing machine between indirect verifica-

A1.2.3 All instruments used to make measurements re-

tions by means of standardized test blocks.

quired by this Annex shall be calibrated traceable to national

A1.1.5 Adherence to this standard and annex provides standards when a system of traceability exists, except as noted

traceability to national standards, except as stated otherwise. otherwise.

Copyright ASTM International

Provided by IHS Markit under license with ASTM

9

No reproduction or networking permitted without license from IHS

You might also like

- Aws d1.1 Ut Inspection ProcedureDocument17 pagesAws d1.1 Ut Inspection ProcedureMohanadNo ratings yet

- Function, Structure, Operation of Engine Null (4JK1)Document36 pagesFunction, Structure, Operation of Engine Null (4JK1)jonathan100% (3)

- KASTO 016 (로크웰 경도 시험기) PDFDocument27 pagesKASTO 016 (로크웰 경도 시험기) PDFTJNo ratings yet

- 26.9 Seismic Qualification Testing of TransformerDocument3 pages26.9 Seismic Qualification Testing of Transformerkrmurali2000No ratings yet

- Calculation of Viscosity-Gravity Constant (VGC) of Petroleum OilsDocument3 pagesCalculation of Viscosity-Gravity Constant (VGC) of Petroleum Oilsebsilvaesther100% (1)

- SOP No. 10 Recommended Standard Operating Procedure For Calibration of Rigid RulesDocument9 pagesSOP No. 10 Recommended Standard Operating Procedure For Calibration of Rigid RuleslukasjoNo ratings yet

- ASTM E74 ExplainedDocument62 pagesASTM E74 ExplainedCharlo GordoNo ratings yet

- Rockwell Hardness of Graphite Materials: Standard Test Method ForDocument3 pagesRockwell Hardness of Graphite Materials: Standard Test Method ForMuhammad NaumanNo ratings yet

- ASTM E18 (2019) - Part8Document1 pageASTM E18 (2019) - Part8david4231993No ratings yet

- Nistspecialpublication960 5Document124 pagesNistspecialpublication960 5nehal3788090No ratings yet

- Rockwell Hardness of Graphite Materials: Standard Test Method ForDocument3 pagesRockwell Hardness of Graphite Materials: Standard Test Method ForLabeed ShamilNo ratings yet

- Curvas ROCDocument2 pagesCurvas ROCRodrigo VattuoneNo ratings yet

- Curvas ROCDocument2 pagesCurvas ROCRodrigo VattuoneNo ratings yet

- ASTM E18 (2019) - Part4Document1 pageASTM E18 (2019) - Part4david4231993No ratings yet

- A 255 - 99 Qti1ns05oqDocument21 pagesA 255 - 99 Qti1ns05oqfekihassanNo ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E18 (2019) - Part25Document1 pageASTM E18 (2019) - Part25david4231993No ratings yet

- 4 - St4nd4rd T3st M3th0d f0r Pull0ut Str3ngth of H4rd3n3d Co0ncr3teDocument1 page4 - St4nd4rd T3st M3th0d f0r Pull0ut Str3ngth of H4rd3n3d Co0ncr3teJOSE CANTERONo ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- Usbr1012 PDFDocument4 pagesUsbr1012 PDFYCNo ratings yet

- OrmatioDocument1 pageOrmatioMechanicalNo ratings yet

- Damaging Power: Oil-InsulatedDocument2 pagesDamaging Power: Oil-InsulatedDante FilhoNo ratings yet

- Akobeng 2007 Acta Paediatrica3Document4 pagesAkobeng 2007 Acta Paediatrica3STEPHANIE DANAE DAINE FRITZNo ratings yet

- C748-98 (2015) Standard Test Method For Rockwell Hardness of Graphite MaterialsDocument3 pagesC748-98 (2015) Standard Test Method For Rockwell Hardness of Graphite MaterialsDuc Nguyen VanNo ratings yet

- CON 700 ManualDocument24 pagesCON 700 ManualVijay YadavNo ratings yet

- Conductivity MeterDocument23 pagesConductivity MeterSachin VaisayNo ratings yet

- Determining Hardenability of Steel: Standard Test Methods ForDocument21 pagesDetermining Hardenability of Steel: Standard Test Methods ForWilliam Ruiz MartinezNo ratings yet

- Astm C748.10372Document3 pagesAstm C748.10372Luis Felipe Cam ChiangNo ratings yet

- SOP10 - 20141022 - ReglasDocument9 pagesSOP10 - 20141022 - ReglasDiego LincangoNo ratings yet

- Calibration of The Electron Binding-Energy Scale of An X-Ray Photoelectron SpectrometerDocument16 pagesCalibration of The Electron Binding-Energy Scale of An X-Ray Photoelectron Spectrometerbenjaminverduzco4No ratings yet

- Astm C748Document2 pagesAstm C748정호철No ratings yet

- Exercises: Lithium BatteriesDocument2 pagesExercises: Lithium BatteriesThanh NhiNo ratings yet

- Procedura Za Proveru VagaDocument4 pagesProcedura Za Proveru VagaDragan LazicNo ratings yet

- ISO 21501-4 Calibratio of Air Particle Counters From A Metrology Perpective PDFDocument8 pagesISO 21501-4 Calibratio of Air Particle Counters From A Metrology Perpective PDFManuel TorresNo ratings yet

- ASTM E18 (2019) - Part16Document1 pageASTM E18 (2019) - Part16david4231993No ratings yet

- Cait NormsDocument4 pagesCait NormsgenerjustnNo ratings yet

- ASTM Precision and Bias StatementsDocument1 pageASTM Precision and Bias StatementsAndrew PiNo ratings yet

- ISO 8217 - Test Methods Precision and InterpretationDocument4 pagesISO 8217 - Test Methods Precision and Interpretationhesigu14No ratings yet

- Lab Manual: Measurement and Quality Assurance WorkshopDocument57 pagesLab Manual: Measurement and Quality Assurance WorkshopBewabaNo ratings yet

- Conductividad NIST 1423 VigenteDocument34 pagesConductividad NIST 1423 Vigentetvhogar garciaNo ratings yet

- Astm E18Document39 pagesAstm E18Poedyaji MawardiNo ratings yet

- ISO 21501-4 Perspectiva MetrológicaDocument8 pagesISO 21501-4 Perspectiva MetrológicaNicolas VargasNo ratings yet

- Section 9: Standard Test ProceduresDocument2 pagesSection 9: Standard Test ProceduresYonh Yunior Ticona CallaNo ratings yet

- Astm D 562-01 Standard Test Method For Consistency of Paints Measuring Krebs Unit Viscosity Using A StormerDocument6 pagesAstm D 562-01 Standard Test Method For Consistency of Paints Measuring Krebs Unit Viscosity Using A StormerGianinaRoncalChávez33% (3)

- ASTM E18 (2019) - Part6Document1 pageASTM E18 (2019) - Part6david4231993No ratings yet

- Fusion of Poly (Vinyl Chloride) (PVC) Compounds Using A Torque RheometerDocument6 pagesFusion of Poly (Vinyl Chloride) (PVC) Compounds Using A Torque RheometerveintavoNo ratings yet

- Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using A Stormer-Type ViscometerDocument7 pagesConsistency of Paints Measuring Krebs Unit (KU) Viscosity Using A Stormer-Type ViscometerSoundara PandianNo ratings yet

- Astm D562 - 2010Document7 pagesAstm D562 - 2010Zahra Sadredini100% (1)

- ANai - 300 - 40030 - EN - Simultaneous Stage 1 Conductivity and TOC Lab Testing of Pharmaceutical WaterDocument3 pagesANai - 300 - 40030 - EN - Simultaneous Stage 1 Conductivity and TOC Lab Testing of Pharmaceutical WaterNguyen Minh NhutNo ratings yet

- Ancoragem em RochaDocument11 pagesAncoragem em RochaJ.GuerhardNo ratings yet

- Guidelines On Determination of Resistivity of Rock SpecimenDocument10 pagesGuidelines On Determination of Resistivity of Rock SpecimenCgpscAspirantNo ratings yet

- Norma Do BetuminosoDocument9 pagesNorma Do BetuminosoAna PinhoNo ratings yet

- Experiment 5 Physics 250 Wheatstone Bridge ApparatusDocument5 pagesExperiment 5 Physics 250 Wheatstone Bridge ApparatusJeff's SKiNo ratings yet

- E1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes TérmicasDocument3 pagesE1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes Térmicasfredy lopezNo ratings yet

- ASTM D2228 Rubber Prop-Abrasion Resistance TestingDocument9 pagesASTM D2228 Rubber Prop-Abrasion Resistance TestingJesse KrebsNo ratings yet

- A02 003A A Comparison of The Integrity Clarity Solubility Station IR Measurement ProbesDocument2 pagesA02 003A A Comparison of The Integrity Clarity Solubility Station IR Measurement ProbesCarol ChiaNo ratings yet

- A High-Voltage Reference Testbed For The Evaluation ofDocument2 pagesA High-Voltage Reference Testbed For The Evaluation ofYolandaIbáñezNo ratings yet

- Traceable High-Frequency Vibration Calibration of Accelerometers in The Temperature Range of - 60 CTO90 C Randy MendozaDocument16 pagesTraceable High-Frequency Vibration Calibration of Accelerometers in The Temperature Range of - 60 CTO90 C Randy MendozamaracaverikNo ratings yet

- Understanding ROC CurveDocument2 pagesUnderstanding ROC Curve古寒州No ratings yet

- Plastics Testing and Characterization: Industrial ApplicationsFrom EverandPlastics Testing and Characterization: Industrial ApplicationsNo ratings yet

- ASTM E384 (2022) - Part8Document1 pageASTM E384 (2022) - Part8david4231993No ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part39Document1 pageASTM E18 (2019) - Part39david4231993No ratings yet

- ASTM E18 (2019) - Part36Document1 pageASTM E18 (2019) - Part36david4231993No ratings yet

- ASTM E384 (2022) - Part1Document1 pageASTM E384 (2022) - Part1david4231993No ratings yet

- ASTM E18 (2019) - Part20Document1 pageASTM E18 (2019) - Part20david4231993No ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part33Document1 pageASTM E18 (2019) - Part33david4231993No ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part11Document1 pageASTM E18 (2019) - Part11david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- ASTM E18 (2019) - Part2Document1 pageASTM E18 (2019) - Part2david4231993No ratings yet

- Y5 Existing Endangered ExtinctDocument2 pagesY5 Existing Endangered Extinctsadviau3No ratings yet

- Smaw 12 Module 1Document7 pagesSmaw 12 Module 1Francis Rico Mutia RufonNo ratings yet

- Latent Autoimmune Diabetes in Adults (LADA)Document5 pagesLatent Autoimmune Diabetes in Adults (LADA)Fina Ahmad FitrianaNo ratings yet

- Stability Study of Cocoa Butter Body Scrub Formulated With Ground Cocoa Pod HuskDocument7 pagesStability Study of Cocoa Butter Body Scrub Formulated With Ground Cocoa Pod Huskudiwaluyo waluyoNo ratings yet

- D. Benos vs. LawilaoDocument7 pagesD. Benos vs. Lawilaochuck_0428No ratings yet

- Lumax LED-Presentation PDFDocument31 pagesLumax LED-Presentation PDFSalman HashmiNo ratings yet

- The Environment (Protection) Act, 1986Document38 pagesThe Environment (Protection) Act, 1986Anugya JhaNo ratings yet

- Prelims in NSTP-CWTS 1Document4 pagesPrelims in NSTP-CWTS 1Janes MalaluanNo ratings yet

- Nestle: Nestlé's Mission Statement (R1)Document11 pagesNestle: Nestlé's Mission Statement (R1)Abdul RehmanNo ratings yet

- TXXXXXXXX Zusatzinformation Entsorgung 0enDocument6 pagesTXXXXXXXX Zusatzinformation Entsorgung 0enBeltazor HellboyNo ratings yet

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document30 pagesTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkNo ratings yet

- Reviewer General Physics 1Document1 pageReviewer General Physics 1Asdf GhjNo ratings yet

- Science of Happiness PSYC 201 Syllabus Fall 2014Document7 pagesScience of Happiness PSYC 201 Syllabus Fall 2014gman61693No ratings yet

- FMCG SectorDocument65 pagesFMCG SectordmaxprasangaNo ratings yet

- CV Manat Ryan Hard NababanDocument1 pageCV Manat Ryan Hard NababanmanatNo ratings yet

- ACS Motion Control - Tech80 SB 1381 ManualDocument183 pagesACS Motion Control - Tech80 SB 1381 ManualPsaNo ratings yet

- Engl5 Problem Solution EssayDocument7 pagesEngl5 Problem Solution Essayapi-511280084No ratings yet

- Parle AgroDocument3 pagesParle AgroKumar GautamNo ratings yet

- CyberbullyingDocument8 pagesCyberbullyingQUINTILLA ALEXXA YNA MARINo ratings yet

- Gastroenterology Clinical Focus High Yield Gi and HepatologyDocument426 pagesGastroenterology Clinical Focus High Yield Gi and HepatologyAhana MukherjeeNo ratings yet

- EDGE CEOMrngBrief-22JulyDocument23 pagesEDGE CEOMrngBrief-22JulyApat PadiNo ratings yet

- B2+ Test Series (32) : Name: - Score: - /100Document4 pagesB2+ Test Series (32) : Name: - Score: - /100Ngân Nguyễn Bùi HoaNo ratings yet

- Unraveling PhobiaDocument19 pagesUnraveling PhobiaCounsel IndiaNo ratings yet

- Tape Mobil JVC.Document16 pagesTape Mobil JVC.EdisonNainggolanNo ratings yet

- KFUPM-ME Department ME 460 Thermal Desalination SystemsDocument2 pagesKFUPM-ME Department ME 460 Thermal Desalination SystemsMajid KhanNo ratings yet

- Ahbab Travels & Tours: UMRAH PACKAGE - 2019 - Per Person in 10 Pax GroupDocument3 pagesAhbab Travels & Tours: UMRAH PACKAGE - 2019 - Per Person in 10 Pax GroupWaqi WaqiNo ratings yet

- Water Kiosk DesignDocument1 pageWater Kiosk DesignAbdirahman Mohamed NurNo ratings yet

- MumhospitallistDocument132 pagesMumhospitallistSufiyan KhedekarNo ratings yet

- Total Supply Chain Management Cost Data CollectionDocument4 pagesTotal Supply Chain Management Cost Data CollectionSuhailNo ratings yet