Professional Documents

Culture Documents

Paver Block Check List

Paver Block Check List

Uploaded by

john paulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paver Block Check List

Paver Block Check List

Uploaded by

john paulCopyright:

Available Formats

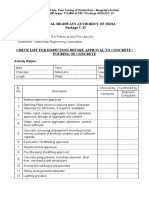

REVANTHA SERVICES PVT LTD RVL - QA/QC-CL

CHECKLIST - PAVER BLOCK CHECK LIST REVISION -R0

Sl No CHECK POINTS YES NO REMARKS

Paving blocks dimension and finishing as per approved material submittal and shop

1

drawing?

2 Aggregate and Sand material approval

3 Paving blocks are from approved source?

Paving blocks dimension and finishing as per approved material submittal and shop

4

drawing?

5 Foundation of kerbstone done as per approved detail

Installation of Kerbs: Concrete haunching, Elevation, placement meet

6

specifications and drawings

Ensure base layer is compacted to a field density not less than 95% of the

7

maximum dry density

8 Sand screeded to 50mm thickness

9 String or chalk line to start and maintain straight bond lines

10 Joint width range among pavers matches specifications

11 Adjust/straighten bond lines prior to initial compaction

12 Cut pavers in place prior to initial compaction of given area

13 Paver surface broom clean prior to initial compaction

Minimum 75 KN/m2 load plate compactor with 0.25 m2 plate area for compacting

14

pavers

15 Broken and chipped pavers marked, removed and replaced after initial compaction

16 Joint sand evenly spread over surface of pavers prior to final compaction

17

Joint sand dry before final compaction commences

Simultaneous sweeping and vibrating sand into joints with minimum of 4 passes of

18

plate compactor

19 No compaction within 2 m of an unrestrained edge of pavers

Remove excess sand after entire pavement is compacted and joints are filled to

20

bottom of chamfer; broom clean

Surface elevation of pavers 6 mm above adjacent drainage inlets, concrete collars, or

21

channels

22 Surface elevations conform to drawings

23 Lippage: no greater than 3 mm difference in height between adjacent pavers

24 Check filling of joints with sand Fill and re-vibrate if necessary

Vendor

Quality Engineer

Representative Site Engineer PM/APM Client-LMW

You might also like

- VALVE CHAMBER ProcedureDocument1 pageVALVE CHAMBER Procedureshanivi vrindavanNo ratings yet

- Construction of Boundary Wall SpecificationsDocument148 pagesConstruction of Boundary Wall SpecificationsTATATAHER75% (4)

- Check List For Inspection Before Approval To Concrete or Pouring of ConcreteDocument2 pagesCheck List For Inspection Before Approval To Concrete or Pouring of ConcreteAnil Kumar T BNo ratings yet

- MOS For Road ConstructionDocument7 pagesMOS For Road ConstructionHussam WaleedNo ratings yet

- Screed-Method StatementDocument5 pagesScreed-Method StatementTATATAHER100% (3)

- Method Statement For Planter WaterproofingDocument8 pagesMethod Statement For Planter WaterproofingMonali Varpe0% (1)

- Training The Ridden Animal Andrew McleanDocument4 pagesTraining The Ridden Animal Andrew Mcleanapi-249334134100% (1)

- Intuitive Knowing As Spiritual ExperienceDocument237 pagesIntuitive Knowing As Spiritual ExperienceHugo Martin100% (1)

- Info 1Document28 pagesInfo 1Veejay Soriano Cuevas0% (1)

- Block Masonary Work Check ListDocument1 pageBlock Masonary Work Check Listjohn paulNo ratings yet

- 02 Checklist For Interlocking Precast Concrete Pavers and Kerbstones PDFDocument1 page02 Checklist For Interlocking Precast Concrete Pavers and Kerbstones PDFDipin Nediyaparambath100% (3)

- Inspect Back Fill & Right of WayDocument26 pagesInspect Back Fill & Right of WaySamuel JohnNo ratings yet

- RD Segm PavingDocument4 pagesRD Segm PavingAurelius GoraNo ratings yet

- Project: Housing Complex at Div For O.I.D.C. Type C: Rowhouse - 3 BHKDocument32 pagesProject: Housing Complex at Div For O.I.D.C. Type C: Rowhouse - 3 BHKAV ChavdaNo ratings yet

- TREMIX FLOORING (For Car Park and Drive Way) : Method StatementDocument12 pagesTREMIX FLOORING (For Car Park and Drive Way) : Method Statementmukesh sharma100% (1)

- Vacuum Dewaterd Concrete Floor 4 Dec 2015Document43 pagesVacuum Dewaterd Concrete Floor 4 Dec 2015manoj.moholeNo ratings yet

- 1600 - Quality Contorl of WorkDocument10 pages1600 - Quality Contorl of Workruwan.smb1No ratings yet

- AbstractDocument8 pagesAbstractcivilNo ratings yet

- Method Statement On Grouted RiprapDocument3 pagesMethod Statement On Grouted RiprapHayle Dela CruzNo ratings yet

- 03 3300 Concrete Recommendations With Polished Concrete (Version 1)Document5 pages03 3300 Concrete Recommendations With Polished Concrete (Version 1)vasantsunerkarNo ratings yet

- t000005030 - Filename2 - Final Tender ScheduleDocument71 pagest000005030 - Filename2 - Final Tender SchedulePratik VermaNo ratings yet

- Gypsum Partition Check ListDocument1 pageGypsum Partition Check ListQAQC GCCNo ratings yet

- Const. of Road, Drain & CulvertDocument8 pagesConst. of Road, Drain & CulvertHiren ThakkarNo ratings yet

- Compaction GroutingDocument4 pagesCompaction GroutingbenNo ratings yet

- Wear Course Placement Checklist: Pre-Production TasksDocument7 pagesWear Course Placement Checklist: Pre-Production TasksDilhara WickramaarachchiNo ratings yet

- Boq R2 - 290914Document25 pagesBoq R2 - 290914raviNo ratings yet

- 4 Civil Work - BOQ SpecificationsDocument64 pages4 Civil Work - BOQ SpecificationsnewattelectricNo ratings yet

- Masonry - Block Joint Mortar 15bDocument1 pageMasonry - Block Joint Mortar 15bmanish260320No ratings yet

- Concrete Floor ScreedDocument1 pageConcrete Floor ScreedQAQC GCCNo ratings yet

- Simplex Infrastructure Limited Aluminium Smelter Plant of Val JharsugudaDocument3 pagesSimplex Infrastructure Limited Aluminium Smelter Plant of Val JharsugudaRajat KoleyNo ratings yet

- Compound Wall Tender (Kadapa)Document90 pagesCompound Wall Tender (Kadapa)div_misNo ratings yet

- Method Statement For PVD Work at SRP ProjectDocument15 pagesMethod Statement For PVD Work at SRP ProjectAnonymous BJnFqHe67% (3)

- Floor Tiling-Method StatementDocument5 pagesFloor Tiling-Method StatementamroNo ratings yet

- Quality Control Supevision On Concrete-Jun V.Document57 pagesQuality Control Supevision On Concrete-Jun V.Mohammad Ali Salem Mauna100% (4)

- Checklist For Supervision of Reinforced Soil Wall PDFDocument4 pagesChecklist For Supervision of Reinforced Soil Wall PDFChin Thau WuiNo ratings yet

- BOQ - External Development WorksDocument5 pagesBOQ - External Development WorksAmit RuhilNo ratings yet

- Volume - Iii Technical Specifications and DrawingsDocument28 pagesVolume - Iii Technical Specifications and DrawingsCIVIL LINE OFFICENo ratings yet

- Granolithic FlooringDocument16 pagesGranolithic FlooringDinesh Perumal50% (2)

- Road & Flexible Pavement Preparation of Subgrade To Receive Road PavementDocument16 pagesRoad & Flexible Pavement Preparation of Subgrade To Receive Road PavementMohd RafiqNo ratings yet

- Atk SSA Presentation R2Document38 pagesAtk SSA Presentation R2Gaurav MathurNo ratings yet

- Cementing Integrity EvaluationDocument67 pagesCementing Integrity EvaluationKalou BoniNo ratings yet

- USOR 2018 of Chief Engineer (Roads & Traffic) W.E.F 20.06.2018Document63 pagesUSOR 2018 of Chief Engineer (Roads & Traffic) W.E.F 20.06.2018adnan khanNo ratings yet

- Admore Gas (PVT) LTD: Bulk Oil Installation Depot at DaulatpurDocument12 pagesAdmore Gas (PVT) LTD: Bulk Oil Installation Depot at DaulatpurBilal Mustafa SiddiquiNo ratings yet

- WMS Concreting WorkDocument4 pagesWMS Concreting WorkHanmant Mortale PatilNo ratings yet

- 2013 BSR NewDocument583 pages2013 BSR NewSamanmala Senarath100% (1)

- Specification - Road Repairs (Ade)Document11 pagesSpecification - Road Repairs (Ade)Sathish KumarNo ratings yet

- Metode Pelaksanaan Pengeringan (Dewatering) PDFDocument34 pagesMetode Pelaksanaan Pengeringan (Dewatering) PDFdimas setiyantoNo ratings yet

- Buku Rujukan Ringkas - Routine Maintenance Work Activities-ScribdDocument10 pagesBuku Rujukan Ringkas - Routine Maintenance Work Activities-ScribdSITI KHADIJAH BINTI OTHMAN (JKR)No ratings yet

- Kerbs & Inl SpecDocument4 pagesKerbs & Inl Specabdulrehman731No ratings yet

- The Mebradrain System: Vertical DrainageDocument32 pagesThe Mebradrain System: Vertical DrainageГригорий ЛевашовNo ratings yet

- Assignment 1-DQUBED1Document4 pagesAssignment 1-DQUBED1berenger yembi renaultNo ratings yet

- Method Statement For EmbankmentDocument5 pagesMethod Statement For EmbankmentAlbertyNo ratings yet

- Chapter (8) Sand Control1Document15 pagesChapter (8) Sand Control1ibrahimletaief1985No ratings yet

- Check ListDocument19 pagesCheck ListPanruti S SathiyavendhanNo ratings yet

- Method Statement Slip Form KerbsDocument4 pagesMethod Statement Slip Form KerbsEric Isidore AgossouNo ratings yet

- Name of Work:-Const. of Additional Class Room in Govt. P.S Julad, Panchayat Bali Upper, Block Narsoo Under PRI Capex Budget For The Year 2022-23Document6 pagesName of Work:-Const. of Additional Class Room in Govt. P.S Julad, Panchayat Bali Upper, Block Narsoo Under PRI Capex Budget For The Year 2022-23CHAIN SINGHNo ratings yet

- 1e. MS 05 DrainageDocument15 pages1e. MS 05 DrainageamzoNo ratings yet

- Sewerage LineDocument15 pagesSewerage LineSriram VjNo ratings yet

- A Builder's Guide to Wells and Septic Systems, Second EditionFrom EverandA Builder's Guide to Wells and Septic Systems, Second EditionNo ratings yet

- Sand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!From EverandSand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!Rating: 5 out of 5 stars5/5 (1)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Block Masonary Work Check ListDocument1 pageBlock Masonary Work Check Listjohn paulNo ratings yet

- Method of Statement For Aac Block WorkDocument10 pagesMethod of Statement For Aac Block Workjohn paul100% (1)

- Method of Statement For Tile Laying Work-Qc-RvlDocument9 pagesMethod of Statement For Tile Laying Work-Qc-Rvljohn paul100% (1)

- Material Specification List R1Document2 pagesMaterial Specification List R1john paulNo ratings yet

- Prakash Jhunjhunwala & Co LLP: Chartered AccountantsDocument9 pagesPrakash Jhunjhunwala & Co LLP: Chartered AccountantsKinshuk SinghNo ratings yet

- Company Analysis Report On M/s Vimal Oil & Foods LTDDocument32 pagesCompany Analysis Report On M/s Vimal Oil & Foods LTDbalaji bysani100% (1)

- Crochet Pattern: Little FrogDocument7 pagesCrochet Pattern: Little Froglina.dmitrenckoNo ratings yet

- ProjectDocument32 pagesProjectFavour NwachukwuNo ratings yet

- 2012 01 20 - Twogether32 EDocument76 pages2012 01 20 - Twogether32 Enivan009sku9645No ratings yet

- De Thi HSG Tieng Anh 8Document10 pagesDe Thi HSG Tieng Anh 8Mai HoaNo ratings yet

- ATR LM ClassDocument30 pagesATR LM ClassKezia Sormin100% (1)

- 03-Speaking Sample Test 3 - DentistryDocument1 page03-Speaking Sample Test 3 - DentistryMorris OETNo ratings yet

- Tiruvannamalai and RajinikanthDocument2 pagesTiruvannamalai and RajinikanthashokhaNo ratings yet

- B737 PneumaticsDocument9 pagesB737 Pneumaticsgreg mNo ratings yet

- Vma108 A4v01Document9 pagesVma108 A4v01bastien067No ratings yet

- 02 000378Document477 pages02 000378JimNo ratings yet

- Integrity Management of Safety Critical Equipment and SystemsDocument10 pagesIntegrity Management of Safety Critical Equipment and SystemsLi QiNo ratings yet

- Preboards 3-PipeDocument4 pagesPreboards 3-PipeChyno KangNo ratings yet

- Despite', in Spite Of', Although', Though' and Even Though'Document4 pagesDespite', in Spite Of', Although', Though' and Even Though'pikorl4327No ratings yet

- Chapter 1Document9 pagesChapter 1Dary OngNo ratings yet

- AaaqsqDocument14 pagesAaaqsqaudy ricardoNo ratings yet

- CRV Led Spec SheetDocument3 pagesCRV Led Spec SheetGabrielGrecoNo ratings yet

- Shear Wall MOSDocument8 pagesShear Wall MOSAsdia Aseffah FathiyaNo ratings yet

- Medsurg Fbao EndtermDocument6 pagesMedsurg Fbao EndtermNevea CariñoNo ratings yet

- Littelfuse Magnetic Sensors and Reed Switches Inductive Load Arc Suppression Application Note PDFDocument2 pagesLittelfuse Magnetic Sensors and Reed Switches Inductive Load Arc Suppression Application Note PDFMarcelo SantibañezNo ratings yet

- Icse Class X Physics Practise Sheet 1 ForceDocument3 pagesIcse Class X Physics Practise Sheet 1 ForceMehnaaz Brar100% (2)

- Business Finance Test PracticeDocument49 pagesBusiness Finance Test PracticeLovan So0% (1)

- III. Complete The Sentences With The Future Continuous Form of The Verbs in The BoxDocument2 pagesIII. Complete The Sentences With The Future Continuous Form of The Verbs in The BoxGuen KitoNo ratings yet

- Sop BM RHF Oprn ProcedureDocument2 pagesSop BM RHF Oprn ProcedurewrbmrhfispNo ratings yet

- MSDS Pozzolith® 100 XRDocument5 pagesMSDS Pozzolith® 100 XRakardosNo ratings yet

- Sesiones de Technical EnglishDocument90 pagesSesiones de Technical EnglishBill Klinthon Chiara100% (1)