Professional Documents

Culture Documents

ASTM E18 (2019) - Part11

ASTM E18 (2019) - Part11

Uploaded by

david4231993Copyright:

Available Formats

You might also like

- ADHD Test DIVA 5-0Document12 pagesADHD Test DIVA 5-0Augustin Gireada100% (4)

- KASTO 016 (로크웰 경도 시험기) PDFDocument27 pagesKASTO 016 (로크웰 경도 시험기) PDFTJNo ratings yet

- TABLE A1.3 Maximum Allowable Repeatability and Error of Testing Machines For Ranges of Standardized Test BlocksDocument10 pagesTABLE A1.3 Maximum Allowable Repeatability and Error of Testing Machines For Ranges of Standardized Test BlocksDiego VargasNo ratings yet

- ASTM E18 (2019) - Part16Document1 pageASTM E18 (2019) - Part16david4231993No ratings yet

- 7.4 - Dust TestDocument2 pages7.4 - Dust TestCh ShahzadNo ratings yet

- 7.5 - Rain TestDocument2 pages7.5 - Rain TestCh ShahzadNo ratings yet

- Control Valve PerformanceDocument3 pagesControl Valve Performancevon D' synsNo ratings yet

- ASTM E18 (2019) - Part14Document1 pageASTM E18 (2019) - Part14david4231993No ratings yet

- Effect of Friction Modifier On Durability and Fuel Economy/frictional Characteristics of Engine OilDocument5 pagesEffect of Friction Modifier On Durability and Fuel Economy/frictional Characteristics of Engine OilAnandNo ratings yet

- Attribute R&RDocument15 pagesAttribute R&RRabiulNo ratings yet

- Turbomachinery Vibration Monitoring PDFDocument150 pagesTurbomachinery Vibration Monitoring PDFTheerayoot Poomchai100% (4)

- Komatsu PC400LC-7L A86001 TESTDocument408 pagesKomatsu PC400LC-7L A86001 TESTHai Van100% (2)

- Engineering Data Sheet - Amberlite Irc86Document1 pageEngineering Data Sheet - Amberlite Irc86Algirdas BaranauskasNo ratings yet

- Fan Motor D155ax-6 Lmf75 Test 50495Document12 pagesFan Motor D155ax-6 Lmf75 Test 50495Interclima SpaNo ratings yet

- Experiment 2: Determination of Viscosity of Food Products Using ViscometerDocument20 pagesExperiment 2: Determination of Viscosity of Food Products Using ViscometerSyusyu HyNo ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- Data FrekuensiDocument3 pagesData Frekuensistrpembuatan807No ratings yet

- EPE2303 Transmission and Distribution - 9. System ReliabilityDocument43 pagesEPE2303 Transmission and Distribution - 9. System ReliabilityBryan KekNo ratings yet

- UricDocument1 pageUricEnrique DuarteNo ratings yet

- Decoding 2000-2004 Lexus Mode 6 DataDocument3 pagesDecoding 2000-2004 Lexus Mode 6 DataTomNo ratings yet

- Is 1828-1 (Iso 7500-1) - 10Document1 pageIs 1828-1 (Iso 7500-1) - 10Svapnesh ParikhNo ratings yet

- D 6895 - 03 - Rdy4otuDocument5 pagesD 6895 - 03 - Rdy4otuNguyễn Bằng NộiNo ratings yet

- Analisis GranulDocument90 pagesAnalisis GranulPiece AdnanNo ratings yet

- VDOTGearOil TAE 2006Document1 pageVDOTGearOil TAE 2006zinbobo htetNo ratings yet

- Zamora Beltranena Daniel AlejandroDocument7 pagesZamora Beltranena Daniel AlejandroNEUROLAB ESCALÓNNo ratings yet

- Daily Analysis Report 2Document1 pageDaily Analysis Report 2henryakun002No ratings yet

- 8-Maintenance and InspectionDocument10 pages8-Maintenance and InspectionmominzadahNo ratings yet

- Instrument:: Reagent PreparationDocument1 pageInstrument:: Reagent PreparationEnrique DuarteNo ratings yet

- Traction Power ReportDocument1 pageTraction Power ReportPraveen Varma VNo ratings yet

- Analisis Dan Output Data Riska ZulfiahDocument16 pagesAnalisis Dan Output Data Riska ZulfiahWilisMilayantiNo ratings yet

- ENG Manual SX-300 NewDocument24 pagesENG Manual SX-300 NewDiana Alejandra Castañón IniestraNo ratings yet

- RLNEDocument8 pagesRLNENEUROLAB ESCALÓNNo ratings yet

- Shatox SX 200Document13 pagesShatox SX 200Remi MathriqaNo ratings yet

- Anexo IiiDocument24 pagesAnexo IiihelberNo ratings yet

- 4.C Saybolt Universal Viscosity and Viscosity INDEX (ASTM D 88-94 D 2161-93 D 2270-93)Document12 pages4.C Saybolt Universal Viscosity and Viscosity INDEX (ASTM D 88-94 D 2161-93 D 2270-93)Rafid JawadNo ratings yet

- Aka 1Document5 pagesAka 1itd steelNo ratings yet

- Steam Turbine Inspection Schedule MaintenanceDocument3 pagesSteam Turbine Inspection Schedule MaintenanceMELCO JITPLNo ratings yet

- ASTM E18 (2019) - Part10Document1 pageASTM E18 (2019) - Part10david4231993No ratings yet

- US200 User ManualDocument145 pagesUS200 User ManualMoogii MonhNo ratings yet

- Aka 2Document5 pagesAka 2itd steelNo ratings yet

- 7SR224 - Argus Complete Technical Manual (101-200)Document100 pages7SR224 - Argus Complete Technical Manual (101-200)Rosa MiñanoNo ratings yet

- CMC Calibration Recommendation ENUDocument7 pagesCMC Calibration Recommendation ENUkarimiNo ratings yet

- Module 3.0 Analyze Phase - 3.4 Hypothesis Testing With Normal DataDocument15 pagesModule 3.0 Analyze Phase - 3.4 Hypothesis Testing With Normal DataStackwell IndiaNo ratings yet

- 3RN10101CB00 Datasheet enDocument3 pages3RN10101CB00 Datasheet enrajNo ratings yet

- MBA01015Document8 pagesMBA01015Arun .vNo ratings yet

- Shelf-Life FDA OvaisDocument8 pagesShelf-Life FDA OvaisOvais08100% (2)

- 保养标准及检测程序Document20 pages保养标准及检测程序jackNo ratings yet

- Raam p5 3 Fta QuantificationDocument17 pagesRaam p5 3 Fta QuantificationGabo Montaño MendozaNo ratings yet

- Leakage Current Tester: DeviceDocument2 pagesLeakage Current Tester: DeviceJuanNo ratings yet

- Inverter Site Tests - PV Plants Connected at Medium VoltageDocument10 pagesInverter Site Tests - PV Plants Connected at Medium VoltageMay OngNo ratings yet

- EnablingDocument7 pagesEnablingGA LNo ratings yet

- ASTM E18 (2019) - Part9Document1 pageASTM E18 (2019) - Part9david4231993No ratings yet

- Application of CoriolisDocument43 pagesApplication of CoriolisangeljosNo ratings yet

- Tugas SEMDocument20 pagesTugas SEMCLARISSA YOLANDINE GUNAWANNo ratings yet

- Use Historical Data FirstDocument14 pagesUse Historical Data FirstKleber NovaisNo ratings yet

- Guide To Acceptancetestsfor Centrifugalpumps: Chapter-3Document7 pagesGuide To Acceptancetestsfor Centrifugalpumps: Chapter-3Srinivas RaoNo ratings yet

- Anexo IiDocument61 pagesAnexo IihelberNo ratings yet

- Acceptance SamplingDocument35 pagesAcceptance SamplingParas ThakurNo ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- Advanced Calculus: An Introduction to Linear AnalysisFrom EverandAdvanced Calculus: An Introduction to Linear AnalysisNo ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E384 (2022) - Part8Document1 pageASTM E384 (2022) - Part8david4231993No ratings yet

- ASTM E384 (2022) - Part1Document1 pageASTM E384 (2022) - Part1david4231993No ratings yet

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part36Document1 pageASTM E18 (2019) - Part36david4231993No ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- ASTM E18 (2019) - Part39Document1 pageASTM E18 (2019) - Part39david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E18 (2019) - Part33Document1 pageASTM E18 (2019) - Part33david4231993No ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part2Document1 pageASTM E18 (2019) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part20Document1 pageASTM E18 (2019) - Part20david4231993No ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- Capabilities by AircraftDocument48 pagesCapabilities by AircraftApuu Na Juak EhNo ratings yet

- Information: Memory LimitDocument11 pagesInformation: Memory LimitUniverse gamerNo ratings yet

- Comparison of Bond Strength Between A Conventional Resin Adhesive and A Resin-Modified Glass Ionomer Adhesive: An in Vitro and in Vivo Study.Document2 pagesComparison of Bond Strength Between A Conventional Resin Adhesive and A Resin-Modified Glass Ionomer Adhesive: An in Vitro and in Vivo Study.Reliance Orthodontic ProductsNo ratings yet

- Math7 q2 - Module 3Document12 pagesMath7 q2 - Module 3Rou Gee100% (1)

- 1642990216class 9 Questions - Sound ChapterDocument9 pages1642990216class 9 Questions - Sound ChapterMANISHA GARGNo ratings yet

- Pedagogical Approaches in Teaching Bachelor of Elementary Education Teacher-CandidatesDocument12 pagesPedagogical Approaches in Teaching Bachelor of Elementary Education Teacher-CandidatesLee Hock SengNo ratings yet

- 29th Vodafone FinalDocument21 pages29th Vodafone FinalPraveen DeekondaNo ratings yet

- Debt and Growth 1Document12 pagesDebt and Growth 1Mame Mandione Laye BoNo ratings yet

- 16 Decidable CfgsDocument26 pages16 Decidable CfgsHassan BilalNo ratings yet

- Sl. Description Quantity (Unit) Unit Price Specification: 1 4k Ultra HD Smart Android Led TVDocument2 pagesSl. Description Quantity (Unit) Unit Price Specification: 1 4k Ultra HD Smart Android Led TVTausif ChowdhuryNo ratings yet

- Mba ZC415 Course HandoutDocument11 pagesMba ZC415 Course HandoutareanNo ratings yet

- Applied Mechanics (Dynamics)Document4 pagesApplied Mechanics (Dynamics)Adhikari SushilNo ratings yet

- Petersham Road Noise and Vibration SummaryDocument1 pagePetersham Road Noise and Vibration SummaryOnir XavierNo ratings yet

- Figure M 39 Ethanol Water MixtureDocument10 pagesFigure M 39 Ethanol Water MixturediegoNo ratings yet

- C1812 Display Logger DatasheetDocument4 pagesC1812 Display Logger DatasheetselnemaisNo ratings yet

- History of Cities and City PlanningDocument8 pagesHistory of Cities and City PlanningmahnoorNo ratings yet

- Physical Science PowerpointDocument32 pagesPhysical Science PowerpointHoniel091112No ratings yet

- Electrochemical Methods. Fundamentals and ApplicationsDocument5 pagesElectrochemical Methods. Fundamentals and ApplicationsJustin WareNo ratings yet

- Data Analytics Using R-Programming NotesDocument100 pagesData Analytics Using R-Programming NotesSHIKHAR MOHANNo ratings yet

- Risk Assessment For Offshore Refuelling Rev 0Document9 pagesRisk Assessment For Offshore Refuelling Rev 0ringbolt100% (1)

- Bassin Du Gharb GeophysiqueDocument9 pagesBassin Du Gharb GeophysiqueKarim El MorabitiNo ratings yet

- SeaQuantum BrochureDocument12 pagesSeaQuantum BrochureLeo TvrdeNo ratings yet

- 20221219 - 1864152 - UNV【Datasheet】XVR301-G3 Series-V1.02 EN - 958075 - 168459 - 0Document4 pages20221219 - 1864152 - UNV【Datasheet】XVR301-G3 Series-V1.02 EN - 958075 - 168459 - 0kiranaomomNo ratings yet

- Target Bohr's ModelDocument4 pagesTarget Bohr's ModelRavindra ChoudharyNo ratings yet

- Rock Mass Classification SystemDocument165 pagesRock Mass Classification SystemtatekNo ratings yet

- Jehangir Ratanji Dadabhoy (JRD) Tata, Faquir Chand (F C) KohliDocument7 pagesJehangir Ratanji Dadabhoy (JRD) Tata, Faquir Chand (F C) KohliljhkjgufuNo ratings yet

- 3.3 Push-Down AutomataDocument18 pages3.3 Push-Down AutomatatigistyeNo ratings yet

- Activity 1 - Animation History and Career OpportunitiesDocument10 pagesActivity 1 - Animation History and Career OpportunitiesVirgilio FeliciaNo ratings yet

- Fluent-Intro 15.0 WS08b Vortex SheddingDocument39 pagesFluent-Intro 15.0 WS08b Vortex Sheddingmatteo_1234No ratings yet

ASTM E18 (2019) - Part11

ASTM E18 (2019) - Part11

Uploaded by

david4231993Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM E18 (2019) - Part11

ASTM E18 (2019) - Part11

Uploaded by

david4231993Copyright:

Available Formats

E18 − 19

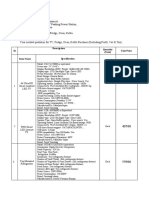

A1.3.4.2 Repeat the hysteresis verification procedure for a TABLE A1.3 Maximum Allowable Repeatability and Error of

maximum of ten measurements and average the last three tests. Testing Machines for Ranges of Standardized Test Blocks

The average measurement shall indicate a hardness number of Maximum Maximum

Range of Standardized

Repeatability, R Error, E

130 6 1.0 Rockwell units when Rockwell ball scales B, E, F, Test BlocksA

(HR units) (HR units)

G, H and K are used, or within 100 6 1.0 Rockwell units when HRA < 70 2.0 ± 1.0

any other Rockwell scale is used. $ 70 and < 80 1.5 ± 1.0

$ 80 1.0 ± 0.5

A1.3.5 Verification of the Testing Cycle—Section 7 specifies HRBW < 60 2.0 ± 2.5

the Rockwell testing cycle by stating requirements and recom- $ 60 and < 88 1.5 ± 2.5

$ 88 1.5 ± 1.0

mendations for five separate parameters of the cycle. The HRC < 35 2.0 ± 1.0

testing machine shall be verified to be capable of meeting the $ 35 and < 60 1.5 ± 1.0

tolerances specified in Table 3 for the following four test cycle $ 60 1.0 ± 0.5

HRD < 51 2.0 ± 1.0

parameters: the dwell time for preliminary force, the time for $ 51 and < 71 1.5 ± 1.0

application of additional force, the dwell time for total force $ 71 1.0 ± 0.5

and the dwell time for elastic recovery. The tolerance for the HREW < 84 1.5 ± 1.0

$ 84 and < 93 1.5 ± 1.0

indenter contact velocity is a recommendation. Direct verifi- $ 93 1.0 ± 1.0

cation of the testing cycle is to be verified by the testing HRFW < 80 1.5 ± 1.0

machine manufacturer at the time of manufacture, and when $ 80 and < 94 1.5 ± 1.0

$ 94 1.0 ± 1.0

the testing machine is returned to the manufacturer for repair HRGW < 55 2.0 ± 1.0

when a problem with the testing cycle is suspected. Verification $ 55 and < 80 2.0 ± 1.0

of the testing cycle is not required as part of the direct $ 80 2.0 ± 1.0

HRHW < 96 2.0 ± 1.0

verification at other times. $ 96 2.0 ± 1.0

A1.3.5.1 Rockwell hardness testing machines manufactured HRKW < 65 1.5 ± 1.0

before the implementation of E18–07 may not have undergone $ 65 and < 85 1.0 ± 1.0

$ 85 1.0 ± 1.0

the direct verification of the machine’s testing cycle. Since this HRLWB 2.0 ± 1.0

verification often must be performed at the manufacturer’s site, HRMWB 2.0 ± 1.0

HRPWB 2.0 ± 1.0

the test cycle verification requirement does not apply to testing HRRWB 2.0 ± 1.0

machines manufactured before the implementation of E18–07, HRSWB 2.0 ± 1.0

unless the testing machine is returned to the manufacturer for HRVWB 2.0 ± 1.0

HR15N < 78 2.0 ± 1.0

repair. $ 78 and < 90 1.5 ± 1.0

A1.3.6 Direct Verification Failure—If any of the direct $ 90 1.0 ± 0.7

HR30N < 55 2.0 ± 1.0

verifications fail the specified requirements, the testing ma- $ 55 and < 77 1.5 ± 1.0

chine shall not be used until it is adjusted or repaired. If the test $ 77 1.0 ± 0.7

forces, depth measuring system, machine hysteresis, or testing HR45N < 37 2.0 ± 1.0

$ 37 and < 66 1.5 ± 1.0

cycle may have been affected by an adjustment or repair, the $ 66 1.0 ± 0.7

affected components shall be verified again by direct verifica- HR15TW < 81 2.0 ± 1.5

tion. $ 81 and < 87 1.5 ± 1.0

$ 87 1.5 ± 1.0

A1.3.7 An indirect verification shall follow a successful HR30TW < 57 2.0 ± 1.5

$ 57 and < 70 1.5 ± 1.0

direct verification. $ 70 1.5 ± 1.0

HR45TW < 33 2.0 ± 1.5

A1.4 Indirect Verification $ 33 and < 53 1.5 ± 1.0

$ 53 1.5 ± 1.0

A1.4.1 An indirect verification of the testing machine shall HR15WWB 2.0 ± 1.0

be performed, at a minimum, in accordance with the schedule HR30WWB 2.0 ± 1.0

HR45WWB 2.0 ± 1.0

given in Table A1.1. The frequency of indirect verifications HR15XWB 2.0 ± 1.0

should be based on the usage of the testing machine. HR30XWB 2.0 ± 1.0

HR45XWB 2.0 ± 1.0

A1.4.2 The testing machine shall be verified for each HR15YWB 2.0 ± 1.0

Rockwell scale that will be used prior to the next indirect HR30YWB 2.0 ± 1.0

verification. Hardness tests made using Rockwell scales that HR45YWB 2.0 ± 1.0

A

have not been verified within the schedule given in Table A1.1 The user may find that high, medium and low range test blocks are unavailable

commercially for some scales. In these cases one or two standardized blocks

do not meet this standard. where available may be used. It is recommended that all high range test blocks for

A1.4.3 Standardized test blocks meeting the requirements Rockwell scales using a ball indenter should be less than 100 HR units.

B

Appropriate ranges of standardized test blocks for the L, M, P, R, S, V, W, X, and

of Annex A4 (see Note 4) shall be used in the appropriate Y scales shall be determined by dividing the usable range of the scale into two

hardness ranges for each scale to be verified. These ranges are ranges, if possible.

given in Table A1.3. Hardness measurements shall be made

only on the calibrated surface of the test block.

Copyright ASTM International

Provided by IHS Markit under license with ASTM

11

No reproduction or networking permitted without license from IHS

You might also like

- ADHD Test DIVA 5-0Document12 pagesADHD Test DIVA 5-0Augustin Gireada100% (4)

- KASTO 016 (로크웰 경도 시험기) PDFDocument27 pagesKASTO 016 (로크웰 경도 시험기) PDFTJNo ratings yet

- TABLE A1.3 Maximum Allowable Repeatability and Error of Testing Machines For Ranges of Standardized Test BlocksDocument10 pagesTABLE A1.3 Maximum Allowable Repeatability and Error of Testing Machines For Ranges of Standardized Test BlocksDiego VargasNo ratings yet

- ASTM E18 (2019) - Part16Document1 pageASTM E18 (2019) - Part16david4231993No ratings yet

- 7.4 - Dust TestDocument2 pages7.4 - Dust TestCh ShahzadNo ratings yet

- 7.5 - Rain TestDocument2 pages7.5 - Rain TestCh ShahzadNo ratings yet

- Control Valve PerformanceDocument3 pagesControl Valve Performancevon D' synsNo ratings yet

- ASTM E18 (2019) - Part14Document1 pageASTM E18 (2019) - Part14david4231993No ratings yet

- Effect of Friction Modifier On Durability and Fuel Economy/frictional Characteristics of Engine OilDocument5 pagesEffect of Friction Modifier On Durability and Fuel Economy/frictional Characteristics of Engine OilAnandNo ratings yet

- Attribute R&RDocument15 pagesAttribute R&RRabiulNo ratings yet

- Turbomachinery Vibration Monitoring PDFDocument150 pagesTurbomachinery Vibration Monitoring PDFTheerayoot Poomchai100% (4)

- Komatsu PC400LC-7L A86001 TESTDocument408 pagesKomatsu PC400LC-7L A86001 TESTHai Van100% (2)

- Engineering Data Sheet - Amberlite Irc86Document1 pageEngineering Data Sheet - Amberlite Irc86Algirdas BaranauskasNo ratings yet

- Fan Motor D155ax-6 Lmf75 Test 50495Document12 pagesFan Motor D155ax-6 Lmf75 Test 50495Interclima SpaNo ratings yet

- Experiment 2: Determination of Viscosity of Food Products Using ViscometerDocument20 pagesExperiment 2: Determination of Viscosity of Food Products Using ViscometerSyusyu HyNo ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- Data FrekuensiDocument3 pagesData Frekuensistrpembuatan807No ratings yet

- EPE2303 Transmission and Distribution - 9. System ReliabilityDocument43 pagesEPE2303 Transmission and Distribution - 9. System ReliabilityBryan KekNo ratings yet

- UricDocument1 pageUricEnrique DuarteNo ratings yet

- Decoding 2000-2004 Lexus Mode 6 DataDocument3 pagesDecoding 2000-2004 Lexus Mode 6 DataTomNo ratings yet

- Is 1828-1 (Iso 7500-1) - 10Document1 pageIs 1828-1 (Iso 7500-1) - 10Svapnesh ParikhNo ratings yet

- D 6895 - 03 - Rdy4otuDocument5 pagesD 6895 - 03 - Rdy4otuNguyễn Bằng NộiNo ratings yet

- Analisis GranulDocument90 pagesAnalisis GranulPiece AdnanNo ratings yet

- VDOTGearOil TAE 2006Document1 pageVDOTGearOil TAE 2006zinbobo htetNo ratings yet

- Zamora Beltranena Daniel AlejandroDocument7 pagesZamora Beltranena Daniel AlejandroNEUROLAB ESCALÓNNo ratings yet

- Daily Analysis Report 2Document1 pageDaily Analysis Report 2henryakun002No ratings yet

- 8-Maintenance and InspectionDocument10 pages8-Maintenance and InspectionmominzadahNo ratings yet

- Instrument:: Reagent PreparationDocument1 pageInstrument:: Reagent PreparationEnrique DuarteNo ratings yet

- Traction Power ReportDocument1 pageTraction Power ReportPraveen Varma VNo ratings yet

- Analisis Dan Output Data Riska ZulfiahDocument16 pagesAnalisis Dan Output Data Riska ZulfiahWilisMilayantiNo ratings yet

- ENG Manual SX-300 NewDocument24 pagesENG Manual SX-300 NewDiana Alejandra Castañón IniestraNo ratings yet

- RLNEDocument8 pagesRLNENEUROLAB ESCALÓNNo ratings yet

- Shatox SX 200Document13 pagesShatox SX 200Remi MathriqaNo ratings yet

- Anexo IiiDocument24 pagesAnexo IiihelberNo ratings yet

- 4.C Saybolt Universal Viscosity and Viscosity INDEX (ASTM D 88-94 D 2161-93 D 2270-93)Document12 pages4.C Saybolt Universal Viscosity and Viscosity INDEX (ASTM D 88-94 D 2161-93 D 2270-93)Rafid JawadNo ratings yet

- Aka 1Document5 pagesAka 1itd steelNo ratings yet

- Steam Turbine Inspection Schedule MaintenanceDocument3 pagesSteam Turbine Inspection Schedule MaintenanceMELCO JITPLNo ratings yet

- ASTM E18 (2019) - Part10Document1 pageASTM E18 (2019) - Part10david4231993No ratings yet

- US200 User ManualDocument145 pagesUS200 User ManualMoogii MonhNo ratings yet

- Aka 2Document5 pagesAka 2itd steelNo ratings yet

- 7SR224 - Argus Complete Technical Manual (101-200)Document100 pages7SR224 - Argus Complete Technical Manual (101-200)Rosa MiñanoNo ratings yet

- CMC Calibration Recommendation ENUDocument7 pagesCMC Calibration Recommendation ENUkarimiNo ratings yet

- Module 3.0 Analyze Phase - 3.4 Hypothesis Testing With Normal DataDocument15 pagesModule 3.0 Analyze Phase - 3.4 Hypothesis Testing With Normal DataStackwell IndiaNo ratings yet

- 3RN10101CB00 Datasheet enDocument3 pages3RN10101CB00 Datasheet enrajNo ratings yet

- MBA01015Document8 pagesMBA01015Arun .vNo ratings yet

- Shelf-Life FDA OvaisDocument8 pagesShelf-Life FDA OvaisOvais08100% (2)

- 保养标准及检测程序Document20 pages保养标准及检测程序jackNo ratings yet

- Raam p5 3 Fta QuantificationDocument17 pagesRaam p5 3 Fta QuantificationGabo Montaño MendozaNo ratings yet

- Leakage Current Tester: DeviceDocument2 pagesLeakage Current Tester: DeviceJuanNo ratings yet

- Inverter Site Tests - PV Plants Connected at Medium VoltageDocument10 pagesInverter Site Tests - PV Plants Connected at Medium VoltageMay OngNo ratings yet

- EnablingDocument7 pagesEnablingGA LNo ratings yet

- ASTM E18 (2019) - Part9Document1 pageASTM E18 (2019) - Part9david4231993No ratings yet

- Application of CoriolisDocument43 pagesApplication of CoriolisangeljosNo ratings yet

- Tugas SEMDocument20 pagesTugas SEMCLARISSA YOLANDINE GUNAWANNo ratings yet

- Use Historical Data FirstDocument14 pagesUse Historical Data FirstKleber NovaisNo ratings yet

- Guide To Acceptancetestsfor Centrifugalpumps: Chapter-3Document7 pagesGuide To Acceptancetestsfor Centrifugalpumps: Chapter-3Srinivas RaoNo ratings yet

- Anexo IiDocument61 pagesAnexo IihelberNo ratings yet

- Acceptance SamplingDocument35 pagesAcceptance SamplingParas ThakurNo ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- Advanced Calculus: An Introduction to Linear AnalysisFrom EverandAdvanced Calculus: An Introduction to Linear AnalysisNo ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E384 (2022) - Part8Document1 pageASTM E384 (2022) - Part8david4231993No ratings yet

- ASTM E384 (2022) - Part1Document1 pageASTM E384 (2022) - Part1david4231993No ratings yet

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part36Document1 pageASTM E18 (2019) - Part36david4231993No ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- ASTM E18 (2019) - Part39Document1 pageASTM E18 (2019) - Part39david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E18 (2019) - Part33Document1 pageASTM E18 (2019) - Part33david4231993No ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part2Document1 pageASTM E18 (2019) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part20Document1 pageASTM E18 (2019) - Part20david4231993No ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- Capabilities by AircraftDocument48 pagesCapabilities by AircraftApuu Na Juak EhNo ratings yet

- Information: Memory LimitDocument11 pagesInformation: Memory LimitUniverse gamerNo ratings yet

- Comparison of Bond Strength Between A Conventional Resin Adhesive and A Resin-Modified Glass Ionomer Adhesive: An in Vitro and in Vivo Study.Document2 pagesComparison of Bond Strength Between A Conventional Resin Adhesive and A Resin-Modified Glass Ionomer Adhesive: An in Vitro and in Vivo Study.Reliance Orthodontic ProductsNo ratings yet

- Math7 q2 - Module 3Document12 pagesMath7 q2 - Module 3Rou Gee100% (1)

- 1642990216class 9 Questions - Sound ChapterDocument9 pages1642990216class 9 Questions - Sound ChapterMANISHA GARGNo ratings yet

- Pedagogical Approaches in Teaching Bachelor of Elementary Education Teacher-CandidatesDocument12 pagesPedagogical Approaches in Teaching Bachelor of Elementary Education Teacher-CandidatesLee Hock SengNo ratings yet

- 29th Vodafone FinalDocument21 pages29th Vodafone FinalPraveen DeekondaNo ratings yet

- Debt and Growth 1Document12 pagesDebt and Growth 1Mame Mandione Laye BoNo ratings yet

- 16 Decidable CfgsDocument26 pages16 Decidable CfgsHassan BilalNo ratings yet

- Sl. Description Quantity (Unit) Unit Price Specification: 1 4k Ultra HD Smart Android Led TVDocument2 pagesSl. Description Quantity (Unit) Unit Price Specification: 1 4k Ultra HD Smart Android Led TVTausif ChowdhuryNo ratings yet

- Mba ZC415 Course HandoutDocument11 pagesMba ZC415 Course HandoutareanNo ratings yet

- Applied Mechanics (Dynamics)Document4 pagesApplied Mechanics (Dynamics)Adhikari SushilNo ratings yet

- Petersham Road Noise and Vibration SummaryDocument1 pagePetersham Road Noise and Vibration SummaryOnir XavierNo ratings yet

- Figure M 39 Ethanol Water MixtureDocument10 pagesFigure M 39 Ethanol Water MixturediegoNo ratings yet

- C1812 Display Logger DatasheetDocument4 pagesC1812 Display Logger DatasheetselnemaisNo ratings yet

- History of Cities and City PlanningDocument8 pagesHistory of Cities and City PlanningmahnoorNo ratings yet

- Physical Science PowerpointDocument32 pagesPhysical Science PowerpointHoniel091112No ratings yet

- Electrochemical Methods. Fundamentals and ApplicationsDocument5 pagesElectrochemical Methods. Fundamentals and ApplicationsJustin WareNo ratings yet

- Data Analytics Using R-Programming NotesDocument100 pagesData Analytics Using R-Programming NotesSHIKHAR MOHANNo ratings yet

- Risk Assessment For Offshore Refuelling Rev 0Document9 pagesRisk Assessment For Offshore Refuelling Rev 0ringbolt100% (1)

- Bassin Du Gharb GeophysiqueDocument9 pagesBassin Du Gharb GeophysiqueKarim El MorabitiNo ratings yet

- SeaQuantum BrochureDocument12 pagesSeaQuantum BrochureLeo TvrdeNo ratings yet

- 20221219 - 1864152 - UNV【Datasheet】XVR301-G3 Series-V1.02 EN - 958075 - 168459 - 0Document4 pages20221219 - 1864152 - UNV【Datasheet】XVR301-G3 Series-V1.02 EN - 958075 - 168459 - 0kiranaomomNo ratings yet

- Target Bohr's ModelDocument4 pagesTarget Bohr's ModelRavindra ChoudharyNo ratings yet

- Rock Mass Classification SystemDocument165 pagesRock Mass Classification SystemtatekNo ratings yet

- Jehangir Ratanji Dadabhoy (JRD) Tata, Faquir Chand (F C) KohliDocument7 pagesJehangir Ratanji Dadabhoy (JRD) Tata, Faquir Chand (F C) KohliljhkjgufuNo ratings yet

- 3.3 Push-Down AutomataDocument18 pages3.3 Push-Down AutomatatigistyeNo ratings yet

- Activity 1 - Animation History and Career OpportunitiesDocument10 pagesActivity 1 - Animation History and Career OpportunitiesVirgilio FeliciaNo ratings yet

- Fluent-Intro 15.0 WS08b Vortex SheddingDocument39 pagesFluent-Intro 15.0 WS08b Vortex Sheddingmatteo_1234No ratings yet