Professional Documents

Culture Documents

Tuv It 14 Atex 060X

Tuv It 14 Atex 060X

Uploaded by

Thughu GhuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tuv It 14 Atex 060X

Tuv It 14 Atex 060X

Uploaded by

Thughu GhuCopyright:

Available Formats

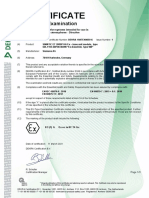

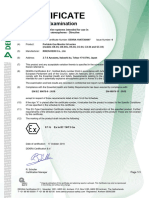

CERTIFICATE

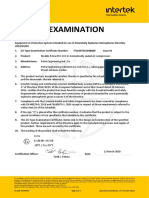

[1] EU-TYPE EXAMINATION CERTIFICATE

[2] Equipment or Protective System intended for use

in potentially explosive atmospheres

Directive 2014/34/EU

[3] EU-Type Examination Certificate number:

TÜV IT 14 ATEX 060 X Rev.1

[4] Equipment or Protective System: Three-phase asynchronous motor type AMD(T)500

[5] Manufacturer: ABB S.p.A.

[6] Address: Viale Dell’Industria, 18

I-20010 Vittuone (MI) * ITALY

[7] This equipment or protective system and any acceptable variation thereto is specified in the

schedule to this certificate and the documents therein referred to.

[8] TÜV Italia, notified body no. 0948 in accordance with Article 17 of Directive 2014/34/EU of the

European Parliament and of the Council, dated 26 February 2014, certifies that this product

has been found to comply with the Essential Health and Safety Requirements relating to the

design and construction of products intended for use in potentially explosive atmospheres

given in Annex II to the Directive.

The examination and test results are recorded in confidential report no. R 14 EX 048

[9] Compliance with the Essential Health and Safety Requirements has been assured by

compliance with:

EN 60079-0:2012+A11:2013; EN60079-1:2014;

EN60079-7:2015+A1:2018; EN60079-11:2012; EN60079-31:2014

[10] If the sign "X" is placed after the certificate number, it indicates that the equipment or protective

system is subject to special conditions for safe use specified in the schedule to this certificate.

[11] This EU - TYPE EXAMINATION CERTIFICATE relates only to the design and construction of

the specified product. Further requirements of the Directive apply to the manufacturing process

and supply of this product. These are not covered by this certificate.

[12] The marking of the product shall include the following:

I M2 Ex db I Mb

II 2G Ex db IIC (or IIB) T4...T3 Gb or

II 2G Ex db eb IIC (or IIB) T4…T3 Gb or

II 2G Ex db ib IIC (or IIB) T4…T3 Gb or

II 2G Ex db eb ib IIC (or IIB) T4…T3 Gb or

II 2D Ex tb IIIC T125°C…T150°C Db

This certificate may only be reproduced in its entirety and without any change, schedule included.

Issue date: 20th September 2018

TÜV Italia S.r.l.

Notified Body N° 0948

Alberto Carelli

Industry Service - Real Estate & Infrastructure

Managing Director

TÜV Italia has been authorized by Italian government to operate as notified body for the certification of equipment or protective

system intended for use in potentially explosive atmospheres. This document is not valid without official signature and logo. The

internal reference code is 722135568. page 1 of 6

PEX-01-M002_r07 del 29/03/2018

[13] SCHEDULE

[14] EU-TYPE EXAMINATION CERTIFICATE

No. TÜV IT 14 ATEX 060 X Rev.1

Certificate History

Revision: Description: Report no: Issue Date:

- First issue - 22/10/2014

Directive and standards updated;

Dust protection and mining service

included;

1 1 20/09/2018

IP degree updated;

Ex separately certified components

and equipment list updated;

[15] Description of equipment

The 3-phase induction motors AMD (T) series, have shaft height 500 mm, with a

bundle of tubes around the frame for air-air cooling (IC511).

If technically required, the cooling air can be forced within the tubes by means of a

separated motor-fan (IC516).

The motors are designed and manufactured in accordance with the protection modes

Ex db or Ex db eb (protection type Ex db eb, when Ex eb certified main terminal

boxes are mounted), for gas groups IIB or IIC and with temperature classes T4 or T3,

mechanical protection degree IP55, IP65 or IP66.

The motors are available in the configurations 2 or more poles.

The main features of the motors are: closed type machine, frame including the bundle

of cooling tubes, self-ventilation or with forced ventilation.

The motors are made with separate compartments for motor, for supply and/or star

point terminal box and for the auxiliary terminal box.

The motors can be equipped with auxiliary devices (motor space heaters, thermal

detectors, vibration sensors, etc.).

The mounting arrangements can be IM1001 (horizontal axis, frame with feet and 1

shaft end), IM1002 (horizontal axis, frame with feet and 2 shaft ends) or IM4011

(vertical axis with shaft end on the lower side).

If requested, stator winding RTDs Ex-i certified as “Ex component” are mounted, the

motor marking becomes as follow:

II 2G Ex db ib IIC (or IIB) T4…T3 Gb

II 2G Ex db eb ib IIC (or IIB) T4…T3 Gb

The RTD element shall be connected with intrinsically safe system according to

EN60079-25 by “ia” or “ib” intrinsically safe device according to EN60079-11.

This certificate may only be reproduced in its entirety and without any change, schedule included.

page 2 of 6

PEX-01-M002_r07 del 29/03/2018

[13] SCHEDULE

[14] EU-TYPE EXAMINATION CERTIFICATE

No. TÜV IT 14 ATEX 060 X Rev.1

Type code:

Rated characteristics

- Maximum power: 1300 kW

The rated power of the various types of motors as a function of poles number, rated

voltage, duty type, temperature class, ambient temperature and type of supply with all

the other electrical characteristics and tolerance prescribed by EN/IEC 60034-0, are

defined by ABB in conformity with characteristics limit here indicated.

The maximum current must be compatible with the values permitted by insulators

bushings and/or line connections used.

- Maximum rated voltage: 11 kV for Ex db eb motors / 13.8 kV for Ex d motors

Supply voltage up to 13.8 kV is available using the Ex d IIB terminal box “segregated

phases” type.

- Rated frequency: 50/60 Hz

- Number of poles: 2 or more

- Duty: S1/S10

The motors with S2 duty can have a maximum power greater than the above limit

according with the following multiplying factor kW (a):

Power level for 60 min a < = 1.15

Power level for 20 min a < = 1.4

- Max. rotational speed: 3600 r.p.m.

- Insulation Class: F (thermal class B or F)

- Ambient temperature: -55°C to +60°C or -40°C to +60°C or -20°C to +60°C

The motor can be designed in three different versions regarding the ingress protection

level:

- IP55 (motor with sleeve bearing. IP testing at IPX5 comply with IEC 60034-5 and

IEC 60079-0)

- IP65 (motor with antifriction bearing. IP testing at IPX6 comply with IEC 60034-5 and

IEC 60079-0))

- IP66 (motor with antifriction bearing. IP testing at IPX6 comply with IEC 60034-5.

This certificate may only be reproduced in its entirety and without any change, schedule included.

page 3 of 6

PEX-01-M002_r07 del 29/03/2018

[13] SCHEDULE

[14] EU-TYPE EXAMINATION CERTIFICATE

No. TÜV IT 14 ATEX 060 X Rev.1

Terminal boxes satisfy IP66 according with their component certificates.

Supply by frequency converter

- Max. rated voltage for Ex d motor : 11.0 kV rms

- Max. rated voltage for Ex db eb motor : 9.0 kV rms; 14 kV peak

- Max. rotational speed : 3600 r.p.m.

- Tamb = -20°C to +60°C or Tamb = -40°C to +60°C or Tamb = -55°C to +60°C

Note 1: Maximum ambient temperature can be reduced to temperature less than +60

°C (as example Tamb = -20°C to +40°C)

The motors designed for operation with frequency converter are equipped with

temperature detectors place inside the stator winding. The operation of the thermal

detector shall guarantee the disconnection of the supply; the resetting of the supply

shall not be automatic. When forced ventilation by auxiliary motor is used, the

operation of the primary motor shall be interlocked to the correct operation of the

forced ventilation.

The temperature measuring devices have the following settings:

Stator winding with insulation class F and temperature limit of class B (T4):

- 125°C Alarm / 130°C Trip

Stator winding with insulation class F (T3):

- 145°C Alarm / 150°C Trip

Bearing:

- 90°C Alarm / 100°C Trip

The resetting of the power supply shall not be automatic.

Warning label

“Restore silicone grease at every opening”

“Use screws quality 8.8 ISO R 898 / I-II ” or

“Use screws ASTM A320 L7”

In case of use of anti condensate heaters:

“Attention: energized resistors”

In case the equipment should be suitable for installation in areas with potential

presence of IIC gas a suitable label will report:

“Warning: potential electrostatic charging hazard – see manual”

[16] Report no. R 14 EX 048

This certificate may only be reproduced in its entirety and without any change, schedule included.

page 4 of 6

PEX-01-M002_r07 del 29/03/2018

[13] SCHEDULE

[14] EU-TYPE EXAMINATION CERTIFICATE

No. TÜV IT 14 ATEX 060 X Rev.1

Routine tests

Minimum ambient temperature to -55°C: the overpressure test on the motor enclosure

shall be carried out at 36 bar for gas group IIC and 31 bar for gas group IIB with static

method (EN60079-1 standard).

Minimum ambient temperature to -40°C: the overpressure test on the motor enclosure

shall be carried out at 33 bar for gas group IIC and 29 bar for gas group IIB with static

method (EN60079-1 standard).

Minimum ambient temperature to -20°C the overpressure test on the motor enclosure

shall be carried out at 20 bar for gas group IIC and 15 bar for gas group IIB with static

method (EN60079-1 standard).

Mining service: values of static overpressure for gas group IIB shall be applied.

The overpressure test on the Ex d mains and auxiliary terminal boxes shall be carried

out at the pressure value reported in the relevant certificates.

Motor with Ex eb terminal box: dielectric strenght test according to EN60079-7 shall

be performed at (2Un+1000)V for at least 60 seconds or 1.2x(2Un+1000)V for at least

100 ms. (Un= rated voltage of the motor).

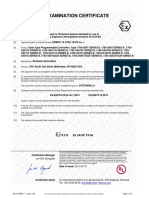

[17] Special conditions for safe use

When Ex-i thermal detectors in the stator windings are used, they (RTDs) must be

connected to an appropriate intrinsically safe system. They must be tested at 500V

to ground and must be grounded whenever dielectric testing of the machine takes

place.

When CT are fitted, for the neutral terminal arrangement the following applies:

adequate precautions shall be taken to ensure that the CT secondaries have a load

connected at all time.

When space heaters are fitted, they have to be interlocked such that they can only

be energized when the motor is de energized.

The flame paths are specified in the manufacturer drawings. For information

regarding the dimension of the flameproof joints the manufacturer shall be contacted.

In order to minimize the risk of hazards caused by electrostatic charges, clean the

motor only with a wet rag or by non-frictional means.

The bearing automatic lubricators shall be started at the same time with the same

settings.

This certificate may only be reproduced in its entirety and without any change, schedule included.

page 5 of 6

PEX-01-M002_r07 del 29/03/2018

[13] SCHEDULE

[14] EU-TYPE EXAMINATION CERTIFICATE

No. TÜV IT 14 ATEX 060 X Rev.1

[18] Essential Health and Safety Requirements

Assured by compliance with the standards set out in the [9].

[19] Drawings and Documents

Listed documents (prot. 240983 + 722135568)

Title: Description: Pages: Rev: Date:

190/ATEX-

Technical Note 32 00 03/09/2014

IECEx/2014

Technical Note

204/ATEX/2016 20 B 05/06/2018

(Certification amendment)

016-ATEX-IEC-

Safety Instruction Manual 20 F 15/09/2017

AMD MOTORS

ABB/186 – 14

Declaration of conformity 01 A 25/10/2016

ATEX060X

General assembly (Antifriction

M519026 02 n.a. 27/05/2014

bearings)

Details Antifriction bearings

M519028 02 n.a. 27/05/2014

assembly

General assembly (Sleeve

M519029 01 n.a. 27/05/2014

bearings)

Details Sleeve bearings

M510879 02 n.a. 12/07/2010

assembly

MTB coupling with motor

M519032 frame (IIB Group) and (IIC 02 n.a. 27/05/2014

Group)

Coupling Aux. terminal box

M519030 01 n.a. 27/05/2014

with motor frame

M500475 Electric motor fan assembly 02 A 28/01/2010

Assembly temperature controls

M500486 01 A 28/01/2010

in the bearings

Plate with instruction for

M500430 01 A 28/09/2009

grease replacement

M500428 Grounding terminals 03 B 28/09/2009

Intermediate enclosure

M514239 02 B 21/10/2015

coupling with motor frame

3GZF500728-34 Shaft sealing 01 B 11/12/2001

3AFP9168732-

Protection cup 01 A 12/03/2018

001

3AFP9178396- Fan Cover Protection for

01 A 22/06/2018

001 Mining application

Fan Cover Protection for

M502532 01 A 22/06/2018

not-mining application

Stator winding Ex-i RTDs

n.a. 07 00 22/03/2012

description

One copy of all documents is kept in TÜV Italia files.

This certificate may only be reproduced in its entirety and without any change, schedule included.

page 6 of 6

PEX-01-M002_r07 del 29/03/2018

You might also like

- 02 BMWActiveHybridX6Document118 pages02 BMWActiveHybridX6Damian Creque100% (3)

- DEMKO 18 ATEX 1986X Rev. 4Document3 pagesDEMKO 18 ATEX 1986X Rev. 4sefazNo ratings yet

- IECEx BAS 10.0099X 009Document6 pagesIECEx BAS 10.0099X 009ESTEBAN DUARTE VIDESNo ratings yet

- 3.0 en-US 2013-10 PL.N3312Document24 pages3.0 en-US 2013-10 PL.N3312Pablo Rincón UrreaNo ratings yet

- TUV IT 13 ATEX 038 X Rev.2Document5 pagesTUV IT 13 ATEX 038 X Rev.2Johnny_Icahn_2021No ratings yet

- Certificate TUV IT 19 ATEX 026 X (May-2019)Document5 pagesCertificate TUV IT 19 ATEX 026 X (May-2019)Mr. RfNo ratings yet

- ACr63-r315L-TUV IT 14 ATEX-050X Eng - Rev.7Document19 pagesACr63-r315L-TUV IT 14 ATEX-050X Eng - Rev.7ratheesh vidyadharanNo ratings yet

- SA Equip SAF35 ITS SA CYCLONE EX ATEX CertificateDocument3 pagesSA Equip SAF35 ITS SA CYCLONE EX ATEX CertificateMuhammad ImanNo ratings yet

- TÜV IT 18 ATEX 030 Q Rev.1Document2 pagesTÜV IT 18 ATEX 030 Q Rev.1tarek.amirecheNo ratings yet

- Imq 10 Atex 018 X - en - Rev Dic IcDocument3 pagesImq 10 Atex 018 X - en - Rev Dic IcarissaNo ratings yet

- Uni Ex CertificatesDocument20 pagesUni Ex Certificatesfelix vicente pellicer martinezNo ratings yet

- Demko - 08 Atex 0726988 XDocument3 pagesDemko - 08 Atex 0726988 Xbxrzcx8m8nNo ratings yet

- Dekra 20 Atex 0100 XDocument3 pagesDekra 20 Atex 0100 XdennisNo ratings yet

- ATEX Certificate 047Document4 pagesATEX Certificate 047arissaNo ratings yet

- Siemens - Ex-BaseUnit, Type X1Document3 pagesSiemens - Ex-BaseUnit, Type X1Herbert RitzerNo ratings yet

- Eu-Type Examination: CertificateDocument3 pagesEu-Type Examination: CertificateDnyDnyNo ratings yet

- Certificate: EU-Type ExaminationDocument3 pagesCertificate: EU-Type ExaminationdennisNo ratings yet

- Acf 4787088Document4 pagesAcf 4787088meeNo ratings yet

- Siemens - Ex-BaseUnit, Type W0Document3 pagesSiemens - Ex-BaseUnit, Type W0Herbert RitzerNo ratings yet

- PMD75 AtexDocument4 pagesPMD75 AtexHOOMAN afaghiNo ratings yet

- Abb PF Purge ControllerDocument6 pagesAbb PF Purge ControllerxentrerNo ratings yet

- Eu-Type Examination Certificate: e e e e e e e e e e e eDocument4 pagesEu-Type Examination Certificate: e e e e e e e e e e e eBaoLCNo ratings yet

- EU Type Examination Certificate CML 19ATEX1192X Issue 0Document8 pagesEU Type Examination Certificate CML 19ATEX1192X Issue 0secondharbour ChinaNo ratings yet

- Kema02atex1006 Ultrasonic Level Trans.Document2 pagesKema02atex1006 Ultrasonic Level Trans.josip miskovicNo ratings yet

- IECEx INE 12.0010X 002Document9 pagesIECEx INE 12.0010X 002Marcos SiqueiraNo ratings yet

- Ed 0016Document3 pagesEd 0016Nausheed SahebNo ratings yet

- ATEX RPA455xDocument4 pagesATEX RPA455xFabio Emanuele BrandaNo ratings yet

- Dekra 21ukex0304uDocument2 pagesDekra 21ukex0304uBazli Raja ShahrumNo ratings yet

- Laboratorio Oficial J. M. Madariaga: Supplementary Eu-Type Examination CertificateDocument3 pagesLaboratorio Oficial J. M. Madariaga: Supplementary Eu-Type Examination CertificateDilara Azqila YasminNo ratings yet

- ITS09ATEX26868X Issue 6Document4 pagesITS09ATEX26868X Issue 6Amine DabbabiNo ratings yet

- Honeywell BW Gasalert Extreme Certificado Atex en SG Jun 17Document2 pagesHoneywell BW Gasalert Extreme Certificado Atex en SG Jun 17barroco.polvoaNo ratings yet

- G2X Certificate ATEX 1Document2 pagesG2X Certificate ATEX 1Iwan NugrohoNo ratings yet

- Ec-Type Examination Certificate: DEMKO 12 ATEX 1263925XDocument3 pagesEc-Type Examination Certificate: DEMKO 12 ATEX 1263925XleunamsayanNo ratings yet

- UP2000 ATEX II CertificationDocument6 pagesUP2000 ATEX II CertificationGeorgeNo ratings yet

- IECEx INE 12.0037X 001Document10 pagesIECEx INE 12.0037X 001Marcos SiqueiraNo ratings yet

- IECEx INE 12.0038X 001Document9 pagesIECEx INE 12.0038X 001Marcos SiqueiraNo ratings yet

- Ec-Type Examination Certificate: Ii 2 GD Ex D Iic T6 GB Ex TB IIIC T80°C DB IP66 Tamb - 20°C To +60°CDocument3 pagesEc-Type Examination Certificate: Ii 2 GD Ex D Iic T6 GB Ex TB IIIC T80°C DB IP66 Tamb - 20°C To +60°Ctuandanhbk10No ratings yet

- DNV2001OSLATEX0176Document5 pagesDNV2001OSLATEX0176Matheus Scofield PachecoNo ratings yet

- Inxpect SRE 200 Series EC-Type - 3 - 00022 - enDocument4 pagesInxpect SRE 200 Series EC-Type - 3 - 00022 - enMaximiliano CascoNo ratings yet

- 04ATEX1249 Iss9 - EDocument7 pages04ATEX1249 Iss9 - EIonut Iulian VieruNo ratings yet

- Type Examination Certificate:: 1201 South 2nd StreetDocument3 pagesType Examination Certificate:: 1201 South 2nd StreetJohn Armely Arias GuerreroNo ratings yet

- 04 Series ATEX DEKRA 19ATEX0097 Issue No.0Document3 pages04 Series ATEX DEKRA 19ATEX0097 Issue No.0Johnson WickyNo ratings yet

- MM5016E EMx40 Rev05 ENGDocument24 pagesMM5016E EMx40 Rev05 ENGKaleem Khan100% (1)

- Test ReportDocument61 pagesTest ReportAlif AdiraNo ratings yet

- CML 21UKEX3099 Iss.0 SignedDocument15 pagesCML 21UKEX3099 Iss.0 SignedXavier LefebvreNo ratings yet

- DEMKO 17 ATEX 1823X Rev. 1Document3 pagesDEMKO 17 ATEX 1823X Rev. 1Carlos MolinaNo ratings yet

- Siemens - Ex-AI 4xTC 2RTD 2-3-4wireDocument3 pagesSiemens - Ex-AI 4xTC 2RTD 2-3-4wireHerbert RitzerNo ratings yet

- Eu-Type Examination CertificateDocument5 pagesEu-Type Examination CertificatePhan Cao An TruongNo ratings yet

- IECEx BAS 10.0045X 004Document6 pagesIECEx BAS 10.0045X 004ESTEBAN DUARTE VIDESNo ratings yet

- DEMKO 16 ATEX 1706U Rev 0 XCEX XCESX IIB H2 20 3591Document3 pagesDEMKO 16 ATEX 1706U Rev 0 XCEX XCESX IIB H2 20 3591Zaki ElsayedNo ratings yet

- Iecex Imq 15.0002XDocument23 pagesIecex Imq 15.0002XFrancesco_CNo ratings yet

- A5E Estnisch PS2 BAkompakt Et-ETDocument294 pagesA5E Estnisch PS2 BAkompakt Et-ETMushfiqur RahmanNo ratings yet

- LDsq08 - 0607 - 0135 - 22 R METROPLAST PRO 2000 ENGLISH REPORTDocument4 pagesLDsq08 - 0607 - 0135 - 22 R METROPLAST PRO 2000 ENGLISH REPORTphmassomaNo ratings yet

- Iecex Certificate of ConformityDocument5 pagesIecex Certificate of ConformityFrancesco_CNo ratings yet

- ITS19ATEX104888X Issue 01Document3 pagesITS19ATEX104888X Issue 01tareqNo ratings yet

- IECEx_FIDI_20.0001X_003Document12 pagesIECEx_FIDI_20.0001X_003Tareq JildehNo ratings yet

- ATEX Ex H ITS16ATEX101534X KM26Document4 pagesATEX Ex H ITS16ATEX101534X KM26ROGELIO QUIJANONo ratings yet

- Iecex Tun 11.0038uDocument6 pagesIecex Tun 11.0038uFrancesco_CNo ratings yet

- Dekra 20atex0105xDocument4 pagesDekra 20atex0105xIonut Iulian VieruNo ratings yet

- Ze Dekra Atex Sqex2 Whex1 Ed6 enDocument14 pagesZe Dekra Atex Sqex2 Whex1 Ed6 enriegel94No ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Product Brief PC sn810 Nvme SSDDocument2 pagesProduct Brief PC sn810 Nvme SSDThughu GhuNo ratings yet

- Miele DGD4635 User ManualDocument104 pagesMiele DGD4635 User ManualThughu GhuNo ratings yet

- Solenoid Valve 22 Type 32302 Series 210 Stainless Steel Internal ThreadDocument2 pagesSolenoid Valve 22 Type 32302 Series 210 Stainless Steel Internal ThreadThughu GhuNo ratings yet

- Cemp MotorDocument23 pagesCemp MotorThughu GhuNo ratings yet

- Manual 750 662 000003 PDF 5b2803f4e207bDocument134 pagesManual 750 662 000003 PDF 5b2803f4e207bThughu GhuNo ratings yet

- CEMP Electric Motors IE1 IE2 IE3 IE4 Catalogue r21Document99 pagesCEMP Electric Motors IE1 IE2 IE3 IE4 Catalogue r21Thughu GhuNo ratings yet

- Im 40447 en Minitrac 31 4 20 Ma Hart Four Wire 2021 03 04Document92 pagesIm 40447 en Minitrac 31 4 20 Ma Hart Four Wire 2021 03 04Thughu GhuNo ratings yet

- Cemp MotorDocument5 pagesCemp MotorThughu GhuNo ratings yet

- GZFM6016-Cable ColumnDocument2 pagesGZFM6016-Cable ColumnThughu GhuNo ratings yet

- Genesis Line Brochure PDFDocument2 pagesGenesis Line Brochure PDFThughu GhuNo ratings yet

- Frame Color Options: CardioDocument3 pagesFrame Color Options: CardioThughu GhuNo ratings yet

- Owner's Manual: Lat MachineDocument16 pagesOwner's Manual: Lat MachineThughu GhuNo ratings yet

- The Flemish Housing Rental Decree 2019Document56 pagesThe Flemish Housing Rental Decree 2019Thughu GhuNo ratings yet

- Nl/En Biochemistry Chemistry Electronicsict Elektromecha Ma em Clinical Ma em Mechanics Ma em Manufacturing Ma em Mobility Ma Bi Applied MB&BT Ma Bi BiomedicalDocument2 pagesNl/En Biochemistry Chemistry Electronicsict Elektromecha Ma em Clinical Ma em Mechanics Ma em Manufacturing Ma em Mobility Ma Bi Applied MB&BT Ma Bi BiomedicalThughu GhuNo ratings yet

- 2 Hoja de Especificacion Pressure VesselDocument1 page2 Hoja de Especificacion Pressure VesselThughu GhuNo ratings yet

- MethanolDocument1 pageMethanolThughu GhuNo ratings yet

- Omega Electronics-Jaipur Mobile Robotics: Industrial Training - 2009Document52 pagesOmega Electronics-Jaipur Mobile Robotics: Industrial Training - 2009Raj K. GoyalNo ratings yet

- 2020 Germanjet Catalog E V1 PDFDocument72 pages2020 Germanjet Catalog E V1 PDFMannan AbdulNo ratings yet

- Installation Manual: Nera F77Document56 pagesInstallation Manual: Nera F77Bhavin DoshiNo ratings yet

- Pioneer DJ Mixer Djm-5000Document158 pagesPioneer DJ Mixer Djm-5000nikola1660No ratings yet

- 6002x FinalReview S2012Document77 pages6002x FinalReview S2012deepakhimmatNo ratings yet

- Cap. 6 - Fire Protection General InformationDocument8 pagesCap. 6 - Fire Protection General InformationtanaureNo ratings yet

- Perseus Examples Radio420Document46 pagesPerseus Examples Radio420rcollins06181675No ratings yet

- PVI VeCoax Pro4 HDMI To QAM HD Digital RF Modulator SpecificationsDocument5 pagesPVI VeCoax Pro4 HDMI To QAM HD Digital RF Modulator SpecificationsDavid WardNo ratings yet

- Drager Narkomed 4 Installation of Ultrasonic Flow SensorDocument13 pagesDrager Narkomed 4 Installation of Ultrasonic Flow Sensorsamlu71No ratings yet

- CSECEEEEINSTR F241 PROGRAMMING & Â - 1 PDFDocument7 pagesCSECEEEEINSTR F241 PROGRAMMING & Â - 1 PDFAjay DhamijaNo ratings yet

- ENER002-2PI User Guide PDFDocument2 pagesENER002-2PI User Guide PDFlujorebNo ratings yet

- Analysisof Photovoltaic Panel Temperature Effectsonits EfficiencyDocument7 pagesAnalysisof Photovoltaic Panel Temperature Effectsonits EfficiencyNhacaNo ratings yet

- Gc2300 SeriesDocument19 pagesGc2300 SeriesRyan DosseyNo ratings yet

- Xjtag Product List enDocument2 pagesXjtag Product List enkmrchetan94No ratings yet

- Vip 410Document224 pagesVip 410Zoltan50% (2)

- GB 2012-2013 E01 - Web-VersjonDocument252 pagesGB 2012-2013 E01 - Web-VersjonTasmanijskaNema100% (1)

- TMCM-1231 Hardware Manual hw1.1 Rev1.02Document25 pagesTMCM-1231 Hardware Manual hw1.1 Rev1.02Ian MechuraNo ratings yet

- Lound Speaker ExDocument1 pageLound Speaker ExMihai MateiNo ratings yet

- 1912 - Achelous UT P 2016 Datasheet PDFDocument15 pages1912 - Achelous UT P 2016 Datasheet PDFGaneshNo ratings yet

- Linkchamp Company File Eng 349851Document13 pagesLinkchamp Company File Eng 349851jeferson lageNo ratings yet

- Datasheet - ST 6245 - MICRO TWINGO 1998-2000 PDFDocument72 pagesDatasheet - ST 6245 - MICRO TWINGO 1998-2000 PDFGERARDONo ratings yet

- UK Tutorial MotorControl PDFDocument27 pagesUK Tutorial MotorControl PDFDefinal ChaniagoNo ratings yet

- 3DPrintMill User Manua V2 2021-01-11Document24 pages3DPrintMill User Manua V2 2021-01-11David Morales MarsalNo ratings yet

- T40 Main Components Warranty Periods List-2Document2 pagesT40 Main Components Warranty Periods List-2pedro manjarres figueredoNo ratings yet

- Versatile MegawattageDocument6 pagesVersatile MegawattagessnivashanNo ratings yet

- RB433AH PresentationDocument8 pagesRB433AH PresentationXavier PazNo ratings yet

- Covalent Review and Training Center Electronics RM 203 929 Consuelo Bldg. N. Reyes St. Sampaloc Manila. (Near FEU) Contact # 09477357168 AC CircuitsDocument2 pagesCovalent Review and Training Center Electronics RM 203 929 Consuelo Bldg. N. Reyes St. Sampaloc Manila. (Near FEU) Contact # 09477357168 AC CircuitsEugene Embalzado Jr.No ratings yet

- Digital Communication Systems (ECE4001) : Dr. Thomas JosephDocument55 pagesDigital Communication Systems (ECE4001) : Dr. Thomas JosephWINORLOSENo ratings yet

- Inductance of Transmission LineDocument12 pagesInductance of Transmission LineGian CoderisNo ratings yet