Professional Documents

Culture Documents

M&M 4TH Tecahnig Plan

M&M 4TH Tecahnig Plan

Uploaded by

sanjaymehtasupaulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M&M 4TH Tecahnig Plan

M&M 4TH Tecahnig Plan

Uploaded by

sanjaymehtasupaulCopyright:

Available Formats

STATE BOARD OF TECHNICAL EDUCATION BIHAR

TEACHING PLAN

Name of Institute :- Shri Ram Polytechnic,Madhubani Institute Code :- 179 Course & Code :- Mechanical, (ME)

Subject Name and Code :- Measurements & Metrology (2025401) Semester:- IVth Name of Faculty :- Prof. Vishwjeet Kumar

Course Outcomes :

• To take the right decisions to optimize resources utilization by improving productivity of the Lands, Buildings, People, Materials, Machines, Money, Methods and Management

effectively.

• To eliminate unproductive activities under the control of the Management, Supervisor, worker and the Design of Products and Processes.

• To use the Charts to record the Activities of the people, materials and Equipment to find alternative methods which minimize waste and to implement the best method.

Chapter Alloted Hrs Date of Date of Teaching

No. Title / Details in Commencing completion of Method Assessment Remark

Curriculum of Topic Topic Media Tools

1 1.1 Introduction: Colour Chalks Assessment

Definition of measurement; Significance of & Green Board, of Class

PPTs, Charts Notebook

measurement. Methods of measurements: and

Direct & Indirect; Generalized measuring Assignment.

system; Standards of measurements: Primary

& Secondary; Factors influencing selection of

measuring instruments; Terms applicable to

measuring instruments: Precision and

Accuracy, Sensitivity and Repeatability,

Range, Threshold, Hysteresis, calibration;

Errors in Measurements: Classification of

errors, Systematic and Random error.

1.2 Measuring instruments:

Introduction; Thread measurements: Thread

gauge micrometre; Angle measurements: Bevel

protractor, Sine Bar; Gauges: plain plug gauge,

ring Gauge, snap gauge, limit gauge;

Comparators: Characteristics of comparators,

Types of comparators.

1.3 Surface finish:

Definition, Terminology of surface finish,

Talysurf surface roughness tester; Co-

ordinating measuring machine.

2.1 Transducers and Strain gauges:

Introduction of Transducers, Characteristics,

classification of transducers, two coil self-

inductance transducer, Piezoelectric

transducer,Strain gauges & Measurements:

Strain gauge, Classification, mounting of strain Assessment

gauges, Strain gauge rosettes-two and three Colour Chalks of Class

2

elements. & Green Board, Notebook

PPTs, Charts and

2.2 Measurement of force, torque, and Assignment

pressure: Introduction to Force measurement:

Spring Balance, Proving ring, Load cell;

Torque measurement:Prony brake, Eddy

current, Hydraulic dynamometer; Pressure

measurement: Mcloed gauge.

3.1 Applied mechanical measurements:

Speed measurement: Classification of

tachometers, Revolution counters, Eddy

current tachometers; Displacement

measurement: Linear variable Differential

transformers (LVDT); Flow measurement:

Rotameters, Turbine meter; Temperature

measurement: Resistance thermometers,

Optical Pyrometer.

Assessment

3.2 Miscellaneous measurements: Colour Chalks of Class

3

Humidity measurement: hair hygrometer; & Green Board, Notebook

Density measurement: hydrometer; Liquid PPTs, Charts and

level measurement: sight glass, Float gauge; Assignment

Biomedical measurement: Sphygmo

monometer.

3.3 Types of Measurements; Method of

Variables; Method of Attributes; Uses of X, R, p and c

charts; Operating Characteristics curve (O.C curve);

Sampling Inspection; Single and Double Sampling plan;

Concept of ISO 9001:2008 Quality Management System

Registration/ Certification procedure; Benefits of ISO to

the organization.

4 4.1 Limits, Fits & Tolerances: Assessment

Concept of Limits, Fits, and Tolerances;

Selective Assembly; Interchangeability; Hole

and Shaft Basis System; Taylor’s Principle;

Design of Plug; Ring Gauges; IS 919- 1993

(Limits, Fits & Tolerances, Gauges} IS 3477-

1973; concept of multi gauging and inspection.

4.2 Angular Measurement: Concept;

Instruments for Angular Measurements; of Class

Working and Use of Universal Bevel Protractor, Colour Chalks

Notebook

& Green Board,

Sine Bar, Spirit Level; Principle of Working of Clinometers; Angle Gauges (With and

PPTs, Charts

Numerical on Settingof Angle Gauges). Assignment

4.3 Screw thread Measurements:

ISO grade and fits of thread; Errors in threads;

Pitch errors; Measurement of different

elements such as major diameter, minor

diameter, effective 10 diameter, pitch; Two

wire method; Thread gauge micrometer;

Working principle of floating carriage dial

micrometer.

5.1 Gear Measurement and Testing:

Analytical and functional inspection; Rolling

test Measurement of tooth thickness (constant

Assessment

chord method); Gear tooth Vernier; Errors in Colour Chalks of Class

5 gears such as backlash, runout, composite. & Green Board, Notebook

PPTs, Charts and

5.2 Machine tool testing: Parallelism;

Assignment

Straightness; Squareness; Coaxially;

roundness; run out; alignment testing of

machine tools as per IS standard procedure.

Reference Books:

1 Metrology & Measurement Annand K Bewoor, Vinay kulakarni Tata McGraw Hill, New Delhi,2009

2 Engineering Metrology R.K. Jain Khanna Publishers, New Delhi,2005.

3 Engineering Metrology K. J. Hume Kalyanipublishers 11Measurement & Metrology -

Rohit Bajaj, FPH

Prof. Vishwjeet Kumar Prof. Deepak kumar choudhary

Name & Signature of the Faculty Name & Signature of the H.O.D

You might also like

- Motor Cat 3176-3196Document17 pagesMotor Cat 3176-3196Fabiano Oliveira67% (3)

- AB315 Properties of AB MAterials For Student PDFDocument66 pagesAB315 Properties of AB MAterials For Student PDFRouge WintersNo ratings yet

- Mechanical Measurement and Metrology PDFDocument2 pagesMechanical Measurement and Metrology PDFsuhas_SCEM0% (1)

- Mechanical Engineering VI Sem SyllabusDocument25 pagesMechanical Engineering VI Sem Syllabussaurabh1116No ratings yet

- 9097 - Metrology & Quality ControlDocument7 pages9097 - Metrology & Quality ControlAhmed Abu-SinnaNo ratings yet

- Bit Sindri, Dhanbad: NAMEOFDEPTT. /CENTRE: Department of Production EngineeringDocument1 pageBit Sindri, Dhanbad: NAMEOFDEPTT. /CENTRE: Department of Production Engineeringtalk2sumantaNo ratings yet

- ME312 Metrology and instrumentationKTUNOTES - IN PDFDocument4 pagesME312 Metrology and instrumentationKTUNOTES - IN PDFpraphultmenonNo ratings yet

- MQC Teachers Manual PDFDocument5 pagesMQC Teachers Manual PDFnavneetkpatil8409No ratings yet

- MEPR205C - El 1 Metrology & Computer Aided InspectionDocument3 pagesMEPR205C - El 1 Metrology & Computer Aided Inspectionዘረአዳም ዘመንቆረርNo ratings yet

- Mechanical Measurement and MetrologyDocument2 pagesMechanical Measurement and MetrologyNarayanarao PalagaraNo ratings yet

- Gujarat Technological University - MeasurementDocument4 pagesGujarat Technological University - MeasurementA SNo ratings yet

- MEC601 Metrology and Quality Engineering 3+1: ObjectivesDocument1 pageMEC601 Metrology and Quality Engineering 3+1: Objectivesnavneetkpatil8409No ratings yet

- ME334 Manufacturing Technology Laboratory - IIDocument5 pagesME334 Manufacturing Technology Laboratory - IInandan144No ratings yet

- Applied Mathematics, Applied Physics, Engineering Graphics, Manufacturing Technology-IIDocument5 pagesApplied Mathematics, Applied Physics, Engineering Graphics, Manufacturing Technology-IIPRASENJIT MUKHERJEENo ratings yet

- M & IDocument12 pagesM & INenu Na RakshasiNo ratings yet

- Mechanical Measurement & Metrology ME211: Nishith ParikhDocument18 pagesMechanical Measurement & Metrology ME211: Nishith ParikhDrMohamed MansourNo ratings yet

- AE304 INDUSTRIAL INSTRUMENTATION Submodules ModifiedDocument3 pagesAE304 INDUSTRIAL INSTRUMENTATION Submodules ModifiedAnjanaNo ratings yet

- University of Pune: T.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Document3 pagesUniversity of Pune: T.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Arvind BhosaleNo ratings yet

- M&M Lesson Plan and SyllabusDocument5 pagesM&M Lesson Plan and Syllabuschandrasekhar reddyNo ratings yet

- MMC SyllabusDocument3 pagesMMC SyllabusTejas DesaiNo ratings yet

- Fundamentals20Measurement V4Document217 pagesFundamentals20Measurement V4Ana Paola Sandoval SánchezNo ratings yet

- Limits, Fits and Tolerances PDFDocument22 pagesLimits, Fits and Tolerances PDFmirztrNo ratings yet

- Syllabus: Department of Mechanical EngineeringDocument2 pagesSyllabus: Department of Mechanical EngineeringChhagan kharolNo ratings yet

- Calibration of Simple Vernier Caliper Using Slip Gauge Made by Nano Material IJERTCONV6IS01006Document3 pagesCalibration of Simple Vernier Caliper Using Slip Gauge Made by Nano Material IJERTCONV6IS01006Maya LamichhaneNo ratings yet

- T.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Document42 pagesT.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Mahesh JawaleNo ratings yet

- TE Mechanical and TE Automobile (2015 Course)Document7 pagesTE Mechanical and TE Automobile (2015 Course)A SNo ratings yet

- Measurement & Metrology SyllabusDocument3 pagesMeasurement & Metrology Syllabusvipsdgr8No ratings yet

- Instrumentation and Measurement: Lesson PlanDocument56 pagesInstrumentation and Measurement: Lesson PlanDanishNo ratings yet

- Measurement of Form ErrorsDocument14 pagesMeasurement of Form Errorssanyam KanungaNo ratings yet

- 3141709Document3 pages3141709Lakum Hitesh100% (2)

- Metrlogy CurriculumDocument3 pagesMetrlogy CurriculumDj GAMINGNo ratings yet

- Metrology and Mechanical MeasurementsDocument118 pagesMetrology and Mechanical MeasurementsNihar ApteNo ratings yet

- Metrology Course Oulines.10batchDocument4 pagesMetrology Course Oulines.10batchTariq AslamNo ratings yet

- Metrology and Instrumentation M 602 3Document1 pageMetrology and Instrumentation M 602 3AnilkumarGopinathanNairNo ratings yet

- II. Metrology (26 Questions) : A. Common Gauges and Measurement Instruments C. Gauge Selection, Handling, and UseDocument1 pageII. Metrology (26 Questions) : A. Common Gauges and Measurement Instruments C. Gauge Selection, Handling, and UseRiaz AhmadNo ratings yet

- Government Polytechnic, Mumbai Instrumentation EngineeringDocument3 pagesGovernment Polytechnic, Mumbai Instrumentation EngineeringChaitanya M MundheNo ratings yet

- Syllabus M.tech MechanicalDocument23 pagesSyllabus M.tech Mechanicalडॉ. कनिष्क शर्माNo ratings yet

- MQC SyllDocument2 pagesMQC SyllAandy KhasdarNo ratings yet

- MetrologyDocument87 pagesMetrologyParabellum GamingNo ratings yet

- Zero Lecture: Session: 2019-20 (VI Sem.)Document5 pagesZero Lecture: Session: 2019-20 (VI Sem.)Chhagan kharolNo ratings yet

- Fundamental Surveying ComputationDocument66 pagesFundamental Surveying ComputationJEAN DE DIEU MUVARANo ratings yet

- CH 1 - Metrology and MeasurementDocument51 pagesCH 1 - Metrology and MeasurementRahul PathakNo ratings yet

- MEC601 Metrology and Quality Engineering 3+1: ObjectivesDocument1 pageMEC601 Metrology and Quality Engineering 3+1: ObjectivesHoney SinghNo ratings yet

- Metrology and Quality Engineering: Chapter 01:fundamentals of MetrologyDocument26 pagesMetrology and Quality Engineering: Chapter 01:fundamentals of MetrologyVenugopal kulkarniNo ratings yet

- AE482 Industrial Instrumentation PDFDocument2 pagesAE482 Industrial Instrumentation PDFShiv GhoradNo ratings yet

- AE482 Industrial Instrumentation (Careeryuga)Document2 pagesAE482 Industrial Instrumentation (Careeryuga)bony bijuNo ratings yet

- Mertology Lab ManualDocument41 pagesMertology Lab ManualMessi LionelNo ratings yet

- Engineering Metrology and MeasurementsDocument128 pagesEngineering Metrology and MeasurementsArvind Bhosale100% (7)

- Blown Up Syllabus: Department of Mechanical EngineeringDocument3 pagesBlown Up Syllabus: Department of Mechanical EngineeringChhagan kharolNo ratings yet

- M & I PDFDocument13 pagesM & I PDFvirendraNo ratings yet

- Subject: Metrology: Academic Year:2017-2018 Branch: Mechanical Engineering Subject: Metrology Year / Sem: Iii / IDocument2 pagesSubject: Metrology: Academic Year:2017-2018 Branch: Mechanical Engineering Subject: Metrology Year / Sem: Iii / IMech DeptNo ratings yet

- State Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeDocument15 pagesState Board of Technical Education &training, Tamilnadu Diploma in Engineering / Technology Syllabus N - SchemeIsrael Dharmaraj100% (1)

- Measurements & Metrology PracticalDocument91 pagesMeasurements & Metrology PracticalAU Aalim Muhammed Salegh Polytechnic CollegeNo ratings yet

- Sensors, Actuators and MeasurementDocument3 pagesSensors, Actuators and MeasurementVinayak Dakre100% (1)

- Nptel: Metrology - Video CourseDocument3 pagesNptel: Metrology - Video CourseLakshya MaletiNo ratings yet

- Unit 1 - Introduction To MetrologyDocument65 pagesUnit 1 - Introduction To MetrologyPranav karnNo ratings yet

- WWW - Learnengineering.In: Me8501 Metrology and Measurements Unit I Basics of MetrologyDocument49 pagesWWW - Learnengineering.In: Me8501 Metrology and Measurements Unit I Basics of MetrologybhuvansparksNo ratings yet

- Mtrology in AircraftDocument22 pagesMtrology in Aircraftkrishnamurari1962No ratings yet

- Engineering Metrology and Measurements Unit 1 2Document82 pagesEngineering Metrology and Measurements Unit 1 2scorpionarnold100% (1)

- Quality of Life Outcomes in Clinical Trials and Health-Care Evaluation: A Practical Guide to Analysis and InterpretationFrom EverandQuality of Life Outcomes in Clinical Trials and Health-Care Evaluation: A Practical Guide to Analysis and InterpretationNo ratings yet

- Cylinder Liner ProjectionDocument4 pagesCylinder Liner ProjectionFernando Daniel Saez VillarrealNo ratings yet

- Manual WorkshopTechnologyDocument62 pagesManual WorkshopTechnologySunny PrabhakarNo ratings yet

- Mechanic Diesel-Volume I of II - TTDocument279 pagesMechanic Diesel-Volume I of II - TTAkshay Kumar KNo ratings yet

- 071 - Babasaheb Phadtare Poly Third Year Mechanical LabDocument11 pages071 - Babasaheb Phadtare Poly Third Year Mechanical Labuday chavanNo ratings yet

- Micrometro DigitalDocument10 pagesMicrometro DigitalfeltofsnakeNo ratings yet

- J4nmo n8kb6Document2 pagesJ4nmo n8kb6UMESHNo ratings yet

- AS Level Physics Practical Paper 3Document15 pagesAS Level Physics Practical Paper 3dulinawishwishNo ratings yet

- Iso 2808-2007Document46 pagesIso 2808-2007Stefan IngmyrNo ratings yet

- Shop Manual DL300-3 / DL350-3 Wheel Loader: Serial Number 10001 and UpDocument21 pagesShop Manual DL300-3 / DL350-3 Wheel Loader: Serial Number 10001 and UpСестрички Смайл50% (2)

- Calibration Tools of PP WorkshopDocument4 pagesCalibration Tools of PP WorkshopBlack Heart Shoaib ZaidiNo ratings yet

- File Alat UkkDocument3 pagesFile Alat UkkAzizNo ratings yet

- Manual Ultrasonic Wall Thickness Material Thickness Gauge InstructionDocument15 pagesManual Ultrasonic Wall Thickness Material Thickness Gauge InstructionCocam CocamNo ratings yet

- MBPP Unit 3 Removal of Turbine Rotor.Document14 pagesMBPP Unit 3 Removal of Turbine Rotor.niko TanNo ratings yet

- New Instruments Required Details (2023-24)Document1 pageNew Instruments Required Details (2023-24)UB StainlessNo ratings yet

- Physics P1 Summarised Notes-1Document157 pagesPhysics P1 Summarised Notes-1simonwanjiku598No ratings yet

- Basic Workshop ModuleDocument76 pagesBasic Workshop ModuleTeklu AnbeseNo ratings yet

- Chapter 1 Lesson 2Document4 pagesChapter 1 Lesson 2Mohd Adam AbdullahNo ratings yet

- Hands Out For Mashop 1Document26 pagesHands Out For Mashop 1chaserNo ratings yet

- MTM Lab ManualDocument49 pagesMTM Lab ManualGowtham Raj KNo ratings yet

- Control Plan - 23768162 - P01Document7 pagesControl Plan - 23768162 - P01ashishNo ratings yet

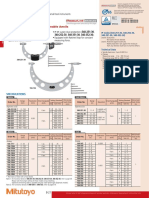

- Mitutoyo Mikrometer Outside 0-150Document1 pageMitutoyo Mikrometer Outside 0-150Aris SetyawanNo ratings yet

- (BS en ISO 9513 - 2002) - Metallic Materials. Calibration of Extensometers Used in Uniaxial Testing.Document20 pages(BS en ISO 9513 - 2002) - Metallic Materials. Calibration of Extensometers Used in Uniaxial Testing.Adel A. AbdelazizNo ratings yet

- Maintenance Practices Bank Module 07Document39 pagesMaintenance Practices Bank Module 07aditya khadeNo ratings yet

- EMG 1203 Manufacturing Processes 1-Dimensional Analysis Notes 2020Document71 pagesEMG 1203 Manufacturing Processes 1-Dimensional Analysis Notes 2020kennedyjembezNo ratings yet

- Reuse and Salvage For Gear Train and Gear Shafts On 3500 Series and C175 EnginesDocument58 pagesReuse and Salvage For Gear Train and Gear Shafts On 3500 Series and C175 Enginesma.powersourceNo ratings yet

- Module6 AER Automotive Measuring ToolsDocument5 pagesModule6 AER Automotive Measuring Toolsericka virayNo ratings yet

- Physics RedefinedDocument586 pagesPhysics RedefinedmunasheNo ratings yet

- PHY - 131 and 154 Lab Manual-2023Document68 pagesPHY - 131 and 154 Lab Manual-2023imperialscout2187No ratings yet