Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

5 viewsM35SCC Trial Mix Design Infra Market

M35SCC Trial Mix Design Infra Market

Uploaded by

smn.ussharCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 10th RA Minarul - R0Document45 pages10th RA Minarul - R0smn.ussharNo ratings yet

- Debashis Das-2Document1 pageDebashis Das-2smn.ussharNo ratings yet

- SMN All Activeties Work Project of Final HIRADocument34 pagesSMN All Activeties Work Project of Final HIRAsmn.ussharNo ratings yet

- T12 S50 32 01Document1 pageT12 S50 32 01smn.ussharNo ratings yet

- Form8 S25264O8W0204241200000 PDFDocument2 pagesForm8 S25264O8W0204241200000 PDFsmn.ussharNo ratings yet

- T12 S50 32 03Document1 pageT12 S50 32 03smn.ussharNo ratings yet

- 4th RA S.K. Construction (Pintu)Document2 pages4th RA S.K. Construction (Pintu)smn.ussharNo ratings yet

- 18th RA Seikh BachchuDocument10 pages18th RA Seikh Bachchusmn.ussharNo ratings yet

- 2.8c Risk Assessment - 007 Excavation Work Using Heavy Equipment Rev. July 2019Document9 pages2.8c Risk Assessment - 007 Excavation Work Using Heavy Equipment Rev. July 2019smn.ussharNo ratings yet

- MTC IMS FO 14A Monthly Safety ReportDocument7 pagesMTC IMS FO 14A Monthly Safety Reportsmn.ussharNo ratings yet

- Smn-Fy 23-24Document17 pagesSmn-Fy 23-24smn.ussharNo ratings yet

- 19th RA Seikh BachchuDocument6 pages19th RA Seikh Bachchusmn.ussharNo ratings yet

- T12 S20 32 01Document1 pageT12 S20 32 01smn.ussharNo ratings yet

- 3rd RA Bill - Mainul Hk.Document3 pages3rd RA Bill - Mainul Hk.smn.ussharNo ratings yet

- SMN MTC-IMS-FO-14A-Monthly-Safety-Report-Xls SMN TATADocument7 pagesSMN MTC-IMS-FO-14A-Monthly-Safety-Report-Xls SMN TATAsmn.ussharNo ratings yet

- DocScanner 31 Jan 2024 3-27 PMDocument1 pageDocScanner 31 Jan 2024 3-27 PMsmn.ussharNo ratings yet

- 3rd RA of R.A. Enterprise of JCB & DumperDocument2 pages3rd RA of R.A. Enterprise of JCB & Dumpersmn.ussharNo ratings yet

- SCMQ - 3122Document9 pagesSCMQ - 3122smn.ussharNo ratings yet

- Nirman Concrete Ledger (Usshar)Document23 pagesNirman Concrete Ledger (Usshar)smn.ussharNo ratings yet

- SMN Labour Salary (Usshar) November - 23Document3 pagesSMN Labour Salary (Usshar) November - 23smn.ussharNo ratings yet

- 6th GST Invoice Birendra DasDocument4 pages6th GST Invoice Birendra Dassmn.ussharNo ratings yet

- 6th GST INVOICE SUPREMEDocument4 pages6th GST INVOICE SUPREMEsmn.ussharNo ratings yet

- 25-02-24 DPRDocument3 pages25-02-24 DPRsmn.ussharNo ratings yet

- Subal Consruction GST Invoice 7Document4 pagesSubal Consruction GST Invoice 7smn.ussharNo ratings yet

- Quotation Normal RSP 800 Ambuja RealtyDocument2 pagesQuotation Normal RSP 800 Ambuja Realtysmn.ussharNo ratings yet

- Offer LatterDocument1 pageOffer Lattersmn.ussharNo ratings yet

- SM Payment Reconsilation 27.11.23 - For As Per SiteDocument36 pagesSM Payment Reconsilation 27.11.23 - For As Per Sitesmn.ussharNo ratings yet

- Blue Star RA7Document4 pagesBlue Star RA7smn.ussharNo ratings yet

- Usshar Labour DetailsDocument3 pagesUsshar Labour Detailssmn.ussharNo ratings yet

M35SCC Trial Mix Design Infra Market

M35SCC Trial Mix Design Infra Market

Uploaded by

smn.usshar0 ratings0% found this document useful (0 votes)

5 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

5 views5 pagesM35SCC Trial Mix Design Infra Market

M35SCC Trial Mix Design Infra Market

Uploaded by

smn.ussharCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 5

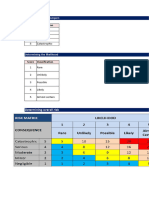

z Holla Infra Market Pvt Limited

Readymix Concrete Div-East

CONCRETE MIX DESIGN

Tithe presont case tho total comentivous material content is mcreased by

|Cementitous material content now is = 830x108

[So the water cementitious ratio now is = 1000 7 = 5900

‘percent of total cementitious material content

480)

percent of total cementitious material content

Seer soos

orcs ‘Content

16000

4300

00

CEMENT Kain

1590.0 Kgim*

ost

5900 x

16049 Kgim*

160.00 Koi?

9000 x

0.00 Kgim?

0.00 Kgim*

Kgim®

212%

(say)

0%

(say)

430.0 —_Kgim* (say)

[Shock for Min. cementitious material content, 260 Kgim*< $80 Kom? (430 Kgim? OPC + 160 Kom? Fly sh) Hence Ok

[Check for Max. Coment (OPC) content, 430 Kom < 450 Kolm, (Hence OK)

|4-8. PROPORTION OF VOLUME OF COARSE AGGREGATE & FINE AGGREGATE CONTENT

From Tables of IS 10262:2019, volume of coarse aggregate corresponding to 10 mm size aggregate & fine aggregate (Zones)

for water-coment ratio of 05

inthis case water-cementiiousratiois 031

increased to docrease the fino aggregate. As water-coment

ot vtume of coarse aggregates increased by [0170 50:319.05]=

082 |

ois lower by

0.039

For pumpabie concrete tase value may be reduced upto 10

[Therefore volume of coarse aggregate 0859

0.837 m

1.00

0.463 m*

Volume of fine aggregate content

[4-9 ax CALCULATION

Total Volume

‘Volume of entrapped air in wot concrote

Volume of coment

1.00 m

0.015 m

Therefore, volume of coarse aggres

4 x

required to be

0.19 the proportion

(atthe rate + 01 fers 0.05 change in water-coment ato)

Therefore, corrected proportion of volume of coarse aggregate for water-cementtious ratio

ot 0589

percent (4 percent considered for SCO)

0558

700

oss?

Mass of comant

‘Specific gravity of cement

4300

3.08

oat m*

Volume of Fly ash

7000)

Mass of Fly ash

‘Specific gravity of Fly ash

460.00

214

0.075 m*

000

Mass of water

‘Specific gravity of waler

1800

mes

0180 mt

Mass of:

7000)

Holla Infra Market Pvt Limited

Ha Readymix Concrete Div-East

‘CONCRETE MIX DESIGN

The exita walor to be added for absovplion by coarse and fine aggregate,

4) For Coarse aggregate 20 mm

Mass of coarse aggregate 20 mm in SSD condition - mass of coarse aggregate 20 mm in dry

condition 00 000 = 0.00 kg

For Goarse aggregate 10mm

‘Mass of coarse aggregate 10 mm in SSD condition - mass of coarse aggregate 10 mm in dry

condition. 8680 86100 = 7.00 Kg

2) For Fine aggregate

Mass of fine aggregate in SSD condition - mass of fine aggregate in dry

condition 701.0 69200 = 9.00 kg

The estimated requirement for added water, therefore, becomes

1800 + 000 + 7.00 + 900

: 1

B.00 Kain

JA-42. MIX PROPORTION AFTER ADJUSTMENT FOR DRY AGGREGATES for TRIAL-1

cemenr 43000 Kgl?

fuvasH * = 160.0 Kiev’

SIUCA sume : 0.0 Kam?

WATER (tobe océed) . 195.0 Kgirw

FINE AGGREGATE . 692.0 Kgim*

COARSE AGGREGATE FRACTION 1 (20 mm) 0.0 Kain

COARSE AGGREGATE FRACTION 2 (10mm) . 61.0 Kaien?

CHemicat apMarxTURE 4.13 Keglen®

Free water-cemontitious materials ratio = ost

A-13, allcharecteristics of SCC shall be measured and the water content and dosage of admbture shall be adjusted for

achieving the required charecteristics based on tial, if equited, However under no circumstances the % dosage

chemical admisture shall be more than 1 % by weight of total cementitious materials content.

Proparod By

ISHOURJA CHATTERJEE

REGIONAL TECHNICAL MANAGER

Regional Office: Block EN-37, 2nd Floor Raj Premiere, SEC-V, Salt-lako, Kolkata - 700091; Central Lab: JL No-10, NowTown,

Pakapole, South 24 Parganas Kolkata - 700135

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 10th RA Minarul - R0Document45 pages10th RA Minarul - R0smn.ussharNo ratings yet

- Debashis Das-2Document1 pageDebashis Das-2smn.ussharNo ratings yet

- SMN All Activeties Work Project of Final HIRADocument34 pagesSMN All Activeties Work Project of Final HIRAsmn.ussharNo ratings yet

- T12 S50 32 01Document1 pageT12 S50 32 01smn.ussharNo ratings yet

- Form8 S25264O8W0204241200000 PDFDocument2 pagesForm8 S25264O8W0204241200000 PDFsmn.ussharNo ratings yet

- T12 S50 32 03Document1 pageT12 S50 32 03smn.ussharNo ratings yet

- 4th RA S.K. Construction (Pintu)Document2 pages4th RA S.K. Construction (Pintu)smn.ussharNo ratings yet

- 18th RA Seikh BachchuDocument10 pages18th RA Seikh Bachchusmn.ussharNo ratings yet

- 2.8c Risk Assessment - 007 Excavation Work Using Heavy Equipment Rev. July 2019Document9 pages2.8c Risk Assessment - 007 Excavation Work Using Heavy Equipment Rev. July 2019smn.ussharNo ratings yet

- MTC IMS FO 14A Monthly Safety ReportDocument7 pagesMTC IMS FO 14A Monthly Safety Reportsmn.ussharNo ratings yet

- Smn-Fy 23-24Document17 pagesSmn-Fy 23-24smn.ussharNo ratings yet

- 19th RA Seikh BachchuDocument6 pages19th RA Seikh Bachchusmn.ussharNo ratings yet

- T12 S20 32 01Document1 pageT12 S20 32 01smn.ussharNo ratings yet

- 3rd RA Bill - Mainul Hk.Document3 pages3rd RA Bill - Mainul Hk.smn.ussharNo ratings yet

- SMN MTC-IMS-FO-14A-Monthly-Safety-Report-Xls SMN TATADocument7 pagesSMN MTC-IMS-FO-14A-Monthly-Safety-Report-Xls SMN TATAsmn.ussharNo ratings yet

- DocScanner 31 Jan 2024 3-27 PMDocument1 pageDocScanner 31 Jan 2024 3-27 PMsmn.ussharNo ratings yet

- 3rd RA of R.A. Enterprise of JCB & DumperDocument2 pages3rd RA of R.A. Enterprise of JCB & Dumpersmn.ussharNo ratings yet

- SCMQ - 3122Document9 pagesSCMQ - 3122smn.ussharNo ratings yet

- Nirman Concrete Ledger (Usshar)Document23 pagesNirman Concrete Ledger (Usshar)smn.ussharNo ratings yet

- SMN Labour Salary (Usshar) November - 23Document3 pagesSMN Labour Salary (Usshar) November - 23smn.ussharNo ratings yet

- 6th GST Invoice Birendra DasDocument4 pages6th GST Invoice Birendra Dassmn.ussharNo ratings yet

- 6th GST INVOICE SUPREMEDocument4 pages6th GST INVOICE SUPREMEsmn.ussharNo ratings yet

- 25-02-24 DPRDocument3 pages25-02-24 DPRsmn.ussharNo ratings yet

- Subal Consruction GST Invoice 7Document4 pagesSubal Consruction GST Invoice 7smn.ussharNo ratings yet

- Quotation Normal RSP 800 Ambuja RealtyDocument2 pagesQuotation Normal RSP 800 Ambuja Realtysmn.ussharNo ratings yet

- Offer LatterDocument1 pageOffer Lattersmn.ussharNo ratings yet

- SM Payment Reconsilation 27.11.23 - For As Per SiteDocument36 pagesSM Payment Reconsilation 27.11.23 - For As Per Sitesmn.ussharNo ratings yet

- Blue Star RA7Document4 pagesBlue Star RA7smn.ussharNo ratings yet

- Usshar Labour DetailsDocument3 pagesUsshar Labour Detailssmn.ussharNo ratings yet