Professional Documents

Culture Documents

Ref CAX

Ref CAX

Uploaded by

Apply SofttechOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ref CAX

Ref CAX

Uploaded by

Apply SofttechCopyright:

Available Formats

DIGITRANS DIGITAL R.F.

PROBE

SIMPLIFIED PROCEDURE FOR CALIBRATION OF REFINERY PROBES

Instead of calibrating probes for refinery liquors and massecuites in brix units by

taking samples and using the regression method, a simpler procedure is to

calibrate the probe against capacitance using a calibrator. In this method, the effect

of changing conductivity due to variations in ash is minimised.

The method still involves use of the regression method but a calibrator type CAX is

used to simulate different massecuite or liquor conditions. 20 calibration points are

used as follows: (refer to the manual for calibration procedure)

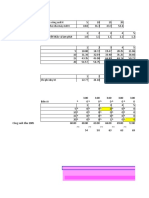

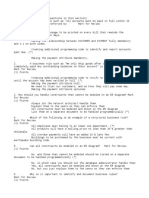

Sample No. Readout % Cap.pF Calibrator switch positions

1 98.6 32 2 0 6 0

2 98.6 32 3 0 6 0

3 98.6 32 6 0 6 0

4 87.9 47 2 0 8 0

5 87.9 47 3 0 8 0

6 87.9 47 6 0 8 0

7 72.1 69 2 0 C 0

8 72.1 69 3 0 C 0

9 72.1 69 6 0 C 0

10 50.0 100 2 0 0 1

11 50.0 100 3 0 0 1

12 50.0 100 6 0 0 1

13 27.1 132 2 0 6 1

14 27.1 132 3 0 6 1

15 27.1 132 6 0 6 1

16 27.1 132 9 0 6 1

17 0.7 169 2 0 C 1

18 0.7 169 3 0 C 1

19 0.7 169 6 0 C 1

20 0.7 169 9 0 C 1

Go to "new calibration" and set calibrator as above for samples 1 to 20. Once this

is entered, go to "add analyses" and key in the percent values for samples 1 to 20.

Once this is entered, go to "regression". The output will then be calibrated to give a

0-100% readout for a capacitance of 170 to 30 pf. This will cover a range of

approximately 50 to 100 brix. K1 and K2 can then be set in the process to adjust

zero and span for the 4-20 ma signal to cover the required range. K1 is the

indicated value required for 4 ma (zero) and K2 the value required for 20

mA output.

You might also like

- AI-Problem Set 1Document13 pagesAI-Problem Set 1Aleli Pamplona100% (1)

- 3 Population Mean WorkbookDocument8 pages3 Population Mean WorkbookJohn SmithNo ratings yet

- Sullair Deluxe Microprocessor Controller1 Operation ManualDocument22 pagesSullair Deluxe Microprocessor Controller1 Operation Manualkotrex_tre3100% (2)

- Operasi Beban MaksimumDocument203 pagesOperasi Beban MaksimumShabrina GhassaniNo ratings yet

- Notes For Digital Probe CalibrationDocument3 pagesNotes For Digital Probe CalibrationApply SofttechNo ratings yet

- Pencapaian Hasil Bayi S/D Desember (%)Document5 pagesPencapaian Hasil Bayi S/D Desember (%)Vivin FadlyahNo ratings yet

- Caso 4 InventariosDocument8 pagesCaso 4 InventariosClari ClaritaNo ratings yet

- Output 4323423Document2 pagesOutput 4323423Madalena BarrosNo ratings yet

- Aporte 2 Momento 2Document18 pagesAporte 2 Momento 2FERNEYNo ratings yet

- Tabla Administracion de ProyectosDocument6 pagesTabla Administracion de Proyectosalexj887.perezNo ratings yet

- Cloth ItemDocument320 pagesCloth ItemmonicaNo ratings yet

- Taller Abiertas de JacksonDocument4 pagesTaller Abiertas de JacksonNicolas Eduardo Gomez HerreraNo ratings yet

- Laporan Eppgbm Februari 2023Document3 pagesLaporan Eppgbm Februari 2023Saras Oka AuliaNo ratings yet

- Global Lenguaje 3º Medios MayDocument3 pagesGlobal Lenguaje 3º Medios Mayastrid.87No ratings yet

- Analysis Evaluation Enzyme Action CatalaseDocument10 pagesAnalysis Evaluation Enzyme Action CatalaseStella CecchiniNo ratings yet

- Pavimento Rigido ChilcaDocument12 pagesPavimento Rigido ChilcaPercy PalominoNo ratings yet

- U (Aubucu)Document6 pagesU (Aubucu)jorge pardoNo ratings yet

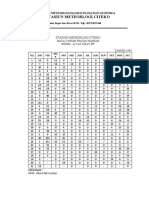

- Stasiun Meteorlogi Citeko Data Curah Hujan Harian POSISI: - 6,7 LS 106,85 BT TAHUN 1991Document1 pageStasiun Meteorlogi Citeko Data Curah Hujan Harian POSISI: - 6,7 LS 106,85 BT TAHUN 1991Muhammad Riezki PersadaNo ratings yet

- Lab 06 GuassDocument7 pagesLab 06 GuassUsama MalikNo ratings yet

- Newton Raphson Submission FileDocument9 pagesNewton Raphson Submission Fileshailesh upadhyayNo ratings yet

- Daily Energy MeasurementDocument6 pagesDaily Energy MeasurementooleegurreeNo ratings yet

- Contoh 1Document23 pagesContoh 1Zaeri TahriziNo ratings yet

- Daily Energy MeasurementDocument6 pagesDaily Energy MeasurementooleegurreeNo ratings yet

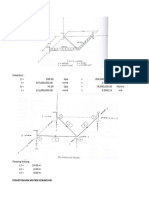

- SSE Truss Analysis v1.04Document1 pageSSE Truss Analysis v1.04SES DESIGNNo ratings yet

- BLSN 2018-DikonversiDocument14 pagesBLSN 2018-DikonversifahriNo ratings yet

- Zona Jumlah Rumah Kebutuhan Air Kebutuhan Rata2 1 2 3 4 5 6 7 8Document6 pagesZona Jumlah Rumah Kebutuhan Air Kebutuhan Rata2 1 2 3 4 5 6 7 8nurvaniNo ratings yet

- Pat Ccut and FillDocument182 pagesPat Ccut and FillCeline SamonteNo ratings yet

- CMSS First QuarterDocument1 pageCMSS First QuarterGeorgie CarcellerNo ratings yet

- Tabel AccDocument2 pagesTabel AccFamily DanuNo ratings yet

- Soal 1:: Tugas Proyek Akhir Software Sistem Tenaga ListrikDocument5 pagesSoal 1:: Tugas Proyek Akhir Software Sistem Tenaga ListrikMuh FadlyNo ratings yet

- UntitledDocument4 pagesUntitledMisael jorge Julca AlmendradesNo ratings yet

- NR Report 1Document10 pagesNR Report 1shailesh upadhyayNo ratings yet

- LB3 MaternalDocument1 pageLB3 MaternalVivin RiyaniNo ratings yet

- Sovle Brite Power CaseDocument3 pagesSovle Brite Power Caseanh nguyễnNo ratings yet

- Experiment 02Document13 pagesExperiment 02Поля КаменчукNo ratings yet

- Contoh Data Regresi DummyDocument10 pagesContoh Data Regresi DummyBayu SaputraNo ratings yet

- Group AssignmentDocument3 pagesGroup Assignmentchegger accountNo ratings yet

- Table: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 CenterxDocument4 pagesTable: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 Centerxpancracio gamerNo ratings yet

- Programación de CortesDocument28 pagesProgramación de Cortescesar89278No ratings yet

- Open RMF Report SpreadsheetsDocument3 pagesOpen RMF Report SpreadsheetswillyNo ratings yet

- DecisionTree Addhealth 1Document7 pagesDecisionTree Addhealth 1Fajar DNo ratings yet

- Curah Hujan 15 THN Paket 1Document147 pagesCurah Hujan 15 THN Paket 1Yudha Agung Rangga MalelaNo ratings yet

- Sta. Candi DukuhDocument12 pagesSta. Candi Dukuhwahyu widartoNo ratings yet

- Supp 7 JDP 271115 PDFDocument4 pagesSupp 7 JDP 271115 PDFSascha KoenenNo ratings yet

- Data Curah Hujan - Cengkareng 2002-2013Document24 pagesData Curah Hujan - Cengkareng 2002-2013Hendy WijayaNo ratings yet

- OK OK OK: Sieve Size, MMDocument8 pagesOK OK OK: Sieve Size, MMAbdo AboretaNo ratings yet

- Investasi Mot MetroDocument2 pagesInvestasi Mot Metroarif_mzNo ratings yet

- Final Code-30 Bus Gauss SiedelDocument6 pagesFinal Code-30 Bus Gauss SiedelDilawar TanvirNo ratings yet

- Tabla CorrientesDocument3 pagesTabla CorrientesSa SaNo ratings yet

- Analisis Hasil TesDocument6 pagesAnalisis Hasil TesmankluetNo ratings yet

- MUETREODocument44 pagesMUETREOnoerNo ratings yet

- Copia de DESRIPIADOR - Y - LONG - TRANSICIONDocument6 pagesCopia de DESRIPIADOR - Y - LONG - TRANSICIONKatherine OñateNo ratings yet

- Sondir S3 - BrondongDocument3 pagesSondir S3 - BrondongAl MasagalaNo ratings yet

- IEEE 10 Generator 39 Bus System: General OutlineDocument7 pagesIEEE 10 Generator 39 Bus System: General Outlineadau100% (1)

- Resumekalibrasi BrsDocument6 pagesResumekalibrasi BrsmuhamadyasinncinNo ratings yet

- RSRAN120 - Relocation ISHO Per cause-RSRAN-RSGS-2-day-rsran WCDMA17 Reports RSRAN120 xml-2021 06 02-13 37 15 854Document69 pagesRSRAN120 - Relocation ISHO Per cause-RSRAN-RSGS-2-day-rsran WCDMA17 Reports RSRAN120 xml-2021 06 02-13 37 15 854Amir VahidiNo ratings yet

- Fire Protection CalculationsDocument193 pagesFire Protection CalculationsPrefer Electrical Engineering And SupplyNo ratings yet

- 1.5 Planillas Est. RS SEASME-ULTIMODocument1,385 pages1.5 Planillas Est. RS SEASME-ULTIMOJose KionNo ratings yet

- Classeur2 (Enregistré Automatiquement) (Enregistré Automatiquement) XXDocument42 pagesClasseur2 (Enregistré Automatiquement) (Enregistré Automatiquement) XXEmmanuel N'KAYONo ratings yet

- Output qpsk3333Document2 pagesOutput qpsk3333Madalena BarrosNo ratings yet

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesFrom EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesRating: 5 out of 5 stars5/5 (3)

- Advance Operation Short enDocument11 pagesAdvance Operation Short enApply SofttechNo ratings yet

- Calibration Sheet A0 A1Document3 pagesCalibration Sheet A0 A1Apply SofttechNo ratings yet

- Technical Visit Report TemplateDocument2 pagesTechnical Visit Report TemplateApply SofttechNo ratings yet

- 2wire Manual r7Document5 pages2wire Manual r7Apply SofttechNo ratings yet

- 01 - PH MeasurementDocument22 pages01 - PH MeasurementApply SofttechNo ratings yet

- Men ct25 0202Document48 pagesMen ct25 0202Apply SofttechNo ratings yet

- 26 - EasyLine Models EL3020 EL3040Document82 pages26 - EasyLine Models EL3020 EL3040Apply SofttechNo ratings yet

- Cover Paper InstrumentDocument5 pagesCover Paper InstrumentApply SofttechNo ratings yet

- 2000 GC ManualDocument406 pages2000 GC ManualApply SofttechNo ratings yet

- DCEM-21xx BrochureDocument4 pagesDCEM-21xx BrochureApply Softtech100% (1)

- Be550012 Ba 2000Document30 pagesBe550012 Ba 2000Apply SofttechNo ratings yet

- 1377 1997Document201 pages1377 1997Ann DodsonNo ratings yet

- PV Modeling PDFDocument57 pagesPV Modeling PDFgilbertomjcNo ratings yet

- Alternative To READ - TEXT Function Module (No More FM Needed) - SAP BlogsDocument32 pagesAlternative To READ - TEXT Function Module (No More FM Needed) - SAP BlogsDeadMan BlackHeartNo ratings yet

- Ai 4 AllDocument31 pagesAi 4 AllOKTA NURIKANo ratings yet

- CIPDocument4 pagesCIPpatel909No ratings yet

- DRB & Ar 331Document314 pagesDRB & Ar 331Abdul Hamid BhattiNo ratings yet

- Course Code EEE-2310 EX-5Document3 pagesCourse Code EEE-2310 EX-5Fardin ChowdhuryNo ratings yet

- Datasheet Solis Solar Inverter 5g Three Phase 100kw 125kw IndiaDocument2 pagesDatasheet Solis Solar Inverter 5g Three Phase 100kw 125kw IndiaaniketNo ratings yet

- Weird Negative Float SituationsDocument15 pagesWeird Negative Float SituationsSoham BanerjeeNo ratings yet

- Evidence CasesDocument3 pagesEvidence CasesAnneCanapiNo ratings yet

- EC8691-Microprocessor and MicrocontrollerDocument11 pagesEC8691-Microprocessor and Microcontrollerrajesh5500No ratings yet

- Manual Micropipetas Discovery ConfortDocument64 pagesManual Micropipetas Discovery ConfortOzéias Batista Dos SantosNo ratings yet

- Computer Science PDFDocument2 pagesComputer Science PDFShekinah Jira Molato Mesa100% (1)

- Qianli Thermal Camera User Guide v3Document4 pagesQianli Thermal Camera User Guide v3Abdulrahman AlabdanNo ratings yet

- Mineralogía DescriptivaDocument38 pagesMineralogía DescriptivaJorge Rios RNo ratings yet

- Denon DCD 1520ae CD Player Review Test LoresDocument7 pagesDenon DCD 1520ae CD Player Review Test LorespetrosNo ratings yet

- Section 4 Quiz Database Design OracleDocument7 pagesSection 4 Quiz Database Design OracleMostragNo ratings yet

- Moisture Particle SizeDocument6 pagesMoisture Particle SizejayaNo ratings yet

- Seismic Inversion by Newtonian Machine Learning: Yuqing Chen and Gerard T. SchusterDocument16 pagesSeismic Inversion by Newtonian Machine Learning: Yuqing Chen and Gerard T. SchusterAlNo ratings yet

- Exceed™ XP 8346CB: Performance PolymerDocument2 pagesExceed™ XP 8346CB: Performance PolymerMaram YasserNo ratings yet

- Molecular Transport EquationsDocument36 pagesMolecular Transport EquationsTareq Abdussalam KhamllagNo ratings yet

- Section 23 - Floco 382 and 383 MetersDocument24 pagesSection 23 - Floco 382 and 383 MetershammamiNo ratings yet

- Fuzzy Methods For Modelling Earthquake Induced Sloshing in Rigid ReservoirsDocument7 pagesFuzzy Methods For Modelling Earthquake Induced Sloshing in Rigid ReservoirsЕлена СтрельниковаNo ratings yet

- D52161GC30 SGDocument494 pagesD52161GC30 SGismailkhan.dbaNo ratings yet

- 6230b LctofDocument2 pages6230b Lctofhienluuduc2011_66877No ratings yet

- 2007 Bomet District Paper 1Document16 pages2007 Bomet District Paper 1Ednah WambuiNo ratings yet

- Ludwik Fleck: Problemy, 1947Document23 pagesLudwik Fleck: Problemy, 1947chelsea_togno123456No ratings yet

- Skull King - 2022 General Strength ProgramDocument2 pagesSkull King - 2022 General Strength ProgramDank StankNo ratings yet