Professional Documents

Culture Documents

TDC 35C8

TDC 35C8

Uploaded by

ramanjotgill.ramanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDC 35C8

TDC 35C8

Uploaded by

ramanjotgill.ramanCopyright:

Available Formats

Sr. No.

: 03

TECHNICAL DELIVERY CONDITION Rev. No.: 02

Date : 02-08-2019

Material Specification IS 9175 : 35C8

Sr.

Description Required Parameters Inspection Method Remarks

No.

1 Process / Mfg Route Method Of Melting may be basic oxygen Furnace or Electric Arc Furnace

Chemistry

%C 0.32 ~ 0.42

%Mn 0.60 ~ 1.0

%S 0.02 ~ 0.040 Max

%P 0.030 Max.

%Si 0.15 ~ 0.35

%Ni 0.25 Max.

%Cr 0.20 Max.

%Mo 0.06 Max. SOURCE

2 Chemistry %Cu 0.35 Max.

By Spectro

%Sn 0.025 Max.

%As 0.01 Max

%Sb 0.01 Max.

%Zn 0.03 Max.

%Zr 0.01 Max.

%Pb 0.01 Max.

%B 0.0005 Max.

CE : %C + %Mn/6 + %Cr/5 + %Mo/4 = 0.50 to 0.54 MAX

Gas Content (PPM)

3 N - 0.018 % Max. By Leco meter

Max.

4 Supply Condition AS ROLLED

As Per ASTM E-381 Plate-I

5 Macro-structure By Acid Etching

C2,R2,S2 Max. Free from Porosity, Flakes & Excessive Seggregation

6 Microstructure Ferrite & Pearlite Microscope

7 Ultrasonic Testing 100% Inspection by UT with deffect Echo Max. 20% of back wall Echo -----

ASTM E45 - Plate 1

A B C D

Sulphide Aluminate Silicate Oxide

8 Inclussion Rating By Microscope

Thin Series (Max.) 4 3 2.5 2

Thick Series (Max.) 2.5 2.5 1.5 1.5

Uniform austenitic grain size of ASTM 5-8 as per ASTM E112 using the McQuaid - Ehn test -

9 Grain Size -------

GRAIN REFINER SHALL BE ALUMINUM

10 Jominy Hardenability n/a

Section Size 90 RCS / 100 dia / 90 dia

11 Section Size Vernier Caliper

Dimension

As per ASTM A29

Tolerances:

Prepared By: Approved By:

Page 1 of 2 Code:- DC-22; Rev:- 00; Eff. Date:- 31-07-2019

Sr.

Description Required Parameters Inspection Method Remarks

No.

Process / Mfg Route Test Bar Diameter

Method Of Melting may be basic oxygen Furnace or Electric Arc Furnace

--------- -----

(mm)

Test Bar H/T Status --------- -----

UTS (MPA) 72000 PSI -----

YS (MPA) 39500 PSI -----

Mechanical

12

Properties

% Elongation 18% -----

% RA --------- -----

SOURCE

Impact Strength --------- -----

As Rolled Hardness 143-197 HBW -----

2 Color Code Per Below: (Also See Remarks)

First Heat Second Heat NOTE:

Color Code Bottom colors will

Top Color Silver Silver Visual

Tracibility Requirements: re-occur after

13

Requirements Bottom each heat

White Black

Color

Heat Code Sticker Visual

Bars must be free from laps, excessive seams, slivers, pipe, voids, internal

Surface Condition cracks,shear distortion or cracking, and any deleterious defect that will Visual

harm the integrity of the component part manufactured from the bar.

Seam depth should not exceed 1.6% of the bar diameter for carbon and

Seam -----

Surface / Material alloy steels

14 process / quality

Requirements: Steels with free machining additives (i.e., sulfur, lead, etc.) must comply

Additives: Free

with this specification. Other free machining additives should use the sulfide Spectro

Machining

plates and limits.

Bars will be produced using aluminum killed steels.

Bars shall be produced from ingot steel unless otherwise specified.

15 Reduction Ratio 7;1 Ratio for carbon Steel TC

16 De-carb Level ----- -----

Acceptable level of

17 As per IS:7283 -----

Surface Defects

18 Upsettability Test No Visible Crack By Acid Etching

19 Multiple Length NA -----

As Per IS : 4075 - 1985 1. No streak more

than I mm length

20 Step down Test As Per IS : 4075 - 1985

2. Max. 3 streaks on any ofthe steps

3. Total Length of streaks not more 15 mm

Material size / Steel heat Material Reduction Grain Size as per ASTM E112 using the McQuaid -

Steel source,

Mill TC to include diameter, number grade ratio Ehn test

Following Test

Inclusion content per ASTM E

21 Certificates Chemical analysis (including residual elements and all grain 100% Ultrasonic & MPI

45

(Required for each refiners), Analysis of, as a minimum, the following elements, Shall

Heat No.) be included in the certification: C, Mn, P, S, Si, Ni, Cr, Mo, Cu, Al, Actual jominy results (when required by this specification), Ideal

V, Nb, B, Ti, diameter per CAT 1E38

Tolerances on Size, Stock Size (mm) Tolerance on Size (mm) Tolerance on out of roundness(mm) Max.

22 Roundness &

Straightness ASTM A-29

Page 2 of 2 Code:- DC-22; Rev:- 00; Eff. Date:- 31-07-2019

You might also like

- 10 Columns (Students) CDocument47 pages10 Columns (Students) Cmarwahusni195No ratings yet

- Chapter 9 Heat Form 2 KSSMDocument7 pagesChapter 9 Heat Form 2 KSSMNadhirah Kamarudin80% (5)

- Specifications FOR Single Storey Residential Building: Prepared byDocument9 pagesSpecifications FOR Single Storey Residential Building: Prepared byruel buntog100% (1)

- Data Collection-High Rise ApartmentsDocument63 pagesData Collection-High Rise Apartmentssubba88% (8)

- TDC - Sad 1040VDocument2 pagesTDC - Sad 1040Vramanjotgill.ramanNo ratings yet

- TDC - SAE 8620 - Rev-04Document2 pagesTDC - SAE 8620 - Rev-04ramanjotgill.ramanNo ratings yet

- TDC - 42CrMo4 - Special MaterialDocument2 pagesTDC - 42CrMo4 - Special Materialramanjotgill.ramanNo ratings yet

- TDC - C22E (613138) - Special MaterialDocument2 pagesTDC - C22E (613138) - Special Materialramanjotgill.ramanNo ratings yet

- Material Specification: TitleDocument3 pagesMaterial Specification: Titlevijay waghNo ratings yet

- 316 PDFDocument1 page316 PDFViswanathan SrkNo ratings yet

- Aaepl: TDC No. AAEPL/RM/lDocument2 pagesAaepl: TDC No. AAEPL/RM/lSandip PandeNo ratings yet

- 9SMNPB28K-14.00 Hex Tc.Document1 page9SMNPB28K-14.00 Hex Tc.Mechtek LabNo ratings yet

- Valimet Data Sheet: Spherical Aluminum Alloy Powder GRADE: AM-357Document1 pageValimet Data Sheet: Spherical Aluminum Alloy Powder GRADE: AM-357Mircea PanteaNo ratings yet

- Certification of Slag Powder January 2022Document1 pageCertification of Slag Powder January 2022Kyaw KhineNo ratings yet

- AleacionesDocument1 pageAleacionesiran josueNo ratings yet

- SMS001R0Document1 pageSMS001R0PRASANTH PRASANTHNo ratings yet

- Grades of Steel Used in Ship BuildingDocument1 pageGrades of Steel Used in Ship Buildingnpankaj1No ratings yet

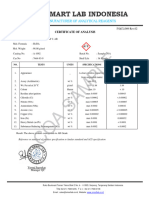

- Coa Sample: Pt. Smart Lab IndonesiaDocument1 pageCoa Sample: Pt. Smart Lab IndonesiaedlinNo ratings yet

- Compare S235JR, E250BRDocument6 pagesCompare S235JR, E250BRGANESHNo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- Metalcor Cual10fe3mn2Document1 pageMetalcor Cual10fe3mn2robertjob34No ratings yet

- TDS Potasa - Inter-Chemie LimitedDocument1 pageTDS Potasa - Inter-Chemie Limitedxibs2009No ratings yet

- TDS Potassium CarbonateDocument2 pagesTDS Potassium CarbonateNha TranNo ratings yet

- Esab Ok 55 (3.2 MM)Document1 pageEsab Ok 55 (3.2 MM)DHANEESH VELLILAPULLINo ratings yet

- Sulphuric Acid 98% ARDocument1 pageSulphuric Acid 98% ARAlbab IndonesiaNo ratings yet

- Coupler Plate RM Pipe TCDocument1 pageCoupler Plate RM Pipe TCshindemitesh17No ratings yet

- Pf-Emco#218-63p Rev.bDocument6 pagesPf-Emco#218-63p Rev.bPhung Cam VanNo ratings yet

- Coupler Plate RM Pipe TC 2Document1 pageCoupler Plate RM Pipe TC 2shindemitesh17No ratings yet

- Russia OilgasDocument6 pagesRussia OilgasAlexanderNo ratings yet

- Special Metals UDIMET® Alloy 250 Maraging SteelDocument1 pageSpecial Metals UDIMET® Alloy 250 Maraging SteelshubhamNo ratings yet

- Date.4th October, 2021 FCO No. 1648/2021: FCO - Electro COPPER CATHODE 99.99% Virgin, RUSSIAN ORIGIN - No.AAADocument2 pagesDate.4th October, 2021 FCO No. 1648/2021: FCO - Electro COPPER CATHODE 99.99% Virgin, RUSSIAN ORIGIN - No.AAAFattahNo ratings yet

- METHANOLDocument1 pageMETHANOLrohanvoraNo ratings yet

- SBV4110392 OK 309L 3.2mmDocument1 pageSBV4110392 OK 309L 3.2mmEko Prastyo96No ratings yet

- Garima Global Private Limited: Material Test CertificateDocument2 pagesGarima Global Private Limited: Material Test CertificateRima AroraNo ratings yet

- MG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetDocument7 pagesMG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetAbdulrahman AlabdanNo ratings yet

- %C %MN %si %CR %S %P %mo %niDocument7 pages%C %MN %si %CR %S %P %mo %nismith willNo ratings yet

- DnvWebpage - Iso 8217 2010Document2 pagesDnvWebpage - Iso 8217 2010AutoModi THNo ratings yet

- Hotwork Internationa - 2017 - Molybdenum ElectrodesDocument2 pagesHotwork Internationa - 2017 - Molybdenum ElectrodesEduardo CandelaNo ratings yet

- Grades of Steel Used in Ship BuildingDocument1 pageGrades of Steel Used in Ship BuildingAnkit MauryaNo ratings yet

- NL - NL FactSheet - Main 01Document1 pageNL - NL FactSheet - Main 01ronaldb322No ratings yet

- Standard Technical Specification Probent-Sp4Document1 pageStandard Technical Specification Probent-Sp4Hilmanie RamadhanNo ratings yet

- Espec. Bridas de AnclajeDocument9 pagesEspec. Bridas de AnclajeRIGOBERTO PONCENo ratings yet

- High Pressure FittingsDocument16 pagesHigh Pressure FittingsEdwin TacoNo ratings yet

- Coolaudio V2181 DatasheetDocument8 pagesCoolaudio V2181 DatasheetcrackintheshatNo ratings yet

- OK 55.00 2.5x350mm - LOT - SFV05174Document1 pageOK 55.00 2.5x350mm - LOT - SFV05174DHANEESH VELLILAPULLINo ratings yet

- Chemical Composition Raw Material Grade: Ref - No JSPL/ANGUL/TDC-003493C Rev. 1 Date of Issue 11/11/2022Document3 pagesChemical Composition Raw Material Grade: Ref - No JSPL/ANGUL/TDC-003493C Rev. 1 Date of Issue 11/11/2022MAHESH BELENo ratings yet

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardsDocument1 pageMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor B.S. Alloy Registered Work's Label StandardschetanNo ratings yet

- Kundalia RB Project - Cage Ladder QAPDocument2 pagesKundalia RB Project - Cage Ladder QAPHarshit AdwaniNo ratings yet

- Zinc Oxide 98 White Coa PDFDocument1 pageZinc Oxide 98 White Coa PDFsikkujegnaNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999No ratings yet

- Test Report: Equipment: Q4 TASMAN/ 214435Document1 pageTest Report: Equipment: Q4 TASMAN/ 214435test qtesNo ratings yet

- D2 SpecificationsDocument1 pageD2 Specificationssara_grNo ratings yet

- Ross Hydrogen Storage 20041216Document18 pagesRoss Hydrogen Storage 20041216Tuhin DuttaNo ratings yet

- Metropolitan Hard Coking Coal 2010 Typical SpecificationDocument1 pageMetropolitan Hard Coking Coal 2010 Typical Specificationnaresh adusumilliNo ratings yet

- OSNA10 Copper-Nickel Sheathing On Offshore StructuresDocument8 pagesOSNA10 Copper-Nickel Sheathing On Offshore Structuresbello imamNo ratings yet

- Inhouse Metallurgical Analysis of Samples Received After Post Endurance TestDocument2 pagesInhouse Metallurgical Analysis of Samples Received After Post Endurance TestVishal MaliNo ratings yet

- CHBHCUYFVSDDocument1 pageCHBHCUYFVSDedrNo ratings yet

- HHA - X-MET8000 Optimum + Expert Performance Document (Alloy) - Thin Window - V1-3Document5 pagesHHA - X-MET8000 Optimum + Expert Performance Document (Alloy) - Thin Window - V1-3Paula InesNo ratings yet

- Flyash Class FDocument2 pagesFlyash Class FmayaNo ratings yet

- Vulcan Smart+ Calibration Datasheets (Dec 2020)Document5 pagesVulcan Smart+ Calibration Datasheets (Dec 2020)Paula InesNo ratings yet

- Template SertifikatDocument1 pageTemplate SertifikatSubhan MuhammadNo ratings yet

- Garima Global Pvt. LTD.: Material Test CertificateDocument2 pagesGarima Global Pvt. LTD.: Material Test CertificateGouravNo ratings yet

- 7e Building Technology 2Document10 pages7e Building Technology 2Gilbert DavidNo ratings yet

- L-Bolt Anchor Bolts: Simpson Strong-Tie Wood Construction Connectors - Canadian Limit States DesignDocument1 pageL-Bolt Anchor Bolts: Simpson Strong-Tie Wood Construction Connectors - Canadian Limit States DesignHakan EzcanNo ratings yet

- POSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Document1 pagePOSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Murti WisnuNo ratings yet

- 4 - Anchor - Bolts - Base - Plate - DD1-2 - Updated Shear KeyDocument38 pages4 - Anchor - Bolts - Base - Plate - DD1-2 - Updated Shear Keytitir bagchiNo ratings yet

- 3 EPS Universal Gas Barrier New 2017Document1 page3 EPS Universal Gas Barrier New 2017trottersitNo ratings yet

- Sambeiro Close Revised Plumbing Bill 2Document7 pagesSambeiro Close Revised Plumbing Bill 2Dapo AlimiNo ratings yet

- BrickShield A1 Brick Slip SystemDocument3 pagesBrickShield A1 Brick Slip SystemAndy PykeNo ratings yet

- Ductile PilesDocument8 pagesDuctile PilesRazvanNo ratings yet

- Fosroc Structuro W420: A Superior High Performance Concrete Hyperplasticiser Based On Polycarboxylate TechnologyDocument2 pagesFosroc Structuro W420: A Superior High Performance Concrete Hyperplasticiser Based On Polycarboxylate TechnologyVincent JavateNo ratings yet

- Conceptual Design of Blanking Tool For Washer Special IJERTV4IS050270 PDFDocument4 pagesConceptual Design of Blanking Tool For Washer Special IJERTV4IS050270 PDFahmad nasarNo ratings yet

- Geo FoamDocument5 pagesGeo Foamnikhil kumarNo ratings yet

- Chapter-2 Building PlanningDocument17 pagesChapter-2 Building PlanningGechNo ratings yet

- Casette Type 2Document7 pagesCasette Type 2Abdallah Irfaan RamjanNo ratings yet

- Shell Structures: Ar.C.Naga Vaishnavi Ar.M.PadmaDocument25 pagesShell Structures: Ar.C.Naga Vaishnavi Ar.M.Padmasindhura100% (1)

- Strength of Materials - Task 1. Chapter 2.Document4 pagesStrength of Materials - Task 1. Chapter 2.Jesus RodeloNo ratings yet

- BT 03Document66 pagesBT 03VINCE NIETONo ratings yet

- Design of A Three-Storey Commercial Building: I. Description of The StructureDocument8 pagesDesign of A Three-Storey Commercial Building: I. Description of The StructureShōya Ishida100% (1)

- Construction and Building Materials: N.K. Lee, H.K. LeeDocument9 pagesConstruction and Building Materials: N.K. Lee, H.K. LeeMohammed Rizwan AliNo ratings yet

- r050210801 Fluid Mechanics For Chemical EngineeringDocument7 pagesr050210801 Fluid Mechanics For Chemical EngineeringSrinivasa Rao GNo ratings yet

- 05 - Short Circuit Strength of Power TransformersDocument10 pages05 - Short Circuit Strength of Power Transformersjm.mankavil6230No ratings yet

- Prob SetDocument4 pagesProb SetJuliet NakilaNo ratings yet

- Module 1 Introduction To CarpentryDocument36 pagesModule 1 Introduction To CarpentryDane100% (3)

- The Elite Pool BrochureDocument28 pagesThe Elite Pool BrochureFort Wayne Elite PoolsNo ratings yet

- Aaac 6201 Type A2 Iec 61089Document1 pageAaac 6201 Type A2 Iec 61089Ayub HasersNo ratings yet

- Cpi RefractoriesDocument51 pagesCpi RefractoriesRobert BrownNo ratings yet