Professional Documents

Culture Documents

Dubilier Resistor Networks Datasheet

Dubilier Resistor Networks Datasheet

Uploaded by

Ghalielectrosoft GesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dubilier Resistor Networks Datasheet

Dubilier Resistor Networks Datasheet

Uploaded by

Ghalielectrosoft GesCopyright:

Available Formats

RESISTORS RESISTOR NETWORK SIL

Low-profile

Epoxy dipped

5 to 13-pin

The Dubilier range of SIL networks features 2% accuracy in a low-

cost package.

The low-profile epoxy package allows the device to be used in

locations where moulded parts do not fit.

Isolated and common-terminal designs are available, allowing the

simple, reliable insertion of up to 12 resistors at once.

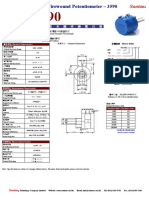

OUTLINE DRAWING

2.5 max

L max

PIN 1 9E-103G 5.2 max

Marking

3.0 ± 0.5

0.5 ± 0.1

3.0 ± 0.1

2.54

± 0.25

SECTION 4

No of Pins 5 6 7 8 9 10 11 12 13

L max 12.7 15.3 17.8 20.4 22.9 25.4 28.0 30.5 33.1

RANGE & TOLERANCES

Parameter Performance Limits

Power Rating per Element 0.125W @ 70°C

Temperature Range -55˚ to +125°C Derating linearly from 70°C

Resistance Range 33Ω to 1MΩ E - 24 series

Resistance Tolerance ± 2% (G)

Temperature Coefficient ± 100 ppm/°C 50Ω ≥ 2.2MΩ

± 250ppm/˚C <50Ω – 2.2MΩ

Max Working Voltage 100V

Max Overload Voltage 200V

ORDERING INFORMATION

9 E 103 G

N° Pins Type Value Tolerance

5 to 13 M = Isolated 3 digit code : 2%

E = Common Last digit is

decade multiplier.

First two digits are

first digits of value.

135

Fax: 01371 875075 www.dubilier.co.uk Tel: 01371 875758

RESISTORS RESISTOR NETWORK SIL

SPECIFICATION

Short Term Overload ∆R/R ± (1% + 0.05Ω)

After application of 21/2 x rated voltage, or the maximum overload voltage, whichever smaller, for a period of 5

secs. Resistance change to be within specification, with no evidence of arcing, burning or charring.

Vibration ∆R/R ± (0.5% + 0.5Ω)

Resistors are to be subjected to vibration of amplitude 0.8mm for 2 hours in each of three mutually

perpendicular directions. The vibration frequency shall be swept from 10 to 55 to 10Hz in 1 minute.

Resistance change to be within specification with no evidence of damage.

Dielectric Strength Components shall withstand twice their rated voltage for 1 minute applied between termination and substrate. No

evidence of arcing, burning or charring.

Solderability ∆R/R ± (1% + 0.05Ω)

After dipping at 260°C ± 5°C for 10 seconds, resistance change to be within specification, with no evidence of

arcing, burning or charring. Terminations shall maintain a minimum of 75% coverage following the procedures of

MIL-STD-202E.

Load Life ∆R/R ± (2% + 0.05Ω)

After 1000 hours application of the rated voltage with a duty cycle of 11/2 hours ON and 1/2 hour OFF, at

70°C. Resistance change to be within specification, with no evidence of arcing, burning or charring.

Moisture Load ∆R/R ± (2% + 0.05Ω)

After 1000 hours application of the rated voltage with a duty cycle of 11/2 hours ON and 1/2 hour OFF, at

40°C and 90-95% RH. Resistance change to be within specification, with no evidence of arcing, burning

or charring.

Voltage Coefficient ∆R/R < 100ppm/V

Flammability Product is conformally coated with epoxy resin conforming to UL94V-0.

SECTION 4

SIL PIN-OUTS

Common (E)

Common parts are characterised by having a number of resistive

elements, all of the same nominal value. All elements are connected to pin 1.

1 2 3 4 5 6 7 8 n-1

n = Number of pins

Isolated (M)

Isolated parts are characterised by having a number of resistive

elements, all of the same nominal value. All elements are independent.

1 2 3 4 5 6 n-1 n

n = Number of pins

136

Fax: 01371 875075 www.dubilier.co.uk Tel: 01371 875758

You might also like

- Sub 01 012Document21 pagesSub 01 012ARYA JENA100% (1)

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- NIC Components NSWC High Voltage SeriesDocument2 pagesNIC Components NSWC High Voltage SeriesNICCompNo ratings yet

- Cement Coated Wirewound Resistors: Electrical DataDocument2 pagesCement Coated Wirewound Resistors: Electrical DataTanay ShahNo ratings yet

- Type SM Series: SMD Moulded Power ResistorDocument9 pagesType SM Series: SMD Moulded Power ResistorHani YaramaniNo ratings yet

- PNP200JR 52 - DatasheetDocument5 pagesPNP200JR 52 - DatasheetsongdashengNo ratings yet

- Bourns CRM0805 DatasheetDocument5 pagesBourns CRM0805 DatasheetbarisNo ratings yet

- Cermet Trimming Potentiometer: Model 67Document4 pagesCermet Trimming Potentiometer: Model 67keyvan cryptoNo ratings yet

- Cl05a104ka5nnnc PDFDocument2 pagesCl05a104ka5nnnc PDFdusk dawnNo ratings yet

- Bourns CRM2512 DatasheetDocument5 pagesBourns CRM2512 DatasheetbarisNo ratings yet

- SBSM Data SheetDocument4 pagesSBSM Data SheetAlex JonesNo ratings yet

- Specification: CL 21 B 105 K A F N N N EDocument3 pagesSpecification: CL 21 B 105 K A F N N N EcometNo ratings yet

- NIC Components NRE-HL SeriesDocument8 pagesNIC Components NRE-HL SeriesNICCompNo ratings yet

- Specification: CL 21 B 105 K B F N N N FDocument2 pagesSpecification: CL 21 B 105 K B F N N N Felias rangelNo ratings yet

- X7R Dielectric: General SpecificationsDocument4 pagesX7R Dielectric: General Specificationsakshay rajNo ratings yet

- Mems Voa Variable Optical Attenuator Data Sheet 560101Document3 pagesMems Voa Variable Optical Attenuator Data Sheet 560101GLsun MallNo ratings yet

- Specification: CL 21 A 226 M A Q N N N FDocument3 pagesSpecification: CL 21 A 226 M A Q N N N Felias rangelNo ratings yet

- Carbon Composition ResistorDocument2 pagesCarbon Composition ResistorEmmanuelSanzNo ratings yet

- Vishay Foil Resistors: FeaturesDocument7 pagesVishay Foil Resistors: FeaturesMahemehr MehrNo ratings yet

- SFR 25Document9 pagesSFR 25Jose Normando SoaresNo ratings yet

- 14FPR090E - Axial Wire Element Current Sense - Ohmite Mfg. Co.Document1 page14FPR090E - Axial Wire Element Current Sense - Ohmite Mfg. Co.KholilNo ratings yet

- Specification: CL 21 F 223 Z B A N N N CDocument3 pagesSpecification: CL 21 F 223 Z B A N N N Csam2976No ratings yet

- X7R Dielectric: General SpecificationsDocument4 pagesX7R Dielectric: General SpecificationsnkswarunNo ratings yet

- CDE (Radial Thru-Hole) SN SeriesDocument4 pagesCDE (Radial Thru-Hole) SN Seriesjghjkhgkh87No ratings yet

- NFM21CC221R1H3 01Document26 pagesNFM21CC221R1H3 01saberNo ratings yet

- Model 89: 3/4" Rectangular Multiturn Cermet Trimming PotentiometerDocument6 pagesModel 89: 3/4" Rectangular Multiturn Cermet Trimming PotentiometerManikanta Sai KumarNo ratings yet

- Product Bulletin: Mof-Mos SeriesDocument2 pagesProduct Bulletin: Mof-Mos Seriesmauricio alfonsoNo ratings yet

- Sfr16S/25/25H: Vishay BccomponentsDocument11 pagesSfr16S/25/25H: Vishay BccomponentsMuhammad BilalNo ratings yet

- Mini Mems Voa Variable Optical Attenuator Dat Sheet 560201Document3 pagesMini Mems Voa Variable Optical Attenuator Dat Sheet 560201GLsun MallNo ratings yet

- Resistor SMD SizesDocument11 pagesResistor SMD Sizescarlos.antouryNo ratings yet

- Alphasense 4Document2 pagesAlphasense 4tonyliu1128No ratings yet

- Componete ElectronicoDocument5 pagesComponete ElectronicoStuxnetNo ratings yet

- NIC Components NRCEDocument2 pagesNIC Components NRCENICCompNo ratings yet

- NIC Components NCSR SeriesDocument5 pagesNIC Components NCSR SeriesNICCompNo ratings yet

- P9 JT Thermistor 1621687Document2 pagesP9 JT Thermistor 1621687ArafetNo ratings yet

- Tegat - Decada Ohm Supply DB877Document7 pagesTegat - Decada Ohm Supply DB877flavio torresNo ratings yet

- T491 Series Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumDocument24 pagesT491 Series Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumSebastian ChaileNo ratings yet

- XDB102 2 (A)Document3 pagesXDB102 2 (A)Young WuNo ratings yet

- Catálogo 2 - Yageodocoutput-1518764Document13 pagesCatálogo 2 - Yageodocoutput-1518764Rafael Román García-sec DNo ratings yet

- Rotative Position Transducer in Conductive Plastic: Main FeaturesDocument2 pagesRotative Position Transducer in Conductive Plastic: Main FeaturesSathish J EceNo ratings yet

- 01 EBG Series PCS 2019Document1 page01 EBG Series PCS 2019Islam El-saiedNo ratings yet

- NTC Thermistor 438959Document5 pagesNTC Thermistor 438959Anonymous eL4Dsp1BaNo ratings yet

- Technical: Single In-Line Conformal Series 770Document3 pagesTechnical: Single In-Line Conformal Series 770MiGuel RodasNo ratings yet

- 多圈的 /圓形/綫繞/面板式 (Multiturn/ Round/ Wirewound) 2 種轉軸的樣式 (2 Shaft Style) sDocument1 page多圈的 /圓形/綫繞/面板式 (Multiturn/ Round/ Wirewound) 2 種轉軸的樣式 (2 Shaft Style) sjonatan arangoNo ratings yet

- KEMETR46Datasheet IEC 60384-14 PDFDocument9 pagesKEMETR46Datasheet IEC 60384-14 PDFHưng HQNo ratings yet

- Honeywell 02212020 Ss94a-1772213Document3 pagesHoneywell 02212020 Ss94a-1772213guruh anindraNo ratings yet

- NIC Components NRE-WX SeriesDocument1 pageNIC Components NRE-WX SeriesNICCompNo ratings yet

- DSA00116625Document7 pagesDSA00116625Ricardo Campos LandaetaNo ratings yet

- Siemon Tera E12 Cable International - Spec SheetDocument2 pagesSiemon Tera E12 Cable International - Spec Sheetinghoc2022No ratings yet

- NIC Components NRGB SeriesDocument5 pagesNIC Components NRGB SeriesNICCompNo ratings yet

- Model 3022 Accelerometer: DimensionsDocument3 pagesModel 3022 Accelerometer: DimensionsRahulNo ratings yet

- Everlight Electronics Co.,Ltd.: Model No: ELS-512EWADocument5 pagesEverlight Electronics Co.,Ltd.: Model No: ELS-512EWAStuxnetNo ratings yet

- T491 Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumDocument23 pagesT491 Industrial Grade Mno: Tantalum Surface Mount Capacitors - Standard TantalumsrtNo ratings yet

- NIC Components NRM SeriesDocument1 pageNIC Components NRM SeriesNICCompNo ratings yet

- Carbon Film ResistorsDocument2 pagesCarbon Film ResistorsGopichandNo ratings yet

- 5.0Mm Infrared Emitting Diode 520E940CDocument4 pages5.0Mm Infrared Emitting Diode 520E940CRonald TucumanNo ratings yet

- XDB102 4Document4 pagesXDB102 4Young WuNo ratings yet

- LC Series - SIP Thick Film Resistor Networks: Electrical SpecificationsDocument1 pageLC Series - SIP Thick Film Resistor Networks: Electrical SpecificationsSyaiful RahmanNo ratings yet

- GDTR3RD7 90 PDFDocument2 pagesGDTR3RD7 90 PDFJuscelino SaraivaNo ratings yet

- Data Sheet: The Sca121T Dual Axis Inclinometer ModulesDocument5 pagesData Sheet: The Sca121T Dual Axis Inclinometer Modulesมนต์ชัย บุญธนลาภNo ratings yet

- Tantalum Surface Mount CapacitorsDocument24 pagesTantalum Surface Mount CapacitorsgausscanaveaNo ratings yet

- SIAI TT3 Attenuator Series v1 0 WEB Oct 19Document6 pagesSIAI TT3 Attenuator Series v1 0 WEB Oct 19Ghalielectrosoft GesNo ratings yet

- Battery charger PUA 80Document9 pagesBattery charger PUA 80Ghalielectrosoft GesNo ratings yet

- B12NM50_STMicroelectronicsDocument17 pagesB12NM50_STMicroelectronicsGhalielectrosoft GesNo ratings yet

- Important InstructionsDocument5 pagesImportant InstructionsGhalielectrosoft GesNo ratings yet

- C9013Document1 pageC9013Ghalielectrosoft GesNo ratings yet

- DatasheetDocument6 pagesDatasheetGhalielectrosoft GesNo ratings yet

- SilverDocument2 pagesSilverGhalielectrosoft GesNo ratings yet

- 9is54389.11 Ewrc 300 500 5000 NT QS en 0422Document16 pages9is54389.11 Ewrc 300 500 5000 NT QS en 0422Ghalielectrosoft GesNo ratings yet

- MPSA05Document1 pageMPSA05Ghalielectrosoft GesNo ratings yet

- User Manual: Label PrinterDocument438 pagesUser Manual: Label PrinterGhalielectrosoft GesNo ratings yet

- 10 GN 1/1 Electric Convection / Steam Oven Forno Convezione / Vapore Elettrico 10 GN 1/1Document13 pages10 GN 1/1 Electric Convection / Steam Oven Forno Convezione / Vapore Elettrico 10 GN 1/1Ghalielectrosoft GesNo ratings yet

- PIPE ComparisonDocument2 pagesPIPE ComparisonDedy WahyudiNo ratings yet

- Negetropic TypeDocument5 pagesNegetropic TypejusditzNo ratings yet

- Electric Current and Resistance: Physics Mr. BermanDocument45 pagesElectric Current and Resistance: Physics Mr. BermanJohnNo ratings yet

- A HRSG System DescriptionDocument25 pagesA HRSG System Descriptionکالرو تحریک اتحاد100% (1)

- Phy CH 8 Final 9thDocument28 pagesPhy CH 8 Final 9thmastersahb302No ratings yet

- HIAB Safety Codes 042014Document14 pagesHIAB Safety Codes 042014Anthony David Martínez VallejoNo ratings yet

- Prices Effective Dated December 01 2022Document8 pagesPrices Effective Dated December 01 2022Ayesha Khan JamilNo ratings yet

- 9 Stereo MSC 4Document60 pages9 Stereo MSC 4Gowtham LecturesNo ratings yet

- Dulevo EngineDocument189 pagesDulevo EngineBheema SolankeNo ratings yet

- RB24EDocument8 pagesRB24EvasqueznildelsonNo ratings yet

- SFL 12Document2 pagesSFL 12Sumitha BaskarNo ratings yet

- Appendix 9D: SPU Electrical Design ChecklistDocument9 pagesAppendix 9D: SPU Electrical Design ChecklistHuan Trinh VanNo ratings yet

- CUMMINS QSX15 Engine - Parts Catalog 79007291 95Document1 pageCUMMINS QSX15 Engine - Parts Catalog 79007291 95Bernard ApuritNo ratings yet

- Fired Heater CO Emission Study ReportDocument15 pagesFired Heater CO Emission Study Reportchemical509No ratings yet

- LUBE Oil AssignmentDocument6 pagesLUBE Oil Assignmentkhansasultan333No ratings yet

- 15 - Wave MotionDocument40 pages15 - Wave MotionDeepakGuptaNo ratings yet

- OMSU51537Document244 pagesOMSU51537eliminar2024No ratings yet

- Sany Asphalt Batching PlantDocument20 pagesSany Asphalt Batching Plantwasco plantNo ratings yet

- What Is Laser PhysicsDocument2 pagesWhat Is Laser PhysicsLuciferNo ratings yet

- Datasheet Solimpeks TSM-200-300 Thermosiphon-Systems Solar-Module-Boiler EU-Turkey 2021 ENGDocument2 pagesDatasheet Solimpeks TSM-200-300 Thermosiphon-Systems Solar-Module-Boiler EU-Turkey 2021 ENGAylimas BadesNo ratings yet

- Om Transa 19e6bcd5Document17 pagesOm Transa 19e6bcd5Abhishek AnandNo ratings yet

- Cambridge Pre-U CertificateDocument40 pagesCambridge Pre-U CertificateKelvin SerimweNo ratings yet

- Hydraulic/Hydrostatic Schematic With SJC and High Flow OptionDocument2 pagesHydraulic/Hydrostatic Schematic With SJC and High Flow OptionalexandrNo ratings yet

- 2Document8 pages2aselok bagbanovnaNo ratings yet

- Case Study: Realization Project - Auroville Earth InstituteDocument16 pagesCase Study: Realization Project - Auroville Earth InstituteLasnaNo ratings yet

- Dometic CF & CFX Fridge TroubleshootingDocument8 pagesDometic CF & CFX Fridge Troubleshootingkatrina.hughesNo ratings yet

- Legacy Positions 6-30-2021Document63 pagesLegacy Positions 6-30-2021Rob PortNo ratings yet

- Fuse Box Diagram Volkswagen Crafter (2017-2020)Document18 pagesFuse Box Diagram Volkswagen Crafter (2017-2020)rhrumanNo ratings yet

- Gothic ArchitectureDocument2 pagesGothic ArchitectureGiovanna CCNo ratings yet