Professional Documents

Culture Documents

ASTM E18 (2019) - Part16

ASTM E18 (2019) - Part16

Uploaded by

david4231993Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM E18 (2019) - Part16

ASTM E18 (2019) - Part16

Uploaded by

david4231993Copyright:

Available Formats

E18 − 19

hysteresis verification is to perform a purely elastic test that A2.6.3.2 Standardized test blocks shall be used in the

results in no permanent indentation. In this way, the level of appropriate hardness ranges for each scale to be verified. These

hysteresis in the flexure of the testing machine can be deter- ranges are given in Table A2.6. The standardizing testing

mined. machine shall not be adjusted during the indirect verification

A2.6.2.9 Perform repeated Rockwell tests using a blunt procedures.

indenter (or the indenter holder surface) acting directly onto the

anvil or a very hard test piece. The tests shall be conducted on TABLE A2.6 Maximum Allowable Repeatability and Error of

a Rockwell scale having the highest test force that is used for Standardizing Machines

normal standardizations. Maximum Maximum

Range of Standardized

A2.6.2.10 Repeat the hysteresis tests for a maximum of ten Test Blocks

Repeatability, R Error, E

measurements and average the last three tests. The average (HR units) (HR units)

measurement shall indicate a hardness number within HRA 20 to 65 1.0 ± 0.5

70 to 78 0.7 ± 0.5

130 6 0.3 Rockwell units when Rockwell ball scales B, E, F, 80 to 84 0.5 ± 0.3

G, H and K are used, or within 100 6 0.3 Rockwell units when HRBW 40 to 59 1.0 ± 0.7

60 to 79 0.7 ± 0.5

any other Rockwell scale is used. 80 to 100 0.7 ± 0.5

A2.6.2.11 Direct Verification Failure—If any of the direct HRC 20 to 30 1.0 ± 0.5

verifications fail the specified requirements, the standardizing 35 to 55 0.7 ± 0.5

60 to 65 0.5 ± 0.3

machine shall not be used until it is adjusted or repaired. Any HRD 40 to 48 1.0 ± 0.5

parameter that may have been affected by an adjustment or 51 to 67 0.7 ± 0.5

repair shall be verified again by direct verification. 71 to 75 0.5 ± 0.3

HREW 70 to 79 0.7 ± 0.5

A2.6.3 Indirect Verification—Indirect verification involves 84 to 90 0.7 ± 0.5

verifying the performance of the standardizing machine by 93 to 100 0.5 ± 0.5

HRFW 60 to 75 0.7 ± 0.5

means of standardized test blocks and indenters. Prior to 80 to 90 0.7 ± 0.5

performing standardizations for any Rockwell scale, an indi- 94 to 100 0.5 ± 0.5

rect verification of the standardizing machine for that scale HRGW 30 to 50 1.0 ± 0.5

55 to 75 1.0 ± 0.5

shall be made within the time period given in Table A2.3. A 80 to 94 1.0 ± 0.5

selected number of Rockwell scales shall be indirectly verified HRHW 80 to 94 1.0 ± 0.5

96 to 100 1.0 ± 0.5

at the time of the direct verification as described below. The HRKW 40 to 60 0.7 ± 0.5

indirect verification of all other Rockwell scales may be made 65 to 80 0.5 ± 0.5

at any time as long as it occurs within the time period given in 85 to 100 0.5 ± 0.5

HRLWA 1.0 ± 0.5

Table A2.3 prior to standardization. HRMWA 1.0 ± 0.5

A2.6.3.1 Immediately following the direct verification, in- HRPWA 1.0 ± 0.5

direct verifications of a selected number of scales shall be HRRWA 1.0 ± 0.5

HRSWA 1.0 ± 0.5

performed to determine the performance of the standardizing HRVWA 1.0 ± 0.5

machine at each force level that the standardizing machine is HR15N 70 to 77 1.0 ± 0.5

capable of applying. An example of an indirect verification for 78 to 88 0.7 ± 0.5

90 to 92 0.5 ± 0.4

a standardizing machine capable of applying all force levels is HR30N 42 to 50 1.0 ± 0.5

given in Table A2.5. It is recommended that Rockwell scales be 55 to 73 0.7 ± 0.5

chosen that will also verify each indenter that will be used. 77 to 82 0.5 ± 0.4

HR45N 20 to 31 1.0 ± 0.5

When national primary standardized test blocks (see Note 37 to 61 0.7 ± 0.5

A2.1) are available, they should be used for the periodic 66 to 72 0.5 ± 0.4

indirect verification. HR15TW 74 to 80 1.0 ± 0.7

81 to 86 0.7 ± 0.5

NOTE A2.1—Primary standardized test blocks are certified at the 87 to 93 0.7 ± 0.5

national standardizing laboratory level. In the United States, the national HR30TW 43 to 56 1.0 ± 0.7

57 to 69 0.7 ± 0.5

Rockwell hardness standardizing laboratory is the National Institute of

70 to 83 0.7 ± 0.5

Standards and Technology (NIST), Gaithersburg, MD 20899. HR45TW 13 to 32 1.0 ± 0.7

33 to 52 0.7 ± 0.5

53 to 73 0.7 ± 0.5

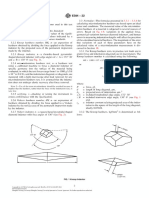

TABLE A2.5 Suggested Rockwell Scales for the Indirect HR15WWA 1.0 ± 0.5

Verification of Machines Capable of Performing Both Regular and HR30WWA 1.0 ± 0.5

HR45WWA 1.0 ± 0.5

Superficial Scale Tests and that Will Use Only Diamond and

HR15XWA 1.0 ± 0.5

1/16 in. (1.588 mm) Diameter Carbide Ball Indenters HR30XWA 1.0 ± 0.5

Preliminary Force Total Force Indenter Rockwell HR45XWA 1.0 ± 0.5

kgf (N) kgf (N) Type Scale HR15YWA 1.0 ± 0.5

HR30YWA 1.0 ± 0.5

10 (98.07) 60 (588.4) diamond HRA

HR45YWA 1.0 ± 0.5

10 (98.07) 100 (980.7) ⁄ in. ball

1 16 HRB

A

10 (98.07) 150 (1471) diamond HRC Appropriate ranges of standardized test blocks for the L, M, P, R, S, V, W, X, and

3 (29.42) 15 (147.1) diamond HR15N Y scales shall be determined by dividing the usable range of the scale into two

3 (29.42) 30 (294.2) 1⁄16 in. ball HR30T ranges, high and low. Standardized test blocks for the R and S scales may be

3 (29.42) 45 (441.3) diamond HR45N available at only one hardness level.

Copyright ASTM International

Provided by IHS Markit under license with ASTM

16

No reproduction or networking permitted without license from IHS

You might also like

- CT Calculation & BEF Report ICADocument24 pagesCT Calculation & BEF Report ICALim EugeneNo ratings yet

- Lab 9 - Motion of FluidsDocument8 pagesLab 9 - Motion of Fluidsconstantine1106No ratings yet

- Controlabilidade FullDocument71 pagesControlabilidade FullRafael SouzaNo ratings yet

- KASTO 016 (로크웰 경도 시험기) PDFDocument27 pagesKASTO 016 (로크웰 경도 시험기) PDFTJNo ratings yet

- 26.9 Seismic Qualification Testing of TransformerDocument3 pages26.9 Seismic Qualification Testing of Transformerkrmurali2000No ratings yet

- Iec 61000-4-15-2010 Ish1-2017Document1 pageIec 61000-4-15-2010 Ish1-2017Venkataramanan S100% (1)

- ASTM E18 (2019) - Part11Document1 pageASTM E18 (2019) - Part11david4231993No ratings yet

- TABLE A1.3 Maximum Allowable Repeatability and Error of Testing Machines For Ranges of Standardized Test BlocksDocument10 pagesTABLE A1.3 Maximum Allowable Repeatability and Error of Testing Machines For Ranges of Standardized Test BlocksDiego VargasNo ratings yet

- ASTM E18 (2019) - Part15Document1 pageASTM E18 (2019) - Part15david4231993No ratings yet

- Is 1828-1 (Iso 7500-1) - 10Document1 pageIs 1828-1 (Iso 7500-1) - 10Svapnesh ParikhNo ratings yet

- ASTM E18 (2019) - Part4Document1 pageASTM E18 (2019) - Part4david4231993No ratings yet

- ASTM E18 (2019) - Part10Document1 pageASTM E18 (2019) - Part10david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- 7.4 - Dust TestDocument2 pages7.4 - Dust TestCh ShahzadNo ratings yet

- ASTM E18 (2019) - Part14Document1 pageASTM E18 (2019) - Part14david4231993No ratings yet

- Tugas SEMDocument20 pagesTugas SEMCLARISSA YOLANDINE GUNAWANNo ratings yet

- 7.5 - Rain TestDocument2 pages7.5 - Rain TestCh ShahzadNo ratings yet

- 975-1043-Matrix Ilc-1017Document1 page975-1043-Matrix Ilc-1017KiranNo ratings yet

- ASTM E18 (2019) - Part9Document1 pageASTM E18 (2019) - Part9david4231993No ratings yet

- Bas en Iso 6507-3Document15 pagesBas en Iso 6507-3Владимир ТрифковићNo ratings yet

- SOP No. 10 Recommended Standard Operating Procedure For Calibration of Rigid RulesDocument9 pagesSOP No. 10 Recommended Standard Operating Procedure For Calibration of Rigid RuleslukasjoNo ratings yet

- Leakage Current Tester: DeviceDocument2 pagesLeakage Current Tester: DeviceJuanNo ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part32Document1 pageASTM E18 (2019) - Part32david4231993No ratings yet

- ASTM E18 (2019) - Part13Document1 pageASTM E18 (2019) - Part13david4231993No ratings yet

- Tolerance CalibrationDocument29 pagesTolerance CalibrationSunil GurubaxaniNo ratings yet

- TABLE 1 Precision of Test On ResidueDocument1 pageTABLE 1 Precision of Test On ResidueJOSE CANTERONo ratings yet

- Calibration Unit: Special FeaturesDocument2 pagesCalibration Unit: Special FeaturesAndres Camilo Salazar Latorre.No ratings yet

- R Is The Resolution ofDocument3 pagesR Is The Resolution ofrp801113717No ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- Engineering Data Sheet - Amberlite Irc86Document1 pageEngineering Data Sheet - Amberlite Irc86Algirdas BaranauskasNo ratings yet

- Jawaban UJIAN BiostatistikDocument5 pagesJawaban UJIAN Biostatistikirvan syahmilNo ratings yet

- ASTM E74 ExplainedDocument62 pagesASTM E74 ExplainedCharlo GordoNo ratings yet

- Experiment 2: Determination of Viscosity of Food Products Using ViscometerDocument20 pagesExperiment 2: Determination of Viscosity of Food Products Using ViscometerSyusyu HyNo ratings yet

- Rockwell Hardness of Graphite Materials: Standard Test Method ForDocument3 pagesRockwell Hardness of Graphite Materials: Standard Test Method ForLabeed ShamilNo ratings yet

- Square Edged Orifice MeterDocument3 pagesSquare Edged Orifice Metervijay kumar honnaliNo ratings yet

- Annex K (Informative) Guide For Specification Writers: Optional Provision Typical SpecificationDocument2 pagesAnnex K (Informative) Guide For Specification Writers: Optional Provision Typical SpecificationGedalías MartínezNo ratings yet

- Uji ValitditasDocument4 pagesUji ValitditasThomas Brilian DanikaNo ratings yet

- Crosstabs: Kriteria Produk Kriteria Keputusan Pemanfaatan CrosstabulationDocument7 pagesCrosstabs: Kriteria Produk Kriteria Keputusan Pemanfaatan Crosstabulationdayat hidayatNo ratings yet

- Calibration PresentationDocument25 pagesCalibration Presentationchirag patelNo ratings yet

- Astm B 647 2000Document3 pagesAstm B 647 2000serkaninanNo ratings yet

- CDAX 605: High-Precision Capacitance and Dissipation Factor Measurement InstrumentDocument3 pagesCDAX 605: High-Precision Capacitance and Dissipation Factor Measurement InstrumentErhan KarabasNo ratings yet

- The Need For Adequate Sampling in A Well-Functioning Market Surveillance SystemDocument14 pagesThe Need For Adequate Sampling in A Well-Functioning Market Surveillance SystemhendrikxiNo ratings yet

- VDOTGearOil TAE 2006Document1 pageVDOTGearOil TAE 2006zinbobo htetNo ratings yet

- Instron Verification and Calibration Services in North AmericaDocument6 pagesInstron Verification and Calibration Services in North AmericaLuân Nguyễn QuỳnhNo ratings yet

- UricDocument1 pageUricEnrique DuarteNo ratings yet

- C748-98 (2015) Standard Test Method For Rockwell Hardness of Graphite MaterialsDocument3 pagesC748-98 (2015) Standard Test Method For Rockwell Hardness of Graphite MaterialsDuc Nguyen VanNo ratings yet

- Free Digital Multimeter Calibration ProcedureDocument10 pagesFree Digital Multimeter Calibration ProcedureGordinhorsNo ratings yet

- 249-317 Tec Aero Tue-C-100-293Document1 page249-317 Tec Aero Tue-C-100-293KiranNo ratings yet

- Explore: Lampiran Uji NormalitasDocument8 pagesExplore: Lampiran Uji NormalitasIrfan SyahroniNo ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- Dokumen - Tips - Introduction To Gage RRDocument17 pagesDokumen - Tips - Introduction To Gage RRSNC NewsNo ratings yet

- MMI Training Viscosity Referrel ASTM D341Document12 pagesMMI Training Viscosity Referrel ASTM D341gabo mangoNo ratings yet

- Turbomachinery Vibration Monitoring PDFDocument150 pagesTurbomachinery Vibration Monitoring PDFTheerayoot Poomchai100% (4)

- Statistik JilidDocument25 pagesStatistik Jilidrisda hanifa rahmanNo ratings yet

- Calibrador SV 111 - SiDocument2 pagesCalibrador SV 111 - SiluisNo ratings yet

- SOP No. 33 Standard Operating Procedure For Calibration of Weight CartsDocument15 pagesSOP No. 33 Standard Operating Procedure For Calibration of Weight CartsMashruk AhamadNo ratings yet

- Test Charts Machines For Surface Grinding With Two Columns For Grinding SlidewaysDocument16 pagesTest Charts Machines For Surface Grinding With Two Columns For Grinding SlidewaysBVS NAGABABUNo ratings yet

- RR Gage MsaDocument2 pagesRR Gage MsaIsaac SaldañaNo ratings yet

- Nistspecialpublication960 5Document124 pagesNistspecialpublication960 5nehal3788090No ratings yet

- Shall Be Prohibited: Annex K - Alternative Technique Piping Porosity RT Recommended To Supplement UTDocument36 pagesShall Be Prohibited: Annex K - Alternative Technique Piping Porosity RT Recommended To Supplement UTAnu AnoopNo ratings yet

- RExp Life STARTDocument6 pagesRExp Life STARTManutenção MGFCNo ratings yet

- Anexo L Aws D1 1Document2 pagesAnexo L Aws D1 1Pacco HmNo ratings yet

- Advanced Calculus: An Introduction to Linear AnalysisFrom EverandAdvanced Calculus: An Introduction to Linear AnalysisNo ratings yet

- ASTM E384 (2022) - Part9Document1 pageASTM E384 (2022) - Part9david4231993No ratings yet

- ASTM E384 (2022) - Part8Document1 pageASTM E384 (2022) - Part8david4231993No ratings yet

- ASTM E384 (2022) - Part6Document1 pageASTM E384 (2022) - Part6david4231993No ratings yet

- ASTM E384 (2022) - Part2Document1 pageASTM E384 (2022) - Part2david4231993No ratings yet

- ASTM E18 (2019) - Part38Document1 pageASTM E18 (2019) - Part38david4231993No ratings yet

- ASTM E18 (2019) - Part39Document1 pageASTM E18 (2019) - Part39david4231993No ratings yet

- ASTM E18 (2019) - Part36Document1 pageASTM E18 (2019) - Part36david4231993No ratings yet

- ASTM E384 (2022) - Part1Document1 pageASTM E384 (2022) - Part1david4231993No ratings yet

- ASTM E18 (2019) - Part33Document1 pageASTM E18 (2019) - Part33david4231993No ratings yet

- ASTM E18 (2019) - Part35Document1 pageASTM E18 (2019) - Part35david4231993No ratings yet

- ASTM E18 (2019) - Part29Document1 pageASTM E18 (2019) - Part29david4231993No ratings yet

- ASTM E18 (2019) - Part34Document1 pageASTM E18 (2019) - Part34david4231993No ratings yet

- ASTM E18 (2019) - Part27Document1 pageASTM E18 (2019) - Part27david4231993No ratings yet

- ASTM E18 (2019) - Part3Document1 pageASTM E18 (2019) - Part3david4231993No ratings yet

- ASTM E18 (2019) - Part22Document1 pageASTM E18 (2019) - Part22david4231993No ratings yet

- ASTM E18 (2019) - Part18Document1 pageASTM E18 (2019) - Part18david4231993No ratings yet

- ASTM E18 (2019) - Part20Document1 pageASTM E18 (2019) - Part20david4231993No ratings yet

- ASTM E18 (2019) - Part11Document1 pageASTM E18 (2019) - Part11david4231993No ratings yet

- ASTM E18 (2019) - Part17Document1 pageASTM E18 (2019) - Part17david4231993No ratings yet

- ASTM E18 (2019) - Part2Document1 pageASTM E18 (2019) - Part2david4231993No ratings yet

- Use of GNSS in Land Surveying and Mapping - 3rd EditionDocument63 pagesUse of GNSS in Land Surveying and Mapping - 3rd EditionNKOSILAMI EMMANUEL BENSON MGUNINo ratings yet

- Thermodynamics Chapter 1Document36 pagesThermodynamics Chapter 1WILYNo ratings yet

- Final Exam - Calculus - PhysicsDocument27 pagesFinal Exam - Calculus - Physicsarvie montemayorNo ratings yet

- TDS 11594139 Performance Test Standards KitDocument4 pagesTDS 11594139 Performance Test Standards KitSamuel SuNo ratings yet

- Footstep Power Generation SystemDocument6 pagesFootstep Power Generation SystemIJRASETPublicationsNo ratings yet

- An Introduction To Auger Electron SpectrosDocument25 pagesAn Introduction To Auger Electron SpectrosWinta BreaNo ratings yet

- Prismatic Open Channel SolutionsDocument27 pagesPrismatic Open Channel SolutionsresearchditNo ratings yet

- Product Information: Toshiba X-Ray Tube D-063 / D-063R / D-063S / D-063SRDocument10 pagesProduct Information: Toshiba X-Ray Tube D-063 / D-063R / D-063S / D-063SRKamilNo ratings yet

- t6 - Wood Physical PropertiesDocument56 pagest6 - Wood Physical PropertiesSYVESTER ANDI ANAK JEKI / UPMNo ratings yet

- ClassificationDocument7 pagesClassificationj9048191078No ratings yet

- QUIZ Chemistry SlidesDocument206 pagesQUIZ Chemistry SlidesVAIBHAV VAIBHAVNo ratings yet

- (Antim Yudh) - Namo Sir - 22febDocument55 pages(Antim Yudh) - Namo Sir - 22febNamo KaulNo ratings yet

- Work Energy and PowerDocument13 pagesWork Energy and PowerLlama jennerNo ratings yet

- Investigationof PMVModelfor Evaluationofthe Outdoor ThermalcomfortDocument7 pagesInvestigationof PMVModelfor Evaluationofthe Outdoor ThermalcomfortHendra CesmamulyaNo ratings yet

- NTi Audio Impedance Testing of Evacuation SystemsDocument9 pagesNTi Audio Impedance Testing of Evacuation SystemsSuperhypoNo ratings yet

- Well Control BasicsDocument23 pagesWell Control BasicsBendali MehdiNo ratings yet

- A Phase-Shift PWM-controlled ZVS Boost Full-Bridge AC-AC Converter For Metal-Surface High-Frequency Induction Heating ApplicationsDocument7 pagesA Phase-Shift PWM-controlled ZVS Boost Full-Bridge AC-AC Converter For Metal-Surface High-Frequency Induction Heating ApplicationsRAMESH JUNJUNo ratings yet

- Phy CH 8 Final 9thDocument28 pagesPhy CH 8 Final 9thmastersahb302No ratings yet

- Electric Charges & Fields. Full Notes21Document15 pagesElectric Charges & Fields. Full Notes21DHANUSH PATEL .MNo ratings yet

- Chapter 6 ElectricityDocument27 pagesChapter 6 ElectricityDom Christian LastNo ratings yet

- 45KW 4P DatasheetDocument5 pages45KW 4P Datasheetvitthal01No ratings yet

- Electrical Data: General Data:: Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument1 pageElectrical Data: General Data:: Data Sheet For Three-Phase Squirrel-Cage-MotorsSalih Ahmed ObeidNo ratings yet

- TEST B MCQsDocument83 pagesTEST B MCQsMaanat Hemant BhadaniNo ratings yet

- ACSEE Physics F5 T4 PropertiesOfMatterDocument4 pagesACSEE Physics F5 T4 PropertiesOfMatterEmmanuel MarijaniNo ratings yet

- MCAT Physics Question PracticeDocument3 pagesMCAT Physics Question PracticeThao NguyenNo ratings yet

- Technical Data of The Fan: RZR 13-1250: To Motor: Siemens-IE3 1LE1003-1CC03-4AB4/IE3Document3 pagesTechnical Data of The Fan: RZR 13-1250: To Motor: Siemens-IE3 1LE1003-1CC03-4AB4/IE3mahmadwasiNo ratings yet