Professional Documents

Culture Documents

Tutorial 2 - @2022

Tutorial 2 - @2022

Uploaded by

Omari MsigitiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial 2 - @2022

Tutorial 2 - @2022

Uploaded by

Omari MsigitiCopyright:

Available Formats

Tutorial 2

Question 1.

a) What do you understand by the term median active corrective maintenance

time?

b) Use the data given on table 1 to calculate:

i. Median active corrective maintenance,

ii. Median active preventive maintenance, and

iii. Maximum active corrective maintenance at 95% confidence level from

the following information (For this sample Z at 95% = 1.65).

Maintenance actions 3,5,8,11 are preventive maintenance actions and the

remaining are breakdown maintenance actions

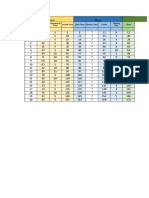

Table 1: List of maintenance times

Maintenance action Total downtime Logistics Delay Administrative

[Minutes] time [Minutes] delay time

[Minutes]

1 148 45 67

2 167 34 44

3 150 68 42

4 132 26 46

5 180 44 66

6 143 23 36

7 243 56 74

8 112 22 30

9 67 12 22

10 120 46 24

11 280 78 42

12 187 45 55

Question 2

i) What do you understand by the term maximum active corrective maintenance

time (Mmax)?

ii) Calculate Mmax at 95% confidence level from the data shown on table 1 and

table 2

iii) Use the data depicted on table 1 and intellectual assumption to calculate the

following data if given that the cycle time was 24,000 minutes:

a) Total Availability A;

b) Inherent Availability A1;

c) Achieved availability Aa;

d) Operational Availability Ao.

Table 1: Downtime of some selected maintenance activities. Activities number 3, 7, 9

and 14 are break down maintenance whereas the rest of activities are

preventive maintenance.

Maintenance Activity No.

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Td 3 4 2 3 4 6 4 2 3 4 6 8 8 10

[Hours]

LDT 75 120 40 45 100 160 98 44 45 90 155 200 230 320

[Min.]

ADT 65 45 25 35 80 140 102 26 35 90 145 160 159 160

[Min.]

Td is the total downtime that includes both the LDT and ADT.

Table 2: Risks/Upper limit variations

Risk Confidence Z Upper limit [min.]

5% 95% 1.65 65.72

10% 90% 1.28 64.89

15% 85% 1.04 64.35

20% 80% 0.84 63.89

You might also like

- Ashrae 15-2022 (Packaged Standard 34-2022)Document5 pagesAshrae 15-2022 (Packaged Standard 34-2022)rpercorNo ratings yet

- Al Maths Pure Unit 6 MsDocument8 pagesAl Maths Pure Unit 6 MsHacjer EiNSTi3NNo ratings yet

- CSETDocument5 pagesCSETLinda SchweitzerNo ratings yet

- Cambridge Studies in International Relations John A. Vasquez The War Puzzle Revisited Cambridge University Press 2009Document507 pagesCambridge Studies in International Relations John A. Vasquez The War Puzzle Revisited Cambridge University Press 2009Isabelle Drăgănescu0% (1)

- Determination of KLaDocument7 pagesDetermination of KLaMahathir Mohmed96% (26)

- 3.2 Spot Speed Study Results, Calculation, Discussion, ConclusionDocument11 pages3.2 Spot Speed Study Results, Calculation, Discussion, Conclusionwho_haris96100% (1)

- Customer Ran. # Arrival Time Start Time Service Time Finish Start Interarrival Time Waiting TimeDocument4 pagesCustomer Ran. # Arrival Time Start Time Service Time Finish Start Interarrival Time Waiting TimeAprilleShaneTiedraNo ratings yet

- Video 1 Voltaj e (V) Tiempo LN (V)Document3 pagesVideo 1 Voltaj e (V) Tiempo LN (V)Luisa Fernanda Galeano RuizNo ratings yet

- Simulasi Single AntrianDocument33 pagesSimulasi Single AntrianRipaldiNo ratings yet

- Client Number Random No. Arrival (Min) Arrival Time Random No. Service (Min)Document2 pagesClient Number Random No. Arrival (Min) Arrival Time Random No. Service (Min)Nikky Bless LeonarNo ratings yet

- Số liệu bài 4, 10Document2 pagesSố liệu bài 4, 10Dũng NguyễnNo ratings yet

- Waiting-Time SimulationDocument6 pagesWaiting-Time SimulationMuhammad FajarNo ratings yet

- Cross Flow Part 1Document5 pagesCross Flow Part 1mohmmad othmanNo ratings yet

- Contoh Sistem Antrian 1 Server Dan 2 ServerDocument15 pagesContoh Sistem Antrian 1 Server Dan 2 ServerKentaroNo ratings yet

- Safety Valve Maintainance ManualDocument18 pagesSafety Valve Maintainance ManualArash MohamadiNo ratings yet

- Nioec SP 00 85Document47 pagesNioec SP 00 85Mohammad AminiNo ratings yet

- Cumulative Drying Time T' (Min) Mass of The Sample M' (G)Document3 pagesCumulative Drying Time T' (Min) Mass of The Sample M' (G)usamaNo ratings yet

- BM TrompcurveDocument1 pageBM Trompcurveniladri.jagatyNo ratings yet

- Sensus Harian Pasien Unit Gawat Darurat April 2019Document1 pageSensus Harian Pasien Unit Gawat Darurat April 2019innaNo ratings yet

- LSFO Calculator: 2.5 FO System Capacity (Liters) 500 Date Time Position FO Consumption (M /HR)Document8 pagesLSFO Calculator: 2.5 FO System Capacity (Liters) 500 Date Time Position FO Consumption (M /HR)dharmawanNo ratings yet

- Rakaa NadiaDocument49 pagesRakaa NadiaRessay 87No ratings yet

- Multiple Choices: Answer SheetDocument1 pageMultiple Choices: Answer SheetemeraldNo ratings yet

- Coin Tossing SimulationDocument8 pagesCoin Tossing SimulationMuhammad FajarNo ratings yet

- Elapsed Time (T) Observati On Number Hydrometer READING (Upper Meniscus) Rh-1000Document12 pagesElapsed Time (T) Observati On Number Hydrometer READING (Upper Meniscus) Rh-1000SamwailNo ratings yet

- Multiple Choices: Answer SheetDocument1 pageMultiple Choices: Answer SheetemeraldNo ratings yet

- CEP14 Lec4 Examples DataDocument12 pagesCEP14 Lec4 Examples DataHapet CasalmeNo ratings yet

- Warehouse and DistributionDocument9 pagesWarehouse and DistributionAsmita KandariNo ratings yet

- Multiple Choices: Answer SheetDocument1 pageMultiple Choices: Answer SheetemeraldNo ratings yet

- Multiple Choices: Answer SheetDocument1 pageMultiple Choices: Answer SheetemeraldNo ratings yet

- Hypothesis Testing v1 - 1Document2 pagesHypothesis Testing v1 - 1VbaluyoNo ratings yet

- Hypothesis Testing of Two Independent Samples: Group A Data Table and StatisticsDocument2 pagesHypothesis Testing of Two Independent Samples: Group A Data Table and StatisticsVbaluyoNo ratings yet

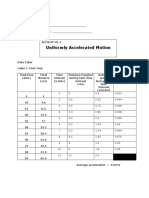

- Calculating Uniformly Accelerated Motion: Experiment # 3Document11 pagesCalculating Uniformly Accelerated Motion: Experiment # 3peter vanderNo ratings yet

- I. Abstrak II. Data Percobaan Tabel 1. Kalibrasi Medan Magnet Data 1Document6 pagesI. Abstrak II. Data Percobaan Tabel 1. Kalibrasi Medan Magnet Data 1nabillahfadiyyahzahraNo ratings yet

- Statistics For AnalyticsDocument6 pagesStatistics For AnalyticsSK ATIAR RAHAMANNo ratings yet

- Output Analysis PracticesDocument9 pagesOutput Analysis Practicestrần thị ngọc trâmNo ratings yet

- Be Careful Not To Add in The Student Number.Document2 pagesBe Careful Not To Add in The Student Number.cuuwj oawidNo ratings yet

- Resumen Monitoria 1Document13 pagesResumen Monitoria 1Camilo RodriguezNo ratings yet

- 03 Poprecni Ramovi 1100 - 1200Document2 pages03 Poprecni Ramovi 1100 - 1200M PNo ratings yet

- 03 Poprecni Ramovi 1100 - 1200Document2 pages03 Poprecni Ramovi 1100 - 1200M PNo ratings yet

- NIOEC-SP-00-77 (1) : Process Design of Emergency MeasuresDocument27 pagesNIOEC-SP-00-77 (1) : Process Design of Emergency MeasuresMohammad AminiNo ratings yet

- Business Statistics Titan Insurance Case StudyDocument4 pagesBusiness Statistics Titan Insurance Case StudyaniketNo ratings yet

- Muh - Sofwwan Tahir EOQDocument4 pagesMuh - Sofwwan Tahir EOQOwen TahirNo ratings yet

- Mental Calculation: Method of PracticeDocument4 pagesMental Calculation: Method of Practicemayna2010No ratings yet

- B-Qrf-Bjss-Questionnaire Response Form - Sept 2019Document3 pagesB-Qrf-Bjss-Questionnaire Response Form - Sept 2019Nur Athirah Che'ZambeliNo ratings yet

- (Simu 2024) Midterm Review - TA ReviewDocument30 pages(Simu 2024) Midterm Review - TA ReviewMai Uyên MyNo ratings yet

- Quality: Method Sheet: Filler - Filling Volume Accuracy Sheet No.: 050101 - 1.01 Date: June 2008Document6 pagesQuality: Method Sheet: Filler - Filling Volume Accuracy Sheet No.: 050101 - 1.01 Date: June 2008Kim KimNo ratings yet

- Boye Edmund Nii LaryeaDocument6 pagesBoye Edmund Nii Laryeaboyeedmund1No ratings yet

- Positive Material Dentification (PMI) : NIOEC-SP-90-04Document11 pagesPositive Material Dentification (PMI) : NIOEC-SP-90-04Mohammad Amini100% (1)

- Multiple Choices: Answer SheetDocument1 pageMultiple Choices: Answer SheetemeraldNo ratings yet

- Uniformly Accelerated Motion: Activity No. 3Document3 pagesUniformly Accelerated Motion: Activity No. 3Bharath CricketNo ratings yet

- Hidrologi - B Tugas V GabuabahDocument4 pagesHidrologi - B Tugas V GabuabahTahuNo ratings yet

- 2015 Grila Corectura Asistent Medical Generalist PDFDocument1 page2015 Grila Corectura Asistent Medical Generalist PDFLazar Iulia-LoredanaNo ratings yet

- StudentDocument6 pagesStudentNgocNo ratings yet

- Aguado ReadingWeek3 Sec14Document3 pagesAguado ReadingWeek3 Sec14EMMANo ratings yet

- Grila Corectura Asistent LaboratorDocument1 pageGrila Corectura Asistent LaboratorLaborator Biodev PrimaveriiNo ratings yet

- Lab. Kimia Organik - Fmipa - UgmDocument1 pageLab. Kimia Organik - Fmipa - UgmBrian ObiedyanNo ratings yet

- ReportDocument74 pagesReporthtet aungNo ratings yet

- Process Design of Fuel Systems: NIOEC-SP-00-65Document34 pagesProcess Design of Fuel Systems: NIOEC-SP-00-65amini_mohiNo ratings yet

- 6.9. Handling Storage & Preservation ProcedureDocument10 pages6.9. Handling Storage & Preservation Procedurerendra syamNo ratings yet

- OUTPUTDocument3 pagesOUTPUTYulistianaEfNo ratings yet

- Multiple Choices: Answer SheetDocument1 pageMultiple Choices: Answer SheetemeraldNo ratings yet

- Multiple Choices: Answer SheetDocument1 pageMultiple Choices: Answer SheetemeraldNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- NS4217.0028.2017Document11 pagesNS4217.0028.2017Omari MsigitiNo ratings yet

- NS1474.0011.2019Document10 pagesNS1474.0011.2019Omari MsigitiNo ratings yet

- Debate PointsDocument2 pagesDebate PointsOmari MsigitiNo ratings yet

- Salary ReviewDocument2 pagesSalary ReviewOmari MsigitiNo ratings yet

- PharmacologyDocument5 pagesPharmacologyOmari MsigitiNo ratings yet

- Tutorial 1 @2022 SolutionDocument9 pagesTutorial 1 @2022 SolutionOmari MsigitiNo ratings yet

- Arellano Humss - DDocument5 pagesArellano Humss - Dcarl guillardaNo ratings yet

- CHEM 580: Computational Chemistry Fall 2020 From Schrodinger To Hartree-FockDocument41 pagesCHEM 580: Computational Chemistry Fall 2020 From Schrodinger To Hartree-FockciwebNo ratings yet

- AllergyDocument35 pagesAllergyAhmed ImranNo ratings yet

- Math Vectors v2Document72 pagesMath Vectors v2Rowanberry11No ratings yet

- IJCRT2006540Document4 pagesIJCRT2006540Bhushan BhoyeNo ratings yet

- The SNG Blueprint Part 1 PDFDocument26 pagesThe SNG Blueprint Part 1 PDFAdrian PatrikNo ratings yet

- Operator'S Manual: FANUC FAST Ethernet FANUC FAST Data ServerDocument240 pagesOperator'S Manual: FANUC FAST Ethernet FANUC FAST Data ServerSergio Trujillo CerroNo ratings yet

- Epson EPL-5800 Service ManualDocument116 pagesEpson EPL-5800 Service ManualHarris FNo ratings yet

- Hypothesis Testing Single SampleDocument39 pagesHypothesis Testing Single SampleThe BluemanNo ratings yet

- Screening and Assessment LDDocument63 pagesScreening and Assessment LDalhati63No ratings yet

- Resensi Novel B.inggris RikaDocument5 pagesResensi Novel B.inggris RikaRizqi RahmaniaNo ratings yet

- Salgado 2017Document15 pagesSalgado 2017ferryararNo ratings yet

- IIAS 1.0.21 - Columnar Incremental Schema Backup and Restore Feature - 1Document12 pagesIIAS 1.0.21 - Columnar Incremental Schema Backup and Restore Feature - 1HS UFNo ratings yet

- Difference Between A Flywheel and A GovernorDocument3 pagesDifference Between A Flywheel and A GovernorRevanKumarBattuNo ratings yet

- Adrian Cooke: LimerickDocument2 pagesAdrian Cooke: Limerickapi-401919939No ratings yet

- Punjab BotanyDocument9 pagesPunjab BotanyAYUSHNEWTONNo ratings yet

- M1 Activity 1 Plenary GROUP2 BSN3BDocument24 pagesM1 Activity 1 Plenary GROUP2 BSN3BKobe Bryan GermoNo ratings yet

- 7.bow-Tie Analysis For Risk ManagementDocument20 pages7.bow-Tie Analysis For Risk ManagementSabah Khan Raja100% (1)

- Ex 3 SIDocument25 pagesEx 3 SIAB123No ratings yet

- 11-40 - SINUMERIK Edge - Concept - AppsDocument15 pages11-40 - SINUMERIK Edge - Concept - AppsAshish PatwardhanNo ratings yet

- References and AddendumsDocument12 pagesReferences and Addendumsapi-268922965No ratings yet

- Not All Mineral Oils Are Equal Exploring The History and Tech Behind Mineral Insulating OilsDocument6 pagesNot All Mineral Oils Are Equal Exploring The History and Tech Behind Mineral Insulating OilsJicheng PiaoNo ratings yet

- My Happy Marriage Volume 01 LNDocument225 pagesMy Happy Marriage Volume 01 LNnailsnailsgoodinbed100% (5)

- Sociology 13th Edition Macionis Test BankDocument20 pagesSociology 13th Edition Macionis Test Bankdoctorsantalumu9coab100% (34)

- Pedrollo CK PumpsDocument4 pagesPedrollo CK Pumpsmail87523No ratings yet

- Agrochem Cals Agrochem Cals: Conference OnDocument43 pagesAgrochem Cals Agrochem Cals: Conference OnGnanendraKumarNo ratings yet