Professional Documents

Culture Documents

Schedule Plan Repair Crankshaft Ariel-PT. TMG

Schedule Plan Repair Crankshaft Ariel-PT. TMG

Uploaded by

Hanan Darmala Hanan0 ratings0% found this document useful (0 votes)

8 views2 pagesschedule plan

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentschedule plan

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

8 views2 pagesSchedule Plan Repair Crankshaft Ariel-PT. TMG

Schedule Plan Repair Crankshaft Ariel-PT. TMG

Uploaded by

Hanan Darmala Hananschedule plan

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 2

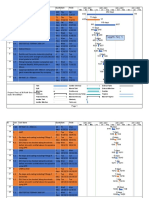

Project Name : Repair Crankhaft Ariel

Customer : PT. Tri Mulya Gemilang

: PT. Pertamina EP Asset 2 Prabumulih

SCHEDULE PLAN REPAIR CRANKSHAFT PT. TRIMULYA GEMILANG / PT.

Date : March ,27, 2024

Location Repair : PT. SSE - Van Der Horst Indonesia

PERTAMINA ASSET 2 PRABUMULIH

Year 2024

Part Month March April ( Leave lebaran Day 6-14 April 2024 ) May

No Description Job

Name s

Date 28 29 29 30 31 1 2 3 4 5 6 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

d

Fase 1 ( Pre-Inspection )

1 Dimensional Check

2 Run Out Check

3 Hardness Check

4 NDT Check

Fase 2 ( Annealing Process )

5 Preparation Jig

6 Heat Treatment Process

7 Holding Process

8 Cooling Process

Crankhshaft Compressor Ariel

9 Final Check After treatment

Fase 2 ( Pre Grinding )

10 Pin Journal 1

11 Pin Journal 2

12 Pin Journal 3

13 Pin Journal 4

14 Main Journal 1, 2, 3, 4

Fase 3 ( Hardchrome Plating )

15 Pin Journal 1

16 Pin Journal 2

17 Pin Journal 3

18 Pin Journal 4

9 Main Journal 1, 2, 3, 4

19

Fase 4 ( Finish Grinding )

20 Pin Journal 1

21 Pin Journal 2

22 Pin Journal 3

23 Pin Journal 4

24 Main Journal 1, 2, 3, 4

Fase 5 ( Final Inspection )

25 Dimensional Check

26 Run Out Check

27 Hardness Check

28 NDT Check

Fase 5 ( Final Inspection )

29 Join Inpsection

Date Issue :

Prepared By, Approved By, Approved By,

Bayu Eka Putra Redi Mardono Y.Darmala Sakti

Engineering Supervisor Whs Eng & Workshop Manager

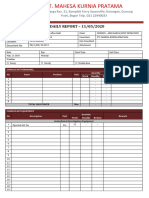

Project Name : Repair Crankcase Ariel

Customer : PT. Tri Mulya Gemilang

: PT. Pertamina EP Asset 2 Prabumulih

SCHEDULE PLAN REPAIR CRANKCASE PT. TRIMULYA GEMILANG / PT. PERTAMINA

Date : March ,27, 2024

Location Repai: PT. SSE - Van Der Horst Indonesia

ASSET 2 PRABUMULIH

Year

Part Month May

No Description Job

Name s

Date 6 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 1 2 3 4 5 6 7 8 9 10 11 12 12 14 15 16 17 18 19 20 21 22 23 24 25 26

d

Fase 1 ( Pre-Inspection )

1 Preparation

2 Crew OTW Prabumulih

Fase 2 (Pre-Inspection )

3 Dimensional Check

4 NDT Check

5 Alignment

Fase 3 ( Setting Line Boring )

6 Setting Shaft Bar

7 Welding Position

Fase 4 ( Running Pre-Machine )

8 Pre- Machining Pocket 1 ( If Necessary ) See After

Inspection

9 Pre- Machining Pocket 2 ( If Necessary)See After

Crankcase Compressor Ariel

Inspection

10 Pre- Machining Pocket 3 ( If Necessary ) See After

Inspection

11 Pre- Machining Pocket 4 ( If Necessary ) See After

Inspection

Fase 5 ( Welding ) Before Metal Spray

12 Welding Side Pocket Bore 1

13 Welding Side Pocket Bore 2

14 Welding Side Pocket Bore 3

15 Welding Side Pocket Bore 4

Fase 7 ( Metal Spray Process )

16 Metal Spray Pocket 1,2,3,4 See after Pre-

inspection

Fase 8 ( Machining Cap on upper area)

17 Machining Cap on seration Area

Fase 9 ( Finish Machining )

18 Finishing Pocket Bore 1

19 Finishing Pocket Bore 2

20 Finishing Pocket Bore 3

21 Finishing Pocket Bore 4

Fase 10 ( Polishing After Machining )

22 Polishing All Boring Pocket

Fase 11 ( Final Inspection )

23 Dimensional Check

24 NDT Check

Alignment Check

Fase 12 ( Final Inspection )

25

Join Inspection ( Install crankshaft to Crankcase )

Date Issue :

Prepared By, Approved By, Approved By,

Bayu Eka Putra Redi Mardono Redi Mardono

Engineering Supervisor Whs Supervisor Whs

You might also like

- Code Examples For dsPIC30F4011Document28 pagesCode Examples For dsPIC30F4011Minh VuNo ratings yet

- Daily Report Periode Agustus 2023Document8 pagesDaily Report Periode Agustus 2023dipo eskaNo ratings yet

- Method Statement For Exposed ColumnsDocument12 pagesMethod Statement For Exposed ColumnsdeviesrigatiNo ratings yet

- Shutdown Activity Gantt Chart1 - PPGM GOH 1 REFURBISHMENTDocument1 pageShutdown Activity Gantt Chart1 - PPGM GOH 1 REFURBISHMENTsyauqi885451No ratings yet

- WPR 001Document11 pagesWPR 001Vinay ShuklaNo ratings yet

- Program Semester (Ganjil)1Document2 pagesProgram Semester (Ganjil)1zazalihasromiNo ratings yet

- Weekly Report - 04Document21 pagesWeekly Report - 04Anisa FebrianaNo ratings yet

- Gantt Chart Template PlanioDocument10 pagesGantt Chart Template PlanioSachin BharadwajNo ratings yet

- Team No.1: Team No.1 Initial Dossier, Site Surveying and MobilizationDocument4 pagesTeam No.1: Team No.1 Initial Dossier, Site Surveying and Mobilizationمهندس حسينNo ratings yet

- Daily Report 11 April 2024 No SignDocument2 pagesDaily Report 11 April 2024 No Signstefanustobing0907No ratings yet

- Daily Report 10 April 2024 No SignDocument2 pagesDaily Report 10 April 2024 No Signstefanustobing0907No ratings yet

- Obtimal New BKJDocument4 pagesObtimal New BKJKhalidperkasaNo ratings yet

- TS No.2 Rev.4Document4 pagesTS No.2 Rev.4مهندس حسينNo ratings yet

- Developer Progres & Performance Report: Sesi Report Process by Leader Name: Date Title Name Date: StatusDocument6 pagesDeveloper Progres & Performance Report: Sesi Report Process by Leader Name: Date Title Name Date: StatusEka KurniawanNo ratings yet

- PDF MaraDocument3 pagesPDF MaraKevin ChangNo ratings yet

- WBS - MC - Task 1Document6 pagesWBS - MC - Task 1Siddhant sharmaNo ratings yet

- Schedule Masking Vacuum PadDocument2 pagesSchedule Masking Vacuum Padfajri asyukronNo ratings yet

- Sweihan Project Status Krinner Screw/ FoundationDocument9 pagesSweihan Project Status Krinner Screw/ FoundationHarshad ShirsathNo ratings yet

- JTT2A Piling Plan For Tank & Non Tank Rec1 - 21 Jan 19Document82 pagesJTT2A Piling Plan For Tank & Non Tank Rec1 - 21 Jan 19irfanNo ratings yet

- Gantt ChartDocument4 pagesGantt ChartAbi ConstructionsNo ratings yet

- Daily Report: Classification (직군) Prev. (전일누계) Attend (출석) Absen (결근) Total (누계)Document2 pagesDaily Report: Classification (직군) Prev. (전일누계) Attend (출석) Absen (결근) Total (누계)ICEDA HumNo ratings yet

- Progress Report From NOV 30-03-2021Document2 pagesProgress Report From NOV 30-03-2021aurinkokelloNo ratings yet

- Pengadaan Pompa Type Reciprocating Pump Api 674 Area Spu-E Dan Spu-F Sangasanga FieldDocument2 pagesPengadaan Pompa Type Reciprocating Pump Api 674 Area Spu-E Dan Spu-F Sangasanga FieldaurinkokelloNo ratings yet

- Calendar of Events2019-2020 - EvenDocument1 pageCalendar of Events2019-2020 - EvenBasavaraj HsNo ratings yet

- 9736-Schedule Analisis 20180813 R3 - PIPDocument36 pages9736-Schedule Analisis 20180813 R3 - PIPaateka02No ratings yet

- BSN Balance Work Monitoring 201125.rev2Document2 pagesBSN Balance Work Monitoring 201125.rev2van binh NguyenNo ratings yet

- Time Sheet Bulanan Periode April 2023Document13 pagesTime Sheet Bulanan Periode April 2023Suto WijoyoNo ratings yet

- WeldingDocument5 pagesWeldingNikos Budi TrapsiloNo ratings yet

- February CalendarDocument1 pageFebruary Calendarapi-243020841No ratings yet

- Time Schedule Installation Panel F1 BuildingDocument1 pageTime Schedule Installation Panel F1 BuildingabdiwahyusejatiNo ratings yet

- 254 - A.O.D - (A.o.d Duck)Document1 page254 - A.O.D - (A.o.d Duck)mitendra singhNo ratings yet

- OKADA - Up Rising Gantt ChartDocument1 pageOKADA - Up Rising Gantt ChartNoriele Paul CruzNo ratings yet

- Project Dry Docking Rampdoor Ali-7 Dan Ali-8: Progress ReportDocument1 pageProject Dry Docking Rampdoor Ali-7 Dan Ali-8: Progress Reportrianto arung payungNo ratings yet

- Jadwal Pengadaan Spare Part Meter TurbinDocument1 pageJadwal Pengadaan Spare Part Meter TurbinGaluh WulandariNo ratings yet

- Project Schedule - (Line Protector) & Update - 240718Document12 pagesProject Schedule - (Line Protector) & Update - 240718laodeasidinNo ratings yet

- 1 Preliminaries Works 20 Days 04/01/21 26/01/21Document15 pages1 Preliminaries Works 20 Days 04/01/21 26/01/21Mohd ShahrizanNo ratings yet

- Gantt Chart Template PlanioDocument10 pagesGantt Chart Template PlanioAkpevweoghene Kelvin IdogunNo ratings yet

- Calendar - Jul-Nov - 2024 - Version - 2Document1 pageCalendar - Jul-Nov - 2024 - Version - 2adbrosstpro13No ratings yet

- Gantt Chart Template PlanioDocument10 pagesGantt Chart Template PlaniookahertaberNo ratings yet

- CookbookDocument53 pagesCookbookshashiNo ratings yet

- 3week Schedule For STG Up To 210921Document2 pages3week Schedule For STG Up To 210921Maz KentirNo ratings yet

- Cleaning Accesories FurnaceDocument1 pageCleaning Accesories Furnaceharisona09No ratings yet

- Annual Report - 2013 Applications: ST ND RD THDocument2 pagesAnnual Report - 2013 Applications: ST ND RD THArchuNo ratings yet

- Planing Lembur Libur LebaranDocument2 pagesPlaning Lembur Libur LebaranratnaNo ratings yet

- TPR For AKL For FR End Cut ToolsDocument7 pagesTPR For AKL For FR End Cut ToolsMuralidhara BangaloreNo ratings yet

- Report Soil Investigation Sheet PileDocument213 pagesReport Soil Investigation Sheet PileO GultomNo ratings yet

- Report Concrete Pedestal Oil TankDocument9 pagesReport Concrete Pedestal Oil Tanksimson rante100% (1)

- 18-24 Maret 2022Document14 pages18-24 Maret 2022BanyuNo ratings yet

- CALENDER OF EVENTS 3rd Sem 2023 - 2024Document5 pagesCALENDER OF EVENTS 3rd Sem 2023 - 2024Varshitha KnNo ratings yet

- Project ScheduleDocument1 pageProject Schedulekwame fosterNo ratings yet

- DW 01 Main Office SAJO 11.05.2020Document2 pagesDW 01 Main Office SAJO 11.05.2020Ilham LintangNo ratings yet

- Ddd-Lmind-09-Pj-Wp-014 Weekly Progress Report 15 Mar 2024 - 21 Mar 2024Document17 pagesDdd-Lmind-09-Pj-Wp-014 Weekly Progress Report 15 Mar 2024 - 21 Mar 2024Danny DidanzNo ratings yet

- Daily Report BG. PST 215 (25 Juni 2020)Document5 pagesDaily Report BG. PST 215 (25 Juni 2020)angga andi ardiansyahNo ratings yet

- Vital Point No 24 Pak AgusDocument1 pageVital Point No 24 Pak AgusRafatharNo ratings yet

- JPL Tower John Jacob JPL CorporationDocument4 pagesJPL Tower John Jacob JPL CorporationAlvin AbilleNo ratings yet

- Commissioning ScheduleDocument1 pageCommissioning Scheduleagus lengoletaNo ratings yet

- JTB 1 Material Status DEG - Updated 12 Apr 2021Document2 pagesJTB 1 Material Status DEG - Updated 12 Apr 2021FirzaNo ratings yet

- Weekly ReportDocument1 pageWeekly Report2024 gaopanNo ratings yet

- DDD Lmind 09 PJ WP 002Document14 pagesDDD Lmind 09 PJ WP 002Danny DidanzNo ratings yet

- Jadwal Pengecekan Atau Penggantian Motor Atau Pompa Pt. Deltamas Prima SentosaDocument2 pagesJadwal Pengecekan Atau Penggantian Motor Atau Pompa Pt. Deltamas Prima SentosaAgus Dwi SutrisnoNo ratings yet

- Controlling Reheat Steam Temperature in Once Through BoilersDocument8 pagesControlling Reheat Steam Temperature in Once Through Boilersபிரசன்னகுமார் ஆனந்தன்100% (1)

- Adi ss7Document29 pagesAdi ss7adityamishra244100% (4)

- Iit Books (Interview of Iitian Rank 3)Document2 pagesIit Books (Interview of Iitian Rank 3)Abhishek BhardwajNo ratings yet

- Land Rover Discovery SportDocument2 pagesLand Rover Discovery SportnikdianaNo ratings yet

- r05310404 Digital CommunicationsDocument7 pagesr05310404 Digital CommunicationsSRINIVASA RAO GANTANo ratings yet

- TP1321 PDFDocument13 pagesTP1321 PDFplacintaruNo ratings yet

- About Barfani DadajiDocument4 pagesAbout Barfani DadajiNaren MukherjeeNo ratings yet

- Lec 21Document14 pagesLec 21deepanshuNo ratings yet

- Foreign Part A: Fire Suppression System S/N Description Unit Foam Proportioning Unit Vertical Bladder Type Ul ListedDocument6 pagesForeign Part A: Fire Suppression System S/N Description Unit Foam Proportioning Unit Vertical Bladder Type Ul ListedNakoraNo ratings yet

- Application of UV Spectrophotometric Method For Estimation of Iron in Tablet Dosage FormDocument2 pagesApplication of UV Spectrophotometric Method For Estimation of Iron in Tablet Dosage Formahmed ismailNo ratings yet

- P 75-92 QTR 2 TG Module 2 Plant and Animal CellsDocument18 pagesP 75-92 QTR 2 TG Module 2 Plant and Animal CellsJane Limsan PaglinawanNo ratings yet

- MDRDocument3 pagesMDRjeffreymacasero100% (1)

- Hot Rolling Mill IndustryDocument12 pagesHot Rolling Mill IndustryJanuar Kurniawan KurniawanNo ratings yet

- List of Map Items Class X 2017-18Document3 pagesList of Map Items Class X 2017-18Mayank GhatpandeNo ratings yet

- Merkur Non-Heated Spray Packages: Instructions/PartsDocument58 pagesMerkur Non-Heated Spray Packages: Instructions/PartsFranklin LewisNo ratings yet

- Electronic Filter Simulation and DesignDocument9 pagesElectronic Filter Simulation and DesignMartinaReyes0% (1)

- SnowblowerDocument28 pagesSnowblowerJim KrebsNo ratings yet

- 9th Science EM WWW - Tntextbooks.inDocument328 pages9th Science EM WWW - Tntextbooks.inMohamed aslamNo ratings yet

- Warning: No Smoking! No Open Flame! While Installing Your Jet KitDocument2 pagesWarning: No Smoking! No Open Flame! While Installing Your Jet KitBrad MonkNo ratings yet

- Design Process in ElectrochemistryDocument92 pagesDesign Process in ElectrochemistryWulan SariNo ratings yet

- Control Charts in SAP QM: Step by StepDocument10 pagesControl Charts in SAP QM: Step by StepPiyush BoseNo ratings yet

- Udaipur WikiDocument19 pagesUdaipur Wikipiyush jainNo ratings yet

- Skin Cancer: Mikias Woldetensay Dermatology & Venereology October 2021Document76 pagesSkin Cancer: Mikias Woldetensay Dermatology & Venereology October 2021CHALIE MEQU100% (1)

- Design of Voltage Source Inverter Using SPWMDocument63 pagesDesign of Voltage Source Inverter Using SPWMAshiti Tufa100% (1)

- Intravenous Fluid Therapy in Adults and ChildrenDocument16 pagesIntravenous Fluid Therapy in Adults and Childrenannisa hayati100% (1)

- CulturalDocument11 pagesCulturalasddsaNo ratings yet

- Nondissipative Clamping Benefits DC-DC ConvertersDocument5 pagesNondissipative Clamping Benefits DC-DC ConvertersMateusz LiszczykNo ratings yet

- Mzee Last Funeral Rite Mass ProgramDocument10 pagesMzee Last Funeral Rite Mass ProgramHenry Kaweesa50% (2)

- Damage Report of Typhoon Tisoy in Masbate PDFDocument10 pagesDamage Report of Typhoon Tisoy in Masbate PDFJunie B. CastilloNo ratings yet