Professional Documents

Culture Documents

HWD0134

HWD0134

Uploaded by

Edwin Jalanoca LlaulliCopyright:

Available Formats

You might also like

- Radio Calculators & Code Decoding for all brandsDocument16 pagesRadio Calculators & Code Decoding for all brandsOBD-IINo ratings yet

- Technical Specification Main WarehouseDocument4 pagesTechnical Specification Main Warehouseadr_kharisma100% (2)

- MS Excel - Grade 5Document14 pagesMS Excel - Grade 5Marvin Rinon100% (1)

- HWD0194Document2 pagesHWD0194Ever Nina LauraNo ratings yet

- U412 - 2 HourDocument4 pagesU412 - 2 Hourmaher58No ratings yet

- De Servicio Freightliner fl70 Service Manual PDFDocument5 pagesDe Servicio Freightliner fl70 Service Manual PDForlandolanchipa67% (3)

- DDX-DDXP-PDX-PDXP-QDX Instruction Book & Part ListDocument13 pagesDDX-DDXP-PDX-PDXP-QDX Instruction Book & Part Listdj22500No ratings yet

- Sistema UL HWD0079 Junta 2 Hrs DrywallDocument2 pagesSistema UL HWD0079 Junta 2 Hrs DrywallRaul Fernando Villarreal VargasNo ratings yet

- System No. C-AJ-2898Document2 pagesSystem No. C-AJ-2898darwish.hiltiNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- CAJ1427Document1 pageCAJ1427mr. mydNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 pagesSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlNo ratings yet

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDNo ratings yet

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamNo ratings yet

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlNo ratings yet

- WL1167Document1 pageWL1167Juvenal GutierrezNo ratings yet

- Ul HWD 0209Document2 pagesUl HWD 0209jlledwinestebanNo ratings yet

- CAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626Document8 pagesCAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626shama093No ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2320Document1 pageSystem PDF Files - 1. UL and cUL Systems - fc2320Emanuel PastlNo ratings yet

- CAJ1317Document1 pageCAJ1317Luis AlbertoNo ratings yet

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 pagesÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoNo ratings yet

- Super Firetemp: Fire Protection SystemsDocument6 pagesSuper Firetemp: Fire Protection SystemstimetemasekNo ratings yet

- C-AJ-2834 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2834 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- HW-D-0038 - 1 of 1: 3M Fire Protection ProductsDocument1 pageHW-D-0038 - 1 of 1: 3M Fire Protection Productskirollos HabibNo ratings yet

- Approval Document ASSET DOC LOC 716Document2 pagesApproval Document ASSET DOC LOC 716fazil yoosufNo ratings yet

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersDocument2 pagesDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimNo ratings yet

- ProSTUD UL V477Document8 pagesProSTUD UL V477K PreitoNo ratings yet

- FC-2000 1.5 Hour Curtain Fire DampersDocument6 pagesFC-2000 1.5 Hour Curtain Fire DampersnuqNo ratings yet

- System No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Document2 pagesSystem No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Lea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- Fabrication Standard of Duct-AcDocument5 pagesFabrication Standard of Duct-AcVicky KumarNo ratings yet

- Approval Document ASSET DOC LOC 145Document2 pagesApproval Document ASSET DOC LOC 145Amir IqbalNo ratings yet

- HW D 0187Document2 pagesHW D 0187Luiggi Zuñiga BarahonaNo ratings yet

- Ulc I523-Cfs JoistDocument2 pagesUlc I523-Cfs JoistSumeet patelNo ratings yet

- FM Design 628 (FB-4003)Document2 pagesFM Design 628 (FB-4003)raviNo ratings yet

- Max 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyDocument2 pagesMax 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyvikaspisalNo ratings yet

- Ductwork SystemDocument8 pagesDuctwork SystemrkssNo ratings yet

- Section 082808hs High Security Perimeter Spec PDFDocument7 pagesSection 082808hs High Security Perimeter Spec PDFمحمد عبد السلام الصوافNo ratings yet

- Fire Stop Design 673Document4 pagesFire Stop Design 673raviNo ratings yet

- Marine Switchboards Main and AuxDocument15 pagesMarine Switchboards Main and AuxBharatiyulam100% (3)

- Specification SmartFenceDocument3 pagesSpecification SmartFenceVimala PonnusamyNo ratings yet

- CAJ1066 Multiples MTDocument1 pageCAJ1066 Multiples MTEdwin G Garcia ChNo ratings yet

- C-AJ-2813 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2813 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- C Aj 2586 PDFDocument1 pageC Aj 2586 PDFEmanuel PastlNo ratings yet

- WL7223Document1 pageWL7223Juvenal GutierrezNo ratings yet

- Duct Bank InformationDocument19 pagesDuct Bank InformationGaneshNo ratings yet

- 2013 Mason Ancon MDC BracketsDocument36 pages2013 Mason Ancon MDC BracketsalwezalokNo ratings yet

- Impasse 2 SpecDocument3 pagesImpasse 2 SpeckavitaNo ratings yet

- Metal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsDocument5 pagesMetal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsAlvaro MejiaNo ratings yet

- Retain: Spare PartsDocument1 pageRetain: Spare PartsAhmed Mohamed Abd ElhakamNo ratings yet

- Technical SpecificationDocument12 pagesTechnical SpecificationAnkit Somani100% (1)

- Powertrack Catalogue 07Document8 pagesPowertrack Catalogue 07w0nderd0gNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- System No. W-J-5116: F Rating - 2 HR T Rating - 1 HRDocument2 pagesSystem No. W-J-5116: F Rating - 2 HR T Rating - 1 HRArulNo ratings yet

- XHEZ.C-AJ-7029 - UL Product IqDocument3 pagesXHEZ.C-AJ-7029 - UL Product Iqfazil yoosufNo ratings yet

- D-22 المواصفة المحدثة للاعمدة المدورةDocument12 pagesD-22 المواصفة المحدثة للاعمدة المدورةAhmed Al-BaghdadiNo ratings yet

- W L 1176Document1 pageW L 1176shama093No ratings yet

- Installation Instructions: Supplied As A Complete Fire-Rated Enclosure To Ensure ComplianceDocument1 pageInstallation Instructions: Supplied As A Complete Fire-Rated Enclosure To Ensure ComplianceAnonymous 59kfV93pf4No ratings yet

- Duct Wrap Architect Specification - 0Document5 pagesDuct Wrap Architect Specification - 0Javed BhattiNo ratings yet

- Cranerunwaybeams 4ed bk180 PDFDocument13 pagesCranerunwaybeams 4ed bk180 PDFMacNo ratings yet

- Steel Fabrication UnitDocument62 pagesSteel Fabrication UnitKhan kingNo ratings yet

- Septembre: Digital ACJ Customer ForumDocument12 pagesSeptembre: Digital ACJ Customer ForumFaraz Khan100% (1)

- Equipment Practice ManualDocument60 pagesEquipment Practice Manualhaseeb ur rehmanNo ratings yet

- Preventive Maintenance Inspection FormDocument1 pagePreventive Maintenance Inspection FormAdam CabarrubiasNo ratings yet

- SAI - TWI India Enrolment Form From As Per Rev25 IndiaDocument4 pagesSAI - TWI India Enrolment Form From As Per Rev25 Indiavarunchopra0501No ratings yet

- New Applicant For CTL Logistic Pandaan Based - 2 FTE Managers Applications WowoxxxDocument1 pageNew Applicant For CTL Logistic Pandaan Based - 2 FTE Managers Applications Wowoxxxrories koffee99No ratings yet

- Civil Engineering License Exam Review: Structural - Session 1Document39 pagesCivil Engineering License Exam Review: Structural - Session 1Chris SwartzNo ratings yet

- Distillation Operation, Control, Design and Troubleshooting Course For Maintenance PersonnelDocument8 pagesDistillation Operation, Control, Design and Troubleshooting Course For Maintenance PersonnelBadiuzzama AzmiNo ratings yet

- 00 - Dri Operations Update To Damam Delegation - Aak - 04102010Document27 pages00 - Dri Operations Update To Damam Delegation - Aak - 04102010SalmanEjazNo ratings yet

- CasesDocument25 pagesCasesLindsey CookNo ratings yet

- Fire Door CatalogDocument29 pagesFire Door CatalogcharibackupNo ratings yet

- BS en 61386-25-2011Document22 pagesBS en 61386-25-2011FrankCapra100% (1)

- Dbms Project SinopsisDocument2 pagesDbms Project Sinopsisvalvemayam50% (2)

- Visual InspectionDocument1 pageVisual InspectionVinod Kumar VermaNo ratings yet

- Akinlade ThesisDocument298 pagesAkinlade Thesis16mariusNo ratings yet

- RifleDocument7 pagesRifleAjayPandeyNo ratings yet

- In Touch With The Medium: Level Monitoring SensorsDocument24 pagesIn Touch With The Medium: Level Monitoring Sensorsm_najmanNo ratings yet

- Assignment 1 Total Quality ManagementDocument7 pagesAssignment 1 Total Quality ManagementKashanAkmalNo ratings yet

- 140918-01-Research Paper For G Value-1Document3 pages140918-01-Research Paper For G Value-1Laorencia PraptiwiNo ratings yet

- Space Engineering: Structural Factors of Safety For Spaceflight HardwareDocument24 pagesSpace Engineering: Structural Factors of Safety For Spaceflight HardwareMariano SerranoNo ratings yet

- Par15 Final ReportDocument242 pagesPar15 Final ReportMustika SaraswatiNo ratings yet

- Drone Journalism: Newsgathering Applications of UAVs in Covering Conflict, Civil Unrest and DisasterDocument42 pagesDrone Journalism: Newsgathering Applications of UAVs in Covering Conflict, Civil Unrest and DisasterCanary TrapNo ratings yet

- Selling On Amazon Fee ScheduleDocument15 pagesSelling On Amazon Fee ScheduleSparshita PadwalNo ratings yet

- Strainer EN558 Serie1Document1 pageStrainer EN558 Serie1Jorge FerrerNo ratings yet

- Absorcion de Carbón ActivadoDocument59 pagesAbsorcion de Carbón ActivadoJosé Julio Pantac LiNo ratings yet

HWD0134

HWD0134

Uploaded by

Edwin Jalanoca LlaulliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HWD0134

HWD0134

Uploaded by

Edwin Jalanoca LlaulliCopyright:

Available Formats

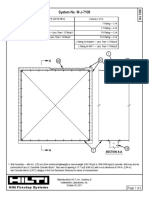

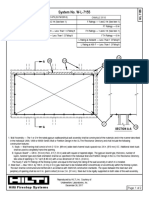

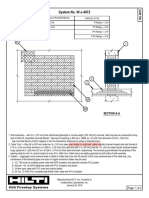

System No.

HW-D-0134

Construction Joints

June 24, 2011

Assembly Rating – 1 and 2 Hr (See Item 2)

L Rating At Ambient – 4 CFM/Lin Ft

L Rating At 400 F – 6 CFM/Lin Ft

Nominal Joint Width – 3/4 In.

Class II Movement Capabilities – 17% Compression or Extension

Head of Wall

1. Floor Assembly – Min 4-1/2 in. (114 mm) thick lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete.

2. Wall Assembly – The 1 or 2 fire rated gypsum wallboard/steel stud wall assembly shall be constructed of the materials and in the manner

described in the individual U400 or V400 Series Wall and Partition Design in the UL Fire Resistance Directory and shall include the

following construction features:

A. Steel Floor And Ceiling Runners – Floor and ceiling runners of wall assembly shall consist of galv steel channels sized to

accommodate steel studs (Item 2B). When U-shaped deflection channel (Item 3A) is used, ceiling runner installed within the deflection

channel with 1 in. (25 mm) gap maintained between the top of ceiling runner and top of deflection channel. When deflection channel is

not used, ceiling runner secured to concrete floor slab with steel masonry anchors spaced a max of 24 in. (610 mm) OC.

A1. Light Gauge Framing* – Slotted Ceiling Runner – As an alternate to the ceiling runner in Item 2A, slotted ceiling runner to consist of

galv steel channel with slotted flanges sized to accommodate steel studs (Item 2B). Slotted ceiling runner secured to concrete floor slab

with steel masonry anchors spaced max 24 in. (610 mm) OC. When slotted ceiling runner is used, deflection channel (Item 3A) shall not

be used.

BRADY CONSTRUCTION INNOVATIONS INC,

DBA SLIPTRACK SYSTEMS – SLP-TRK

CLARKWESTERN BUILDING SYSTEMS INC – Type SLT, SLT-H

MARINO/WARE, DIV OF WARE INDUSTRIES INC – Type SLT

METAL-LITE INC – The System

SCAFCO STEEL STUD MANUFACTURING CO

TELLING INDUSTRIES L L C – True-Action Deflection Track

A2. Light Gauge Framing* – Notched Ceiling Runner – As an alternate to the ceiling runners in Items 2A through 2A2, notched ceiling

runners to consist of C-shaped galv steel channel with notched return flanges sized to accommodate steel studs (Item 2B). Notched

ceiling runner secured to concrete floor slab with steel masonry anchors spaced max 24 in. (610 mm) OC. When notched ceiling runner

is used, deflection channel (Item 3A) shall not be used.

OLMAR SUPPLY INC – Type SCR

B. Studs – Steel studs to be min 3-5/8 in. (92 mm) wide. Studs cut 1/2 to 3/4 in. (13 to 19 mm) less in length than assembly height. Studs

attached to ceiling runner with sheet metal screws a min of 1/2 in. (13 mm) below bottom of deflection channel, when deflection channel

is used. When deflection channel is not used, steel studs shall not be secured to ceiling runner. When slotted ceiling runner (Item 2A1) is

used, steel studs secured to slotted ceiling runner with No. 8 by 1/2 in. (13 mm) long wafer head steel screws at midheight of slot on each

side of wall. Stud spacing not to exceed 24 in. (610 mm) OC.

C. Gypsum Board* – Gypsum board sheets installed to a min total thickness of 5/8 in. (16 mm) and 1-1/4 in. (32 mm) on each side of wall

HWD

for a 1 or 2 hr rated assemblies, respectively. Wall to be constructed as specified in the individual Wall and Partition Design in the UL

Fire Resistance Directory, except that a nom 3/4 in. (19 mm) gap shall be maintained between the top of the gypsum board and the lower

surface of the floor. The screws attaching the gypsum board to studs at the top of the wall shall be located 1 in. (25 mm) below the bottom

of the U-shaped deflection channel (Item 3A) or slotted ceiling runner (Item 2A1).

The hourly fire rating of the joint system is dependent on the hourly fire rating of the wall.

3Fire Protection Products ProductSupport

Product Support Line

Line

www.3m.com/firestop HW-D-0134 • 1 of 2 1-800-328-1687

1-800-328-1687

System No. HW-D-0134 continued

Construction Joints

3. Joint System – Max separation between bottom of floor and top of wall is 3/4 in. (19 mm). The joint system is designed to

accommodate a max 17 percent compression or extension from its installed width. The joint system consists of a deflection channel

forming material and a fill material, as follows:

A. Deflection Channel – (Optional) – A nom 3-3/4 in. (95 mm) wide by min 2 in. (51 mm) deep min 24 ga steel U-shaped channel.

Deflection channel secured to concrete floor slab with steel masonry anchors or by welds spaced max 24 in. (610 mm) OC. The ceiling

runner (Item 2A) is installed within the deflection channel to maintain a 1 in. (25 mm) gap between the top of the ceiling runner and the

top of the deflection channel. The ceiling runner is not fastened to the deflection channel.

B. Fill, Void or Cavity Material* – Caulk – Min 5/8 in. (16 mm) thickness of fill material installed on each side of the wall between the

top of the gypsum board and bottom of floor, flush with each surface of gypsum board.

3M COMPANY – FD-150+

*Bearing the UL Classification Mark

Reprinted from the Online Certifications Directory with permission from Underwriters Laboratories Inc.

Copyright © 2011 Underwriters Laboratories Inc.®

Head of Wall

HWD

3Fire Protection Products Product Support Line

www.3m.com/firestop HW-D-0134 • 2 of 2 1-800-328-1687

You might also like

- Radio Calculators & Code Decoding for all brandsDocument16 pagesRadio Calculators & Code Decoding for all brandsOBD-IINo ratings yet

- Technical Specification Main WarehouseDocument4 pagesTechnical Specification Main Warehouseadr_kharisma100% (2)

- MS Excel - Grade 5Document14 pagesMS Excel - Grade 5Marvin Rinon100% (1)

- HWD0194Document2 pagesHWD0194Ever Nina LauraNo ratings yet

- U412 - 2 HourDocument4 pagesU412 - 2 Hourmaher58No ratings yet

- De Servicio Freightliner fl70 Service Manual PDFDocument5 pagesDe Servicio Freightliner fl70 Service Manual PDForlandolanchipa67% (3)

- DDX-DDXP-PDX-PDXP-QDX Instruction Book & Part ListDocument13 pagesDDX-DDXP-PDX-PDXP-QDX Instruction Book & Part Listdj22500No ratings yet

- Sistema UL HWD0079 Junta 2 Hrs DrywallDocument2 pagesSistema UL HWD0079 Junta 2 Hrs DrywallRaul Fernando Villarreal VargasNo ratings yet

- System No. C-AJ-2898Document2 pagesSystem No. C-AJ-2898darwish.hiltiNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- CAJ1427Document1 pageCAJ1427mr. mydNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 pagesSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlNo ratings yet

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDNo ratings yet

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamNo ratings yet

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlNo ratings yet

- WL1167Document1 pageWL1167Juvenal GutierrezNo ratings yet

- Ul HWD 0209Document2 pagesUl HWD 0209jlledwinestebanNo ratings yet

- CAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626Document8 pagesCAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626shama093No ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2320Document1 pageSystem PDF Files - 1. UL and cUL Systems - fc2320Emanuel PastlNo ratings yet

- CAJ1317Document1 pageCAJ1317Luis AlbertoNo ratings yet

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 pagesÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoNo ratings yet

- Super Firetemp: Fire Protection SystemsDocument6 pagesSuper Firetemp: Fire Protection SystemstimetemasekNo ratings yet

- C-AJ-2834 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2834 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- HW-D-0038 - 1 of 1: 3M Fire Protection ProductsDocument1 pageHW-D-0038 - 1 of 1: 3M Fire Protection Productskirollos HabibNo ratings yet

- Approval Document ASSET DOC LOC 716Document2 pagesApproval Document ASSET DOC LOC 716fazil yoosufNo ratings yet

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersDocument2 pagesDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimNo ratings yet

- ProSTUD UL V477Document8 pagesProSTUD UL V477K PreitoNo ratings yet

- FC-2000 1.5 Hour Curtain Fire DampersDocument6 pagesFC-2000 1.5 Hour Curtain Fire DampersnuqNo ratings yet

- System No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Document2 pagesSystem No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Lea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- Fabrication Standard of Duct-AcDocument5 pagesFabrication Standard of Duct-AcVicky KumarNo ratings yet

- Approval Document ASSET DOC LOC 145Document2 pagesApproval Document ASSET DOC LOC 145Amir IqbalNo ratings yet

- HW D 0187Document2 pagesHW D 0187Luiggi Zuñiga BarahonaNo ratings yet

- Ulc I523-Cfs JoistDocument2 pagesUlc I523-Cfs JoistSumeet patelNo ratings yet

- FM Design 628 (FB-4003)Document2 pagesFM Design 628 (FB-4003)raviNo ratings yet

- Max 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyDocument2 pagesMax 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyvikaspisalNo ratings yet

- Ductwork SystemDocument8 pagesDuctwork SystemrkssNo ratings yet

- Section 082808hs High Security Perimeter Spec PDFDocument7 pagesSection 082808hs High Security Perimeter Spec PDFمحمد عبد السلام الصوافNo ratings yet

- Fire Stop Design 673Document4 pagesFire Stop Design 673raviNo ratings yet

- Marine Switchboards Main and AuxDocument15 pagesMarine Switchboards Main and AuxBharatiyulam100% (3)

- Specification SmartFenceDocument3 pagesSpecification SmartFenceVimala PonnusamyNo ratings yet

- CAJ1066 Multiples MTDocument1 pageCAJ1066 Multiples MTEdwin G Garcia ChNo ratings yet

- C-AJ-2813 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2813 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- C Aj 2586 PDFDocument1 pageC Aj 2586 PDFEmanuel PastlNo ratings yet

- WL7223Document1 pageWL7223Juvenal GutierrezNo ratings yet

- Duct Bank InformationDocument19 pagesDuct Bank InformationGaneshNo ratings yet

- 2013 Mason Ancon MDC BracketsDocument36 pages2013 Mason Ancon MDC BracketsalwezalokNo ratings yet

- Impasse 2 SpecDocument3 pagesImpasse 2 SpeckavitaNo ratings yet

- Metal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsDocument5 pagesMetal Roof Systems in High-Wind Regions: Purpose: Metal Roofing OptionsAlvaro MejiaNo ratings yet

- Retain: Spare PartsDocument1 pageRetain: Spare PartsAhmed Mohamed Abd ElhakamNo ratings yet

- Technical SpecificationDocument12 pagesTechnical SpecificationAnkit Somani100% (1)

- Powertrack Catalogue 07Document8 pagesPowertrack Catalogue 07w0nderd0gNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- System No. W-J-5116: F Rating - 2 HR T Rating - 1 HRDocument2 pagesSystem No. W-J-5116: F Rating - 2 HR T Rating - 1 HRArulNo ratings yet

- XHEZ.C-AJ-7029 - UL Product IqDocument3 pagesXHEZ.C-AJ-7029 - UL Product Iqfazil yoosufNo ratings yet

- D-22 المواصفة المحدثة للاعمدة المدورةDocument12 pagesD-22 المواصفة المحدثة للاعمدة المدورةAhmed Al-BaghdadiNo ratings yet

- W L 1176Document1 pageW L 1176shama093No ratings yet

- Installation Instructions: Supplied As A Complete Fire-Rated Enclosure To Ensure ComplianceDocument1 pageInstallation Instructions: Supplied As A Complete Fire-Rated Enclosure To Ensure ComplianceAnonymous 59kfV93pf4No ratings yet

- Duct Wrap Architect Specification - 0Document5 pagesDuct Wrap Architect Specification - 0Javed BhattiNo ratings yet

- Cranerunwaybeams 4ed bk180 PDFDocument13 pagesCranerunwaybeams 4ed bk180 PDFMacNo ratings yet

- Steel Fabrication UnitDocument62 pagesSteel Fabrication UnitKhan kingNo ratings yet

- Septembre: Digital ACJ Customer ForumDocument12 pagesSeptembre: Digital ACJ Customer ForumFaraz Khan100% (1)

- Equipment Practice ManualDocument60 pagesEquipment Practice Manualhaseeb ur rehmanNo ratings yet

- Preventive Maintenance Inspection FormDocument1 pagePreventive Maintenance Inspection FormAdam CabarrubiasNo ratings yet

- SAI - TWI India Enrolment Form From As Per Rev25 IndiaDocument4 pagesSAI - TWI India Enrolment Form From As Per Rev25 Indiavarunchopra0501No ratings yet

- New Applicant For CTL Logistic Pandaan Based - 2 FTE Managers Applications WowoxxxDocument1 pageNew Applicant For CTL Logistic Pandaan Based - 2 FTE Managers Applications Wowoxxxrories koffee99No ratings yet

- Civil Engineering License Exam Review: Structural - Session 1Document39 pagesCivil Engineering License Exam Review: Structural - Session 1Chris SwartzNo ratings yet

- Distillation Operation, Control, Design and Troubleshooting Course For Maintenance PersonnelDocument8 pagesDistillation Operation, Control, Design and Troubleshooting Course For Maintenance PersonnelBadiuzzama AzmiNo ratings yet

- 00 - Dri Operations Update To Damam Delegation - Aak - 04102010Document27 pages00 - Dri Operations Update To Damam Delegation - Aak - 04102010SalmanEjazNo ratings yet

- CasesDocument25 pagesCasesLindsey CookNo ratings yet

- Fire Door CatalogDocument29 pagesFire Door CatalogcharibackupNo ratings yet

- BS en 61386-25-2011Document22 pagesBS en 61386-25-2011FrankCapra100% (1)

- Dbms Project SinopsisDocument2 pagesDbms Project Sinopsisvalvemayam50% (2)

- Visual InspectionDocument1 pageVisual InspectionVinod Kumar VermaNo ratings yet

- Akinlade ThesisDocument298 pagesAkinlade Thesis16mariusNo ratings yet

- RifleDocument7 pagesRifleAjayPandeyNo ratings yet

- In Touch With The Medium: Level Monitoring SensorsDocument24 pagesIn Touch With The Medium: Level Monitoring Sensorsm_najmanNo ratings yet

- Assignment 1 Total Quality ManagementDocument7 pagesAssignment 1 Total Quality ManagementKashanAkmalNo ratings yet

- 140918-01-Research Paper For G Value-1Document3 pages140918-01-Research Paper For G Value-1Laorencia PraptiwiNo ratings yet

- Space Engineering: Structural Factors of Safety For Spaceflight HardwareDocument24 pagesSpace Engineering: Structural Factors of Safety For Spaceflight HardwareMariano SerranoNo ratings yet

- Par15 Final ReportDocument242 pagesPar15 Final ReportMustika SaraswatiNo ratings yet

- Drone Journalism: Newsgathering Applications of UAVs in Covering Conflict, Civil Unrest and DisasterDocument42 pagesDrone Journalism: Newsgathering Applications of UAVs in Covering Conflict, Civil Unrest and DisasterCanary TrapNo ratings yet

- Selling On Amazon Fee ScheduleDocument15 pagesSelling On Amazon Fee ScheduleSparshita PadwalNo ratings yet

- Strainer EN558 Serie1Document1 pageStrainer EN558 Serie1Jorge FerrerNo ratings yet

- Absorcion de Carbón ActivadoDocument59 pagesAbsorcion de Carbón ActivadoJosé Julio Pantac LiNo ratings yet