Professional Documents

Culture Documents

Qap-324-03 01 2024

Qap-324-03 01 2024

Uploaded by

qcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Qap-324-03 01 2024

Qap-324-03 01 2024

Uploaded by

qcCopyright:

Available Formats

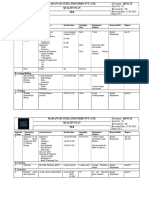

QUALITY ASSURANCE PLAN

MANUFACTURING OF DUCTING - FGC OUTLET TO ESP INLET, ESP INLET TO ID FAN, ID FAN OUTLET TO STACK

CLIENT : M/s UNIVERSAL BIOMASS ENERGY PRIVATE LIMITED, CHANNU, PUNJAB

Ref Doc ID : MI/ENGG/WAP/23-24/324-001 DTD 03.01.2023

CONSULTANT ; M/s BWE BERKES INDIA PVT LTD

Agency

Quantum of Ultimate Client /

Sl No Component / Activity Characterstics Type of Check Check Specs Format / Record MIIPL Consultant Remarks

A INCOMING INSPECTIONS - RAW MATERIALS

Identification,

Verification of RMTC / Test

1 MS Plates Chemical,

M.T.C.

100% IS 2062 E 350

Certificate ✓ ✓ R

Mechanical

Identification, RMTC / Mill

M.S. Rolled Sections - Structurals, Verification of

2

Hollow Pipes, Bars, Etc.

Chemical,

M.T.C.

100% IS 2062 E 250 Certificate Test ✓ ✓ R

Mechanical, Certificate

Welding Consumables (Wire / Flux / As per std norms Document Review / Manufacturer's

3

Electrodes) for M.S. Material & approved specs Test Certificates

100% IS 816, IS 9595

Test Certificate ✓ ✓ R

B IN PROCESS INSPECTION

Identity of Plates, Detailed drawings Drawing / MIIPL +

1 Nominal Layout Approval

dimensions

Review 100%

approved by BWE SAEL, BWE ✓ ✓

Dimensions,

Detailed drawings Drawing / MIIPL +

2 Templates / Jigs Intersection Lines, Measurement 20%

approved by BWE SAEL, BWE ✓ ✓ for drill matching

Guaging

Cutting, Edge Preperations, Profile Identity of Plates, Detailed drawings Drawing / MIIPL +

3

Bending dimensions

Review 100%

approved by BWE SAEL, BWE ✓ ✓

Visual /

Fitment / Assembly of Plates and Dimensional - M Tape / Caliper / Detailed drawings

4

structures Measurmenet Vernier

100%

approved by BWE

Log Book ✓ ✓

check

Checked & Released by :

R - Review W - Witness QC DEPTT, MIIPL

SONU D, 7885

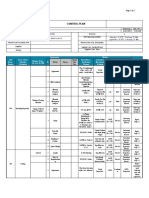

QUALITY ASSURANCE PLAN

MANUFACTURING OF DUCTING - FGC OUTLET TO ESP INLET, ESP INLET TO ID FAN, ID FAN OUTLET TO STACK

CLIENT : M/s UNIVERSAL BIOMASS ENERGY PRIVATE LIMITED, CHANNU, PUNJAB

Ref Doc ID : MI/ENGG/WAP/23-24/324-001 DTD 03.01.2023

CONSULTANT ; M/s BWE BERKES INDIA PVT LTD

Agency

Quantum of Ultimate Client /

Sl No Component / Activity Characterstics Type of Check Check Specs Format / Record MIIPL Consultant Remarks

Checks for Surface

Defects,

D.P. Inspection

5 Welding Wire / Flux / Electrodes Dimensional

Testing

Random IS 816, IS 9595

Reports ✓ ✓

Checks,

D.P. Tests

Electrode / Flux,

baking (as ensure to have

as per

5.1 applicable), moisture free

requirement

IS 816, IS 9595 Log Book ✓ ✓

Before Welding position of job for electrodes & flux

welding, pre heat.

WPS / PQR &

5.1.1

WPQ

Review as per standards as per standards Document ✓ ✓ R

Visual 100%

Welding through

Measurement of

Parameters, Ampmeter &

5.2 During Welding

Sequence of

Cuttent & Voltage

Voltmeter

IS 816, IS 9595 Log Book ✓ ✓

Control of Distortion

Welding Readings

Visual

Visual, Gauging, DP

Weld size, Finish,

Test, Fillet Size,

soundness of Approved WPS / Approved WPS /

5.3 After completion of Welding

weld, Overall

Peneteration, Leg

PQR / WPQ PQR / WPQ

Weld Data Sheet ✓ ✓

length, Throat

dimensions

Thickness

C INSPECTION & NDE

Surface Defects,

Approved Visual

1 Visual Testing surface of finsihed Testing Overall

Testing Procedure

Inspection Report ✓ ✓ R

fittment / assy.

Approved DPT

2 DP Testing Surface defects Visual & Testing 100%

Procedure

DPT Report ✓ ✓ R

Checked & Released by :

R - Review W - Witness QC DEPTT, MIIPL

SONU D, 7885

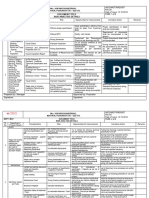

QUALITY ASSURANCE PLAN

MANUFACTURING OF DUCTING - FGC OUTLET TO ESP INLET, ESP INLET TO ID FAN, ID FAN OUTLET TO STACK

CLIENT : M/s UNIVERSAL BIOMASS ENERGY PRIVATE LIMITED, CHANNU, PUNJAB

Ref Doc ID : MI/ENGG/WAP/23-24/324-001 DTD 03.01.2023

CONSULTANT ; M/s BWE BERKES INDIA PVT LTD

Agency

Quantum of Ultimate Client /

Sl No Component / Activity Characterstics Type of Check Check Specs Format / Record MIIPL Consultant Remarks

D SURFACE PREPARATION & PAINTING

Sand Blasting to Standard SA 2.5 & Profile of surface

Painting as per specs - Zinc Anode preparation, Profile, visual

Technical

304MZ (equivalent to Sigmazinc 158 coverage, color inspection, DFT by Stage Inspection

1

Primer) - Inside Outside 75 mirons + shade, uniformity Elcometer &

100% specification /

Report ✓ ✓ W

Approved drawings

Lumerous HR/47 (equivalent to and Measurment Document Review

Sigmatherm 350) - 30 Microns of DFT

Indication

Stage Inspection

2 Marking & Etching Orientation Mark Visual / Marker 100% As per drg remarks

Report ✓ ✓ R

(North Mark)

E FINAL INSPECTION

Visual

Dimensions,

Visual, P.O.

Document Review P.O. Specifications & Final Inspection

1 Final Inspection of Structures

Identity -

Measurement & Specifications &

Drawings Report ✓ ✓ W

Verification Drawings

Structure Name,

Size etc

Relevant As per PO, Drawings

1 Final Documentation

Documents

Verification 100%

& Specs

Dossier ✓ ✓ R

Checked & Released by :

QC DEPTT, MIIPL

R - Review W - Witness SONU D, 7885

You might also like

- Inspection Test Plan Check Hold Points For Piping WorksDocument4 pagesInspection Test Plan Check Hold Points For Piping WorksYoucef Chorfa100% (2)

- PPT2 AnsDocument5 pagesPPT2 Anskristelle0marisseNo ratings yet

- QAP For Civil Work Rites 22.03.2018 PDFDocument9 pagesQAP For Civil Work Rites 22.03.2018 PDFVinay Kamat100% (1)

- Quality Assurance Protocol: Raw MaterialDocument2 pagesQuality Assurance Protocol: Raw MaterialShah Newaz Kabir100% (1)

- QAP For Bitumen JobDocument2 pagesQAP For Bitumen JobSasanka SekharNo ratings yet

- YzcvfDocument2 pagesYzcvfCheeragNo ratings yet

- Quality Assurance Plan For Casting PartsDocument14 pagesQuality Assurance Plan For Casting Partsanand bandekarNo ratings yet

- Inspection Test PlanDocument141 pagesInspection Test PlanKoya ThangalNo ratings yet

- Qap Eot CraneDocument5 pagesQap Eot CraneAmit KumarNo ratings yet

- Qap For Electrical PanelsDocument5 pagesQap For Electrical Panelsmukeshsaini17751No ratings yet

- ITP For Fabrication & Erection of TanksDocument20 pagesITP For Fabrication & Erection of Tanksosers100% (1)

- Certificat de Vérification Des Performances Et D'étalonnage Détecteur de Métaux SODDocument7 pagesCertificat de Vérification Des Performances Et D'étalonnage Détecteur de Métaux SODaparministriesNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Quality RequirementsDocument26 pagesQuality RequirementsDilip PatilNo ratings yet

- ITP-Steel Structure NewDocument5 pagesITP-Steel Structure NewPrasanta ParidaNo ratings yet

- FQP For AAC Block WorkDocument1 pageFQP For AAC Block WorkHimanshu ChaudharyNo ratings yet

- Qap 8000ce Reactor - Repat - 1Document2 pagesQap 8000ce Reactor - Repat - 1AliasgarNo ratings yet

- QAP - ITP - Steel Girder ApproachDocument21 pagesQAP - ITP - Steel Girder ApproachPartha Gangopadhyay100% (1)

- Quality Assurance Plan For PEBDocument2 pagesQuality Assurance Plan For PEBBipin Vihari DasNo ratings yet

- Ms QAPDocument6 pagesMs QAPArup karanNo ratings yet

- Qap - NRLDocument1 pageQap - NRLStructures ProductionNo ratings yet

- Proposed QAP For Adani Internal CTR JobDocument2 pagesProposed QAP For Adani Internal CTR JobSasanka SekharNo ratings yet

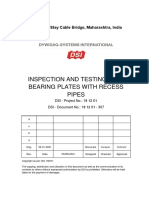

- 191201-307 - Inspection and Testing Plan Bearing Plates With Recess PipesDocument2 pages191201-307 - Inspection and Testing Plan Bearing Plates With Recess Pipesmonu yadavNo ratings yet

- QAPDocument6 pagesQAPRahul ChandanNo ratings yet

- CP20200804-A Model Control Plan - FoundationsDocument6 pagesCP20200804-A Model Control Plan - Foundationsmanno200No ratings yet

- Amc QapDocument8 pagesAmc QapSasanka SekharNo ratings yet

- EXternal ITP PDFDocument8 pagesEXternal ITP PDFjaineranaNo ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- SQAP Starter or Control Panel Part - IIDocument9 pagesSQAP Starter or Control Panel Part - IIMukeshNo ratings yet

- ISRO EOT Crane QAPDocument17 pagesISRO EOT Crane QAPSuleman Khan100% (1)

- QAP - Screen Box - Rev 00 StampedDocument1 pageQAP - Screen Box - Rev 00 StampedRaj KumarNo ratings yet

- QAP New Customer Nov23Document1 pageQAP New Customer Nov23RND DRAWNo ratings yet

- Control PlanDocument4 pagesControl PlanJosué PérezNo ratings yet

- QAP LotahalDocument1 pageQAP LotahalRahul YadavNo ratings yet

- 6973-51 Welding PlantDocument1 page6973-51 Welding Plantabdulhanan86457No ratings yet

- Civil FQP 22.11.22Document5 pagesCivil FQP 22.11.22Sankha Subhra JashNo ratings yet

- Inspection MatrixDocument2 pagesInspection MatrixFabian BellNo ratings yet

- Qap Sa420Document3 pagesQap Sa420Abhishek NagNo ratings yet

- Qap M030128-00Document19 pagesQap M030128-00Pinki Mitra DasNo ratings yet

- Inspection Plan For Pipe LineDocument4 pagesInspection Plan For Pipe LineArfanAliNo ratings yet

- QAP Final - ASSAMNZRMM11Document2 pagesQAP Final - ASSAMNZRMM11Jaspreet SinghNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)Document3 pagesVedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)Sasanka SekharNo ratings yet

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocument4 pagesRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksVijaya Barani100% (1)

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- Bird Guard MQP RGTLDocument3 pagesBird Guard MQP RGTLKumara SubramanianNo ratings yet

- QAP Railing-Details 63 OT KMCDocument21 pagesQAP Railing-Details 63 OT KMCFaiyaz KhanNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- Cofmow ItpDocument7 pagesCofmow ItpAjay HazarikaNo ratings yet

- 17 - Risk Analysis Rev-1Document5 pages17 - Risk Analysis Rev-1vinuNo ratings yet

- QAP Highmast 42672 D6ac45Document2 pagesQAP Highmast 42672 D6ac45Kritika Chaudhary Chandra MohanNo ratings yet

- Receipt Inspection Quality PlanDocument1 pageReceipt Inspection Quality Plankulkarnimegha87No ratings yet

- 6 - Testing & Commissioning Data - ItpDocument10 pages6 - Testing & Commissioning Data - ItpzainahmedscribdNo ratings yet

- Checklist For Rebar and Concrete WorkDocument4 pagesChecklist For Rebar and Concrete WorkDwinto RachmadNo ratings yet

- Quality Assurance PlanDocument4 pagesQuality Assurance PlanSasanka SekharNo ratings yet

- Dokumen - Tips - Quality Assurance Plan Project of Work Construction of Steel Foot Over BridgeDocument7 pagesDokumen - Tips - Quality Assurance Plan Project of Work Construction of Steel Foot Over BridgeLAXMIDHAR BEHERANo ratings yet

- Sample Test Certificate (24.12.2022)Document1 pageSample Test Certificate (24.12.2022)PalaniyandiNo ratings yet

- Plan de Surveillance Pièce PlastiqueDocument2 pagesPlan de Surveillance Pièce PlastiqueFida GhanmiNo ratings yet

- 191201-306 - Inspection and Testing Plan Anchor BoxesDocument2 pages191201-306 - Inspection and Testing Plan Anchor Boxesmonu yadavNo ratings yet

- Annual Report 2013 PT Perdana Bangun Pusaka TBKDocument119 pagesAnnual Report 2013 PT Perdana Bangun Pusaka TBKputri ayuNo ratings yet

- Diagnostic G12Document4 pagesDiagnostic G12Oliver C SilvanoNo ratings yet

- Data Sheet Triac Es, As, Ns Series Butterfly ValvesDocument28 pagesData Sheet Triac Es, As, Ns Series Butterfly Valves4Chat GptNo ratings yet

- Yamato AZ6500, 6502, 6505, 6506, 6507, 6520, 6525Document80 pagesYamato AZ6500, 6502, 6505, 6506, 6507, 6520, 6525Fernando RodriguezNo ratings yet

- InvoiceDocument1 pageInvoiceShahil Kumar ShawNo ratings yet

- IB Economics Chapter 1 NotesDocument6 pagesIB Economics Chapter 1 NotesPauline OngchanNo ratings yet

- Datalink Technical HandbookDocument50 pagesDatalink Technical HandbookIvan MilosevicNo ratings yet

- Distribution of The Respondents According To Their Demographic ProfileDocument3 pagesDistribution of The Respondents According To Their Demographic ProfileKate Meryl SangcapNo ratings yet

- Urban PlanningDocument20 pagesUrban PlanningRomi MewadaNo ratings yet

- CH 05Document61 pagesCH 05zero contentNo ratings yet

- Monitor FJM 100Document4 pagesMonitor FJM 100Ahmed Said IbrahimNo ratings yet

- New Open Sweet ShopDocument2 pagesNew Open Sweet Shopflowersofgod.1010No ratings yet

- Bmaowa - GBM 23 - 2024 - Q2Document48 pagesBmaowa - GBM 23 - 2024 - Q2Anirban DeyNo ratings yet

- FR 1 Assignment 1 IAS 16 08112022 071429am 15102023 114037amDocument2 pagesFR 1 Assignment 1 IAS 16 08112022 071429am 15102023 114037amAnasNo ratings yet

- Moxy HotelsDocument36 pagesMoxy HotelsYunna BulatnikovaNo ratings yet

- Ch.9 Cost AnalysisDocument29 pagesCh.9 Cost AnalysisWinnydetuo WinwinNo ratings yet

- JULIO A. MOCEGA & ASSOCIATES, INC., Invoices For TranscriptsDocument1 pageJULIO A. MOCEGA & ASSOCIATES, INC., Invoices For Transcriptslarry-612445No ratings yet

- Mindrill Composite Catalogue - IndiaDocument20 pagesMindrill Composite Catalogue - IndiaSNo ratings yet

- On The Distribution of Explosion Time of StochastiDocument18 pagesOn The Distribution of Explosion Time of StochastiapuntesjmznNo ratings yet

- CV Juboyan 2023Document5 pagesCV Juboyan 2023api-239764933No ratings yet

- Kinked Demand Curve Theory of Oligopoly - MECO.SEM3.MBADocument2 pagesKinked Demand Curve Theory of Oligopoly - MECO.SEM3.MBAsarita sahooNo ratings yet

- Demand Side Policies CanadaDocument3 pagesDemand Side Policies CanadaIva ChadikovskaNo ratings yet

- Lecture Notes For Mathematical StatisticsDocument184 pagesLecture Notes For Mathematical StatisticsCarlos Huerta SalasNo ratings yet

- Fabricator ES 410icDocument10 pagesFabricator ES 410icaxisd47No ratings yet

- Pipe Riser Support Systems: Mason Industries, IncDocument4 pagesPipe Riser Support Systems: Mason Industries, Incconstantin.iacomi3837No ratings yet

- Fill in The Blanks.: Unit-9 Rampur: A Village EconomyDocument3 pagesFill in The Blanks.: Unit-9 Rampur: A Village Economyrai venugopalNo ratings yet

- Control Interno - Marco Integrado: Resumen EjecutivoDocument3 pagesControl Interno - Marco Integrado: Resumen EjecutivoLisardo LunaNo ratings yet

- Question 1Document11 pagesQuestion 1selvasrijaNo ratings yet

- Depl. ING KIT410 MP Kit Levigatura Portatile X 60 100 125 + Ricambi 3.0 20111Document2 pagesDepl. ING KIT410 MP Kit Levigatura Portatile X 60 100 125 + Ricambi 3.0 20111azer tyNo ratings yet