Professional Documents

Culture Documents

WI BR Outer Hanger

WI BR Outer Hanger

Uploaded by

druvemediaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WI BR Outer Hanger

WI BR Outer Hanger

Uploaded by

druvemediaCopyright:

Available Formats

EMU Workshop, Mahalaxmi, Western Railway, Mumbai

Work Instruction

Chapter Title: WORK INSTRUCTIONS FOR MAINTENANCE OF BRAKE RIGGING

ISO 9001:2015 Issue No: 02 Rev. No: 00 Doc No WI/BR/01

Date: 20.04.2023 Rev. date: Nil Page 1 of 1

Repairing of outer hanger

1. Unload a bin of outer hanger near outer hanger repairing, bushing and de-bushing area.

2. Remove all old bushes from outer hanger

3. Clean an outer hanger by using a wire brush in order to remove dirt, dust or any unwanted matter

etc. from its surface.

4. Check both the holes of outer hanger by using GO, NO- GO gauge in order to determine correctness of

the holes if found not ok then the same is to be rejected.

5. Check an outer hanger visually for any defects like the scoring mark, crack, bend and pitted etc.

6. The cracked, pitted, heavy scored and bend outer hanger which are beyond repair are rejected.

7. The bend that is repairable is repaired by hammering and dressing it on an anvil

8. Inspection of all repaired outer hanger by inspection staff

9. Fit new nylon bushes to outer hanger by using a suitable mallet hammer.

10. Insert a pin for brake rigging in every piece and Check of gap between pin and bush which is to be

maintained to 1 mm

11. Collect all repaired and bushed outer hanger in a green pallet for further use.

Approved By - Dy.CEE Stamp of controlled/uncontrolled copy Issued By- PE

ANIL Digitally signed by ANIL

KUMAR

KUMAR Date: 2023.04.20

11:02:02 +05'30'

P45W14

You might also like

- Calibration Certificate of Vernier Calipers PG 1pdf PDFDocument1 pageCalibration Certificate of Vernier Calipers PG 1pdf PDFsaid323280% (5)

- Tower Light Almeer 101Document2 pagesTower Light Almeer 101groshan20No ratings yet

- WI BR Brake HeadDocument1 pageWI BR Brake HeaddruvemediaNo ratings yet

- WI BR Brake BeamDocument2 pagesWI BR Brake BeamdruvemediaNo ratings yet

- WI - BR - Palm Pull RodDocument1 pageWI - BR - Palm Pull RoddruvemediaNo ratings yet

- WI BR LeverDocument1 pageWI BR LeverdruvemediaNo ratings yet

- WI BR WashingDocument1 pageWI BR WashingdruvemediaNo ratings yet

- WI BR StrippingDocument2 pagesWI BR StrippingdruvemediaNo ratings yet

- Cold Mounting and Unmounting Bearing - Asyraaf SyahmiDocument6 pagesCold Mounting and Unmounting Bearing - Asyraaf SyahmiMuhammad Asyraaf Syahmi bin YazidNo ratings yet

- Metrology Lab 1solDocument5 pagesMetrology Lab 1solBro38867No ratings yet

- 033-Siemens Healthcare Private Limited, FDocument2 pages033-Siemens Healthcare Private Limited, Fsibi-shplNo ratings yet

- Installation of Externally Seated Radial Ball Bearings - Asyraaf SyahmiDocument6 pagesInstallation of Externally Seated Radial Ball Bearings - Asyraaf SyahmiMuhammad Asyraaf Syahmi bin YazidNo ratings yet

- Vol-Iv Boughtout ManualDocument170 pagesVol-Iv Boughtout ManualSreenivas kNo ratings yet

- Bearings Failures PDFDocument5 pagesBearings Failures PDFPàváñ RøçkzzNo ratings yet

- Report On Vertical Load Test On 500Mm Dia, 7.30 Meters Deep Initial Pile Tp-2, BangaloreDocument15 pagesReport On Vertical Load Test On 500Mm Dia, 7.30 Meters Deep Initial Pile Tp-2, BangaloreRavi BojankiNo ratings yet

- 01 Montagem BF Re CGDocument9 pages01 Montagem BF Re CGvergelNo ratings yet

- Operator Cabin Mounting Bolts Replacement and Platform Repair - Rev0Document2 pagesOperator Cabin Mounting Bolts Replacement and Platform Repair - Rev0shakhowiNo ratings yet

- 2 - Calibration Table - Tank 101Document14 pages2 - Calibration Table - Tank 101Friezt Lavoizer FialNo ratings yet

- D-Shackles 6.5 TONDocument1 pageD-Shackles 6.5 TONLingam sasthaNo ratings yet

- Chainpully Block 5ton Good Will EngDocument1 pageChainpully Block 5ton Good Will EngLingam sasthaNo ratings yet

- MOS Precast PilingDocument5 pagesMOS Precast PilingPuzzelsProductionNo ratings yet

- Delivery Challan-936Document1 pageDelivery Challan-936Ananka FastenersNo ratings yet

- IRDA Lic. No-121271 IIISLA No - L/N/10045 Department - Marine C, Engg., Misc. & MotorDocument6 pagesIRDA Lic. No-121271 IIISLA No - L/N/10045 Department - Marine C, Engg., Misc. & Motorauto scannerNo ratings yet

- 6BD1 Torque and SequenceDocument4 pages6BD1 Torque and Sequencearnel gonzalesNo ratings yet

- Rev Appr Wo - Prish - Ajmera PriveDocument4 pagesRev Appr Wo - Prish - Ajmera Priveshahdarshil43No ratings yet

- Certificate of Examination and Test of Lifting Gears, Lifting Appliances & Lifting EquipmentsDocument1 pageCertificate of Examination and Test of Lifting Gears, Lifting Appliances & Lifting EquipmentsAkhilNo ratings yet

- 009 PAINTING AND COATING OF CONCRETE FOUNDATION LIGHTING POLES Rev. 01Document9 pages009 PAINTING AND COATING OF CONCRETE FOUNDATION LIGHTING POLES Rev. 01Marwa FaroukNo ratings yet

- Offer For Amc Service Visit (Fm-Ul) Pump 24-25Document3 pagesOffer For Amc Service Visit (Fm-Ul) Pump 24-25shannusriram44No ratings yet

- Amc 20.1.21Document2 pagesAmc 20.1.21Ayush SharmaNo ratings yet

- 0.25 HP Motor - Test CertificateDocument1 page0.25 HP Motor - Test CertificatedilipNo ratings yet

- 400 User ManualDocument1 page400 User Manualsupendra phuyalNo ratings yet

- Derrick Screen Condition Check-Up & Evaluation Report - May20 - 2023Document7 pagesDerrick Screen Condition Check-Up & Evaluation Report - May20 - 2023ruelonepieceNo ratings yet

- 6.0 MS For Block WorkDocument4 pages6.0 MS For Block WorkVijendra SharmaNo ratings yet

- Or45046479 Technical SpecificationDocument8 pagesOr45046479 Technical SpecificationRolando B. RielNo ratings yet

- Olympian Service Bulletin: SB 0044 - PCADocument5 pagesOlympian Service Bulletin: SB 0044 - PCANacer ZehaniNo ratings yet

- Reliance Structures Pvt. LTD (3103)Document2 pagesReliance Structures Pvt. LTD (3103)pm.shailendratiwariNo ratings yet

- Yoke 1Document1 pageYoke 1wintwah.myantestNo ratings yet

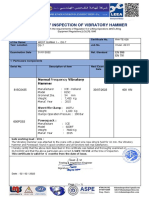

- Rhi-Te-028 VibroDocument1 pageRhi-Te-028 VibroMkd OfficialNo ratings yet

- E46 Subframe RepairDocument3 pagesE46 Subframe RepairantNo ratings yet

- The Oriental Insurance Company LimitedDocument2 pagesThe Oriental Insurance Company LimitedSachi MensiNo ratings yet

- 4ja1 4JB1Document4 pages4ja1 4JB1sebin134No ratings yet

- RJ01GD0134Document3 pagesRJ01GD0134Sachin PandeyNo ratings yet

- Inspection & Monitoring - BearingsDocument4 pagesInspection & Monitoring - BearingsChia PeterNo ratings yet

- B075 2008 1125R Transmission Jet RecallDocument8 pagesB075 2008 1125R Transmission Jet Recallbarbiturico64No ratings yet

- GA450Document2 pagesGA450timingtoolNo ratings yet

- S-1029-Anvira Technologies-Sy-Adp-11.03.2024Document1 pageS-1029-Anvira Technologies-Sy-Adp-11.03.2024benn savyasachiNo ratings yet

- Utaati Utangwa Quotation 3rd FebDocument1 pageUtaati Utangwa Quotation 3rd FebsaikacyberemailNo ratings yet

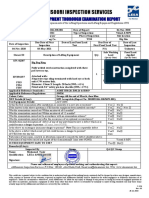

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- SEKN5047 - Introduction of Ultrasonic Measurement ToolDocument3 pagesSEKN5047 - Introduction of Ultrasonic Measurement ToolMrAlbert2009No ratings yet

- E Ic Mar 2023 91323Document1 pageE Ic Mar 2023 91323RAHUL MAHAJANNo ratings yet

- CPGK-S-00000202 - I1 - 201504 C100D2R Campaign 2274 Power Cable ChafingDocument20 pagesCPGK-S-00000202 - I1 - 201504 C100D2R Campaign 2274 Power Cable ChafingAlejandro Paul Puma FuentesNo ratings yet

- Bme163120 Muhammad Ashir Internship ReportDocument11 pagesBme163120 Muhammad Ashir Internship ReportMuhammad Ashir100% (1)

- Counterweight and Roller Removal Inspection and InstallationDocument7 pagesCounterweight and Roller Removal Inspection and InstallationAlma BravoNo ratings yet

- Safety Belt Service - 6 Ton WTCDocument1 pageSafety Belt Service - 6 Ton WTCkichupunathil1012No ratings yet

- Motorised-Two Wheelers Liability Only Policy - Zone A Motor Insurance Certificate Cum Policy ScheduleDocument2 pagesMotorised-Two Wheelers Liability Only Policy - Zone A Motor Insurance Certificate Cum Policy ScheduleRevanth RajNo ratings yet

- Final SOP For WeldingDocument10 pagesFinal SOP For WeldingBhaskar KolichelimaNo ratings yet

- MQA Lab ReportDocument15 pagesMQA Lab ReportMuhammad Waleed TariqNo ratings yet

- Two Wheeler Policy PDFDocument2 pagesTwo Wheeler Policy PDFVijaya SimhaNo ratings yet

- Wheel Loss Sensor WHeely SafeDocument4 pagesWheel Loss Sensor WHeely SafevijayNo ratings yet