Professional Documents

Culture Documents

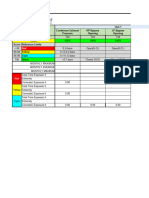

IST Sample Outage Report 1

IST Sample Outage Report 1

Uploaded by

Jonas PadillaCopyright:

Available Formats

You might also like

- ASV 2800 2810 Posi Track Loader Parts Manual DownloadDocument61 pagesASV 2800 2810 Posi Track Loader Parts Manual DownloadShiv Kumar0% (1)

- 3FB7Document7 pages3FB7fauzan datasheetNo ratings yet

- Technical Data Hamm 3412HT + 3412 HTP - Eng PDFDocument2 pagesTechnical Data Hamm 3412HT + 3412 HTP - Eng PDFClaudio RiquelmeNo ratings yet

- D155 Idler Installation Checksheet - Rev1Document5 pagesD155 Idler Installation Checksheet - Rev1miswansabani86No ratings yet

- Fitting Inspection Report (Built-Up Section) : Project Name: BLDG: Customer Name: PH No: Job No: DateDocument2 pagesFitting Inspection Report (Built-Up Section) : Project Name: BLDG: Customer Name: PH No: Job No: DateMd. Sahabul IslamNo ratings yet

- Flyer M 10id 12 ENDocument2 pagesFlyer M 10id 12 ENTrevor SalazarNo ratings yet

- Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDocument3 pagesHydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNo ratings yet

- Datasheet Crx-25iaDocument1 pageDatasheet Crx-25iajocelyn.peynet.universal.robotsNo ratings yet

- Datasheet M-1iA-05SDocument1 pageDatasheet M-1iA-05Sketan rsNo ratings yet

- Fitting Inspection Report (Built-Up Section) : BLDG: PH No: Date: Project Name: Customer Name: Job NoDocument1 pageFitting Inspection Report (Built-Up Section) : BLDG: PH No: Date: Project Name: Customer Name: Job NoMd. Sahabul IslamNo ratings yet

- Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDocument3 pagesHydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNo ratings yet

- Tool-Holder SANDVIKDocument8 pagesTool-Holder SANDVIKRodolfo Garduño ColínNo ratings yet

- Báo Cáo Test DaikouDocument1 pageBáo Cáo Test Daikoutuananhngo19096No ratings yet

- Fully Enclosed: Fast, Strong andDocument2 pagesFully Enclosed: Fast, Strong andjosjcrsNo ratings yet

- 8FG10-J35 SpecManual 2302Document66 pages8FG10-J35 SpecManual 2302Patricio CastroNo ratings yet

- TSR Overhaul EngineDocument8 pagesTSR Overhaul EnginewahyudiNo ratings yet

- Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDocument3 pagesHydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNo ratings yet

- Installation Instruction: Locking Assemblies of Types TAS 3012/RB/3015Document4 pagesInstallation Instruction: Locking Assemblies of Types TAS 3012/RB/3015Jose Patricio Obreque RiosNo ratings yet

- Datasheet-Cr7ia L EnglishDocument1 pageDatasheet-Cr7ia L EnglishNgộ Không TônNo ratings yet

- MTG Teeth AdapterDocument2 pagesMTG Teeth AdapterMaimun maimunNo ratings yet

- Sb100579 - Iriz Persona Troubleshooting Method Steering Noise IssueDocument9 pagesSb100579 - Iriz Persona Troubleshooting Method Steering Noise Issuesuain0074No ratings yet

- Thyssenkrupp Elevator: Stage 1 BDocument3 pagesThyssenkrupp Elevator: Stage 1 Bgajendrabanshiwal8905No ratings yet

- Ss 8fbe 10 20 eDocument33 pagesSs 8fbe 10 20 eJA. AhadiNo ratings yet

- Datasheet M-10iA-10MDocument1 pageDatasheet M-10iA-10MGTutorNo ratings yet

- ARC Mate 100 Robot Working RangeDocument1 pageARC Mate 100 Robot Working RangeTamii LópezNo ratings yet

- Technical Service Bulletin: Combined TSB / Service Action: Forte (TD) Front Strut Noise Repair (Sa047)Document4 pagesTechnical Service Bulletin: Combined TSB / Service Action: Forte (TD) Front Strut Noise Repair (Sa047)Trọng Nghĩa VõNo ratings yet

- Port Application Tyres: Technical Data Chart For XL-GRIP Available atDocument2 pagesPort Application Tyres: Technical Data Chart For XL-GRIP Available atRaman AutarNo ratings yet

- XD929 Small LoderDocument1 pageXD929 Small LoderEric SunNo ratings yet

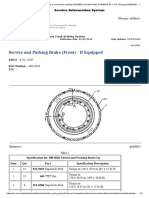

- KENR8737 - Service and Parking Brake (Front) - If Equipped - PDF (188-5020)Document3 pagesKENR8737 - Service and Parking Brake (Front) - If Equipped - PDF (188-5020)Anderson Oliveira SilvaNo ratings yet

- Deskpit - Simgears - Flight Simulator Part Replicas For GamersDocument3 pagesDeskpit - Simgears - Flight Simulator Part Replicas For GamersDamn FaustNo ratings yet

- Handling Robot: Fast, Slim and AccurateDocument2 pagesHandling Robot: Fast, Slim and AccuratePavitra ShahNo ratings yet

- To Reach Narrow Spaces: Compact DesignDocument2 pagesTo Reach Narrow Spaces: Compact DesignjosjcrsNo ratings yet

- Product Data Sheet Damcos BRC 500 en 60338Document4 pagesProduct Data Sheet Damcos BRC 500 en 60338cvfNo ratings yet

- Datasheet M-10iD-8LDocument1 pageDatasheet M-10iD-8LjosjcrsNo ratings yet

- Datasheet M 10ia 10MDocument1 pageDatasheet M 10ia 10MHeriberto LopezNo ratings yet

- Datasheet M-10iA-12Document1 pageDatasheet M-10iA-12EVA motionNo ratings yet

- F6QA1G747M2QS: Fbar/Saw Devices For Mobile Communications (Saw Type)Document2 pagesF6QA1G747M2QS: Fbar/Saw Devices For Mobile Communications (Saw Type)Bouhafs AbdelkaderNo ratings yet

- CRX-10 Robot Working Range: 10 KG 1418 MMDocument1 pageCRX-10 Robot Working Range: 10 KG 1418 MMMelike KısmetNo ratings yet

- 157 Broch 1Document2 pages157 Broch 1Fabian Barrientos MansillaNo ratings yet

- 8FBN15 30 Spec2018Document12 pages8FBN15 30 Spec2018Kristono HadiNo ratings yet

- Report P2u XCMG 800D #Exxc051 - PT - Kai-Tabang - HM3076Document9 pagesReport P2u XCMG 800D #Exxc051 - PT - Kai-Tabang - HM3076Dedy DarmansyahNo ratings yet

- Taper Grip Bushing Installation Guide: Apply Thin Layer of Anti-Seize Paste To Male Threads of Bushing OnlyDocument4 pagesTaper Grip Bushing Installation Guide: Apply Thin Layer of Anti-Seize Paste To Male Threads of Bushing OnlyberkahharianNo ratings yet

- d14.001.1 IS TS VBXX-D ENUSDocument1 paged14.001.1 IS TS VBXX-D ENUSbincoleto5536No ratings yet

- Installation Checklist (NEXIEZ-MR) : Project NameDocument20 pagesInstallation Checklist (NEXIEZ-MR) : Project NameEtienneNo ratings yet

- Commissioning InstructionsDocument5 pagesCommissioning InstructionsGurmukhSinghNo ratings yet

- Product Data Sheet Damcos BRC 250 en 60334Document4 pagesProduct Data Sheet Damcos BRC 250 en 60334Конструкторский отдел РосНефтеГазИнструментNo ratings yet

- Rema SlideDocument4 pagesRema SlidedexNo ratings yet

- Specification: Wheel LoaderDocument2 pagesSpecification: Wheel LoaderAkyasNo ratings yet

- Datasheet M 3ia 12HDocument1 pageDatasheet M 3ia 12H63 MGNo ratings yet

- 2 MM × 2 MM Solder Tail Straight & Right Angle, Surface Mount StraightDocument5 pages2 MM × 2 MM Solder Tail Straight & Right Angle, Surface Mount StraightVan HuynhNo ratings yet

- Populate Housings Data ServletDocument1 pagePopulate Housings Data ServletRafael FrancoNo ratings yet

- Sany 150ton Load ChartDocument21 pagesSany 150ton Load ChartAkhilesh kumar100% (1)

- F6 - Pvcexcon 1LR5 W12 U0v07 FaDocument1 pageF6 - Pvcexcon 1LR5 W12 U0v07 FaCustomer ServiceNo ratings yet

- Anant Corr. MOM 7-08-18Document4 pagesAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- Autocarro Galleria - SANDVIK TC790 Electric - ENDocument4 pagesAutocarro Galleria - SANDVIK TC790 Electric - ENMaurizio De LucaNo ratings yet

- Datasheet M-710iC-70TDocument1 pageDatasheet M-710iC-70TjosjcrsNo ratings yet

- Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDocument3 pagesHydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1BH96J56EW35MARDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1BH96J56EW35MARAnthony MarkNo ratings yet

- Montacarga Toyota 8FG 8FDDocument24 pagesMontacarga Toyota 8FG 8FDGyogi Mitsuta100% (1)

- Kce10-91-V120-Ed High Mounted Stop Assembly Gap Adjusting & Paint Damage Repairment (Ceed 5door) (Revised Kce09-91-V240-Ed)Document5 pagesKce10-91-V120-Ed High Mounted Stop Assembly Gap Adjusting & Paint Damage Repairment (Ceed 5door) (Revised Kce09-91-V240-Ed)Alexandru NicolaNo ratings yet

- Logs 20230530Document1 pageLogs 20230530Jonas PadillaNo ratings yet

- Coal-Fired Thermal Power PlantDocument157 pagesCoal-Fired Thermal Power PlantJonas PadillaNo ratings yet

- Failure of Application Server 01 in Unit 4Document1 pageFailure of Application Server 01 in Unit 4Jonas PadillaNo ratings yet

- Kaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Document7 pagesKaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Jonas PadillaNo ratings yet

- Control Valves Thermal ImagingDocument5 pagesControl Valves Thermal ImagingJonas PadillaNo ratings yet

- ReimbursementDocument1 pageReimbursementJonas PadillaNo ratings yet

- Critical Operating Parameter Monitoring Reference - BoilerDocument1 pageCritical Operating Parameter Monitoring Reference - BoilerJonas PadillaNo ratings yet

- Drawing ListDocument976 pagesDrawing ListJonas PadillaNo ratings yet

- Critical Operating ParametersDocument4 pagesCritical Operating ParametersJonas PadillaNo ratings yet

- Critical Operating Parameters - TURBINEDocument6 pagesCritical Operating Parameters - TURBINEJonas PadillaNo ratings yet

- Condenser Inlet-Outlet OptimizationDocument3 pagesCondenser Inlet-Outlet OptimizationJonas PadillaNo ratings yet

- List of Break Dance MovesDocument11 pagesList of Break Dance MovesAkshai KsNo ratings yet

- Properties of Electrons, Their Interactions With Matter and Applications in Electron MicrosDocument23 pagesProperties of Electrons, Their Interactions With Matter and Applications in Electron MicroswkpfckgwNo ratings yet

- Seeing Into The Soul: N Fourteenth Century IenaDocument4 pagesSeeing Into The Soul: N Fourteenth Century Ienasalveregina1917No ratings yet

- Alicia SzczurekDocument1 pageAlicia Szczurekapi-284398686No ratings yet

- Ii Sem Case Study - I PartDocument9 pagesIi Sem Case Study - I PartVenkatesh100% (1)

- Islamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafDocument90 pagesIslamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafEwinNo ratings yet

- Client:: Structural Analysis and Design Report Office BuildingDocument27 pagesClient:: Structural Analysis and Design Report Office BuildingRoshan KejariwalNo ratings yet

- Evs - Final Unit 3 - Environment Management & Sustainable DevelopmentDocument105 pagesEvs - Final Unit 3 - Environment Management & Sustainable DevelopmentchhaviNo ratings yet

- Math 7 Post TestDocument2 pagesMath 7 Post TestDonabel Carios100% (3)

- NASPGHAN Guidelines For Training in Pediatric.1 PDFDocument38 pagesNASPGHAN Guidelines For Training in Pediatric.1 PDFTeodora Patraucean100% (2)

- Governance, Business Ethics, Risk Management and Control ActivityDocument1 pageGovernance, Business Ethics, Risk Management and Control ActivityEu RiNo ratings yet

- Numerical MethodsDocument25 pagesNumerical MethodsSamip RegmiNo ratings yet

- Tarun Sharma (2007EME18) Nikhil Sharma (2007EME33) Ishan Chib (2007EME30) Sumit Khajuria (2007EME37)Document20 pagesTarun Sharma (2007EME18) Nikhil Sharma (2007EME33) Ishan Chib (2007EME30) Sumit Khajuria (2007EME37)Tarun SharmaNo ratings yet

- Vision of Narayana Murthy For A Better IndiaDocument2 pagesVision of Narayana Murthy For A Better IndiadushyantNo ratings yet

- Charity Begins at HomeDocument1 pageCharity Begins at HomeAtharva KadamNo ratings yet

- The Socio/cultural Theory and Education: Students, Teachers and KnowledgeDocument17 pagesThe Socio/cultural Theory and Education: Students, Teachers and KnowledgeChammey Nhyiraba Quajo-koJoNo ratings yet

- Estelle DarcyDocument1 pageEstelle DarcyTasnim Ben AmmarNo ratings yet

- The Literary Formofthe QuranDocument10 pagesThe Literary Formofthe QuranTrina CanizoNo ratings yet

- Chemistry F1 T2 Schemes 2023Document44 pagesChemistry F1 T2 Schemes 2023Eustina MumbireNo ratings yet

- DAC AnalysisDocument19 pagesDAC Analysisమురళీధర్ ఆది ఆంధ్రుడుNo ratings yet

- Gertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Document5 pagesGertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Zaiu DaiuNo ratings yet

- Family Nursing Care Plan #2: Education of Their Child As Foreseeable CrisisDocument3 pagesFamily Nursing Care Plan #2: Education of Their Child As Foreseeable CrisisBakushido33% (9)

- The Education of Albert Einstein: Clayton A. GearhartDocument23 pagesThe Education of Albert Einstein: Clayton A. GearhartJudith Banabatac OreganoNo ratings yet

- ToC - Industrial Motor Market - Fact - MRDocument16 pagesToC - Industrial Motor Market - Fact - MRLiora Vanessa DopacioNo ratings yet

- Dear Sirs and Madams Cover LetterDocument4 pagesDear Sirs and Madams Cover Letterc2yyr2c3100% (1)

- Makerere UniversityDocument40 pagesMakerere UniversityWinnie Janice100% (1)

- Advanced DirectiveDocument11 pagesAdvanced DirectivecaseyscribdNo ratings yet

- (2022, Review, Saran) 3D Printing of Composite Materials - A Short ReviewDocument5 pages(2022, Review, Saran) 3D Printing of Composite Materials - A Short ReviewNam Huu TranNo ratings yet

- Oracle Rac Pratice On Virtual BoxDocument94 pagesOracle Rac Pratice On Virtual BoxpandsinNo ratings yet

IST Sample Outage Report 1

IST Sample Outage Report 1

Uploaded by

Jonas PadillaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IST Sample Outage Report 1

IST Sample Outage Report 1

Uploaded by

Jonas PadillaCopyright:

Available Formats

Installation & Commissioning Manual GT-I05-21

Installation Work Module

Gearbox Installation Record

GT Order & Project Name: Issued by / Date: Record Issued: Gearbox Type / S/N: Operation data:

Workshop Installation Type RENK TB-800 Running hours 22879

STG C6054/ Berk Pai Wasin.S/20/03/22 Site Installation / Field Service S/N 917249/100 No. of starts 55

Gearbox Twist: Max 0.02 mm/m Gearbox Slope: Max 0.2 mm/m

0 A 0 [0.05mm/m] 0 0 [0.05mm/m]

Generator side Generator side Turbine side

LS LS HS

We reserve all rights in this document and in the information

Turbine side

contained therein. Reproduction, use or disclosure to third

HS

Parties without express authority is strictly forbidden.

© Siemens Industrial Turbomachinery AB

0 B 0 [0.05mm/m]

Bearing adjustment: Max 0.15mm Gearbox Twist:

Intentionally twisted during installation

Not twisted (within tolerances)

mm

Tooth Contact Pattern (at no load):

(Attach the recorded pattern in page 3)

Within tolerances

Non conformance, accepted by responsible dept.

Not checked (If Gearbox have not been adjusted at site)

mm mm

Tooth Contact Pattern (at full load):

(Dykem red)

Checked before dismantling of gear box

Checked after start up

Within tolerances

Non conformance, accepted by responsible dept.

Not checked

mm Gearbox Keys:

Tack welded

Record shim pack thickness when adjusted Fully welded

Feet Bolts

Tightened with N/A Nm

Note! Split Line twist between the sides A and B shall not exceed 0.02 mm/m,

if the casing is not deliberately twisted to obtain correct tooth contact

pattern!

Restricted SE-612 83 FINSPONG, Sweden Siemens Industrial Turbomachinery AB

Revision: C Page 1/3

Responsible Dept.: Installation & Commissioning, Gas Turbines

Installation & Commissioning Manual GT-I05-21

Installation Work Module

Gearbox Installation Record

GT Order & Project Name: Issued by / date: Record Issued: Gearbox Type / S/N: Operation data:

Workshop Installation Type RENK TB-800 Running hours 22879

STG C6054/ Berk Pai Wasin.S/27/11/20 Site Installation / Field Service S/N 917249/100 No. of starts 55

Bearing Clearances (Field service only)

Generator side

LS

Bearing Radial Axial

No. clearance clearance

(mm) (mm)

11 0.37 N/A

12 0.38 If applicable

21 0.46 N/A

We reserve all rights in this document and in the information

22 0.43 If applicable

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

© Siemens Industrial Turbomachinery AB

Note: SGT-800 has tilting pad bearings at position #21 & #22.

Apply correction factor to the measured value to get the correct

nominal clearance value.

Turbine side

HS

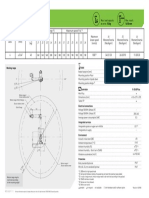

Shaft Sealing Clearances (Field service and first installation of gearbox)

Pinion shaft Wheel shaft

Seal Clearance Seal Clearance

Bearing no. 21 Bearing no. 11

Position (mm) (mm)

0° 0.40 0.40

45° 0.35 0.35

0° 90° 0.30 0.10

315° 45°

135° 0.10 0.05

270° 90° 180° 0.00 0.00

225°

225° 0.05 0.05

135°

180° 270° 0.20 0.15

315° 0.30 0.30

Measurements taken at 8 positions in rotation direction

Note: SGT-500 Reverse direction of rotation.

Gear box teeth back lash (Field service only)

Back lash (as found) 0.65 mm

Restricted SE-612 83 FINSPONG, Sweden Siemens Industrial Turbomachinery AB

Revision: C Page 2/3

Responsible Dept.: Installation & Commissioning, Gas Turbines

Installation & Commissioning Manual GT-I05-21

Installation Work Module

Gearbox Installation Record

GT Order & Project Name: Issued by / Date: Record Issued: Gearbox Type / S/N: Operation data:

Workshop Installation Type RENK TB-800 Running hours 22879

STG C6054/ Berk Pai Wasin.S/23/03/22 Site Installation / Field Service S/N 917249/100 No. of starts 55

Gearbox Twist: Max 0.02 mm/m Gearbox Slope: Max 0.2 mm/m

0 A 0 [0.01mm/m] 0 0 [0.01mm/m]

Generator side Generator side Turbine side

LS LS HS

We reserve all rights in this document and in the information

Turbine side

contained therein. Reproduction, use or disclosure to third

HS

Parties without express authority is strictly forbidden.

© Siemens Industrial Turbomachinery AB

0 B 0 [0.01mm/m]

Bearing adjustment: Max 0.15mm Gearbox Twist:

Intentionally twisted during installation

Not twisted (within tolerances)

mm

Tooth Contact Pattern (at no load):

(Attach the recorded pattern in page 3)

Within tolerances

Non conformance, accepted by responsible dept.

Not checked (If Gearbox have not been adjusted at site)

mm mm

Tooth Contact Pattern (at full load):

(Dykem red)

Checked before dismantling of gear box

Checked after start up

Within tolerances

Non conformance, accepted by responsible dept.

Not checked

mm Gearbox Keys:

Tack welded

Record shim pack thickness when adjusted Fully welded

Feet Bolts

Tightened with N/A Nm

Note! Split Line twist between the sides A and B shall not exceed 0.02 mm/m,

if the casing is not deliberately twisted to obtain correct tooth contact

pattern!

Restricted SE-612 83 FINSPONG, Sweden Siemens Industrial Turbomachinery AB

Revision: C Page 1/3

Responsible Dept.: Installation & Commissioning, Gas Turbines

Installation & Commissioning Manual GT-I05-21

Installation Work Module

Gearbox Installation Record

GT Order & Project Name: Issued by / date: Record Issued: Gearbox Type / S/N: Operation data:

Workshop Installation Type RENK TB-800 Running hours 22879

STG C6054/ Berk Pai Wasin.S/23/03/22 Site Installation / Field Service S/N 917249/100 No. of starts 55

Bearing Clearances (Field service only)

Generator side

LS

Bearing Radial Axial

No. clearance clearance

(mm) (mm)

11 0.37 N/A

12 0.37 If applicable

21 0.46 N/A

We reserve all rights in this document and in the information

22 0.44 If applicable

contained therein. Reproduction, use or disclosure to third

Parties without express authority is strictly forbidden.

© Siemens Industrial Turbomachinery AB

Note: SGT-800 has tilting pad bearings at position #21 & #22.

Apply correction factor to the measured value to get the correct

nominal clearance value.

Turbine side

HS

Shaft Sealing Clearances (Field service and first installation of gearbox)

Pinion shaft Wheel shaft

Seal Clearance Seal Clearance

Bearing no. 21 Bearing no. 11

Position (mm) (mm)

0° 0.40 0.40

45° 0.35 0.35

0° 90° 0.30 0.10

315° 45°

135° 0.10 0.05

270° 90° 180° 0.00 0.00

225°

225° 0.05 0.05

135°

180° 270° 0.20 0.15

315° 0.30 0.30

Measurements taken at 8 positions in rotation direction

Note: SGT-500 Reverse direction of rotation.

Gear box teeth back lash (Field service only)

Back lash (as found) 0.65 mm

Restricted SE-612 83 FINSPONG, Sweden Siemens Industrial Turbomachinery AB

Revision: C Page 2/3

Responsible Dept.: Installation & Commissioning, Gas Turbines

You might also like

- ASV 2800 2810 Posi Track Loader Parts Manual DownloadDocument61 pagesASV 2800 2810 Posi Track Loader Parts Manual DownloadShiv Kumar0% (1)

- 3FB7Document7 pages3FB7fauzan datasheetNo ratings yet

- Technical Data Hamm 3412HT + 3412 HTP - Eng PDFDocument2 pagesTechnical Data Hamm 3412HT + 3412 HTP - Eng PDFClaudio RiquelmeNo ratings yet

- D155 Idler Installation Checksheet - Rev1Document5 pagesD155 Idler Installation Checksheet - Rev1miswansabani86No ratings yet

- Fitting Inspection Report (Built-Up Section) : Project Name: BLDG: Customer Name: PH No: Job No: DateDocument2 pagesFitting Inspection Report (Built-Up Section) : Project Name: BLDG: Customer Name: PH No: Job No: DateMd. Sahabul IslamNo ratings yet

- Flyer M 10id 12 ENDocument2 pagesFlyer M 10id 12 ENTrevor SalazarNo ratings yet

- Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDocument3 pagesHydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNo ratings yet

- Datasheet Crx-25iaDocument1 pageDatasheet Crx-25iajocelyn.peynet.universal.robotsNo ratings yet

- Datasheet M-1iA-05SDocument1 pageDatasheet M-1iA-05Sketan rsNo ratings yet

- Fitting Inspection Report (Built-Up Section) : BLDG: PH No: Date: Project Name: Customer Name: Job NoDocument1 pageFitting Inspection Report (Built-Up Section) : BLDG: PH No: Date: Project Name: Customer Name: Job NoMd. Sahabul IslamNo ratings yet

- Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDocument3 pagesHydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNo ratings yet

- Tool-Holder SANDVIKDocument8 pagesTool-Holder SANDVIKRodolfo Garduño ColínNo ratings yet

- Báo Cáo Test DaikouDocument1 pageBáo Cáo Test Daikoutuananhngo19096No ratings yet

- Fully Enclosed: Fast, Strong andDocument2 pagesFully Enclosed: Fast, Strong andjosjcrsNo ratings yet

- 8FG10-J35 SpecManual 2302Document66 pages8FG10-J35 SpecManual 2302Patricio CastroNo ratings yet

- TSR Overhaul EngineDocument8 pagesTSR Overhaul EnginewahyudiNo ratings yet

- Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDocument3 pagesHydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNo ratings yet

- Installation Instruction: Locking Assemblies of Types TAS 3012/RB/3015Document4 pagesInstallation Instruction: Locking Assemblies of Types TAS 3012/RB/3015Jose Patricio Obreque RiosNo ratings yet

- Datasheet-Cr7ia L EnglishDocument1 pageDatasheet-Cr7ia L EnglishNgộ Không TônNo ratings yet

- MTG Teeth AdapterDocument2 pagesMTG Teeth AdapterMaimun maimunNo ratings yet

- Sb100579 - Iriz Persona Troubleshooting Method Steering Noise IssueDocument9 pagesSb100579 - Iriz Persona Troubleshooting Method Steering Noise Issuesuain0074No ratings yet

- Thyssenkrupp Elevator: Stage 1 BDocument3 pagesThyssenkrupp Elevator: Stage 1 Bgajendrabanshiwal8905No ratings yet

- Ss 8fbe 10 20 eDocument33 pagesSs 8fbe 10 20 eJA. AhadiNo ratings yet

- Datasheet M-10iA-10MDocument1 pageDatasheet M-10iA-10MGTutorNo ratings yet

- ARC Mate 100 Robot Working RangeDocument1 pageARC Mate 100 Robot Working RangeTamii LópezNo ratings yet

- Technical Service Bulletin: Combined TSB / Service Action: Forte (TD) Front Strut Noise Repair (Sa047)Document4 pagesTechnical Service Bulletin: Combined TSB / Service Action: Forte (TD) Front Strut Noise Repair (Sa047)Trọng Nghĩa VõNo ratings yet

- Port Application Tyres: Technical Data Chart For XL-GRIP Available atDocument2 pagesPort Application Tyres: Technical Data Chart For XL-GRIP Available atRaman AutarNo ratings yet

- XD929 Small LoderDocument1 pageXD929 Small LoderEric SunNo ratings yet

- KENR8737 - Service and Parking Brake (Front) - If Equipped - PDF (188-5020)Document3 pagesKENR8737 - Service and Parking Brake (Front) - If Equipped - PDF (188-5020)Anderson Oliveira SilvaNo ratings yet

- Deskpit - Simgears - Flight Simulator Part Replicas For GamersDocument3 pagesDeskpit - Simgears - Flight Simulator Part Replicas For GamersDamn FaustNo ratings yet

- Handling Robot: Fast, Slim and AccurateDocument2 pagesHandling Robot: Fast, Slim and AccuratePavitra ShahNo ratings yet

- To Reach Narrow Spaces: Compact DesignDocument2 pagesTo Reach Narrow Spaces: Compact DesignjosjcrsNo ratings yet

- Product Data Sheet Damcos BRC 500 en 60338Document4 pagesProduct Data Sheet Damcos BRC 500 en 60338cvfNo ratings yet

- Datasheet M-10iD-8LDocument1 pageDatasheet M-10iD-8LjosjcrsNo ratings yet

- Datasheet M 10ia 10MDocument1 pageDatasheet M 10ia 10MHeriberto LopezNo ratings yet

- Datasheet M-10iA-12Document1 pageDatasheet M-10iA-12EVA motionNo ratings yet

- F6QA1G747M2QS: Fbar/Saw Devices For Mobile Communications (Saw Type)Document2 pagesF6QA1G747M2QS: Fbar/Saw Devices For Mobile Communications (Saw Type)Bouhafs AbdelkaderNo ratings yet

- CRX-10 Robot Working Range: 10 KG 1418 MMDocument1 pageCRX-10 Robot Working Range: 10 KG 1418 MMMelike KısmetNo ratings yet

- 157 Broch 1Document2 pages157 Broch 1Fabian Barrientos MansillaNo ratings yet

- 8FBN15 30 Spec2018Document12 pages8FBN15 30 Spec2018Kristono HadiNo ratings yet

- Report P2u XCMG 800D #Exxc051 - PT - Kai-Tabang - HM3076Document9 pagesReport P2u XCMG 800D #Exxc051 - PT - Kai-Tabang - HM3076Dedy DarmansyahNo ratings yet

- Taper Grip Bushing Installation Guide: Apply Thin Layer of Anti-Seize Paste To Male Threads of Bushing OnlyDocument4 pagesTaper Grip Bushing Installation Guide: Apply Thin Layer of Anti-Seize Paste To Male Threads of Bushing OnlyberkahharianNo ratings yet

- d14.001.1 IS TS VBXX-D ENUSDocument1 paged14.001.1 IS TS VBXX-D ENUSbincoleto5536No ratings yet

- Installation Checklist (NEXIEZ-MR) : Project NameDocument20 pagesInstallation Checklist (NEXIEZ-MR) : Project NameEtienneNo ratings yet

- Commissioning InstructionsDocument5 pagesCommissioning InstructionsGurmukhSinghNo ratings yet

- Product Data Sheet Damcos BRC 250 en 60334Document4 pagesProduct Data Sheet Damcos BRC 250 en 60334Конструкторский отдел РосНефтеГазИнструментNo ratings yet

- Rema SlideDocument4 pagesRema SlidedexNo ratings yet

- Specification: Wheel LoaderDocument2 pagesSpecification: Wheel LoaderAkyasNo ratings yet

- Datasheet M 3ia 12HDocument1 pageDatasheet M 3ia 12H63 MGNo ratings yet

- 2 MM × 2 MM Solder Tail Straight & Right Angle, Surface Mount StraightDocument5 pages2 MM × 2 MM Solder Tail Straight & Right Angle, Surface Mount StraightVan HuynhNo ratings yet

- Populate Housings Data ServletDocument1 pagePopulate Housings Data ServletRafael FrancoNo ratings yet

- Sany 150ton Load ChartDocument21 pagesSany 150ton Load ChartAkhilesh kumar100% (1)

- F6 - Pvcexcon 1LR5 W12 U0v07 FaDocument1 pageF6 - Pvcexcon 1LR5 W12 U0v07 FaCustomer ServiceNo ratings yet

- Anant Corr. MOM 7-08-18Document4 pagesAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- Autocarro Galleria - SANDVIK TC790 Electric - ENDocument4 pagesAutocarro Galleria - SANDVIK TC790 Electric - ENMaurizio De LucaNo ratings yet

- Datasheet M-710iC-70TDocument1 pageDatasheet M-710iC-70TjosjcrsNo ratings yet

- Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDocument3 pagesHydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1BH96J56EW35MARDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1BH96J56EW35MARAnthony MarkNo ratings yet

- Montacarga Toyota 8FG 8FDDocument24 pagesMontacarga Toyota 8FG 8FDGyogi Mitsuta100% (1)

- Kce10-91-V120-Ed High Mounted Stop Assembly Gap Adjusting & Paint Damage Repairment (Ceed 5door) (Revised Kce09-91-V240-Ed)Document5 pagesKce10-91-V120-Ed High Mounted Stop Assembly Gap Adjusting & Paint Damage Repairment (Ceed 5door) (Revised Kce09-91-V240-Ed)Alexandru NicolaNo ratings yet

- Logs 20230530Document1 pageLogs 20230530Jonas PadillaNo ratings yet

- Coal-Fired Thermal Power PlantDocument157 pagesCoal-Fired Thermal Power PlantJonas PadillaNo ratings yet

- Failure of Application Server 01 in Unit 4Document1 pageFailure of Application Server 01 in Unit 4Jonas PadillaNo ratings yet

- Kaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Document7 pagesKaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Jonas PadillaNo ratings yet

- Control Valves Thermal ImagingDocument5 pagesControl Valves Thermal ImagingJonas PadillaNo ratings yet

- ReimbursementDocument1 pageReimbursementJonas PadillaNo ratings yet

- Critical Operating Parameter Monitoring Reference - BoilerDocument1 pageCritical Operating Parameter Monitoring Reference - BoilerJonas PadillaNo ratings yet

- Drawing ListDocument976 pagesDrawing ListJonas PadillaNo ratings yet

- Critical Operating ParametersDocument4 pagesCritical Operating ParametersJonas PadillaNo ratings yet

- Critical Operating Parameters - TURBINEDocument6 pagesCritical Operating Parameters - TURBINEJonas PadillaNo ratings yet

- Condenser Inlet-Outlet OptimizationDocument3 pagesCondenser Inlet-Outlet OptimizationJonas PadillaNo ratings yet

- List of Break Dance MovesDocument11 pagesList of Break Dance MovesAkshai KsNo ratings yet

- Properties of Electrons, Their Interactions With Matter and Applications in Electron MicrosDocument23 pagesProperties of Electrons, Their Interactions With Matter and Applications in Electron MicroswkpfckgwNo ratings yet

- Seeing Into The Soul: N Fourteenth Century IenaDocument4 pagesSeeing Into The Soul: N Fourteenth Century Ienasalveregina1917No ratings yet

- Alicia SzczurekDocument1 pageAlicia Szczurekapi-284398686No ratings yet

- Ii Sem Case Study - I PartDocument9 pagesIi Sem Case Study - I PartVenkatesh100% (1)

- Islamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafDocument90 pagesIslamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafEwinNo ratings yet

- Client:: Structural Analysis and Design Report Office BuildingDocument27 pagesClient:: Structural Analysis and Design Report Office BuildingRoshan KejariwalNo ratings yet

- Evs - Final Unit 3 - Environment Management & Sustainable DevelopmentDocument105 pagesEvs - Final Unit 3 - Environment Management & Sustainable DevelopmentchhaviNo ratings yet

- Math 7 Post TestDocument2 pagesMath 7 Post TestDonabel Carios100% (3)

- NASPGHAN Guidelines For Training in Pediatric.1 PDFDocument38 pagesNASPGHAN Guidelines For Training in Pediatric.1 PDFTeodora Patraucean100% (2)

- Governance, Business Ethics, Risk Management and Control ActivityDocument1 pageGovernance, Business Ethics, Risk Management and Control ActivityEu RiNo ratings yet

- Numerical MethodsDocument25 pagesNumerical MethodsSamip RegmiNo ratings yet

- Tarun Sharma (2007EME18) Nikhil Sharma (2007EME33) Ishan Chib (2007EME30) Sumit Khajuria (2007EME37)Document20 pagesTarun Sharma (2007EME18) Nikhil Sharma (2007EME33) Ishan Chib (2007EME30) Sumit Khajuria (2007EME37)Tarun SharmaNo ratings yet

- Vision of Narayana Murthy For A Better IndiaDocument2 pagesVision of Narayana Murthy For A Better IndiadushyantNo ratings yet

- Charity Begins at HomeDocument1 pageCharity Begins at HomeAtharva KadamNo ratings yet

- The Socio/cultural Theory and Education: Students, Teachers and KnowledgeDocument17 pagesThe Socio/cultural Theory and Education: Students, Teachers and KnowledgeChammey Nhyiraba Quajo-koJoNo ratings yet

- Estelle DarcyDocument1 pageEstelle DarcyTasnim Ben AmmarNo ratings yet

- The Literary Formofthe QuranDocument10 pagesThe Literary Formofthe QuranTrina CanizoNo ratings yet

- Chemistry F1 T2 Schemes 2023Document44 pagesChemistry F1 T2 Schemes 2023Eustina MumbireNo ratings yet

- DAC AnalysisDocument19 pagesDAC Analysisమురళీధర్ ఆది ఆంధ్రుడుNo ratings yet

- Gertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Document5 pagesGertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Zaiu DaiuNo ratings yet

- Family Nursing Care Plan #2: Education of Their Child As Foreseeable CrisisDocument3 pagesFamily Nursing Care Plan #2: Education of Their Child As Foreseeable CrisisBakushido33% (9)

- The Education of Albert Einstein: Clayton A. GearhartDocument23 pagesThe Education of Albert Einstein: Clayton A. GearhartJudith Banabatac OreganoNo ratings yet

- ToC - Industrial Motor Market - Fact - MRDocument16 pagesToC - Industrial Motor Market - Fact - MRLiora Vanessa DopacioNo ratings yet

- Dear Sirs and Madams Cover LetterDocument4 pagesDear Sirs and Madams Cover Letterc2yyr2c3100% (1)

- Makerere UniversityDocument40 pagesMakerere UniversityWinnie Janice100% (1)

- Advanced DirectiveDocument11 pagesAdvanced DirectivecaseyscribdNo ratings yet

- (2022, Review, Saran) 3D Printing of Composite Materials - A Short ReviewDocument5 pages(2022, Review, Saran) 3D Printing of Composite Materials - A Short ReviewNam Huu TranNo ratings yet

- Oracle Rac Pratice On Virtual BoxDocument94 pagesOracle Rac Pratice On Virtual BoxpandsinNo ratings yet