Professional Documents

Culture Documents

Layout 5abcd

Layout 5abcd

Uploaded by

vikesh1993Copyright:

Available Formats

You might also like

- Share EXCEL SHEET FOR CBR TESTDocument1 pageShare EXCEL SHEET FOR CBR TESTTarun100% (1)

- Fuel Injection Pump Data SCANIA DC9Document2 pagesFuel Injection Pump Data SCANIA DC9Mateen Younas100% (1)

- Haver Roto PackerDocument24 pagesHaver Roto Packercassindrome100% (2)

- ICRU 29 Dose Specification For Reporting External Beam Therapy With Photons and Electrons PDFDocument29 pagesICRU 29 Dose Specification For Reporting External Beam Therapy With Photons and Electrons PDFDiego MauricioNo ratings yet

- CYLINDER - ktmHEAD Lay Out (ALICON)Document4 pagesCYLINDER - ktmHEAD Lay Out (ALICON)vikesh1993No ratings yet

- CS Nipple 21K-62-71310Document1 pageCS Nipple 21K-62-71310Inspirasi Kreasi SejahteraNo ratings yet

- Shaft Selector and Shifting (5841 2671 7909) ..Document11 pagesShaft Selector and Shifting (5841 2671 7909) ..Sourabh PradhanNo ratings yet

- K0na - PipeDocument2 pagesK0na - Pipevikesh1993No ratings yet

- 434 MFRDocument10 pages434 MFRHarsh JindalNo ratings yet

- Final Inspection - Tata Ace DiscDocument3 pagesFinal Inspection - Tata Ace DiscazadNo ratings yet

- EAG567 - Inspection ReportDocument2 pagesEAG567 - Inspection ReportDurai NaiduNo ratings yet

- 545 7489 (Eag349) - IsirDocument2 pages545 7489 (Eag349) - IsirDurai NaiduNo ratings yet

- SSV 2019 Brakes Maverick Shop Supp 219100971-030Document7 pagesSSV 2019 Brakes Maverick Shop Supp 219100971-030Coke Ker JetspeedNo ratings yet

- Glorious Electronics India Private Limited: Sample Inspection ReportDocument2 pagesGlorious Electronics India Private Limited: Sample Inspection ReportYogesh YadavNo ratings yet

- Vulcan Core Industries: Sample Inspection CertificateDocument1 pageVulcan Core Industries: Sample Inspection CertificateazadNo ratings yet

- Flange DrawingDocument1 pageFlange DrawingM-NazimNo ratings yet

- Compact Conductor Calculation-1Document4 pagesCompact Conductor Calculation-1Gautama Chandra PradiptaNo ratings yet

- Al TG CaseDocument19 pagesAl TG CaseSurendra SinghNo ratings yet

- Pdi Report: JN Engg Works DATE: 1/8/18Document32 pagesPdi Report: JN Engg Works DATE: 1/8/18Anil kumarNo ratings yet

- A Appearance No Burr, Rust, Crack, Paint Defect Visual: Part No. Part Name ModelDocument24 pagesA Appearance No Burr, Rust, Crack, Paint Defect Visual: Part No. Part Name ModelSanjayNo ratings yet

- PommelDocument3 pagesPommelVilasNo ratings yet

- BRKT Brake PedalDocument8 pagesBRKT Brake PedalSanjayNo ratings yet

- Inspection ReportDocument30 pagesInspection ReportSanjayNo ratings yet

- Vulcan Core Industries: Sample Inspection CertificateDocument1 pageVulcan Core Industries: Sample Inspection CertificateazadNo ratings yet

- Cost Impact Due To Rate Increase in Raw Material: Existing Raw Material Working Revised Raw Material WorkingDocument1 pageCost Impact Due To Rate Increase in Raw Material: Existing Raw Material Working Revised Raw Material WorkingIqbal singh DhanjalNo ratings yet

- Free Flow Cum Pressure Drop Calculations For Filter & StrainerDocument1 pageFree Flow Cum Pressure Drop Calculations For Filter & StrainergauravNo ratings yet

- Catalogue Spec PCWDocument1 pageCatalogue Spec PCWsiranepNo ratings yet

- Injection Pump Test Specifications 092000-512#Document3 pagesInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- 2316C79401 FirDocument1 page2316C79401 FirInder SabhrawalNo ratings yet

- Injection Pump Test Specifications 191000-490#Document3 pagesInjection Pump Test Specifications 191000-490#Miguel Rojas100% (1)

- Pdi Report: JN Engg Works DATE: 29/8/18Document31 pagesPdi Report: JN Engg Works DATE: 29/8/18Anil kumarNo ratings yet

- Clutch Overhaul: Group 21BDocument6 pagesClutch Overhaul: Group 21BPedro BatistaNo ratings yet

- 108 - t1, 31.08.2015 Pdi - Qad-28 Sample Inspection Reportslide Chair - Machine (Ber.319-111108)Document1 page108 - t1, 31.08.2015 Pdi - Qad-28 Sample Inspection Reportslide Chair - Machine (Ber.319-111108)azadNo ratings yet

- Vulcan Core Industries: Sample Inspection CertificateDocument1 pageVulcan Core Industries: Sample Inspection CertificateazadNo ratings yet

- CB0C050F0Document12 pagesCB0C050F0roshni mehraNo ratings yet

- Blade Rod Cycle TimeDocument6 pagesBlade Rod Cycle TimeNeeraj KatariaNo ratings yet

- Excel Sheet For CBR TestDocument1 pageExcel Sheet For CBR TestFariha Azad100% (3)

- t5!18!01 2016 Qad 28 Sample Inspection Reportslide Chair Machine Ber 319 11116Document1 paget5!18!01 2016 Qad 28 Sample Inspection Reportslide Chair Machine Ber 319 11116Sarah FetahNo ratings yet

- 092000-5360-1 Lionn Auto SoftwaresDocument3 pages092000-5360-1 Lionn Auto SoftwaresLionn MartinsNo ratings yet

- Isir - Jaw 121028-00Document2 pagesIsir - Jaw 121028-00rahulkumarqa01No ratings yet

- Power Cables With Their Electricals Characteristics, Overall Length and WeightDocument6 pagesPower Cables With Their Electricals Characteristics, Overall Length and WeightRoumya Darshan RayNo ratings yet

- Free Flow Cum Pressure Drop Calculations For Filter & StrainerDocument18 pagesFree Flow Cum Pressure Drop Calculations For Filter & StrainergauravNo ratings yet

- AC Fans Static Calculation Final-1Document20 pagesAC Fans Static Calculation Final-1Hendrias A.SNo ratings yet

- Inj .P Ump Calibration Data Inj .P Ump Calibration DataDocument1 pageInj .P Ump Calibration Data Inj .P Ump Calibration DataBaytolgaNo ratings yet

- 164-01-01-007 Locating Pin - Dia 2.8Document1 page164-01-01-007 Locating Pin - Dia 2.8cawojNo ratings yet

- CB1C006F0Document6 pagesCB1C006F0roshni mehraNo ratings yet

- SVR-324 SL60 Leveler Foot (Sanjay) 9-4-23Document1 pageSVR-324 SL60 Leveler Foot (Sanjay) 9-4-23sachinNo ratings yet

- PX436 Rev1Document2 pagesPX436 Rev1Leah Cassandra BernardoNo ratings yet

- SPC Study Activity No. 1.3.11Document1 pageSPC Study Activity No. 1.3.11toyota952No ratings yet

- Minotrol 16: LOT Control L ABX LysebioDocument3 pagesMinotrol 16: LOT Control L ABX LysebioTristiana yuliantiNo ratings yet

- Scr452 - 20.01.2016 Pdi - Qad-28 Sample Inspection Reportcheck Rail - Machine (Scr-452)Document1 pageScr452 - 20.01.2016 Pdi - Qad-28 Sample Inspection Reportcheck Rail - Machine (Scr-452)azadNo ratings yet

- Inspection FAN FA 5 NewDocument1 pageInspection FAN FA 5 Newtrafalgarlaw2150No ratings yet

- 164-01-01-000 Locating PinsDocument2 pages164-01-01-000 Locating PinscawojNo ratings yet

- Minotrol 16: LOT Control L ABX LyseDocument3 pagesMinotrol 16: LOT Control L ABX LyseDWI NATULANINo ratings yet

- 103 - 714 SERIES: CharacteristicsDocument2 pages103 - 714 SERIES: CharacteristicsNGUYEN MEDICALNo ratings yet

- CBR ReportDocument5 pagesCBR ReportPhanindra NathNo ratings yet

- Work Order For Ext Mic CalibrationDocument1 pageWork Order For Ext Mic CalibrationBåd BøyNo ratings yet

- Summary of Materials Identification Results: Fence Lanavet Antenna Garoua Veterinary LabDocument1 pageSummary of Materials Identification Results: Fence Lanavet Antenna Garoua Veterinary LabTienou Kamga ThomasNo ratings yet

- Vimal Enterprises: Inspection Report K-Sector, X-296 Midc Waluj Aurangabad-431136Document1 pageVimal Enterprises: Inspection Report K-Sector, X-296 Midc Waluj Aurangabad-431136Jayesh MahaleNo ratings yet

- Terex A300 LoadsDocument22 pagesTerex A300 LoadssekharbrsNo ratings yet

- Barra Balanceadora Mitsubishi L200 2.5 2011-2015Document2 pagesBarra Balanceadora Mitsubishi L200 2.5 2011-2015Alvaro RAMIREZ GARCIANo ratings yet

- CH 1 IntroductionDocument19 pagesCH 1 IntroductionYAVANA BNo ratings yet

- FDOT BB978 RPTDocument14 pagesFDOT BB978 RPTirfanquadriNo ratings yet

- The Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFDocument116 pagesThe Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFKizuna L. ChanthavongNo ratings yet

- 6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitDocument17 pages6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitMuthu AlaguRajNo ratings yet

- Wolfe WaveDocument3 pagesWolfe Wavemohamed ibrahimNo ratings yet

- RF Characterisation Tooway PDFDocument20 pagesRF Characterisation Tooway PDFLiviu CasuneanuNo ratings yet

- EXPERIMENT2 (Spring Constant) - 2Document8 pagesEXPERIMENT2 (Spring Constant) - 2Maruf AhmedNo ratings yet

- Column Hydraulics NotesDocument4 pagesColumn Hydraulics NotessatishchemengNo ratings yet

- Casting: Definition, Types, Steps Involved in Casting, Advantages, Disadvantages, Importance (PDF)Document7 pagesCasting: Definition, Types, Steps Involved in Casting, Advantages, Disadvantages, Importance (PDF)Munem ShahriarNo ratings yet

- Ductile Brittle TransitionDocument7 pagesDuctile Brittle TransitionAndrea CalderaNo ratings yet

- WT045CDocument2 pagesWT045CDewa BayuNo ratings yet

- 400 RRDocument20 pages400 RRjimmy barusNo ratings yet

- C1212857-1015-18awg-16-0.254bc-Tew Baoh01Document2 pagesC1212857-1015-18awg-16-0.254bc-Tew Baoh01HugoSpktNo ratings yet

- Design of CribsDocument38 pagesDesign of Cribsjatin singlaNo ratings yet

- Data SheetDocument4 pagesData SheetRachel FloresNo ratings yet

- 3311071.017 DometicRooftopACMechanicalComfortSingleZoneControl SVM AMER (En) 2012 01Document63 pages3311071.017 DometicRooftopACMechanicalComfortSingleZoneControl SVM AMER (En) 2012 01Adrian LedesmaNo ratings yet

- Mixture - WikipediaDocument5 pagesMixture - Wikipediatsvmpm1765No ratings yet

- Nonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiDocument66 pagesNonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiJorge Luis Garcia ZuñigaNo ratings yet

- Angle Construction Upper PrimaryDocument39 pagesAngle Construction Upper Primarybukenya MosesNo ratings yet

- Optical AberrationDocument20 pagesOptical AberrationShubhangi ShuklaNo ratings yet

- On The Role of Spatial Phase and Phase Correlation in Vision, Illusion, and CognitionDocument14 pagesOn The Role of Spatial Phase and Phase Correlation in Vision, Illusion, and Cognitiondw wwNo ratings yet

- Ring Design Chapter08Document1 pageRing Design Chapter08ismail güleçNo ratings yet

- SpaceshipsDocument3 pagesSpaceshipsPaul McNeil100% (1)

- FT GenedDocument15 pagesFT GenedDino CamposNo ratings yet

- Fan TerminologyDocument12 pagesFan TerminologymukeshkumarjNo ratings yet

- General Notes Fairfax County VADocument5 pagesGeneral Notes Fairfax County VApatriciaNo ratings yet

- Indicator Controller Cum TransmitterDocument1 pageIndicator Controller Cum TransmitterTrumen Technologies PVT LtdNo ratings yet

Layout 5abcd

Layout 5abcd

Uploaded by

vikesh1993Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Layout 5abcd

Layout 5abcd

Uploaded by

vikesh1993Copyright:

Available Formats

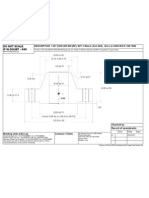

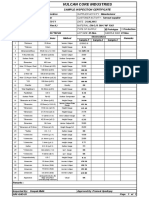

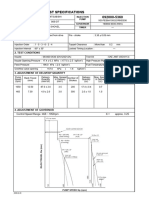

Fromat no Format no BINOLA/QA/F/71

Layout Inspection report Rev.no Rev.no 0

Rev. date Rev. date

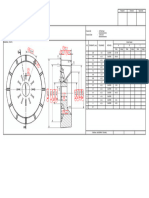

Model Name: B104D Item Name: CYL. HEAD

Customer: BAJAJ AUTO LTD. Drg. No.: 55PF0037

Insp. Date 6.7.2023 Cavity No.: 5A-5B-5C-5D

S.N. Parameters Specifications Tol min max Inspn. Method. Cavity 5A Status Cavity 5B Status Cavity 5C Status Cavity 5D Status Remark

SECTION A-A

1 Angle 27 ±2 25 29 CMM 27.15' OK 27.21' OK 27.30' OK 27.20' OK

2 Angle 31 ±2 29 33 CMM 31.30' OK 31.30' OK 31.25' OK 31'.90 OK

Exhaust Spring face

3 2 ±0.3 1.7 2.3 CMM 1.85 OK 1.87 OK 2.01 OK 1.95 OK

M/cing allowance

4 Exhaust guide distance 49.17 ±0.5 48.67 49.67 CMM AFTER MACHINING

5 Distance 36.24 ±0.5 35.74 36.74 CMM 36.32 OK 36.02 OK 36.10 OK 36.13 OK

Exhaust seat area

6 16.27 ±0.5 15.77 16.77 CMM AFTER MACHINING

m/cing allowance

7 Distance 12.2 ±0.5 11.7 12.7 CMM REFERANCE DIMN.

8 Distance 15.91 ±0.5 15.41 16.41 CMM AFTER MACHINING

9 Diameter 36.34 ±0.5 35.84 36.84 CMM 36.15 OK 36.1 OK 36.09 OK 36.02 OK

10 Distance 49.81 ±0.2 49.61 50.01 CMM AFTER MACHINING

11 Distance 2 ±0.5 1.5 2.5 CMM 1.97 OK 2.1 OK 1.85 OK 1.91 OK

Inlet seat area m/cing

12 1.5 ±0.5 1 2 CMM 1.25 OK 1.22 OK 1.31 OK 1.30 OK

allowance

13 Diameter 25.5 ±0.5 25 26 VC AFTER MACHINING

14 Distance 1.5 ±0.5 1 2 CMM 1.39 OK 1.37 OK 1.41 OK 1.38 OK

15 Inlet Spring face 1.5 ±0.5 1 2 CMM 1.51 OK 1.49 OK 1.47 OK 1.47 OK

16 Diameter 22 ±0.5 21.5 22.5 CMM AFTER MACHINING

17 Distance 1.5 ±0.5 1 2 CMM 1.43 OK 1.41 OK 1.49 OK 1.5 OK

SECTION J-J

18 Dimension 1 ±0.5 0.5 1.5 CMM 1.30 OK 1.31 OK 1.35 OK 1.29 OK

SECTION G-G

19 M/C Allow 1.5 ±0.5 1 2 CMM 1.45 OK 1.51 OK 1.48 OK 1.47 OK

SECTION E-E

20 Angle 37 ±1 36 38 CMM 37.15' OK 37.20' OK 37.15' OK 37.15' OK

21 Dimension 27.5 ± 0.5 27 28 CMM 27.59 OK 27.56 OK 27.59 OK 27.55 OK

22 Locating Pin CD 71.5 ±0.2 71.3 71.7 CMM 71.58 OK 71.54 OK 71.43 OK 71.52 OK

23 Dimension 27 ±0.2 26.8 27.2 27.10 OK 27.07 OK 27.00 OK 27.14 OK

Supplier identification

24 AS PER 3D MODEL

mark

BAJAJ Mark TYPE 'D'

25 AS PER 3D MODEL

AS PER ABS00001

26 Locating Pin CD 59 ±0.2 58.8 59.2 CMM 59.07 OK 59.04 OK 58.93 OK 59.02 OK

27 Dimension 34 ±0.3 33.7 34.3 CMM 34.13 OK 34 OK 34.14 OK 34.10 OK

28 Dimension 28.44 ±0.5 27.94 28.94 CMM 28.77 OK 28.72 OK 28.72 OK 28.69 OK

29 Dimension 4.1 ±0.3 3.8 4.4 CMM

30 Dimension 0.4 ±0.3 0.1 0.7 CMM

31 Angle 26.5 ±1 25.5 27.5 CMM 27.5' OK 27.10' OK 27.16' OK 27.18' OK

32 Angle 9 ±1 8 10 CMM 9.10' OK 9.20' OK 9.15' OK 9.15' OK

33 Dimension 57.05 ±0.7 56.35 57.75 CMM 57.25 OK 57.51 OK 57.65 OK 57.22 OK

Calender Mark AS PER

34 AS PER 3D MODEL

ABS00118

PART NO.IN RELIEF OF

35 AS PER 3D MODEL

0.5 DEPTH

36 DIE NO. & CAVITY NO. AS PER 3D MODEL

37 Dimension 51.4 ±0.7 50.7 52.1 CMM

38 DATE SHIFT MARK AS PER 3D MODEL

39 Dimension 69.65 ±0.7 68.95 70.35 CMM

V' PROJECTION DETAILS

40 Dimension 0.7 ±0.3 0.4 1 AS PER 3D MODEL

41 Angle 90 ±1 89 91 AS PER 3D MODEL

VIEW 'W'

42 Angle 14 ±1 13 15 CMM 14.10' OK 14.14' OK 14.10' OK 9.18' OK

43 Dimension 16.5 ±0.5 16 17 CMM AFTER MACHINING

SECTIONH H-H

44 Diameter 34.2 ±0.5 33.7 34.7 VC AFTER MACHINING

45 Dimension 0.5 ±0.3 0.2 0.8 CMM/VC AFTER MACHINING

PUNCH MARK UPTO

46 AS PER 3D MODEL

30% ACCEPTED ON

47 Dimension 12 ±0.5 11.5 12.5 VC AFTER MACHINING

48 Dimension 1.5 ±0.5 1 2 CMM AFTER MACHINING

49 Dimension 1.5 ±0.5 1 2 CMM AFTER MACHINING

50 Dimension 3 ±0.5 2.5 3.5 VC AFTER MACHINING

VIEW 'U1'

51 Distance 33.45 ±0.5 32.95 33.95 CMM AFTER MACHINING

VIEW 'U'

52 Distance 2.87 ±0.5 2.37 3.37 CMM 3.05 OK 2.97 OK 2.89 OK 2.85 OK

SECTION F1-F1

53 M/C Allow 1.5 ±0.5 1 2 CMM/HG 1.70 OK 1.40 OK 1.62 OK 1.38 OK

54 CC depth 7.7 ,+0.3 7.7 8.2 CMM 7.82 OK 7.8 OK 7.86 OK 7.91 OK

55 Dimension 3.8 ±0.5 3.3 4.3 CMM/HG 3.79 OK 3.86 OK 3.94 OK 3.79 OK

Checked By; Approved By;

VIEW 'V1'

56 Angle 30 ±1 29 31 CMM 3015' OK 3010' OK 3025' OK 3018' OK

57 Distance 21.9 ±0.2 21.7 22.1 CMM 22.03 OK 21.796 OK 21.92 OK 21.98 OK

DETAIL 'Q'

58 Depth 1.5 ±0.3 1.2 1.8 CONTOUR 1.43 OK 1.32 OK 1.28 OK 1.39 OK

59 Angle 5 ±1 4 6 CMM 520' OK 525' OK 520' OK 525' OK

60 Radius 1 ±0.5 0.5 1.5 RADIUS GAUGE R1 OK R1 OK R1 OK R1 OK

61 Dimension 10 ±0.5 9.5 10.5 VC 9.87 OK 9.71 OK 9.92 OK 9.86 OK

62 Diameter 8.5 ±0.5 8 9 VC/CMM 8.50 OK 8.49 OK 8.47 OK 8.49 OK

63 Diameter 11.5 ±0.5 11 12 VC/CMM 11.62 OK 11.49 OK 11.67 OK 11.43 OK

SECTION B-B

64 Dimension 28 ±0.5 27.5 28.5 VC/CMM AFTER MACHINING

65 Dimension 1.5 ±0.5 1 2 CMM 1.43 OK 1.52 OK 1.58 OK 1.62 OK

66 m/cing Allowance 1.5 ±0.5 1 2 CMM 1.30 OK 1.32 OK 1.27 OK 1.37 OK

67 Dimension 10 ±0.5 9.5 10.5 CMM AFTER MACHINING

68 Distance 23.4 ±0.5 22.9 23.9 VC/CMM AFTER MACHINING

69 m/cing Allowance 1.5 ±0.5 1 2 CMM 1.30 OK 1.32 OK 1.27 OK 1.37 OK

70 Diameter 35 ±0.5 34.5 35.5 CMM AFTER MACHINING

71 m/cing Allowance 1.5 ±0.5 1 2 VC/CMM 1.60 OK 1.42 OK 1.75 OK 1.70 OK

72 m/cing Allowance 1.5 ±0.5 1 2 VC/CMM 1.59 OK 1.64 OK 1.39 OK 1.49 OK

73 Distance 23.4 ±0.5 22.9 23.9 VC AFTER MACHINING

74 Dimension 28 ±0.5 27.5 28.5 CMM AFTER MACHINING

75 Dimension 13.4 ±0.3 13.1 13.7 CMM AFTER MACHINING

76 m/cing Allowance 1.5 ±0.5 1 2 CMM 1.32 OK 1.35 OK 1.29 OK 1.40 OK

77 m/cing Allowance 1.5 ±0.5 1 2 CMM 1.32 OK 1.35 OK 1.29 OK 1.40 OK

SECTION C-C

78 Distance 97 ±0.7 96.3 97.7 VC 96.90 OK 97.1 OK 97.21 OK 97.05 OK

79 Distance 50.5 ±0.5 50 51 HG/CMM AFTER MACHINING

80 m/cing Allowance 1.5 ±0.5 1 2 HG/CMM 1.52 OK 1.24 OK 1.51 OK 1.52 OK

81 m/cing Allowance 1.5 ±0.5 1 2 HG/CMM 1.49 OK 1.52 OK 1.32 OK 1.42 OK

82 m/cing Allowance 1.5 ±0.5 1 2 HG/CMM 1.52 OK 1.37 OK 1.30 OK 1.39 OK

SECTION A-A( from model)

83 Depth 0.11 ±0.3 -0.19 0.41 CMM REFERANCE DIMN.

84 Distance 6.19 ±0.3 5.89 6.49 CMM REFERANCE DIMN.

85 Distance 7.33 ±0.3 7.03 7.63 CMM REFERANCE DIMN.

86 Dimension 12.2 ±0.3 11.9 12.5 CMM REFERANCE DIMN.

87 Dimension 0.05 ±0.3 -0.25 0.55 CMM REFERANCE DIMN.

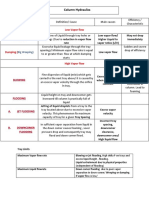

NOTES

General Wall Thickness

88

4 ±0.5

Unspecified Casting

89

Radius R2 Min.

Unspecified Draft

90

Angle 1.5°

No burrs and blow

91

holes

Sand falling must be

done completally

92

specially inner side of

ports

Apply shot blasting

93

prior to machineing

Air passage should be

94

free from flashes

Unspecified dimension

95 tolerance should be as

per ABS00002

Casting should be

96 supplied as per ABS-00-

204

NOTES ON PORT

Maximum surface

97 roughness of ports to

be 50S

Dimension to be held

98 within ±0.3 (length)

and ±0.30' (Angle)

For wall thickness

around ports (formed

by two sandcores)

99

Min. wall thickness for

Exhaust port 5.2±0.6

Min. wall thickness for

Inlet port 5.2±0.6

Remarks:-

Checked by : Virendra Approved by : MR. SHAMBHU YADAV

Checked By; Approved By;

You might also like

- Share EXCEL SHEET FOR CBR TESTDocument1 pageShare EXCEL SHEET FOR CBR TESTTarun100% (1)

- Fuel Injection Pump Data SCANIA DC9Document2 pagesFuel Injection Pump Data SCANIA DC9Mateen Younas100% (1)

- Haver Roto PackerDocument24 pagesHaver Roto Packercassindrome100% (2)

- ICRU 29 Dose Specification For Reporting External Beam Therapy With Photons and Electrons PDFDocument29 pagesICRU 29 Dose Specification For Reporting External Beam Therapy With Photons and Electrons PDFDiego MauricioNo ratings yet

- CYLINDER - ktmHEAD Lay Out (ALICON)Document4 pagesCYLINDER - ktmHEAD Lay Out (ALICON)vikesh1993No ratings yet

- CS Nipple 21K-62-71310Document1 pageCS Nipple 21K-62-71310Inspirasi Kreasi SejahteraNo ratings yet

- Shaft Selector and Shifting (5841 2671 7909) ..Document11 pagesShaft Selector and Shifting (5841 2671 7909) ..Sourabh PradhanNo ratings yet

- K0na - PipeDocument2 pagesK0na - Pipevikesh1993No ratings yet

- 434 MFRDocument10 pages434 MFRHarsh JindalNo ratings yet

- Final Inspection - Tata Ace DiscDocument3 pagesFinal Inspection - Tata Ace DiscazadNo ratings yet

- EAG567 - Inspection ReportDocument2 pagesEAG567 - Inspection ReportDurai NaiduNo ratings yet

- 545 7489 (Eag349) - IsirDocument2 pages545 7489 (Eag349) - IsirDurai NaiduNo ratings yet

- SSV 2019 Brakes Maverick Shop Supp 219100971-030Document7 pagesSSV 2019 Brakes Maverick Shop Supp 219100971-030Coke Ker JetspeedNo ratings yet

- Glorious Electronics India Private Limited: Sample Inspection ReportDocument2 pagesGlorious Electronics India Private Limited: Sample Inspection ReportYogesh YadavNo ratings yet

- Vulcan Core Industries: Sample Inspection CertificateDocument1 pageVulcan Core Industries: Sample Inspection CertificateazadNo ratings yet

- Flange DrawingDocument1 pageFlange DrawingM-NazimNo ratings yet

- Compact Conductor Calculation-1Document4 pagesCompact Conductor Calculation-1Gautama Chandra PradiptaNo ratings yet

- Al TG CaseDocument19 pagesAl TG CaseSurendra SinghNo ratings yet

- Pdi Report: JN Engg Works DATE: 1/8/18Document32 pagesPdi Report: JN Engg Works DATE: 1/8/18Anil kumarNo ratings yet

- A Appearance No Burr, Rust, Crack, Paint Defect Visual: Part No. Part Name ModelDocument24 pagesA Appearance No Burr, Rust, Crack, Paint Defect Visual: Part No. Part Name ModelSanjayNo ratings yet

- PommelDocument3 pagesPommelVilasNo ratings yet

- BRKT Brake PedalDocument8 pagesBRKT Brake PedalSanjayNo ratings yet

- Inspection ReportDocument30 pagesInspection ReportSanjayNo ratings yet

- Vulcan Core Industries: Sample Inspection CertificateDocument1 pageVulcan Core Industries: Sample Inspection CertificateazadNo ratings yet

- Cost Impact Due To Rate Increase in Raw Material: Existing Raw Material Working Revised Raw Material WorkingDocument1 pageCost Impact Due To Rate Increase in Raw Material: Existing Raw Material Working Revised Raw Material WorkingIqbal singh DhanjalNo ratings yet

- Free Flow Cum Pressure Drop Calculations For Filter & StrainerDocument1 pageFree Flow Cum Pressure Drop Calculations For Filter & StrainergauravNo ratings yet

- Catalogue Spec PCWDocument1 pageCatalogue Spec PCWsiranepNo ratings yet

- Injection Pump Test Specifications 092000-512#Document3 pagesInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- 2316C79401 FirDocument1 page2316C79401 FirInder SabhrawalNo ratings yet

- Injection Pump Test Specifications 191000-490#Document3 pagesInjection Pump Test Specifications 191000-490#Miguel Rojas100% (1)

- Pdi Report: JN Engg Works DATE: 29/8/18Document31 pagesPdi Report: JN Engg Works DATE: 29/8/18Anil kumarNo ratings yet

- Clutch Overhaul: Group 21BDocument6 pagesClutch Overhaul: Group 21BPedro BatistaNo ratings yet

- 108 - t1, 31.08.2015 Pdi - Qad-28 Sample Inspection Reportslide Chair - Machine (Ber.319-111108)Document1 page108 - t1, 31.08.2015 Pdi - Qad-28 Sample Inspection Reportslide Chair - Machine (Ber.319-111108)azadNo ratings yet

- Vulcan Core Industries: Sample Inspection CertificateDocument1 pageVulcan Core Industries: Sample Inspection CertificateazadNo ratings yet

- CB0C050F0Document12 pagesCB0C050F0roshni mehraNo ratings yet

- Blade Rod Cycle TimeDocument6 pagesBlade Rod Cycle TimeNeeraj KatariaNo ratings yet

- Excel Sheet For CBR TestDocument1 pageExcel Sheet For CBR TestFariha Azad100% (3)

- t5!18!01 2016 Qad 28 Sample Inspection Reportslide Chair Machine Ber 319 11116Document1 paget5!18!01 2016 Qad 28 Sample Inspection Reportslide Chair Machine Ber 319 11116Sarah FetahNo ratings yet

- 092000-5360-1 Lionn Auto SoftwaresDocument3 pages092000-5360-1 Lionn Auto SoftwaresLionn MartinsNo ratings yet

- Isir - Jaw 121028-00Document2 pagesIsir - Jaw 121028-00rahulkumarqa01No ratings yet

- Power Cables With Their Electricals Characteristics, Overall Length and WeightDocument6 pagesPower Cables With Their Electricals Characteristics, Overall Length and WeightRoumya Darshan RayNo ratings yet

- Free Flow Cum Pressure Drop Calculations For Filter & StrainerDocument18 pagesFree Flow Cum Pressure Drop Calculations For Filter & StrainergauravNo ratings yet

- AC Fans Static Calculation Final-1Document20 pagesAC Fans Static Calculation Final-1Hendrias A.SNo ratings yet

- Inj .P Ump Calibration Data Inj .P Ump Calibration DataDocument1 pageInj .P Ump Calibration Data Inj .P Ump Calibration DataBaytolgaNo ratings yet

- 164-01-01-007 Locating Pin - Dia 2.8Document1 page164-01-01-007 Locating Pin - Dia 2.8cawojNo ratings yet

- CB1C006F0Document6 pagesCB1C006F0roshni mehraNo ratings yet

- SVR-324 SL60 Leveler Foot (Sanjay) 9-4-23Document1 pageSVR-324 SL60 Leveler Foot (Sanjay) 9-4-23sachinNo ratings yet

- PX436 Rev1Document2 pagesPX436 Rev1Leah Cassandra BernardoNo ratings yet

- SPC Study Activity No. 1.3.11Document1 pageSPC Study Activity No. 1.3.11toyota952No ratings yet

- Minotrol 16: LOT Control L ABX LysebioDocument3 pagesMinotrol 16: LOT Control L ABX LysebioTristiana yuliantiNo ratings yet

- Scr452 - 20.01.2016 Pdi - Qad-28 Sample Inspection Reportcheck Rail - Machine (Scr-452)Document1 pageScr452 - 20.01.2016 Pdi - Qad-28 Sample Inspection Reportcheck Rail - Machine (Scr-452)azadNo ratings yet

- Inspection FAN FA 5 NewDocument1 pageInspection FAN FA 5 Newtrafalgarlaw2150No ratings yet

- 164-01-01-000 Locating PinsDocument2 pages164-01-01-000 Locating PinscawojNo ratings yet

- Minotrol 16: LOT Control L ABX LyseDocument3 pagesMinotrol 16: LOT Control L ABX LyseDWI NATULANINo ratings yet

- 103 - 714 SERIES: CharacteristicsDocument2 pages103 - 714 SERIES: CharacteristicsNGUYEN MEDICALNo ratings yet

- CBR ReportDocument5 pagesCBR ReportPhanindra NathNo ratings yet

- Work Order For Ext Mic CalibrationDocument1 pageWork Order For Ext Mic CalibrationBåd BøyNo ratings yet

- Summary of Materials Identification Results: Fence Lanavet Antenna Garoua Veterinary LabDocument1 pageSummary of Materials Identification Results: Fence Lanavet Antenna Garoua Veterinary LabTienou Kamga ThomasNo ratings yet

- Vimal Enterprises: Inspection Report K-Sector, X-296 Midc Waluj Aurangabad-431136Document1 pageVimal Enterprises: Inspection Report K-Sector, X-296 Midc Waluj Aurangabad-431136Jayesh MahaleNo ratings yet

- Terex A300 LoadsDocument22 pagesTerex A300 LoadssekharbrsNo ratings yet

- Barra Balanceadora Mitsubishi L200 2.5 2011-2015Document2 pagesBarra Balanceadora Mitsubishi L200 2.5 2011-2015Alvaro RAMIREZ GARCIANo ratings yet

- CH 1 IntroductionDocument19 pagesCH 1 IntroductionYAVANA BNo ratings yet

- FDOT BB978 RPTDocument14 pagesFDOT BB978 RPTirfanquadriNo ratings yet

- The Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFDocument116 pagesThe Project For Improvement of Power Sector Management in The Lao People's Democratic Republic PDFKizuna L. ChanthavongNo ratings yet

- 6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitDocument17 pages6684-PIP-101-MB-0001 - 000 - 02 - Piping List For Indmax UnitMuthu AlaguRajNo ratings yet

- Wolfe WaveDocument3 pagesWolfe Wavemohamed ibrahimNo ratings yet

- RF Characterisation Tooway PDFDocument20 pagesRF Characterisation Tooway PDFLiviu CasuneanuNo ratings yet

- EXPERIMENT2 (Spring Constant) - 2Document8 pagesEXPERIMENT2 (Spring Constant) - 2Maruf AhmedNo ratings yet

- Column Hydraulics NotesDocument4 pagesColumn Hydraulics NotessatishchemengNo ratings yet

- Casting: Definition, Types, Steps Involved in Casting, Advantages, Disadvantages, Importance (PDF)Document7 pagesCasting: Definition, Types, Steps Involved in Casting, Advantages, Disadvantages, Importance (PDF)Munem ShahriarNo ratings yet

- Ductile Brittle TransitionDocument7 pagesDuctile Brittle TransitionAndrea CalderaNo ratings yet

- WT045CDocument2 pagesWT045CDewa BayuNo ratings yet

- 400 RRDocument20 pages400 RRjimmy barusNo ratings yet

- C1212857-1015-18awg-16-0.254bc-Tew Baoh01Document2 pagesC1212857-1015-18awg-16-0.254bc-Tew Baoh01HugoSpktNo ratings yet

- Design of CribsDocument38 pagesDesign of Cribsjatin singlaNo ratings yet

- Data SheetDocument4 pagesData SheetRachel FloresNo ratings yet

- 3311071.017 DometicRooftopACMechanicalComfortSingleZoneControl SVM AMER (En) 2012 01Document63 pages3311071.017 DometicRooftopACMechanicalComfortSingleZoneControl SVM AMER (En) 2012 01Adrian LedesmaNo ratings yet

- Mixture - WikipediaDocument5 pagesMixture - Wikipediatsvmpm1765No ratings yet

- Nonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiDocument66 pagesNonlinear Modeling of RC Structures Using Opensees: University of Naples Federico IiJorge Luis Garcia ZuñigaNo ratings yet

- Angle Construction Upper PrimaryDocument39 pagesAngle Construction Upper Primarybukenya MosesNo ratings yet

- Optical AberrationDocument20 pagesOptical AberrationShubhangi ShuklaNo ratings yet

- On The Role of Spatial Phase and Phase Correlation in Vision, Illusion, and CognitionDocument14 pagesOn The Role of Spatial Phase and Phase Correlation in Vision, Illusion, and Cognitiondw wwNo ratings yet

- Ring Design Chapter08Document1 pageRing Design Chapter08ismail güleçNo ratings yet

- SpaceshipsDocument3 pagesSpaceshipsPaul McNeil100% (1)

- FT GenedDocument15 pagesFT GenedDino CamposNo ratings yet

- Fan TerminologyDocument12 pagesFan TerminologymukeshkumarjNo ratings yet

- General Notes Fairfax County VADocument5 pagesGeneral Notes Fairfax County VApatriciaNo ratings yet

- Indicator Controller Cum TransmitterDocument1 pageIndicator Controller Cum TransmitterTrumen Technologies PVT LtdNo ratings yet