Professional Documents

Culture Documents

WI - BR - Palm Pull Rod

WI - BR - Palm Pull Rod

Uploaded by

druvemediaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WI - BR - Palm Pull Rod

WI - BR - Palm Pull Rod

Uploaded by

druvemediaCopyright:

Available Formats

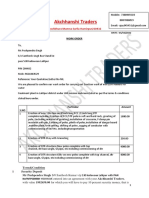

EMU Workshop, Mahalaxmi, Western Railway, Mumbai

Work Instruction

Chapter Title: WORK INSTRUCTIONS FOR MAINTENANCE OF BRAKE RIGGING

ISO 9001:2015 Issue No: 02 Rev. No: 00 Doc No WI/BR/01

Date: 20.04.2023 Rev. date: Nil Page 1 of 1

Repairing procedure of PALM PULL ROD

1. Palm pull rods received from washing station are loaded to the palm pull rod bushing and de-bushing

table.

2. Outstretch all palm pull rods on bushing and de-bushing table properly.

3. Remove all the nylon bushes from every palm pull rod.

4. Strip safety chain links by gas cutter.

5. Check the correctness of the holes of palm pull rod by using GO NO-GO gauge if found unsuitable in

GO NO-GO gauging then same is rejected

6. Clean all palm pull rods by wire brush in order to remove dirt dust if present on its body.

7. Inspection of palm pull rods by inspection staff for bend, pitted, scoring and crack etc.

8. If irreparable pitting, scoring and crack detected then reject the palm pull rod.

9. Repairable pitting, scoring and crack are removed by suitable arc welding technique.

10. Straighten all bends by hammering and dressing.

11. Fit new nylon bush to each hole of the palm pull rod by using a mallet

12. Provide black paint to each palm pull rod and send all palm pull rod for fitment in outgoing rake.

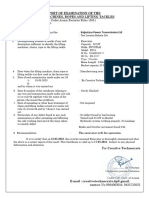

Approved By - Dy.CEE Stamp of controlled/uncontrolled copy Issued By- PE

Digitally signed by ANIL

ANIL KUMAR KUMAR

Date: 2023.04.20 11:02:59

+05'30'

P45W14

You might also like

- Broken Needle PolicyDocument9 pagesBroken Needle Policyelisav89% (9)

- Method Statement - Pressing of Plate To Be Pipe - SignDocument9 pagesMethod Statement - Pressing of Plate To Be Pipe - SignrichadNo ratings yet

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingFrom EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingRating: 4.5 out of 5 stars4.5/5 (9)

- Humed Method Statement For Mono-Poles InstallationDocument3 pagesHumed Method Statement For Mono-Poles InstallationUtibe EkongNo ratings yet

- 4HF1 4HG1Document5 pages4HF1 4HG1Arifin Arif100% (2)

- WI BR Outer HangerDocument1 pageWI BR Outer HangerdruvemediaNo ratings yet

- WI BR LeverDocument1 pageWI BR LeverdruvemediaNo ratings yet

- WI BR Brake HeadDocument1 pageWI BR Brake HeaddruvemediaNo ratings yet

- WI BR Brake BeamDocument2 pagesWI BR Brake BeamdruvemediaNo ratings yet

- WI BR WashingDocument1 pageWI BR WashingdruvemediaNo ratings yet

- WI BR StrippingDocument2 pagesWI BR StrippingdruvemediaNo ratings yet

- 2 - Calibration Table - Tank 101Document14 pages2 - Calibration Table - Tank 101Friezt Lavoizer FialNo ratings yet

- D-Shackles 6.5 TONDocument1 pageD-Shackles 6.5 TONLingam sasthaNo ratings yet

- Cold Mounting and Unmounting Bearing - Asyraaf SyahmiDocument6 pagesCold Mounting and Unmounting Bearing - Asyraaf SyahmiMuhammad Asyraaf Syahmi bin YazidNo ratings yet

- MOS Precast PilingDocument5 pagesMOS Precast PilingPuzzelsProductionNo ratings yet

- Certificate of Examination and Test of Lifting Gears, Lifting Appliances & Lifting EquipmentsDocument1 pageCertificate of Examination and Test of Lifting Gears, Lifting Appliances & Lifting EquipmentsAkhilNo ratings yet

- Rhi-Te-028 VibroDocument1 pageRhi-Te-028 VibroMkd OfficialNo ratings yet

- Yoke 1Document1 pageYoke 1wintwah.myantestNo ratings yet

- LiftingRegister CRT-60908Document1 pageLiftingRegister CRT-60908Muhammad FaiSalNo ratings yet

- 3.2 Galvanizing Thickness Gauge Calibration CertificateDocument1 page3.2 Galvanizing Thickness Gauge Calibration CertificateGolden RosesNo ratings yet

- ProjectInvocefile 1Document63 pagesProjectInvocefile 1b.kyoot.90No ratings yet

- Autolift 3000 User ManualDocument16 pagesAutolift 3000 User ManualAntonioPalloneNo ratings yet

- MN301-100-QC-SSR-0030 ClosureDocument14 pagesMN301-100-QC-SSR-0030 ClosureGSkoruNo ratings yet

- Metrology Lab 1solDocument5 pagesMetrology Lab 1solBro38867No ratings yet

- L021 - OHSE Piling Work Permit Cum Checklist FormatDocument1 pageL021 - OHSE Piling Work Permit Cum Checklist FormatRajib MondalNo ratings yet

- Organisation Chart-29th Mar, 2023 UpdatedDocument2 pagesOrganisation Chart-29th Mar, 2023 UpdatedsecretarymaintenanceNo ratings yet

- XL650 InstructionsDocument59 pagesXL650 InstructionsLeonardo SilveiraNo ratings yet

- Contruction Equipment Checklist (Asphalt Cutter, Hand Compactors, Concrete Vibrators, Etc)Document1 pageContruction Equipment Checklist (Asphalt Cutter, Hand Compactors, Concrete Vibrators, Etc)DLPS HSENo ratings yet

- Raiseboring Equipment Pilot Bits BrochureDocument4 pagesRaiseboring Equipment Pilot Bits BrochureDenisNo ratings yet

- TPI Certificate Wheel Loader - 2226 - RA - May24 - Mabela - MTTCADocument2 pagesTPI Certificate Wheel Loader - 2226 - RA - May24 - Mabela - MTTCAmaniksasthaNo ratings yet

- TRI 1008 Quality CardingDocument17 pagesTRI 1008 Quality Cardingalcon1No ratings yet

- Time Sheet Team Install Pump CEP UP Indramayu - AstomoDocument1 pageTime Sheet Team Install Pump CEP UP Indramayu - AstomoKukuh Perkasa WirayudaNo ratings yet

- Liftting Plan - With Winch MachineDocument3 pagesLiftting Plan - With Winch Machineshahhussain1031No ratings yet

- Time Sheet Team Install Pump CEP UP Indramayu - SuryantoDocument1 pageTime Sheet Team Install Pump CEP UP Indramayu - SuryantoKukuh Perkasa WirayudaNo ratings yet

- W LZId KXNSD JRB Yn EDocument2 pagesW LZId KXNSD JRB Yn Ejainidivyansh914No ratings yet

- E-Invoice: Abans PLCDocument3 pagesE-Invoice: Abans PLCsakunviduranga1998No ratings yet

- Eco World Security Patrol Report (September)Document4 pagesEco World Security Patrol Report (September)ShafiqNo ratings yet

- Checklist For Grinding MachineDocument1 pageChecklist For Grinding MachinePrajnay ShettyNo ratings yet

- Spark - Eastern Peripheral Road Project (Epr) Weekly Quality MeetingDocument6 pagesSpark - Eastern Peripheral Road Project (Epr) Weekly Quality Meetingengr.s.a.malik6424No ratings yet

- '23!06!24 QH332-10097 500hr Service Zulu LithiumDocument3 pages'23!06!24 QH332-10097 500hr Service Zulu LithiumSilex MatsikaNo ratings yet

- Shiva Silks, NamakkalDocument2 pagesShiva Silks, Namakkalselladuraimuthusamy37No ratings yet

- Shiva Silks, NamakkalDocument2 pagesShiva Silks, Namakkalselladuraimuthusamy37No ratings yet

- TPI Certificate Excavator - 5048 - LA - May24 - Mabela - MTTCADocument2 pagesTPI Certificate Excavator - 5048 - LA - May24 - Mabela - MTTCAmaniksasthaNo ratings yet

- PUSHPENDRADocument3 pagesPUSHPENDRAajay SinghNo ratings yet

- Limpet Set-UpDocument1 pageLimpet Set-UpSales Creative EngineeringNo ratings yet

- SodapdfDocument3 pagesSodapdfajay SinghNo ratings yet

- Quotation (PVR Theature, Latur)Document4 pagesQuotation (PVR Theature, Latur)Ankita Baban GavadeNo ratings yet

- Cintec: Masonry Anchoring & Reinforcement SystemsDocument19 pagesCintec: Masonry Anchoring & Reinforcement SystemsBrinzaNo ratings yet

- Boat Log Sheet For DailyDocument2 pagesBoat Log Sheet For DailyiahmedNo ratings yet

- Olympian Service Bulletin: SB 0044 - PCADocument5 pagesOlympian Service Bulletin: SB 0044 - PCANacer ZehaniNo ratings yet

- Cable Tray Installation ChecklistDocument2 pagesCable Tray Installation Checklistbaban100% (1)

- Fuel Hose Reel Model 89010 & 102962 Series "A": SafetyDocument3 pagesFuel Hose Reel Model 89010 & 102962 Series "A": SafetyLuis Carlos González LondoñoNo ratings yet

- Excavator TpiDocument18 pagesExcavator TpiPrem KumarNo ratings yet

- CW213623 - Sokaij - Mx-4307-00001-Bolt Torquing Procedure.Document19 pagesCW213623 - Sokaij - Mx-4307-00001-Bolt Torquing Procedure.jeszzymenNo ratings yet

- Wffiffi&e$ffi: Factory:-FactoryDocument1 pageWffiffi&e$ffi: Factory:-FactoryR.Raghu NathanNo ratings yet

- Installation of New ChlorinatorDocument4 pagesInstallation of New ChlorinatorRL SanNo ratings yet

- Dokumen - Tips - Manual Motor Perkins 1104d Euro 3Document236 pagesDokumen - Tips - Manual Motor Perkins 1104d Euro 3Marianny MedinaNo ratings yet

- Shri Vinayaka EngineersDocument20 pagesShri Vinayaka EngineersPrem KumarNo ratings yet

- Chainpully Block 5ton Good Will EngDocument1 pageChainpully Block 5ton Good Will EngLingam sasthaNo ratings yet

- Calibration Certificate Compression Machine C0065-22 (2000 KN)Document1 pageCalibration Certificate Compression Machine C0065-22 (2000 KN)muhirwa raymondNo ratings yet