Professional Documents

Culture Documents

BK91-1310-CPF-000-CNS-PCD-0058 - 0 - Procedure For Material Identification and Traceability-C1

BK91-1310-CPF-000-CNS-PCD-0058 - 0 - Procedure For Material Identification and Traceability-C1

Uploaded by

Panneer SelvamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BK91-1310-CPF-000-CNS-PCD-0058 - 0 - Procedure For Material Identification and Traceability-C1

BK91-1310-CPF-000-CNS-PCD-0058 - 0 - Procedure For Material Identification and Traceability-C1

Uploaded by

Panneer SelvamCopyright:

Available Formats

PROCEDURE FOR Doc. No.

BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 1 of 12

BLOCK9 DEVELOPMENT PROJECT PHASE 1

EPCC OF CPF-OIL TREATMENT SYSTEM

AND AUXILIARY SYSTEMS PROJECT

PROCEDURE FOR MATERIAL IDENTIFICATION

AND TRACEABILITY

Document No: BK91-1310-CPF-000-CNS-PCD-0058

30/10/2022

ISSUED FOR

0 15-10-2022 Dong Liuyang Zhang Xiyong Xu Shiyong ZengLiang

USE

REV. DESCRIPTION DATE PREP’D CHK’D REV’D APP’D

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

PROCEDURE FOR Doc. No. BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 2 of 12

REV DATE REVISION DETAILS

0 15/10/2022 ISSUED FOR USE

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

PROCEDURE FOR Doc. No. BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 3 of 12

Contents

1.0 Purpose .............................................................................................................................. 4

2.0 Scope ................................................................................................................................. 4

3.0 Definitions and Abbreviations .......................................................................................... 4

4.0 References Document....................................................................................................... 4

5.0 Roles and Responsibility .................................................................................................. 5

6.0 Procedure .......................................................................................................................... 5

6.1 General ............................................................................................................................... 5

6.2 Piping Materials................................................................................................................... 6

6.3 Steel Pipe............................................................................................................................ 7

6.4 Flange ............................................................................................................................... 10

6.5 Valve ................................................................................................................................. 10

6.6 Instrument Position Number Material ................................................................................ 10

6.7 Cable ................................................................................................................................ 10

6.8 Bridge................................................................................................................................ 11

6.9 Material Traceability .......................................................................................................... 11

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

PROCEDURE FOR Doc. No. BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 4 of 12

1.0 Purpose

The purpose of this procedure is to properly identify materials, to correctly distinguish and

prevent misuse of materials and traceability.

2.0 Scope

This procedure applies to all materials for this project.

3.0 Definitions and Abbreviations

COMPANY Kuwait Energy Basra Limited Subsidiary of United Energy Group

Limited(KEBL)

PMC China Huanqiu Contracting & Engineering Co., Ltd(HQC)

CONTRACTOR China CAMC Engineering Co., Ltd(CAMCE) and CNOOC

Petrochemical Engineering Co., Ltd(CNOOCPEC)

PROJECT EPCC OF CPF-OIL TREATMENT SYSTEM AND AUXILIARY SYSTEM

PROJECT

4.0 References Document

BK91-1310-CPF-000-PUR-PLN-0004_0 Equipment and Material Preservation and

Protection Procedure

BK91-1310-CPF-000-PUR-MMP-0001_0 Site material management procedure

ASME B31.3 Process Piping

ASME B16.5 Pipe Flanges

ASME B16.9 But welded Fittings

ASME B16.11 Socket Welded Fittings

BS 381C Specification for Colours for identification,

Coding and special purposes

ISO 10204 Metallic Products – Types of Inspection

Documents

ISO 17292 Metal Ball Valves for Petroleum,

Petrochemical and Allied Industry

MSS-SP-25 Standard Marking System for Valves,

Fittings, Flanges and Unions

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

PROCEDURE FOR Doc. No. BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 5 of 12

5.0 Roles and Responsibility

The construction technology department is responsible for the implementation and control

of material identification and traceability, and is responsible for the transmission,

recording and management of all kinds of identification.

Material Control department is responsible for material identification, filling in and keeping

identification records, making, using and managing identification cards

Material Manager

Responsible for all the material control activities during purchasing, transportation,

material inspection and site warehousing.

Responsible for all the material & equipment supplied by contractor for incorporation

in to the permanent works.

Plan and prepare the procedure to make sure the material traceability shall be

recorded to identify the original material certificate for piping material and component

even after the completion of pipe installation.

Material Controller

Responsible for performance and execution of receiving inspection activities including

proper preservation activities and documentation.

Responsible for material coding and identification. Make sure the identification of

material is to meet the original certificate.

Prepare the MIR ( Material Inspection Report) and OS&D Report (Over Shortage and

Damage Report).

QA/QC Engineer

Responsible for perform the verification process of materials for quality and

documentation of findings.

Responsible for material inspection and test as client/PMC requirements.

Responsible for verify and correct the wrong, nonconformance and damaged

identification.

Warehouse Keeper

Perform the warehousing activities including receiving and distribute equipment and

materials and proper preservation activities.

Responsible for the Materials Receiving Report, and Materials Balance Report.

Maintenance the materials in storage and make sure the identification of materials is

in good condition.

6.0 Procedure

6.1 General

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

PROCEDURE FOR Doc. No. BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 6 of 12

When placing an order to the supplier, the material purchasing department shall not only

require the supplier to provide material certificate and qualification certificate, but also

require the supplier to mark the name, batch number, specification, model and quality

grade of the material. When the materials are purchased, the warehouse acceptance

procedures should be handled, the purchase records and materials ledger should be

established.

The information sheet shall clearly mark the purchase date, quantity, use, release date

and use part of materials. When receiving materials, there should be evidence of

receiving materials.

The materials entering the warehouse should be classified and labeled to indicate the

name, batch number, specification, model, quantity, purchase date, source, etc.

The materials piled in the open air shall be stacked separately and neatly according to

their varieties and specifications, and the material names, specifications, models, quality

grades, inspection and test status and other information shall be marked with signs.

The signage of the material should be set up in an obvious position near the passageway

of the material storage area, and the signage should be clear and eye -catching. Labels

for materials stored in the warehouse shall be hung above the material shelf.

6.2 Marking Method and Marking Materials

Required markings shall be applied by those methods permitted by the product

specification. However, the following limitations apply:

Hard stamping shall only be applied using "low-stress”(rounded) type die

stamps.

Ink stamped marks shall be made in suitably prepared areas and such marks

shall be protected by clear varnish. Ink stamped marks shall not be used where

permanent marking is required.

Any hard stamped or ink stamped markings are to be highlighted by encircling

with a white painted circle, except where such marks are continuous over the

major portion of the item.

Any paints, inks or varnish shall be durable and marks shall be capable of

remaining legible for at least four years from delivery.

Subject to weather, marine atmosphere and handling. Such marking materials shall not

be injurious to the items being marked and in particular, shall be sulphur-free and not

contain Halogens, Antimony, Arsenic, Copper, Lead, Mercury, Sodium, Vanadium or Zinc

in individual concentrations greater than 0.3% by weight in the dry film.

6.3 Piping Materials

Piping materials include steel pipes, fittings, flanges, valves, gaskets and fasteners.

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

PROCEDURE FOR Doc. No. BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 7 of 12

All piping materials must be individually marked according to the corresponding

manufacturing standard,

The logo shall include at least the following:

Colour coding

Nominal diameter or outer diameter

Thickness, schedule and/or rating as appropriate

Material & Grade

The cast or heat number which correlates the item to the applicable material

certificate

Standard number.

Manufacturer name or trademark

Where small size precludes such individual markings, i.e. socket weld/screwed fittings

and nipples 1" N.B. and smaller, compression fittings, etc, each box/package containing

the same items or pieces shall have the appropriate requisition item number durably

marked on it.

6.4 Steel Pipe

Information of all stainless-steel pipes shall be directly marked on the outer surface of the

steel pipes, and information of other steel pipes shall be marked after rust removal and

painting. Information of steel pipes with diameters > DN150 shall be printed on the inner

surface, and information of steel pipes with diameters ≤ DN150 shall be printed on the

outer surface to avoid ambiguity caused by long-term storage.

Each bundle of packed steel pipes should be attached with no less than 2 information

labels, including at least the following information: material code, outer diameter and wall

thickness, material, standard number, manufacturer's name or trademark, total length and

number of pipes.

Discrimination colors shall be painted on the outer surface of all pipes except galvanized

pipe. One strip of water-proof paint, 25mm wide, shall be provided for each pipe length.

The stripes shall be circumferential, will be on ends with 50mm apart from weld bevel.

One discrimination color shall be one solid line. The color identification shall be clearly

indicated and shall not be easily erasable.

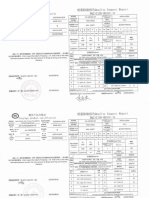

Color coding locations of pipe are shown below,

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

PROCEDURE FOR Doc. No. BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 8 of 12

Identification markings and discrimination colors for piping materials,

Item Material ASTM Specification Discrimination

Color

ASTM A106Gr.B(NACE), Silver

1.1 Carbon steel

seamless + UNS N08825 Clad,

NACE

API SPEC 5L-PSL2-X52NS, Skye-Blue

NACE, Seamless

API 5L Gr.X60 Purple

A672 Gr.C65, CL.12 Pink

A672 Gr.C65, CL.22 White

ASTM A234 Gr. WPB (NACE), White-Silver

Seamless

ASTM A694 F52, NACE Silver-Blue

A333 Gr.6 Yellow

1.2 LTCS

A671 Gr.CC65, CL.22 w/S2 Yellow-Green

1.25Cr-1/2Mo A335 Gr.P11 Orange

1.3

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

PROCEDURE FOR Doc. No. BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 9 of 12

A691 Gr.1.1/4CR, CL.22 Orange-Red

2.25Cr-1Mo SA335 Gr.P22 Yellow-Silver

1.4

9Cr-1Mo A335 Gr.P9 Orange-Orange

1.5

9Cr-1Mo-V A335 Gr.P91

1.6

18Cr-8Ni A312 Gr.TP304/304L Dual Black

2.1

Cert.

A358 Gr.304/304L Dual Cert.,

CL.1

16Cr-12Ni-2Mo A312 Gr.TP316/316L Green

2.2

A358 Gr.316/316L Green-Gray

18Cr-10Ni-Ti A376 Gr.TP321 A358 Gr.321, Gray-Blue

2.3

CL.1

00Cr22Ni5Mo3N UNS S31803,(NACE) Green-white

2.4

22Cr-5Ni-3Mo-N UNS S32205, (NACE) Brown-Black

2.5

Ni-Cu Alloy ASTM B423 UNS N08825, Yellow-Black

2.6

NACE, Seamless

Nickel Alloy ASTM B366-WPNICMC (UNS Blue-Black

2.7

N08825), NACE, WP-S

ASTM B564 UNS N08825, Green-Black

2.8

NACE

ASTM B705 UNS N08825, Orange-Black

2.9

CLASS 2, NACE

6.5 Bolting

In addition to the requirements of the material specification, individual studs and nuts

shall be marked in accordance with the manufacturing standard, including manufacturer's

marks and grade number.

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

PROCEDURE FOR Doc. No. BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 10 of 12

6.6 Gasket

In addition to the requirements of the material specification, all gaskets and jointing shall

be marked with the manufacturer's trade name / trademark and the material grade.

Marking of Ring Joint, Spiral Wound and Jacketed gaskets shall incorporate ASME

B16.20 requirements. All spiral wound gaskets shall be colour coded by painting the outer

edge in total. Colours shall be as shown in Table 19 of ASME B16.20.

6.7 Flange

Flange information shall be uniformly marked on the outermost surface with steel seals,

which shall be clearly visible.

6.8 Valve and Strainers

The material code of the valve shall be uniformly marked on the nameplate. For small

sized valves that are difficult to be marked, stainless steel wire and stainless-steel label

shall be used to mark them. When the valve is delivered in bulk, the material code,

nominal diameter, pound class and material information must be marked on the outer

package or in the form of a tag.

Each complete item, each pressure part (e.g. body, bonnet, cover, welded flange or

welded nipple) and all body/bonnet/cover bolting shall be marked as required by the

applicable product specification. Trim material shall be stated. Each pressure part

shall be individually identifiable to its material certificate by the following:

Marking individual pressure parts with applicable cast or heat number;

Marking of the item and its component material certificates with an appropriate

manufacturing batch number which correlates the item to its component

certificates;

Firesafe soft seated valves shall be marked with seat material, temperature

limitations and state Firesafe;

Where applicable flow arrows shall be marked or cast into the valve body.

6.9 Instrument Position Number Material

Instrument position number material refers to the instrument material with position

number, including thermometer, flow meter, level meter, control valve, etc. The position

number should be uniformly marked on the nameplate. For the small size material that is

difficult to mark, stainless steel wire bolt stainless steel label method should be used to

mark.

6.10 Cable

Both sides of the cable coil must be marked with: coil number, cable model, specification,

length, manufacturer's name or trademark, starting point and ending point meter mark.

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

PROCEDURE FOR Doc. No. BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 11 of 12

Product certificate, test report packed in sealed waterproof bag, and fixed on the plate

must be firm not falling off.

6.11 Bridge

Each bridge shall be marked on both sides with the following permanent signs, clearly

written: model, specification, manufacturer's name or trademark.

The cover plate and partition board shall be packed separately in bundles, and the label

shall contain at least the following contents: model, specification, total quantity,

manufacturer's name or trademark.

6.12 Material Traceability

Material traceability is defined as the method and procedure to trace piping material and

component back to the original material certificate or to the material specification, grade,

size and schedule/rating, by means of proper identification marking of material and

component, such as heat number, code number, colour coding or equipment, throughout

warehousing, pre-fabrication, construction and operation period.

When there is a project quality problem, the material can be traced back according to the

project location, construction date, use of materials, according to the material ledger,

material receipt and purchase documents of materials; The construction process can also

be traced as problems with material use are found. The traceability of the construction

process can be traced according to the parts of the project with problems, the

construction date, the operation personnel, and the relevant construction records, quality

evaluation tables and construction logs of the project.

6.9.1 Tagged Item

Each Tagged item completed at Vendor’s shop shall be identifiable and traceable by

Tag Number and accompanied with Vendor’s Manufacturing Data Record.

Shell and annular bottom plate materials shall be traceable back to the original material

certificate after assembly along with an as-bult drawings.

6.9.2 Pipe materials in receiving stage

Material shall be placed in the designated receiving area segregated from materials

categories, in order to proceed with traceable continuity. This segregation shall be

maintained throughout all receiving and dispensing activities.

CONTRACTOR shall perform receiving inspection to check the marking, colour coding,

overage, shortage and damage of delivered materials.

In addition to the above, CONTRACTOR shall check the receipt of “Inspection Release

Notice (RN)” corresponding to the materials delivered. Materials without such a

document shall remain in the designated receiving hold areas, until the acceptable

document will be available.

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

PROCEDURE FOR Doc. No. BK91-1310-CPF-000-CNS-PCD-0058

MATERIAL Revision 0

IDENTIFICATION Date of Issue 15/10/2022

AND TRACEABILITY

Page 12 of 12

Materials with “Inspection Release Notice” shall be examined, by CONTRACTOR, to

verify that specification marking fully meets the project requirements and corresponds

to the accepted certification.

Nonconforming materials shall be segregated in the nonconforming hold area and

subsequently processed similarly to nonconforming process.

6.9.3 Prefabrication and Construction Stage

Materials shall be controlled and identified by material identification, which can trace

back to original Material Certificate. In addition, piping materials shall be controlled by

colour coding. When cutting pipes, identification marks shall be transferred and be

identified (colour code shall still remain) so that each pressure retaining piping material

shall have the traceability to the original Material Certificate, grade, siza and

schedule/rating after assembly.

CONTRACTOR shall monitor correct material identification and/or color coding

throughout prefabrication, construction and installation activities.

At the completion of an individual fabrication, CONTRACTOR shall verify and

document on the drawings that correct material identification was made and physical

material identification is legible.

Template No.: BK91-1000-000-GEN-TMP-0011

Revision: 3

Date: 06.07.2021

You might also like

- BK91-1310-CPF-000-PMT-LST-0001 - A - Project Contact ListDocument9 pagesBK91-1310-CPF-000-PMT-LST-0001 - A - Project Contact Listraaz.rocky.2023No ratings yet

- Bell 429 Helicopter - High Resolution PanelDocument1 pageBell 429 Helicopter - High Resolution Panelguicordova0% (1)

- 5.1 Vendor Quality PlanDocument52 pages5.1 Vendor Quality PlanPanneer SelvamNo ratings yet

- 5.1 Vendor Quality PlanDocument52 pages5.1 Vendor Quality PlanPanneer SelvamNo ratings yet

- 7022H 400 MS 0000 828 RCDocument18 pages7022H 400 MS 0000 828 RCA.A100% (1)

- Pco 3 For Close Control Units 201728a02Document72 pagesPco 3 For Close Control Units 201728a02Laurentiu Lapusescu50% (2)

- Organizational StructureDocument12 pagesOrganizational StructureLenaldy Nuari Garnoko100% (4)

- BK91-1310-CPF-000-PMT-MAN-0001 - A - Project Management Manual-C2Document8 pagesBK91-1310-CPF-000-PMT-MAN-0001 - A - Project Management Manual-C2raaz.rocky.2023No ratings yet

- BK91-1310-CPF-000-PMT-MAN-0001 - A - Project Management ManualDocument8 pagesBK91-1310-CPF-000-PMT-MAN-0001 - A - Project Management Manualraaz.rocky.2023No ratings yet

- BK91-1310-CPF-000-CNS-CHK-0001 - 0 - Welding and Welding Consumable Control Checklist-C1Document11 pagesBK91-1310-CPF-000-CNS-CHK-0001 - 0 - Welding and Welding Consumable Control Checklist-C1Panneer SelvamNo ratings yet

- BK91 1310 CPF 000 QAC PCD 0006 - 0 - Corrective and Preventive Action Procedure - C1Document11 pagesBK91 1310 CPF 000 QAC PCD 0006 - 0 - Corrective and Preventive Action Procedure - C1Panneer SelvamNo ratings yet

- BK91 1310 CPF 000 QAC PCD 0017 - C - Color Code For Piping Material Identification ProcedureDocument14 pagesBK91 1310 CPF 000 QAC PCD 0017 - C - Color Code For Piping Material Identification ProcedurePanneer SelvamNo ratings yet

- BK91-1310-CPF-999-PIP-SPC-0004 - 3 - Specification For Piping Fabrication - C1Document22 pagesBK91-1310-CPF-999-PIP-SPC-0004 - 3 - Specification For Piping Fabrication - C1Panneer SelvamNo ratings yet

- Bk91 1310 CPF Ved 016 Qac h13 0001 - B - Positive Material Identification Procedure For Basket FiltersDocument8 pagesBk91 1310 CPF Ved 016 Qac h13 0001 - B - Positive Material Identification Procedure For Basket FiltersPanneer SelvamNo ratings yet

- TDG 0040 Ver 3 - 0 Item Specific Guidelines & Schedule of Technical Requirements For Manufacture and Supply of FISHPLATES and FISHPLATE BARSDocument16 pagesTDG 0040 Ver 3 - 0 Item Specific Guidelines & Schedule of Technical Requirements For Manufacture and Supply of FISHPLATES and FISHPLATE BARSPreeti goswamiNo ratings yet

- BK91-1316-CPF-000-CMS-PCD-0017 - B - Commissioning and Start-Up Procedure-C2Document88 pagesBK91-1316-CPF-000-CMS-PCD-0017 - B - Commissioning and Start-Up Procedure-C2Panneer SelvamNo ratings yet

- BK91-1310-CPF-000-QAC-ITP-0024 - D - ITP of Welding C1Document26 pagesBK91-1310-CPF-000-QAC-ITP-0024 - D - ITP of Welding C1Panneer SelvamNo ratings yet

- Abj 89 103778 Ba 6070 00024 0000 01Document16 pagesAbj 89 103778 Ba 6070 00024 0000 01Nithin GNo ratings yet

- BK91-1310-CPF-999-PIP-SPC-0007 - B - Specification For Piping Materials Line Class Summary - c1Document178 pagesBK91-1310-CPF-999-PIP-SPC-0007 - B - Specification For Piping Materials Line Class Summary - c1Panneer SelvamNo ratings yet

- C48. SMEP 2900 QA 6180 0034 - PMI Procedure (PetroNDT) - Rev 01C - ApprovedDocument37 pagesC48. SMEP 2900 QA 6180 0034 - PMI Procedure (PetroNDT) - Rev 01C - Approvedfikril shaharudinNo ratings yet

- BK91 1310 CPF 000 QAC PLN 0001 - 0 - Project Quality Plan C1Document92 pagesBK91 1310 CPF 000 QAC PLN 0001 - 0 - Project Quality Plan C1Panneer SelvamNo ratings yet

- Hva ErpDocument143 pagesHva ErpAlif FirdausNo ratings yet

- Attenchment - Pipe Support Specification and Drawings For Reference (Template)Document11 pagesAttenchment - Pipe Support Specification and Drawings For Reference (Template)Kingsly NovaNo ratings yet

- Method Statement Hot InsulationDocument14 pagesMethod Statement Hot InsulationSaleem AkhtarNo ratings yet

- Kak Ayt Rec Cms 0006 Concrete Works Rev.a00Document10 pagesKak Ayt Rec Cms 0006 Concrete Works Rev.a00rickie7809No ratings yet

- 20SRV002-NGL-QC-ITP-001 Rev C0Document11 pages20SRV002-NGL-QC-ITP-001 Rev C0mohd as shahiddin jafri100% (1)

- Koc Design BasisDocument92 pagesKoc Design BasisgyanwapiNo ratings yet

- 14 662000 4800000322 Mob Mec MST 000021 - 01Document21 pages14 662000 4800000322 Mob Mec MST 000021 - 01HassanNo ratings yet

- BK91-1310-CPF-999-MAW-SPC-0009 - 1 - Specification For Piping Welding - C1Document28 pagesBK91-1310-CPF-999-MAW-SPC-0009 - 1 - Specification For Piping Welding - C1Panneer SelvamNo ratings yet

- A MTL Pro 000 38673 CDocument21 pagesA MTL Pro 000 38673 CHussein Adnan FneishNo ratings yet

- QAC-PRD-014 Numbering of Project Document - OK - CopyDocument12 pagesQAC-PRD-014 Numbering of Project Document - OK - CopyAjeng Fransiska SihombingNo ratings yet

- 21008-TRHT-SP-QC-00-OO-002_0Document16 pages21008-TRHT-SP-QC-00-OO-002_0AslaouiNo ratings yet

- Mpmy PM PRC 0002 - 1.0 Equipment and Tag Numbering ProcedureDocument21 pagesMpmy PM PRC 0002 - 1.0 Equipment and Tag Numbering ProcedureAnonymous 1ykzuaxWgYNo ratings yet

- STR-ISEJ - Final - 19 - 09 - 2022Document10 pagesSTR-ISEJ - Final - 19 - 09 - 2022Preeti goswamiNo ratings yet

- Supraco - CEMP - Rev.C - Patuha - Final Draft - 031121Document78 pagesSupraco - CEMP - Rev.C - Patuha - Final Draft - 031121muhammad fitrah ashariNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument25 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNo ratings yet

- MS For Flange Management and Bolt TighteningDocument18 pagesMS For Flange Management and Bolt TighteningVasilica BArbarasaNo ratings yet

- Quality Control Procedure Index) - Rev.2Document3 pagesQuality Control Procedure Index) - Rev.2valent aviolandaNo ratings yet

- MES For GRP Pipes InstallationDocument23 pagesMES For GRP Pipes InstallationTaiwo Oshin100% (2)

- KNPC Project Spec - CP Design BasisDocument40 pagesKNPC Project Spec - CP Design Basis이선엽No ratings yet

- OMPC - CS.DQR.001.04-2022 - I75r0 - MSI L1C DQR May 2022Document56 pagesOMPC - CS.DQR.001.04-2022 - I75r0 - MSI L1C DQR May 2022Ghi OmNo ratings yet

- Ms-Dd-A3000-Str-Pln-0003 - Rev0 - 02-INSPECTION TEST PROCEDURE AND INSPECTION TEST PLAN (ITP)Document25 pagesMs-Dd-A3000-Str-Pln-0003 - Rev0 - 02-INSPECTION TEST PROCEDURE AND INSPECTION TEST PLAN (ITP)sameerNo ratings yet

- 1.5 Assurance ProcessDocument9 pages1.5 Assurance Processaswar100% (1)

- 2006-4200-0L-0001 Rev C General Quality Requirements Specification - ApprovedDocument20 pages2006-4200-0L-0001 Rev C General Quality Requirements Specification - Approvedxuanson_1988No ratings yet

- NCR 002 - Bengkokan Besi Slab Control RoomDocument2 pagesNCR 002 - Bengkokan Besi Slab Control RoomAl Farisi FirdausNo ratings yet

- BK91-1324-EPL-000-QAC-PLN-0001 - 0 - Project Quality Plan-C1Document72 pagesBK91-1324-EPL-000-QAC-PLN-0001 - 0 - Project Quality Plan-C1Panneer SelvamNo ratings yet

- AllignmentDocument19 pagesAllignmentSyed WaseemNo ratings yet

- Ms-Dd-A3000-Str-Pln-0003 - 0-Inspection Test Procedure and Inspection Test Plan (Itp)Document18 pagesMs-Dd-A3000-Str-Pln-0003 - 0-Inspection Test Procedure and Inspection Test Plan (Itp)sameerNo ratings yet

- 1-Procedure For Material Control at SiteDocument27 pages1-Procedure For Material Control at Siteezhila964No ratings yet

- Method Statement For Pipe Sleeve InstallationDocument7 pagesMethod Statement For Pipe Sleeve InstallationmieadidassNo ratings yet

- Proprietary & Confidential: PM AuthorisationDocument34 pagesProprietary & Confidential: PM AuthorisationMuhammad Najam AbbasNo ratings yet

- BP Khazzan Concrete KZ02-CV-SPE-68-2002-C02Document82 pagesBP Khazzan Concrete KZ02-CV-SPE-68-2002-C02MD Francis DuqmNo ratings yet

- BK91-1310-CPF-000-QAC-ITP-0035 - A - ITP of Pipe Support Work-C1Document11 pagesBK91-1310-CPF-000-QAC-ITP-0035 - A - ITP of Pipe Support Work-C1Panneer SelvamNo ratings yet

- MPS Anode Installation Belida - KPI R0 - Signed TIMASDocument19 pagesMPS Anode Installation Belida - KPI R0 - Signed TIMASAlfian ImaduddinNo ratings yet

- 06-Feb-2020 Page 1 of 13: Unit: General - Applicable To ALL Sub Areas On The ProjectDocument13 pages06-Feb-2020 Page 1 of 13: Unit: General - Applicable To ALL Sub Areas On The Projectmtirzo69No ratings yet

- MOE Issue 2 Rev 02 DT 30-05-2023 - CompressedDocument466 pagesMOE Issue 2 Rev 02 DT 30-05-2023 - CompressedBenzeer TanhaNo ratings yet

- 1.5 Assurance ProcessDocument9 pages1.5 Assurance ProcessaswarNo ratings yet

- 10 152111 4800000601 Pet Mec SPC 000001 - 01Document18 pages10 152111 4800000601 Pet Mec SPC 000001 - 01helalsolimanNo ratings yet

- J910-DT03-P0ZEN-040003 SQCP-0102 (Control and Preparation of Procedures) - Rev.0 (AWC)Document9 pagesJ910-DT03-P0ZEN-040003 SQCP-0102 (Control and Preparation of Procedures) - Rev.0 (AWC)Budi SetiawanNo ratings yet

- 1-Method of Statment - ConduitsDocument17 pages1-Method of Statment - ConduitsSyed AtherNo ratings yet

- BK91 1324 EPL 000 CNS PCD 0024 - 0 - HDD Crossing Procedure - C1Document21 pagesBK91 1324 EPL 000 CNS PCD 0024 - 0 - HDD Crossing Procedure - C1Panneer SelvamNo ratings yet

- Method Statement For Installation of Chain Link Fence and GateDocument10 pagesMethod Statement For Installation of Chain Link Fence and GateBerry UmpolaNo ratings yet

- KAK-AYT-REC-CMS-0002 Installation of Duct Bank Rev.A01Document10 pagesKAK-AYT-REC-CMS-0002 Installation of Duct Bank Rev.A01rickie7809No ratings yet

- Process Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesFrom EverandProcess Analytical Technology: Spectroscopic Tools and Implementation Strategies for the Chemical and Pharmaceutical IndustriesKatherine A. BakeevNo ratings yet

- CAMCE QA QC Team Updates On Approval Dated 01.08.2023Document1 pageCAMCE QA QC Team Updates On Approval Dated 01.08.2023Panneer SelvamNo ratings yet

- BK91 1310 CPF Pip RT 0015 1Document5 pagesBK91 1310 CPF Pip RT 0015 1Panneer SelvamNo ratings yet

- BK91-1310-CPF-169-PIP-IDX-0001 - 1 - Piping Isometric Drawing Index For Fuel Gas System - C4Document71 pagesBK91-1310-CPF-169-PIP-IDX-0001 - 1 - Piping Isometric Drawing Index For Fuel Gas System - C4Panneer SelvamNo ratings yet

- 111 Remaining Construction Work Schedule-20231206-ADocument1 page111 Remaining Construction Work Schedule-20231206-APanneer SelvamNo ratings yet

- Bk91-1310-Cpf-182-Pip-Lay-0001 - 0 - Piping Layout For Chemical Injection Skid (01) - C1Document1 pageBk91-1310-Cpf-182-Pip-Lay-0001 - 0 - Piping Layout For Chemical Injection Skid (01) - C1Panneer SelvamNo ratings yet

- BK91-1310-CPF-999-PIP-SPC-0007 - B - Specification For Piping Materials Line Class Summary - c1Document178 pagesBK91-1310-CPF-999-PIP-SPC-0007 - B - Specification For Piping Materials Line Class Summary - c1Panneer SelvamNo ratings yet

- Welding Summary Sheet: Package:1310-U112-SO-HT-008Document5 pagesWelding Summary Sheet: Package:1310-U112-SO-HT-008Panneer SelvamNo ratings yet

- BK91 1310 CPF Pip MT 0041 5Document1 pageBK91 1310 CPF Pip MT 0041 5Panneer SelvamNo ratings yet

- BK91-1310-CPF-000-QAC-ITP-0024 - D - ITP of Welding C1Document26 pagesBK91-1310-CPF-000-QAC-ITP-0024 - D - ITP of Welding C1Panneer SelvamNo ratings yet

- BK91-1318-01-FSF-000-PIP-RFI-0029 Request For Inspection of Carbon Steel Pipe Material - SignedDocument293 pagesBK91-1318-01-FSF-000-PIP-RFI-0029 Request For Inspection of Carbon Steel Pipe Material - SignedPanneer SelvamNo ratings yet

- BK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentDocument67 pagesBK91 1328 01 FSF 000 PIP RFI 0070 Pipe Fitting AttachmentPanneer SelvamNo ratings yet

- BK91 1332 01 FSF 000 PIP RFI 0092 - Final Visual Examination of Completed Welds FH Q (Y) Wellpad Piping As Per Attachment 11 - SignedDocument2 pagesBK91 1332 01 FSF 000 PIP RFI 0092 - Final Visual Examination of Completed Welds FH Q (Y) Wellpad Piping As Per Attachment 11 - SignedPanneer SelvamNo ratings yet

- BK91 1332 01 FSF 000 PIP RFI 0101 - Final Visual Examination of Completed Welds FH Q (Y) Wellpad Piping As Per Attachment 12 - SignedDocument2 pagesBK91 1332 01 FSF 000 PIP RFI 0101 - Final Visual Examination of Completed Welds FH Q (Y) Wellpad Piping As Per Attachment 12 - SignedPanneer SelvamNo ratings yet

- Bk91 1310 CPF Ved 016 Qac h13 0001 - B - Positive Material Identification Procedure For Basket FiltersDocument8 pagesBk91 1310 CPF Ved 016 Qac h13 0001 - B - Positive Material Identification Procedure For Basket FiltersPanneer SelvamNo ratings yet

- BK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsDocument69 pagesBK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsPanneer SelvamNo ratings yet

- Welding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempDocument1 pageWelding Procedure Specification (WPS) Pipeline: Lower Than PQR Preheat TempPanneer SelvamNo ratings yet

- 16271A0334. SeminarDocument13 pages16271A0334. SeminaranilbabuNo ratings yet

- Ski Jump Info CVF & Others Testing 28 May 2014 pp163Document163 pagesSki Jump Info CVF & Others Testing 28 May 2014 pp163SpazSinbad2100% (1)

- EED - B.Tech - Instruction Mannual For Report WrittingDocument9 pagesEED - B.Tech - Instruction Mannual For Report WrittingSrivastava BodakuntiNo ratings yet

- DEPP Programmer's Reference ManualDocument5 pagesDEPP Programmer's Reference ManualRaul Gil BayardoNo ratings yet

- FI - PK.FIT.001 - BASE 1: Fitting Guide Base CabinetDocument1 pageFI - PK.FIT.001 - BASE 1: Fitting Guide Base CabinetChris MilnerNo ratings yet

- ElectronDocument7 pagesElectronJackNo ratings yet

- FDMC 8884Document7 pagesFDMC 8884Kholit LitNo ratings yet

- Fem PDFDocument3 pagesFem PDFJavedNo ratings yet

- OUTdoorCTVT CatalogueDocument28 pagesOUTdoorCTVT CataloguemesinNo ratings yet

- APA TablesDocument7 pagesAPA TablesMohd Hafis SahariNo ratings yet

- v4 BDC Precertification WorksheetDocument52 pagesv4 BDC Precertification WorksheetViancahossenNo ratings yet

- 80096503-001-E ID TECH SecureMag OPOS User's ManualDocument34 pages80096503-001-E ID TECH SecureMag OPOS User's ManualEvangelista Francisco LacombaNo ratings yet

- BD Multicolor Fluorochrome SpecsDocument1 pageBD Multicolor Fluorochrome SpecsKatona imreNo ratings yet

- Nyloflex FTF enDocument2 pagesNyloflex FTF enThe1LegendNo ratings yet

- Omega Product Price List PDFDocument10 pagesOmega Product Price List PDFVCNo ratings yet

- Hexweb - Honeycomb Attributes and Properties PDFDocument40 pagesHexweb - Honeycomb Attributes and Properties PDFkolle_sdestefaNo ratings yet

- LED Street LightingDocument4 pagesLED Street LightingmswgtsNo ratings yet

- L10-Casting DesignDocument42 pagesL10-Casting DesignKhayrulIslam100% (2)

- C4.16B Lissajous PatternDocument8 pagesC4.16B Lissajous PatternVINAY GAUTAMNo ratings yet

- SWOT AnalysisDocument15 pagesSWOT AnalysisobnI_100% (2)

- Topics For Research: 1. Airport Terminal 2. Aviation Center 3. Hangars and CargoDocument21 pagesTopics For Research: 1. Airport Terminal 2. Aviation Center 3. Hangars and CargopriyankaNo ratings yet

- Ultrasonic Range Meter ReportDocument75 pagesUltrasonic Range Meter Reportkopiko100% (1)

- Civic Center Design GuidelinesDocument18 pagesCivic Center Design GuidelinesaldridgeNo ratings yet

- Ease and Wizz Read MeDocument3 pagesEase and Wizz Read MeMario ParraNo ratings yet

- Brookfield Viscometer AssignmentDocument4 pagesBrookfield Viscometer AssignmentRicardo VelozNo ratings yet

- Hastelloy C276 Lap Joint Flange 900LB 900# CLASS900Document2 pagesHastelloy C276 Lap Joint Flange 900LB 900# CLASS900Yilia WangNo ratings yet

- Hema Sysmex CSDocument8 pagesHema Sysmex CSMaya RustamNo ratings yet