Professional Documents

Culture Documents

TGPL-AD-HSE01-TEM-001 HIRA Mech. Work-01-2

TGPL-AD-HSE01-TEM-001 HIRA Mech. Work-01-2

Uploaded by

Shubham ShuklaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TGPL-AD-HSE01-TEM-001 HIRA Mech. Work-01-2

TGPL-AD-HSE01-TEM-001 HIRA Mech. Work-01-2

Uploaded by

Shubham ShuklaCopyright:

Available Formats

TGPL-AD-HSE01-

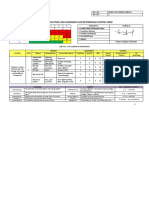

HAZARD IDENTIFICATION AND RISK ASSESSMENT (HIRA)

TEM001

Activity: Date HIRA Conducted at Site:

Site Address: Chainage:

Hazard Identification Risk Assessment Additional Person Responsible for

Inherent Risk Residual Risk Mitigation implementation of

Sub Activity / Risk

Hazard Description Potential Consequence Risk Current Controls Risk measures, if current controls and

Activity Steps C L C L Category

(IXL) (CXL) any mitigation measures

•Follow the Permit system & SOP.

Cut injury due to disc

body injury 4 4 16 3 2 6 Medium Risk

cutting/Grinding

•Tool

box talk with the working crew.

• Carry out JHA before start the work.

Flying of foreign particles Eye Injury 2 4 8 1 3 3 Medium Risk

Welding flash Burn Injury 2 4 8 •Use of goggles, face shielding, welding Helmet. 1 3 3 Medium Risk

Slip / Trip / Fall Body Injury 2 4 8 •Proper laying of welding cable. 1 2 2 Low Risk

•Provision of drinking water.

Cutting/Welding/

Grinding & Tie-in

Joint

heat stroke/ dehydration

Unconsciousness 3 3 9 2 2 4 Medium Risk

due to heat

•Ensure emergency vehicle should available

• Ensure fire extingusher should available.

High noise due to grinding Hearing loss 3 3 9 2 2 4 Medium Risk

•Ensure first aid box,

should available

Rev A.-17.06.2019 Torrent GAS CGD Project Page 1 of 1

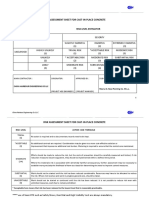

Occupational Dieases/ • Use of nose mask.

Release of copper slag dust 3 4 12 2 3 6 Medium Risk

air contamination

Hearing loss/ air

High noise 3 4 12 • Use of earplug. 2 3 6 Medium Risk

pollution

Blasting/Coating Back fire during coating Fire/ Explosion 4 4 16 •Ensure that hose pipe should proper clamping. 3 2 6 Medium Risk

Contat with open flame Burn Injury 2 4 8 •Use of ladder hand glove. 1 3 3 Medium Risk

Damage of blastinig hose Injury to body parts 3 4 12 •Not use damage hose pipe. 2 2 4 Medium Risk

Slip / Trip / Fall Body Injury 3 4 12 •Proper laying of hose pipe. 2 2 4 Medium Risk

•Use of 11KVA hand gloves.

conatct with damaged/

Electrocution/ fatal 4 3 12 3 2 6 Medium Risk

exposed electrical cable

Holiday Test •Use of electric shock resistant safety shoe.

Contact with high voltage

Electrocution/ fatal 4 3 12 3 2 6 Medium Risk

current during holiday test

Slip / Trip / Falling of

Lifting( Body injury 3 4 12 •Material stacking should in proper way. 2 2 4 Medium Risk

Loading/Unloadin Material

•Avoid work near over head cable.

g, Stringing Overhead Electrical wire Fatality 4 3 12 3 2 6 Medium Risk

Lowering)

Material Overloading Property Damage 3 2 6 • Don't lift overloading. 2 1 2 Low Risk

Fall of pipe/material due to • Proper hook and pin arrangement.

Fatality 4 3 12 3 2 6 Medium Risk

Improper Material Stacking

•Safe movment of vehicle, Proper barricading work area.,

Road traffic Accident Fatality 4 4 16 3 2 6 Medium Risk

Signage displayed related to work.

•Use of electric shock resistance hand glove.

Under ground Electrical

fatal/ body injury 5 3 15 4 1 4 Medium Risk

Cable

•Soil kept away

from trench edge.

Trail-Pit ,

Excavation &

Backfilling

Utility damage waste of resource 2 5 10 •Proper housekeeping should be done and Snake B Gon 1 3 3 Medium Risk

& Boric Powder use at site.

Collapse of trench fatal/ body injury 4 3 12 3 2 6 Medium Risk

Traffic hazard/vehicular

fatal/ body injury 4 4 16 3 2 6 Medium Risk

movement

•Availibility of Naza200.

fall of person in trench body injury 3 4 12 2 1 2 Low Risk

Snake/Insect bite Fatality 5 4 20 3 2 6 Medium Risk

Rev A.-17.06.2019 Torrent GAS CGD Project Page 2 of 2

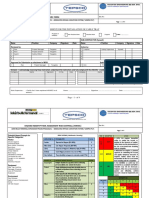

•Availibility of Naza200.

COVID-19 Fatality 5 4 20 3 2 6 Medium Risk

Identify and implement Controls & Recovery measures to reduce the Risk to ALARP and provide documented demonstration of ALARP by Bow- Hierachy of controls:

15-25 1. Elimination - remove the hazard;

Tie or equivalent methodology

Contractor Supervisor: (Name and Sign) 2. Substitution - replace a process or a substance

HIRA Prepared By

with a less hazardous one;

Identify and implement Controls and Recovery measures to reduce the Risk to As Low As Reasonably Practicable (ALARP). provide

08 - 12 3.Engineering - redesigning equipment or a

documented demonstration of ALARP by Bow-Tie or equivalent methodology

TPE: (Name and Sign) process;

4. Administration - training, instructions, safe

04 - 06 Manage for continuous improvement through the effective implementation of HSE management System

working practices;

HIRA Reviewed By 5. Personal Protective Equipment -Helmet, Safety

01 - 03 Manage for continuous improvement, although business may set lower priority for further Risk reduction

TGPL In-charge/AIC/DIC: (Name and Sign) Shoes, etc.

Review during Shift change:

DD/MM/YYYY and 00:00 Hrs Contractor: (Name and Sign) TPIA/PMC: (Name and Sign) TGPL: (Name and Sign)

Review during Shift change:

DD/MM/YYYY and 00:00 Hrs Contractor: (Name and Sign) TPIA/PMC: (Name and Sign) TGPL: (Name and Sign)

Review during Shift change:

DD/MM/YYYY and 00:00 Hrs Contractor: (Name and Sign) TPIA/PMC: (Name and Sign) TGPL: (Name and Sign)

Review during Shift change:

DD/MM/YYYY and 00:00 Hrs Contractor: (Name and Sign) TPIA/PMC: (Name and Sign) TGPL: (Name and Sign)

Review during Shift change:

DD/MM/YYYY and 00:00 Hrs Contractor: (Name and Sign) TPIA/PMC: (Name and Sign) TGPL: (Name and Sign)

Review during Shift change:

DD/MM/YYYY and 00:00 Hrs Contractor: (Name and Sign) TPIA/PMC: (Name and Sign) TGPL: (Name and Sign)

Rev A.-17.06.2019 Torrent GAS CGD Project Page 3 of 3

You might also like

- Risk Assessment For Sheet PilingDocument33 pagesRisk Assessment For Sheet Pilingsajin75% (24)

- Rmdjv-pj74-Hiradc-subc 10 (Turfing & Landscaping)Document2 pagesRmdjv-pj74-Hiradc-subc 10 (Turfing & Landscaping)myn maliQue100% (1)

- Risk Assessment Sheet For Installation of Wooden DoorsDocument3 pagesRisk Assessment Sheet For Installation of Wooden DoorsYash Sharma100% (1)

- 25.tank Water Fill TestDocument4 pages25.tank Water Fill TestShubham ShuklaNo ratings yet

- Risk Assesment - Excav - Jointing, LayingDocument11 pagesRisk Assesment - Excav - Jointing, Layingraj Kumar100% (1)

- Olifantsvlei: General Site Operations - Flame CuttingDocument4 pagesOlifantsvlei: General Site Operations - Flame CuttinggrantNo ratings yet

- Ethical Analysis of Dominos Limited Pizza Delivery Policy Working VersionDocument11 pagesEthical Analysis of Dominos Limited Pizza Delivery Policy Working Versionapi-502151650No ratings yet

- Al1 - Result and DiscussionDocument8 pagesAl1 - Result and Discussionhari6622No ratings yet

- HDD HiraDocument1 pageHDD Hiragoswami editing zone100% (1)

- RMDJV Pj74 Hiradc Subc 02 (Survey Work)Document1 pageRMDJV Pj74 Hiradc Subc 02 (Survey Work)myn maliQue100% (1)

- JHA CarpentryDocument2 pagesJHA Carpentryjohn jaycoh veranoNo ratings yet

- Rmdjv-pj74-Hiradc-subc 04 (Site Clearing & Earthwork)Document2 pagesRmdjv-pj74-Hiradc-subc 04 (Site Clearing & Earthwork)myn maliQueNo ratings yet

- Activity Being Assessed: Risk Assessment For Skate Park ConstructionDocument9 pagesActivity Being Assessed: Risk Assessment For Skate Park ConstructionTerence Tsam0% (1)

- Risk Assessment Sheet - PaintingDocument5 pagesRisk Assessment Sheet - PaintingYash Sharma89% (9)

- Safety AwarenessDocument27 pagesSafety AwarenessSuraj JhaNo ratings yet

- JHA fINALDocument2 pagesJHA fINALjohn jaycoh veranoNo ratings yet

- NDT HiraDocument3 pagesNDT Hiragoswami editing zoneNo ratings yet

- RMDJV Pj74 Hiradc Subc 05a (Piling Work)Document1 pageRMDJV Pj74 Hiradc Subc 05a (Piling Work)myn maliQue100% (1)

- Cast-In Place Concrete - Risk Assessment SheetDocument3 pagesCast-In Place Concrete - Risk Assessment SheetYash SharmaNo ratings yet

- SKC S Aerosol Safety Data Sheet EnglishDocument5 pagesSKC S Aerosol Safety Data Sheet EnglishkhairurNo ratings yet

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- Risk Assessment Sheet For Installation of Wooden DoorsDocument3 pagesRisk Assessment Sheet For Installation of Wooden Doorsrajat100% (1)

- 1 - R.A. - 003 - CompactionDocument2 pages1 - R.A. - 003 - CompactionmahmoudabidaliNo ratings yet

- Job Hazard Analysis & Risk Assessment Hot WorkDocument10 pagesJob Hazard Analysis & Risk Assessment Hot WorknavaniNo ratings yet

- Assg1 HIRACDocument12 pagesAssg1 HIRACFairuza MNasirNo ratings yet

- Confined Space EntryDocument4 pagesConfined Space Entrykwame fosterNo ratings yet

- Lifting Operations RA LdwcnsDocument3 pagesLifting Operations RA LdwcnsUmair Khan100% (1)

- Rmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)Document1 pageRmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)myn maliQueNo ratings yet

- Bms Hiradc 003Document5 pagesBms Hiradc 003Md Shahidil AminNo ratings yet

- Presentation WPADocument13 pagesPresentation WPAadamNo ratings yet

- 20161104-NW SHEF RA Boxing of Swordfish WingsDocument4 pages20161104-NW SHEF RA Boxing of Swordfish Wingsmark.wilsonNo ratings yet

- Hirac MondeDocument8 pagesHirac MondeledromechjohnNo ratings yet

- RMDJV Pj74 Hiradc Subc 01 (Soil Investigation)Document2 pagesRMDJV Pj74 Hiradc Subc 01 (Soil Investigation)myn maliQueNo ratings yet

- JHA - CTB Wielding WorksDocument2 pagesJHA - CTB Wielding Worksjohn jaycoh veranoNo ratings yet

- 9-2 Moem Hirarc Apr 2017Document1 page9-2 Moem Hirarc Apr 2017PHH9834No ratings yet

- Lim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMDocument2 pagesLim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMVaradaraju ThirunavukkarasanNo ratings yet

- Jha Lighting ArrestorDocument3 pagesJha Lighting ArrestorRavi thokalNo ratings yet

- TGPL-AD-HSE01-TEM-HIRA X-Ray 02-1Document2 pagesTGPL-AD-HSE01-TEM-HIRA X-Ray 02-1Shubham ShuklaNo ratings yet

- HIRARC ExampleDocument18 pagesHIRARC ExamplePRINCE DAVID ART TOLEDONo ratings yet

- Rmdjv-Pj74-Hiradc-Subc 11 (PVD)Document2 pagesRmdjv-Pj74-Hiradc-Subc 11 (PVD)myn maliQueNo ratings yet

- JHA DemolationDocument2 pagesJHA Demolationjohn jaycoh veranoNo ratings yet

- PROCESS RA Maidstone Animation Stop Motion BaysDocument4 pagesPROCESS RA Maidstone Animation Stop Motion BayslydsonewordNo ratings yet

- Infrascan SwmsDocument5 pagesInfrascan Swmsapi-271287158No ratings yet

- Risk AssesmentDocument2 pagesRisk AssesmentSatish KumarNo ratings yet

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoNo ratings yet

- RMDJV-PJ74-HIRADC-SUBE 03 (Installation of Outdoor Equipment)Document2 pagesRMDJV-PJ74-HIRADC-SUBE 03 (Installation of Outdoor Equipment)myn maliQueNo ratings yet

- Rmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)Document1 pageRmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)myn maliQueNo ratings yet

- SJP & THA #007 - Rough in Electrical SystemsDocument1 pageSJP & THA #007 - Rough in Electrical SystemsShuhaib MDNo ratings yet

- HIRA - Insulation WorkDocument3 pagesHIRA - Insulation WorkMELCO JITPLNo ratings yet

- Scaffolding Erection and Dismantling CwhohsDocument3 pagesScaffolding Erection and Dismantling CwhohsmurasolimaranNo ratings yet

- Hirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODDocument4 pagesHirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODMohd Faiz MohdNo ratings yet

- 45 - Method Statements For Erection of Steel PDFDocument1 page45 - Method Statements For Erection of Steel PDFAbdul RahmanNo ratings yet

- JHA - Butt WieldingDocument2 pagesJHA - Butt Wieldingjohn jaycoh veranoNo ratings yet

- Hira - Erection Work - Metal Scope - DPWDocument18 pagesHira - Erection Work - Metal Scope - DPWrubinakumari136No ratings yet

- Method Statement For Anti Termite TreatmentDocument7 pagesMethod Statement For Anti Termite TreatmentSagar Aliasjackey100% (2)

- Risk Assessment/Management Form CivilDocument1 pageRisk Assessment/Management Form CivilGyanendra Narayan NayakNo ratings yet

- Paint WorkDocument1 pagePaint WorkNarender BhardwajNo ratings yet

- Risk Assessment/Management Form CivilDocument1 pageRisk Assessment/Management Form CivilGyanendra Narayan NayakNo ratings yet

- BIAL Project: Contractor's OH&S Hazard Identification & Risk Assessment Register Larsen & Toubro Limited 1 2 Valid ForDocument2 pagesBIAL Project: Contractor's OH&S Hazard Identification & Risk Assessment Register Larsen & Toubro Limited 1 2 Valid Forelahi MohammedNo ratings yet

- 005-JSA X-Ray & Gamma Ray RadiographyDocument7 pages005-JSA X-Ray & Gamma Ray RadiographyMoaatazz NouisriNo ratings yet

- A Practical Approach to Hazard Identification for Operations and Maintenance WorkersFrom EverandA Practical Approach to Hazard Identification for Operations and Maintenance WorkersNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- Staff NameDocument1 pageStaff NameShubham ShuklaNo ratings yet

- JHA X-Ray 02-2Document2 pagesJHA X-Ray 02-2Shubham ShuklaNo ratings yet

- Valve RT Report 1Document2 pagesValve RT Report 1Shubham ShuklaNo ratings yet

- Inspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Document4 pagesInspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Shubham ShuklaNo ratings yet

- Job Procedure For Tanks Work: 10 of Ramadan City, Industrial Area A1, EgyptDocument10 pagesJob Procedure For Tanks Work: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Hira HDDDocument3 pagesHira HDDShubham ShuklaNo ratings yet

- Job Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For PWHT of Storage Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDocument13 pagesJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- Master FormatsDocument93 pagesMaster FormatsShubham ShuklaNo ratings yet

- Inspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Document6 pagesInspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Shubham ShuklaNo ratings yet

- 24.tank Oil Chalk TestDocument3 pages24.tank Oil Chalk TestShubham Shukla100% (1)

- Job Procedure For Vacuum Test of Tanks: 10 of Ramadan City, Industrial Area A1, EgyptDocument5 pagesJob Procedure For Vacuum Test of Tanks: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaNo ratings yet

- 2 Job Procedure For IMIRDocument6 pages2 Job Procedure For IMIRShubham ShuklaNo ratings yet

- Annexure IiDocument21 pagesAnnexure IiShubham ShuklaNo ratings yet

- Form 9560 Nbel Form Mech 51, Rev.0Document1 pageForm 9560 Nbel Form Mech 51, Rev.0Shubham ShuklaNo ratings yet

- Annexure IDocument42 pagesAnnexure IShubham ShuklaNo ratings yet

- APPENDIX "A": Details of ExperienceDocument10 pagesAPPENDIX "A": Details of ExperienceShubham ShuklaNo ratings yet

- Asme Section Ix InterpretationDocument70 pagesAsme Section Ix InterpretationShubham ShuklaNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesShubham ShuklaNo ratings yet

- EntrepreneurshipDocument22 pagesEntrepreneurshipCharu ModiNo ratings yet

- ASR 3E Book 3 Unit 1Document66 pagesASR 3E Book 3 Unit 1Lee YuhshiNo ratings yet

- Global Supply Chain Planning: Peripheral ForecastDocument31 pagesGlobal Supply Chain Planning: Peripheral Forecastranga.ramanNo ratings yet

- Superfoods: English Level Pre - A1Document4 pagesSuperfoods: English Level Pre - A1Ana CelestinoNo ratings yet

- Name: Jeth A. Mahusay Course: BSA-3 Schedule: TTH-4:00-5:30 PM Subject: Accounting For Business Combinations Instructor: Ms. Ana Mae Magbanua, CPADocument2 pagesName: Jeth A. Mahusay Course: BSA-3 Schedule: TTH-4:00-5:30 PM Subject: Accounting For Business Combinations Instructor: Ms. Ana Mae Magbanua, CPAJeth MahusayNo ratings yet

- Cuckoo Search (CS) Algorithm - Matlab CodeDocument4 pagesCuckoo Search (CS) Algorithm - Matlab CodeGogyNo ratings yet

- Sounder-Strobe-Combination AXL05: Loud Signalling Device With 32 Different Signals and A 2.5 Joule Strobe LightDocument2 pagesSounder-Strobe-Combination AXL05: Loud Signalling Device With 32 Different Signals and A 2.5 Joule Strobe LightBrayan Jauregui GutierrezNo ratings yet

- Tata Motors ReportDocument5 pagesTata Motors ReportrastehertaNo ratings yet

- RV ToolsDocument101 pagesRV ToolsĐỗ HoànNo ratings yet

- Supplier Guidelines - v2 PDFDocument64 pagesSupplier Guidelines - v2 PDFsidNo ratings yet

- Centrifugal Pump Piping Design LayoutDocument19 pagesCentrifugal Pump Piping Design LayoutzhangjieNo ratings yet

- AppealDocument9 pagesAppealKalpana GundumoluNo ratings yet

- Pulana Martha Malatji - 2023 - 06 - 27Document2 pagesPulana Martha Malatji - 2023 - 06 - 27Vee-kay Vicky KatekaniNo ratings yet

- Ramey DynareDocument16 pagesRamey DynarenicoadoNo ratings yet

- Lecture 3 - Consumer TheoryDocument24 pagesLecture 3 - Consumer TheoryJico BumagatNo ratings yet

- Pete The Cat Activity SheetsDocument5 pagesPete The Cat Activity SheetsJeni Zhang67% (9)

- 4577XXXXXXXXXX19 - 13 07 2023Document3 pages4577XXXXXXXXXX19 - 13 07 2023avisinghoo7No ratings yet

- Ey Fin Tech Market Opportunities 2019 PDFDocument24 pagesEy Fin Tech Market Opportunities 2019 PDFMohamed AliNo ratings yet

- FINAL Tesla Inc. Vs Tesla Power India Private Limited & Ors.Document6 pagesFINAL Tesla Inc. Vs Tesla Power India Private Limited & Ors.ayushmankrvilsNo ratings yet

- Free Proxy ListDocument5 pagesFree Proxy ListWalid TorkhaniNo ratings yet

- 21 Tison Vs CADocument1 page21 Tison Vs CAJayNo ratings yet

- Bonus: "Listen, I've Got A Spare Ten Minutes, I Was Just On My Way To Grab A Quick Coffee, Come and Join Me... "Document2 pagesBonus: "Listen, I've Got A Spare Ten Minutes, I Was Just On My Way To Grab A Quick Coffee, Come and Join Me... "asfdsdafsdafNo ratings yet

- Mispa Viva PDFDocument2 pagesMispa Viva PDFMC Sai Thiha0% (1)

- En 13384-3 EnglishDocument29 pagesEn 13384-3 EnglishолегNo ratings yet

- Roof Tile: Insulated Panel SystemDocument48 pagesRoof Tile: Insulated Panel SystemCormac DooleyNo ratings yet

- Module 3 - Limitations On The Power of TaxationDocument15 pagesModule 3 - Limitations On The Power of TaxationGerard Relucio OroNo ratings yet

- Essay On Rising Prices in IndiaDocument2 pagesEssay On Rising Prices in Indiasoumi_sumi16100% (1)

- Reading Comprehension For Secondary StudentsDocument10 pagesReading Comprehension For Secondary StudentsWinniethePoohPoohNo ratings yet

- Whats New in 1610 and 1710 Release For SAP S4 HANA FinanceDocument9 pagesWhats New in 1610 and 1710 Release For SAP S4 HANA FinanceLokamNo ratings yet