Professional Documents

Culture Documents

Check List LV Power Cables and Wires Installation Indoor Cable

Check List LV Power Cables and Wires Installation Indoor Cable

Uploaded by

Naing Win TunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check List LV Power Cables and Wires Installation Indoor Cable

Check List LV Power Cables and Wires Installation Indoor Cable

Uploaded by

Naing Win TunCopyright:

Available Formats

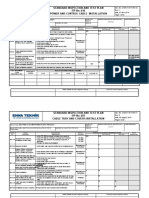

PROJECT NAME

CHECK LIST FOR: Form No:

LV power cables and wires installation Rev. No : 0

(Indoor LV Cables & Wires) Page : 1 of 2

SUBCONTRACTOR X CONTRACTOR

SECTION OF WORK: Electrical LOCATION:

LEVEL: WIR No.:

STAGE ITEM Checked by Checked by Date

CONSUL

S/C CONT

TANT

Check the Approved shop drawings and

SETTING Builders work drawings approval

OUT

Check level, Size as per approved shop

drawings.

Check for Services Clearances, and the same

MEP/CIVIL approved by company site team (civil)

1. Check the routing of LV cables/wires is as

per approved shop drawings.

2. Check the cable spacing by at least on

cable diameter (of larger cable) throughout the

length of the cable run.

3. Check the proper dressing of LV

cables/wires; cables are secured to cable tray

using straps/ties.

4. Ensure that wiring of more than one phase

is not done in an outlet box or switch box, other

than one designated for multi-phase use.

Installation of LV Cables and wires

5. Check required sufficient space is provided

wherever junction box, fittings and DB's are

coming for termination.

6. Check for colour coding of LV cables/wires

at all terminations within distribution boards and

equipment’s.

7. Check the LV cables are tight by cable ties

properly.

8. Check the LV cables/wires terminations are

done properly.

9. Check the LV cables/wires glands & lug

type, size & termination kit are from approved

makers.

10. Checks the LV cables insulation is free from

damage during the pulling process.

11. Check the connection from panel to panel

with identification labels.

PROJECT NAME

CHECK LIST FOR: Form No:

LV power cables and wires installation Rev. No : 0

(Indoor LV Cables & Wires) Page : 2 of 2

SUBCONTRACTOR X CONTRACTOR

SECTION OF WORK: Electrical LOCATION:

LEVEL: WIR No.:

STAGE ITEM Checked by Checked by Date

CONSUL

S/C CONT

TANT

1. Adequate lights are provided in the Work

Area prior to installation.

2. All terminations cables have been checked

for any damage or improper connections.

3. Ensure that barricade & warning boards on

the area are available prior to installation.

SAFETY PRECAUTIONS

4. Ensure no obstacles in the area. Maintain

proper housekeeping.

5. Ensure all personnel performing the

installation shall have proper training &

experience.

6. Ensure all electrical tools to be used in the

installation are not damage.

7. Adequate lights are provided in the Work

Area prior to installation.

8. Ensure all Personal performing the

installation shall have necessary personal

protective equipment.

For S/C QA/QC: Date: FOR CONTRACTOR Date: For Consultant Date:

QA/QC: Rep.:

Name: Sign: Name: Sign: Name: Sign:

You might also like

- Check List For Cable Glanding & TerminationDocument1 pageCheck List For Cable Glanding & TerminationImran Khan100% (4)

- Cable Tray Inspection ListDocument1 pageCable Tray Inspection ListTreesa Archnana100% (3)

- CHECKLIST For Installation of Power CablesDocument1 pageCHECKLIST For Installation of Power CablesTHEOPHILUS ATO FLETCHER100% (5)

- Checklist For Under Ground Water Piping InstallationDocument1 pageChecklist For Under Ground Water Piping InstallationBelal Alrwadieh100% (1)

- Check List For: Pre-Commissioning - Visual Inspection) : Video Surveillance System (CCTV) Testing and CommissioningDocument1 pageCheck List For: Pre-Commissioning - Visual Inspection) : Video Surveillance System (CCTV) Testing and Commissioningeid albouriny100% (1)

- 0-WD792-CJ250-01504 - Rev.A - Inspection and Test Plan For Instrument Cables (Checklist)Document2 pages0-WD792-CJ250-01504 - Rev.A - Inspection and Test Plan For Instrument Cables (Checklist)ResearcherNo ratings yet

- Checklist For Earthing & Bonding System InstallationDocument1 pageChecklist For Earthing & Bonding System InstallationPrashant Kadam100% (1)

- Pre Commissioning Check ListDocument4 pagesPre Commissioning Check ListbajrangNo ratings yet

- Method Statement For Installation of High Voltage HV Cables Above & Under Ground - Safe Work Method of StatementDocument4 pagesMethod Statement For Installation of High Voltage HV Cables Above & Under Ground - Safe Work Method of StatementMohammed K. HayderNo ratings yet

- Check List LV Power Cables and Wires Installation Outdoor CableDocument2 pagesCheck List LV Power Cables and Wires Installation Outdoor CableNaing Win TunNo ratings yet

- Method Statement For MV Power Cables & Accessories InstallationDocument2 pagesMethod Statement For MV Power Cables & Accessories InstallationAdil Hasanov100% (1)

- Qic-Qsp-Uni-Tdr-Cl-0417 (A) (3) Rev001Document2 pagesQic-Qsp-Uni-Tdr-Cl-0417 (A) (3) Rev001Ragab EisaNo ratings yet

- Checklist For Installation of Structural CablingDocument2 pagesChecklist For Installation of Structural CablingInfas YahyaNo ratings yet

- Qic-Qsp-Uni-Tdr-Cl-0417 (B) (3) Rev001Document3 pagesQic-Qsp-Uni-Tdr-Cl-0417 (B) (3) Rev001Ragab EisaNo ratings yet

- Check List For MCC and Capacitor Bank InstallationDocument2 pagesCheck List For MCC and Capacitor Bank InstallationNaing Win TunNo ratings yet

- Check List For DB InstallationDocument2 pagesCheck List For DB InstallationNaing Win TunNo ratings yet

- Check List For MDB InstallationDocument2 pagesCheck List For MDB InstallationNaing Win TunNo ratings yet

- Standard Inspection and Test Plan ITP No: 610 Power and Control Cable InstallationDocument23 pagesStandard Inspection and Test Plan ITP No: 610 Power and Control Cable InstallationSivakumar Ullamparthi0% (1)

- Check List For Sub Main Distribution Board InstallationDocument2 pagesCheck List For Sub Main Distribution Board InstallationNaing Win TunNo ratings yet

- Checklist For Structured Cabling System & Accessories InstallationDocument1 pageChecklist For Structured Cabling System & Accessories InstallationInfas YahyaNo ratings yet

- Checklist For Earthing & Bonding System InstallationDocument1 pageChecklist For Earthing & Bonding System InstallationPrashant Kadam100% (2)

- Overhead LinesDocument3 pagesOverhead LinesengrandyNo ratings yet

- Checklist For UPS & Accessories InstallationDocument1 pageChecklist For UPS & Accessories InstallationguspriyNo ratings yet

- SSE-QC-ELE-525-Cable LayingDocument3 pagesSSE-QC-ELE-525-Cable LayingBhalsingh JangraNo ratings yet

- Checklist For Sleeves & Puddle Flang InstallationDocument1 pageChecklist For Sleeves & Puddle Flang InstallationBelal Alrwadieh0% (1)

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocument9 pagesRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanNo ratings yet

- Cable GlandingDocument5 pagesCable GlandingSourav RanaNo ratings yet

- Checklist CablesDocument2 pagesChecklist CablesSourav RanaNo ratings yet

- Low Voltage Power Cable Installation & Test RecordDocument1 pageLow Voltage Power Cable Installation & Test RecordKarla AzenetNo ratings yet

- Overhead Lines Andy PMDocument3 pagesOverhead Lines Andy PMengrandyNo ratings yet

- 5 - Tank Itp - Inspection & Test Plan For TanksDocument5 pages5 - Tank Itp - Inspection & Test Plan For TanksmandiNo ratings yet

- Checklist For Installation of Lightning Protection SystemDocument1 pageChecklist For Installation of Lightning Protection SystemNaing Win TunNo ratings yet

- Weil-qe&I-cl-002 Cable Glanding and TerminationDocument1 pageWeil-qe&I-cl-002 Cable Glanding and TerminationSayed AhammadNo ratings yet

- Ohl TestDocument5 pagesOhl TestAnonymous ExWAN2xjFJNo ratings yet

- Qic-Qsp-Uni-Tdr-Cl-0418 (3) Rev001Document3 pagesQic-Qsp-Uni-Tdr-Cl-0418 (3) Rev001Ragab EisaNo ratings yet

- Checklist For Access Control System InstallationDocument1 pageChecklist For Access Control System InstallationRommel Espinosa ParasNo ratings yet

- Checklist For Above Ground Water Piping InstallationDocument1 pageChecklist For Above Ground Water Piping InstallationBelal Alrwadieh50% (2)

- Weil Qe&i CL 003 Installtion of CablesDocument1 pageWeil Qe&i CL 003 Installtion of CablesSayed AhammadNo ratings yet

- Job Procedure 05 For CABLE LAYING & TERMINATIONDocument6 pagesJob Procedure 05 For CABLE LAYING & TERMINATIONSoumik KarNo ratings yet

- Cable Laying ChecklistDocument2 pagesCable Laying Checklisteiplstaff.nav2No ratings yet

- Checklist Underground FF Piping InstallationDocument1 pageChecklist Underground FF Piping Installationbeho2000No ratings yet

- Pre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningDocument2 pagesPre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningNaing Win TunNo ratings yet

- Checklist For Installation For Fire Fighting Piping System and Accessories Under GroundDocument1 pageChecklist For Installation For Fire Fighting Piping System and Accessories Under Groundvishalkadam57No ratings yet

- Mechanical Completion L.V. Power, Control and Telecomm / Instrument CablesDocument4 pagesMechanical Completion L.V. Power, Control and Telecomm / Instrument CablesJalal AlbadriNo ratings yet

- Check List For Fire Alarm & Voice Evacuation SystemDocument1 pageCheck List For Fire Alarm & Voice Evacuation SystemmohammadNo ratings yet

- KAFD-Checklist PVC ConduitingDocument3 pagesKAFD-Checklist PVC ConduitingPERVEZ AHMAD KHANNo ratings yet

- 3.1 Installation of Wires and Cables & TestingDocument5 pages3.1 Installation of Wires and Cables & TestingMedrouaNo ratings yet

- Method Statement - Cable LayingDocument5 pagesMethod Statement - Cable LayingsoubhagyaNo ratings yet

- Distribution PanelDocument5 pagesDistribution PanelSourav RanaNo ratings yet

- Cables Trays G+TDocument5 pagesCables Trays G+TSuresh PasumarthiNo ratings yet

- Electrical Inspections ChecklistDocument6 pagesElectrical Inspections Checklistasyraf azaharyNo ratings yet

- Method Statement Cable TerminationDocument3 pagesMethod Statement Cable TerminationfaizbukhariNo ratings yet

- Construction Check Sheet Power & Auxilliary Transformer E-012ADocument2 pagesConstruction Check Sheet Power & Auxilliary Transformer E-012AhrimklimNo ratings yet

- Cable LayingDocument6 pagesCable LayingSourav RanaNo ratings yet

- Updated Temp - Substation - ChecklistDocument22 pagesUpdated Temp - Substation - ChecklistWunNaNo ratings yet

- WMS For Cable Laying & TerminationDocument5 pagesWMS For Cable Laying & Terminationeiplstaff.nav2No ratings yet

- Check List For LV PanelsDocument1 pageCheck List For LV PanelsAhmed GamalNo ratings yet

- Residential Plumbing Inspection Checklist TemplateDocument6 pagesResidential Plumbing Inspection Checklist TemplateNaing Win TunNo ratings yet

- Free Plumbing Inspection Checklist Template - ServiceTitanDocument19 pagesFree Plumbing Inspection Checklist Template - ServiceTitanNaing Win TunNo ratings yet

- WES.128 - Electrical Visual Inspection - Trunking System - SafetyCultureDocument3 pagesWES.128 - Electrical Visual Inspection - Trunking System - SafetyCultureNaing Win TunNo ratings yet

- Inspection and Testing Procedure of Drainage Piping After InstallationDocument10 pagesInspection and Testing Procedure of Drainage Piping After InstallationNaing Win TunNo ratings yet

- Institution of Gas Engineers and ManagerDocument162 pagesInstitution of Gas Engineers and ManagerNaing Win TunNo ratings yet

- ChecklistDocument13 pagesChecklistNaing Win TunNo ratings yet

- Method Statement For Welding Works - Welding TechniquesDocument15 pagesMethod Statement For Welding Works - Welding TechniquesNaing Win TunNo ratings yet

- Chapter 7 - MV and Smoke Control System (Performance Base)Document2 pagesChapter 7 - MV and Smoke Control System (Performance Base)Naing Win TunNo ratings yet

- Check List For MDB InstallationDocument2 pagesCheck List For MDB InstallationNaing Win TunNo ratings yet

- Check List For DB InstallationDocument2 pagesCheck List For DB InstallationNaing Win TunNo ratings yet

- Chapter 7 - MV and Smoke Control SystemDocument21 pagesChapter 7 - MV and Smoke Control SystemNaing Win TunNo ratings yet

- Chapter 6 - Fire Fighting SystemDocument23 pagesChapter 6 - Fire Fighting SystemNaing Win TunNo ratings yet

- Chapter 3 - Structural Fire PrecautionsDocument81 pagesChapter 3 - Structural Fire PrecautionsNaing Win TunNo ratings yet

- Appendix J - Fire Safety Requirements On Fire Safety Requirements For Petroleum Service StationDocument13 pagesAppendix J - Fire Safety Requirements On Fire Safety Requirements For Petroleum Service StationNaing Win TunNo ratings yet

- Chapter 4 - Site Planning & External Fire Fighting ProvisionsDocument13 pagesChapter 4 - Site Planning & External Fire Fighting ProvisionsNaing Win TunNo ratings yet

- Chapter 2 - Means of EscapeDocument46 pagesChapter 2 - Means of EscapeNaing Win TunNo ratings yet

- Chapter 3 - Structural Fire Precautions (Performance Base)Document2 pagesChapter 3 - Structural Fire Precautions (Performance Base)Naing Win TunNo ratings yet

- Chapter 1 - GeneralDocument40 pagesChapter 1 - GeneralNaing Win TunNo ratings yet

- Appendix K - Reduced Water Storage Requirements For Sprinkler Systems in Buildings - For Ordinary Hazard GroupsDocument3 pagesAppendix K - Reduced Water Storage Requirements For Sprinkler Systems in Buildings - For Ordinary Hazard GroupsNaing Win TunNo ratings yet

- Appendix I - Water Supply Requirtements For Wet Riser SystemDocument1 pageAppendix I - Water Supply Requirtements For Wet Riser SystemNaing Win TunNo ratings yet

- Appendix F - Notes On The Use of Intumescent Paints For Protection To Structural Steel Members of BuildingsDocument2 pagesAppendix F - Notes On The Use of Intumescent Paints For Protection To Structural Steel Members of BuildingsNaing Win TunNo ratings yet

- Appendix B - Fire Safety Requirements For Chemical - Hazmat WarehouseDocument9 pagesAppendix B - Fire Safety Requirements For Chemical - Hazmat WarehouseNaing Win TunNo ratings yet

- Appendix A - Fire Safety Requirements Affecting Shophouses Under ConservationDocument8 pagesAppendix A - Fire Safety Requirements Affecting Shophouses Under ConservationNaing Win TunNo ratings yet

- DUCTSIZEDocument1 pageDUCTSIZENaing Win TunNo ratings yet

- QUOTEDocument2 pagesQUOTENaing Win TunNo ratings yet

- UTILSDocument1 pageUTILSNaing Win TunNo ratings yet

- MCCSIZEDocument2 pagesMCCSIZENaing Win TunNo ratings yet

- EXTLIGHTDocument2 pagesEXTLIGHTNaing Win TunNo ratings yet

- Trunking Size CalculationDocument1 pageTrunking Size CalculationNaing Win TunNo ratings yet

- LIGHTDocument4 pagesLIGHTNaing Win TunNo ratings yet

- Elel Norcal MDFDocument6 pagesElel Norcal MDFFlorinMacoveiNo ratings yet

- Sikatop®-77 D: Product Data SheetDocument2 pagesSikatop®-77 D: Product Data SheetCuanna ButterlyNo ratings yet

- Aerial - Lifty & Scissor Lift - Safety - TrainingDocument32 pagesAerial - Lifty & Scissor Lift - Safety - TrainingfawnNo ratings yet

- KZB / KZB-Q: Maintenance SeminarDocument132 pagesKZB / KZB-Q: Maintenance Seminarstelios nikoladosNo ratings yet

- Reference: AASHTO Guide For The Design of Pavement Structures, 1993Document25 pagesReference: AASHTO Guide For The Design of Pavement Structures, 1993Kevin SotoNo ratings yet

- IP MS 09 GroutingDocument4 pagesIP MS 09 GroutingZubair Ahmed KhaskheliNo ratings yet

- ASTM Acceptance CriteriaDocument10 pagesASTM Acceptance Criteriabeshnu garanaikNo ratings yet

- Selkirk DSP Installation ManualDocument7 pagesSelkirk DSP Installation ManualRonNo ratings yet

- Katalog Izodom ENGDocument9 pagesKatalog Izodom ENGДмитрий ЧиндаровNo ratings yet

- Pipeline Construction Specification (Pcs-01) Sp-1208Document80 pagesPipeline Construction Specification (Pcs-01) Sp-1208samkarthik47100% (1)

- Duct Pressure Loss Calculations For Air - Handling Units: Tersam UtilityDocument10 pagesDuct Pressure Loss Calculations For Air - Handling Units: Tersam UtilityVipul HodawdekarNo ratings yet

- Rajput Architecture of The Mewar From 13Document8 pagesRajput Architecture of The Mewar From 13Gaurav MishraNo ratings yet

- Project Concept Paper Template - ADBDocument22 pagesProject Concept Paper Template - ADBPiyush ParagNo ratings yet

- Heat ExchangerDocument36 pagesHeat ExchangerUsman MansuriNo ratings yet

- Handout 1 Rig HyrdaulicsDocument13 pagesHandout 1 Rig HyrdaulicsMarco PlaysNo ratings yet

- Lecture 4Document18 pagesLecture 4Ap kowshikNo ratings yet

- Ngc1 Epcc Exe Kqks Sbnro PMG MPR 011 (May 22)Document86 pagesNgc1 Epcc Exe Kqks Sbnro PMG MPR 011 (May 22)hanafiNo ratings yet

- John Smith: Assistant Project ManagerDocument2 pagesJohn Smith: Assistant Project ManagersaurabhbectorNo ratings yet

- Initial Filling HRSG Valve PositionDocument8 pagesInitial Filling HRSG Valve Positionmuhammad fawaz abizarNo ratings yet

- Tarc Tripundra BrochureDocument40 pagesTarc Tripundra BrochureAspire AssetsNo ratings yet

- IFPSA Master Symbol Chart PDFDocument1 pageIFPSA Master Symbol Chart PDFanush_swaminathanNo ratings yet

- 6F Rigido P2Document11 pages6F Rigido P2calidadjmsingNo ratings yet

- BoQ 1Document1 pageBoQ 1shajbabyNo ratings yet

- New SHAHIN CV by JhanviDocument4 pagesNew SHAHIN CV by Jhanviachuprathap30No ratings yet

- Cat KGV 07 17Document16 pagesCat KGV 07 17GILBERTO YOSHIDANo ratings yet

- p800 Px800 Plastic EomDocument52 pagesp800 Px800 Plastic Eomdhavalesh1No ratings yet

- AsdDocument3 pagesAsdMuStafaAbbasNo ratings yet

- Precast Segmental Concrete BridgesDocument2 pagesPrecast Segmental Concrete BridgesmemomsmNo ratings yet

- DRAINAGE Full Report Based On MSMADocument13 pagesDRAINAGE Full Report Based On MSMAelleyashahari100% (2)

- Mechanical MCQ PDFDocument4 pagesMechanical MCQ PDFramkumar100% (1)