Professional Documents

Culture Documents

Helicopter I Iic I: Technical Bulletin

Helicopter I Iic I: Technical Bulletin

Uploaded by

sebastian cruzCopyright:

Available Formats

You might also like

- 72-00-00 ENGINE - INSPECTION/CHECK-2 Pratt & Whitney CanadaDocument78 pages72-00-00 ENGINE - INSPECTION/CHECK-2 Pratt & Whitney CanadaAlexandre Manco100% (1)

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- Feminism Final PaperDocument19 pagesFeminism Final PaperRubee Lee Won Ag100% (1)

- Combination of Microneedling and Glycolic Acid Peels For TheDocument7 pagesCombination of Microneedling and Glycolic Acid Peels For Thealejandrogonzalez89No ratings yet

- 212 86 92 - RepairedDocument11 pages212 86 92 - Repairedsebastian cruzNo ratings yet

- BHT 206 16 209Document8 pagesBHT 206 16 209edsel jose diaz sarmientoNo ratings yet

- 212 TB 09 210Document5 pages212 TB 09 210Jose Edwin Roldan RiosNo ratings yet

- 212 Si 04Document30 pages212 Si 04Hector BoliboNo ratings yet

- SIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2Document39 pagesSIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2kenji roberto santanaNo ratings yet

- Technical Bulletin: Bell HelicopterDocument1 pageTechnical Bulletin: Bell HelicopterHenry Fabian Peña MartinezNo ratings yet

- TCM C90 - 0200 Engine Type Certificate - E-252 - Rev 29Document3 pagesTCM C90 - 0200 Engine Type Certificate - E-252 - Rev 29Randy WaltonNo ratings yet

- Vessel/S&T Heat Exchanger Standard Details (Metric Units)Document7 pagesVessel/S&T Heat Exchanger Standard Details (Metric Units)Jamil AhmadNo ratings yet

- Service Bulletin PDFDocument8 pagesService Bulletin PDFamrjheyNo ratings yet

- Caterpillar 854gDocument34 pagesCaterpillar 854gBrust Elmer ANo ratings yet

- Boeing 737-4H6 SpecDocument5 pagesBoeing 737-4H6 SpecDa23ll AlderichNo ratings yet

- Uscg 009623 PDFDocument383 pagesUscg 009623 PDFAnbarasan AnandhanNo ratings yet

- B747-8 Fuel ManifoldDocument31 pagesB747-8 Fuel ManifoldDagmawiNo ratings yet

- Service Bulletin: CaravanDocument12 pagesService Bulletin: CaravanladyNo ratings yet

- Piping Engineering: Marathon Petroleum Co. Project Specific AddendumDocument17 pagesPiping Engineering: Marathon Petroleum Co. Project Specific AddendumChirag ShahNo ratings yet

- ON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNDocument7 pagesON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNEdson CarvalhoNo ratings yet

- SB C208 Stall WarningDocument14 pagesSB C208 Stall WarningrobertobrouNo ratings yet

- ASB 412-00-106 - Tail Rotor (T - R) Blade 212-010-750-009 - 011 - 105 - 107 Tip Block Retention Modification Rev. D - 18-Mar-2005Document9 pagesASB 412-00-106 - Tail Rotor (T - R) Blade 212-010-750-009 - 011 - 105 - 107 Tip Block Retention Modification Rev. D - 18-Mar-2005yu gangNo ratings yet

- DAC1 24 03 Rev 2Document4 pagesDAC1 24 03 Rev 2vanNo ratings yet

- Wings - Aileron Drain Hole Inspection SBDocument8 pagesWings - Aileron Drain Hole Inspection SBstiveNo ratings yet

- 330 Adjustment of Pivot DoorDocument31 pages330 Adjustment of Pivot Doorhx344375No ratings yet

- ASB 407-16-114-RC Page 1 of 2 Approved For Public ReleaseDocument10 pagesASB 407-16-114-RC Page 1 of 2 Approved For Public ReleaseluisNo ratings yet

- Planos Estándar de Obras Estructurales, Pavimentos y Drenaje para Gas OilDocument33 pagesPlanos Estándar de Obras Estructurales, Pavimentos y Drenaje para Gas OilMiguel MendezNo ratings yet

- D231000144 Pib 001Document31 pagesD231000144 Pib 001xlzyydf2015No ratings yet

- United Technologles Pratt&Whitney: Middletown Plant Aircraft Road Middletown, Connecticut 06457Document7 pagesUnited Technologles Pratt&Whitney: Middletown Plant Aircraft Road Middletown, Connecticut 06457amir ghaznaviNo ratings yet

- Technical Bulletin Bell Helicopter: Subject: Cyclic and Collective JackshaftsDocument10 pagesTechnical Bulletin Bell Helicopter: Subject: Cyclic and Collective JackshaftsHenry Fabian Peña MartinezNo ratings yet

- Inbound 7539317969539081851Document17 pagesInbound 7539317969539081851Yoel UtrillaNo ratings yet

- 407 MD 01 S02Document16 pages407 MD 01 S02Jonathan Cristhan Sanchez PérezNo ratings yet

- 212 Asb 08 130Document7 pages212 Asb 08 130Walberto PachecoNo ratings yet

- A320 NE0 Fuel or Hydraulic or Oil Leakage LimitsDocument19 pagesA320 NE0 Fuel or Hydraulic or Oil Leakage LimitsArjuna SamaranayakeNo ratings yet

- 407TB407TB19129Document9 pages407TB407TB19129e.a.m.v.9.8.1.2No ratings yet

- DS19310 SM5110244 05 04 02 01Document0 pagesDS19310 SM5110244 05 04 02 01parascoliNo ratings yet

- 12165-70 - 1 Sundry Instr.Document328 pages12165-70 - 1 Sundry Instr.kodrysNo ratings yet

- REHS8790Document10 pagesREHS8790Daniel DonosoNo ratings yet

- 48 BD 08Document34 pages48 BD 08Mayur UrkudeNo ratings yet

- Installation and Parts Manual: FOR Caterpillar D8T & D9T TractorsDocument28 pagesInstallation and Parts Manual: FOR Caterpillar D8T & D9T TractorsJusaNadaNo ratings yet

- Truck Medium MC2 Clutch Output Shaft BearingDocument2 pagesTruck Medium MC2 Clutch Output Shaft BearingmichaelNo ratings yet

- ON A/C 103-103: Reference Qty DesignationDocument21 pagesON A/C 103-103: Reference Qty DesignationIvan KryskoNo ratings yet

- Technical Bulletin: InoperativeDocument3 pagesTechnical Bulletin: Inoperativesebastian cruzNo ratings yet

- 206L-16-179 March 2017Document9 pages206L-16-179 March 2017turboshaftNo ratings yet

- Alert Service Bulletin 429-13-08 PSL 7000000041: BHT-429-MM Chapters 5 53Document12 pagesAlert Service Bulletin 429-13-08 PSL 7000000041: BHT-429-MM Chapters 5 53Samir PeraltaNo ratings yet

- ASB 412-14-160B Page 1 of 7 Export Classification C, ECCN EAR99 Approved For Public ReleaseDocument7 pagesASB 412-14-160B Page 1 of 7 Export Classification C, ECCN EAR99 Approved For Public Releasesebastian eduardoNo ratings yet

- TM 55 1905 217 20PDocument309 pagesTM 55 1905 217 20PAnonymous P6xkczNo ratings yet

- GL-SB0002 - Center Section Rib Replacement - REV NRDocument9 pagesGL-SB0002 - Center Section Rib Replacement - REV NRmarks.leyjaNo ratings yet

- 3-7L MerCruiser All Service BulletinsDocument83 pages3-7L MerCruiser All Service BulletinsGerrit DekkerNo ratings yet

- 49-BD-08 - Amendment - 1 - Sep - 2016Document21 pages49-BD-08 - Amendment - 1 - Sep - 2016Tanmoy DeyNo ratings yet

- Technical Specification I-ET-0000.00-0000-219-P9U-001Document26 pagesTechnical Specification I-ET-0000.00-0000-219-P9U-001mariliaNo ratings yet

- SB190-23-0002 Communication - Gatelink System Generic Io and Custom Io Interface CorrectionDocument14 pagesSB190-23-0002 Communication - Gatelink System Generic Io and Custom Io Interface CorrectionKevin AnguloNo ratings yet

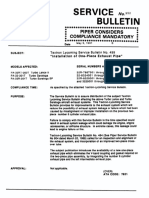

- Service Bulletin: Single EngineDocument9 pagesService Bulletin: Single EngineHenryNo ratings yet

- Isms Draft Additional Insulation Blanket Top LevelDocument4 pagesIsms Draft Additional Insulation Blanket Top LevelEkaterineNo ratings yet

- SB 53-3513r1 Aft Pressure Bulkhead InspectionDocument12 pagesSB 53-3513r1 Aft Pressure Bulkhead InspectionGarrett ReeveNo ratings yet

- Asb - 212 10 140Document12 pagesAsb - 212 10 140smartasss100% (1)

- 212 Si 01Document36 pages212 Si 01Hector BoliboNo ratings yet

- Piper SB 952 One Piece Exhaust Pipe InstallationDocument6 pagesPiper SB 952 One Piece Exhaust Pipe InstallationGeorgios AsimakopoulosNo ratings yet

- Sr220 Case - PartesDocument882 pagesSr220 Case - PartesJorge Diaz Nestor MonsalveNo ratings yet

- DAC1 79 01 Rev 0Document10 pagesDAC1 79 01 Rev 0vanNo ratings yet

- ON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty DesignationDocument27 pagesON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty Designationkien Duy PhanNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Comparative Report On Fast Food Study in Thailand, Indonesia and Vietnam in 2015Document48 pagesComparative Report On Fast Food Study in Thailand, Indonesia and Vietnam in 2015Daksh SetiaNo ratings yet

- Name: Teacher: Date: Score:: Probability Using A SpinnerDocument2 pagesName: Teacher: Date: Score:: Probability Using A SpinnerSara ShaiboonNo ratings yet

- Maxis Fibre Astro IPTV Frequently Asked Questions (FAQ)Document38 pagesMaxis Fibre Astro IPTV Frequently Asked Questions (FAQ)Maxis FibreNo ratings yet

- Kagalanggalangang Katipuanan NG Mga Anak NG Bayan" (KKK) On July 7, 1892 in A House OnDocument7 pagesKagalanggalangang Katipuanan NG Mga Anak NG Bayan" (KKK) On July 7, 1892 in A House OnCaila PanerioNo ratings yet

- Regular: Akkurat LL AraDocument23 pagesRegular: Akkurat LL ArablackinNo ratings yet

- 74108800G2DissolutionTester PDFDocument97 pages74108800G2DissolutionTester PDFDona GayossoNo ratings yet

- Trimestral LogicDocument4 pagesTrimestral LogicGabriel FigueroaNo ratings yet

- RAI Business Survey - Round 6 - OverallDocument7 pagesRAI Business Survey - Round 6 - OverallSriniNo ratings yet

- 9 JarockDocument3 pages9 JarockChukwuebuka Okechukwu (KingNebx)No ratings yet

- Lesson Plan in Technology For Teaching and LearningDocument6 pagesLesson Plan in Technology For Teaching and LearningNiña Mae CabsagNo ratings yet

- Program HMMTFebruary2014Document10 pagesProgram HMMTFebruary2014xSonyWIiNo ratings yet

- KHXHNV - Translation Practice - Lesson 10 - Modals in English 2Document10 pagesKHXHNV - Translation Practice - Lesson 10 - Modals in English 2van loi nguyenNo ratings yet

- NVLTDocument46 pagesNVLTTrang TrươngNo ratings yet

- Case2 Starbucks' MissionDocument13 pagesCase2 Starbucks' Missionsehrish iqbalNo ratings yet

- 1 PBDocument9 pages1 PBTariku KolchaNo ratings yet

- Future Simple Tense - InterrogativeDocument5 pagesFuture Simple Tense - InterrogativeanthonyleonNo ratings yet

- Application of Trigonometry Solved Board Q Paper-2Document8 pagesApplication of Trigonometry Solved Board Q Paper-2Kunal SagarNo ratings yet

- Resume For Oilfield JobDocument4 pagesResume For Oilfield Jobafiwhlkrm100% (2)

- Manual de Usuario Eaton Evolution 1150 Tower (Español - 158 Páginas)Document3 pagesManual de Usuario Eaton Evolution 1150 Tower (Español - 158 Páginas)John SanabriaNo ratings yet

- Steps Involved in Business Process ReengineeringDocument2 pagesSteps Involved in Business Process ReengineeringHarrison NchoeNo ratings yet

- Ra 8189Document13 pagesRa 8189Jv FerminNo ratings yet

- Captain Jack On FF Predict Price Movement Hi - Res PDFDocument60 pagesCaptain Jack On FF Predict Price Movement Hi - Res PDFMushfiq FaysalNo ratings yet

- What Is An Injunction? When Can You Get One?Document2 pagesWhat Is An Injunction? When Can You Get One?FindLawNo ratings yet

- 2020 q3 Sportback ManualDocument38 pages2020 q3 Sportback Manualjose luis RamirezNo ratings yet

- Development of Atomic TheoryDocument28 pagesDevelopment of Atomic TheoryRenelynn SiloNo ratings yet

- Week 1&2-CPHM PDFDocument4 pagesWeek 1&2-CPHM PDFAziz AyobNo ratings yet

- Mail Merge Feature in Word 2010Document2 pagesMail Merge Feature in Word 2010Gitanjali NayakNo ratings yet

- USF Elementary Education Lesson Plan Template (S 2014) SchwarzDocument7 pagesUSF Elementary Education Lesson Plan Template (S 2014) Schwarzapi-309598345No ratings yet

Helicopter I Iic I: Technical Bulletin

Helicopter I Iic I: Technical Bulletin

Uploaded by

sebastian cruzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Helicopter I Iic I: Technical Bulletin

Helicopter I Iic I: Technical Bulletin

Uploaded by

sebastian cruzCopyright:

Available Formats

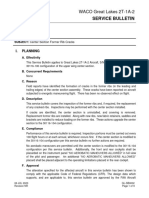

TECHNICAL BULLETIN NO.

212-82-64

Bell Helicopter i ;T I

iiC DATE 9-2-82

DATE Division of Textron Inc

PAGENO. 1 of 4

REV. Post Office Box 482 * Fort Worth. Texas 76101PAGE NO. 1 of 4

MODEL AFFECTED: 212

SUBJECT: BAFFLE - TOP ENGINE COWL - P/N

212-060-823-101, MODIFICATION OF

HELICOPTERSAFFECTED: Model 212 helicopters S/N 30501 thru

30999, 31101 thru 31256, 32101 thru

32143 and 32201 thru 32262.

[Model 212 helicopters S/N 31257 and

sub and 32143 and sub will be in

compliance with this bulletin when

delivered.]

COMPLIANCE: At the customer's option. Recommended

this task be accomplished during an

inspection that requires engine cowl

removal.

DESCRIPTION:

Reports have been received of baffle assembly, P/N 212-060-823-

101, cracking in the bend radius of the screen along attaching

edges. Addition of stiffeners to these bend areas will

eliminate this problem.

FAA APPROVAL:

The engineering changes in this bulletin are FAA approved.

MANPOWER:

It is estimated that approximately 24 manhours will be required

to modify both baffles in the top engine cowl. Manhours are

based on "hands-on" time and may vary with personnel and

facilities available.

MATERIALS:

The following materials may be procured from normal authorized

BHTI supply outlets.

Part Number Nomenclature Quantity

(BHTI Stock No.) Baffle Ship

* NAS1738MW4-2 or NAS1738M4-2 Rivet 32 64

MMS20470AD3-2 Rivet 38 76

MS20470AD3-3 Rivet 38 76

MIL-P-23377 Primer A/R A/R

(MILP23377C PT) Pri

AN APPROPRIATE ENTRY SHOULD BE MADE IN THE AIRCRAFT LOG BOOK UPON ACCOMPLISHMENT

IF OWNERSHIP OF AIRCRAFT HAS CHANGED PLEASE FORWARD TO NEW OWNER

T.B. No. 212-82-64

Page 2 of 4

The following material should be procured from commercial source.

Baffle Shi

.016 x 1.380 x 18.25 321 (QQ-S-766) Cres. Steel 4

NOTE: .020 thickness may be used in lieu of .016

347 Cres. Steel may be used in lieu of 321

Cres. Steel.

WEIGHT AND BALANCE:

Weight Fuse Station Moment

+1.0 Lbs. 188 +188 Inch Lbs.

ELECTRICAL LOAD DATA:

Not affected

SPECIAL TOOLS:

None

REFERENCES:

212 Maintenance Manual, Chapter 20.

PUBLICATIONS AFFECTED:

None

ACCOMPLISHMENT INSTRUCTIONS:

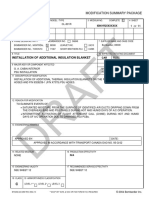

1. Fabricate eight angle stiffeners to dimensions shown in

Figure 1, Stiffener Detail. Stiffeners should be made

from .016 or .020, 321 or 347 Cres. Steel.

2. Drill out rivets securing baffle, P/N 212-060-823-101,

to engine cowl.

3. Center two stiffeners on long side of baffle assembly and

clamp in place as shown in Section AA, Figure 1.

4. Pick up baffle to cowl rivet attachment pattern through

horizontal leg of upper stiffeners.

5. Layout and drill, with #41 drill, a 19 hole pattern for

installation of MS20470AD3-2 Rivets through the horizontal

leg of the lower stiffener and baffle as shown in Section

AA of Figure 1.

6. Layout and drill, with #41 drill, a 19 hole pattern for

installation of MS20470AD3-3 Rivets through vertical legs

of stiffeners and baffle as shown in Section AA of Figure 1.

T.B. 212-82-64

Page 3 of 4

7. Remove stiffeners from Baffle, deburr all holes in stiffeners

and baffle.

8. Rivet stiffeners to baffle, using rivets identified in Steps

5 and 6, dipped in MIL-P-23377 Epoxy Polyamide Primer.

9. Install baffle on engine cowl, using NAS1738MW4-2 Rivet.

10. Touch up cowl finish following procedure in Maintenance

Manual.

TYPICAL BOTH SIDES

BAFFEL P/N

212-060-823-101

^^/ \9<,,, . + /x r PTHROUGH LEGS

VERTICAL

0.75 ,jP. EXISTING RIVET PATTERN

STIFFENER 212-060-823-101

TB212-2

BAFFEL MODIFICATION DETAILS

FIGURE 1

You might also like

- 72-00-00 ENGINE - INSPECTION/CHECK-2 Pratt & Whitney CanadaDocument78 pages72-00-00 ENGINE - INSPECTION/CHECK-2 Pratt & Whitney CanadaAlexandre Manco100% (1)

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- Feminism Final PaperDocument19 pagesFeminism Final PaperRubee Lee Won Ag100% (1)

- Combination of Microneedling and Glycolic Acid Peels For TheDocument7 pagesCombination of Microneedling and Glycolic Acid Peels For Thealejandrogonzalez89No ratings yet

- 212 86 92 - RepairedDocument11 pages212 86 92 - Repairedsebastian cruzNo ratings yet

- BHT 206 16 209Document8 pagesBHT 206 16 209edsel jose diaz sarmientoNo ratings yet

- 212 TB 09 210Document5 pages212 TB 09 210Jose Edwin Roldan RiosNo ratings yet

- 212 Si 04Document30 pages212 Si 04Hector BoliboNo ratings yet

- SIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2Document39 pagesSIN 2348 Rev. K Service Instruction Manual 206B Driveshaft 2kenji roberto santanaNo ratings yet

- Technical Bulletin: Bell HelicopterDocument1 pageTechnical Bulletin: Bell HelicopterHenry Fabian Peña MartinezNo ratings yet

- TCM C90 - 0200 Engine Type Certificate - E-252 - Rev 29Document3 pagesTCM C90 - 0200 Engine Type Certificate - E-252 - Rev 29Randy WaltonNo ratings yet

- Vessel/S&T Heat Exchanger Standard Details (Metric Units)Document7 pagesVessel/S&T Heat Exchanger Standard Details (Metric Units)Jamil AhmadNo ratings yet

- Service Bulletin PDFDocument8 pagesService Bulletin PDFamrjheyNo ratings yet

- Caterpillar 854gDocument34 pagesCaterpillar 854gBrust Elmer ANo ratings yet

- Boeing 737-4H6 SpecDocument5 pagesBoeing 737-4H6 SpecDa23ll AlderichNo ratings yet

- Uscg 009623 PDFDocument383 pagesUscg 009623 PDFAnbarasan AnandhanNo ratings yet

- B747-8 Fuel ManifoldDocument31 pagesB747-8 Fuel ManifoldDagmawiNo ratings yet

- Service Bulletin: CaravanDocument12 pagesService Bulletin: CaravanladyNo ratings yet

- Piping Engineering: Marathon Petroleum Co. Project Specific AddendumDocument17 pagesPiping Engineering: Marathon Petroleum Co. Project Specific AddendumChirag ShahNo ratings yet

- ON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNDocument7 pagesON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNEdson CarvalhoNo ratings yet

- SB C208 Stall WarningDocument14 pagesSB C208 Stall WarningrobertobrouNo ratings yet

- ASB 412-00-106 - Tail Rotor (T - R) Blade 212-010-750-009 - 011 - 105 - 107 Tip Block Retention Modification Rev. D - 18-Mar-2005Document9 pagesASB 412-00-106 - Tail Rotor (T - R) Blade 212-010-750-009 - 011 - 105 - 107 Tip Block Retention Modification Rev. D - 18-Mar-2005yu gangNo ratings yet

- DAC1 24 03 Rev 2Document4 pagesDAC1 24 03 Rev 2vanNo ratings yet

- Wings - Aileron Drain Hole Inspection SBDocument8 pagesWings - Aileron Drain Hole Inspection SBstiveNo ratings yet

- 330 Adjustment of Pivot DoorDocument31 pages330 Adjustment of Pivot Doorhx344375No ratings yet

- ASB 407-16-114-RC Page 1 of 2 Approved For Public ReleaseDocument10 pagesASB 407-16-114-RC Page 1 of 2 Approved For Public ReleaseluisNo ratings yet

- Planos Estándar de Obras Estructurales, Pavimentos y Drenaje para Gas OilDocument33 pagesPlanos Estándar de Obras Estructurales, Pavimentos y Drenaje para Gas OilMiguel MendezNo ratings yet

- D231000144 Pib 001Document31 pagesD231000144 Pib 001xlzyydf2015No ratings yet

- United Technologles Pratt&Whitney: Middletown Plant Aircraft Road Middletown, Connecticut 06457Document7 pagesUnited Technologles Pratt&Whitney: Middletown Plant Aircraft Road Middletown, Connecticut 06457amir ghaznaviNo ratings yet

- Technical Bulletin Bell Helicopter: Subject: Cyclic and Collective JackshaftsDocument10 pagesTechnical Bulletin Bell Helicopter: Subject: Cyclic and Collective JackshaftsHenry Fabian Peña MartinezNo ratings yet

- Inbound 7539317969539081851Document17 pagesInbound 7539317969539081851Yoel UtrillaNo ratings yet

- 407 MD 01 S02Document16 pages407 MD 01 S02Jonathan Cristhan Sanchez PérezNo ratings yet

- 212 Asb 08 130Document7 pages212 Asb 08 130Walberto PachecoNo ratings yet

- A320 NE0 Fuel or Hydraulic or Oil Leakage LimitsDocument19 pagesA320 NE0 Fuel or Hydraulic or Oil Leakage LimitsArjuna SamaranayakeNo ratings yet

- 407TB407TB19129Document9 pages407TB407TB19129e.a.m.v.9.8.1.2No ratings yet

- DS19310 SM5110244 05 04 02 01Document0 pagesDS19310 SM5110244 05 04 02 01parascoliNo ratings yet

- 12165-70 - 1 Sundry Instr.Document328 pages12165-70 - 1 Sundry Instr.kodrysNo ratings yet

- REHS8790Document10 pagesREHS8790Daniel DonosoNo ratings yet

- 48 BD 08Document34 pages48 BD 08Mayur UrkudeNo ratings yet

- Installation and Parts Manual: FOR Caterpillar D8T & D9T TractorsDocument28 pagesInstallation and Parts Manual: FOR Caterpillar D8T & D9T TractorsJusaNadaNo ratings yet

- Truck Medium MC2 Clutch Output Shaft BearingDocument2 pagesTruck Medium MC2 Clutch Output Shaft BearingmichaelNo ratings yet

- ON A/C 103-103: Reference Qty DesignationDocument21 pagesON A/C 103-103: Reference Qty DesignationIvan KryskoNo ratings yet

- Technical Bulletin: InoperativeDocument3 pagesTechnical Bulletin: Inoperativesebastian cruzNo ratings yet

- 206L-16-179 March 2017Document9 pages206L-16-179 March 2017turboshaftNo ratings yet

- Alert Service Bulletin 429-13-08 PSL 7000000041: BHT-429-MM Chapters 5 53Document12 pagesAlert Service Bulletin 429-13-08 PSL 7000000041: BHT-429-MM Chapters 5 53Samir PeraltaNo ratings yet

- ASB 412-14-160B Page 1 of 7 Export Classification C, ECCN EAR99 Approved For Public ReleaseDocument7 pagesASB 412-14-160B Page 1 of 7 Export Classification C, ECCN EAR99 Approved For Public Releasesebastian eduardoNo ratings yet

- TM 55 1905 217 20PDocument309 pagesTM 55 1905 217 20PAnonymous P6xkczNo ratings yet

- GL-SB0002 - Center Section Rib Replacement - REV NRDocument9 pagesGL-SB0002 - Center Section Rib Replacement - REV NRmarks.leyjaNo ratings yet

- 3-7L MerCruiser All Service BulletinsDocument83 pages3-7L MerCruiser All Service BulletinsGerrit DekkerNo ratings yet

- 49-BD-08 - Amendment - 1 - Sep - 2016Document21 pages49-BD-08 - Amendment - 1 - Sep - 2016Tanmoy DeyNo ratings yet

- Technical Specification I-ET-0000.00-0000-219-P9U-001Document26 pagesTechnical Specification I-ET-0000.00-0000-219-P9U-001mariliaNo ratings yet

- SB190-23-0002 Communication - Gatelink System Generic Io and Custom Io Interface CorrectionDocument14 pagesSB190-23-0002 Communication - Gatelink System Generic Io and Custom Io Interface CorrectionKevin AnguloNo ratings yet

- Service Bulletin: Single EngineDocument9 pagesService Bulletin: Single EngineHenryNo ratings yet

- Isms Draft Additional Insulation Blanket Top LevelDocument4 pagesIsms Draft Additional Insulation Blanket Top LevelEkaterineNo ratings yet

- SB 53-3513r1 Aft Pressure Bulkhead InspectionDocument12 pagesSB 53-3513r1 Aft Pressure Bulkhead InspectionGarrett ReeveNo ratings yet

- Asb - 212 10 140Document12 pagesAsb - 212 10 140smartasss100% (1)

- 212 Si 01Document36 pages212 Si 01Hector BoliboNo ratings yet

- Piper SB 952 One Piece Exhaust Pipe InstallationDocument6 pagesPiper SB 952 One Piece Exhaust Pipe InstallationGeorgios AsimakopoulosNo ratings yet

- Sr220 Case - PartesDocument882 pagesSr220 Case - PartesJorge Diaz Nestor MonsalveNo ratings yet

- DAC1 79 01 Rev 0Document10 pagesDAC1 79 01 Rev 0vanNo ratings yet

- ON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty DesignationDocument27 pagesON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty Designationkien Duy PhanNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Comparative Report On Fast Food Study in Thailand, Indonesia and Vietnam in 2015Document48 pagesComparative Report On Fast Food Study in Thailand, Indonesia and Vietnam in 2015Daksh SetiaNo ratings yet

- Name: Teacher: Date: Score:: Probability Using A SpinnerDocument2 pagesName: Teacher: Date: Score:: Probability Using A SpinnerSara ShaiboonNo ratings yet

- Maxis Fibre Astro IPTV Frequently Asked Questions (FAQ)Document38 pagesMaxis Fibre Astro IPTV Frequently Asked Questions (FAQ)Maxis FibreNo ratings yet

- Kagalanggalangang Katipuanan NG Mga Anak NG Bayan" (KKK) On July 7, 1892 in A House OnDocument7 pagesKagalanggalangang Katipuanan NG Mga Anak NG Bayan" (KKK) On July 7, 1892 in A House OnCaila PanerioNo ratings yet

- Regular: Akkurat LL AraDocument23 pagesRegular: Akkurat LL ArablackinNo ratings yet

- 74108800G2DissolutionTester PDFDocument97 pages74108800G2DissolutionTester PDFDona GayossoNo ratings yet

- Trimestral LogicDocument4 pagesTrimestral LogicGabriel FigueroaNo ratings yet

- RAI Business Survey - Round 6 - OverallDocument7 pagesRAI Business Survey - Round 6 - OverallSriniNo ratings yet

- 9 JarockDocument3 pages9 JarockChukwuebuka Okechukwu (KingNebx)No ratings yet

- Lesson Plan in Technology For Teaching and LearningDocument6 pagesLesson Plan in Technology For Teaching and LearningNiña Mae CabsagNo ratings yet

- Program HMMTFebruary2014Document10 pagesProgram HMMTFebruary2014xSonyWIiNo ratings yet

- KHXHNV - Translation Practice - Lesson 10 - Modals in English 2Document10 pagesKHXHNV - Translation Practice - Lesson 10 - Modals in English 2van loi nguyenNo ratings yet

- NVLTDocument46 pagesNVLTTrang TrươngNo ratings yet

- Case2 Starbucks' MissionDocument13 pagesCase2 Starbucks' Missionsehrish iqbalNo ratings yet

- 1 PBDocument9 pages1 PBTariku KolchaNo ratings yet

- Future Simple Tense - InterrogativeDocument5 pagesFuture Simple Tense - InterrogativeanthonyleonNo ratings yet

- Application of Trigonometry Solved Board Q Paper-2Document8 pagesApplication of Trigonometry Solved Board Q Paper-2Kunal SagarNo ratings yet

- Resume For Oilfield JobDocument4 pagesResume For Oilfield Jobafiwhlkrm100% (2)

- Manual de Usuario Eaton Evolution 1150 Tower (Español - 158 Páginas)Document3 pagesManual de Usuario Eaton Evolution 1150 Tower (Español - 158 Páginas)John SanabriaNo ratings yet

- Steps Involved in Business Process ReengineeringDocument2 pagesSteps Involved in Business Process ReengineeringHarrison NchoeNo ratings yet

- Ra 8189Document13 pagesRa 8189Jv FerminNo ratings yet

- Captain Jack On FF Predict Price Movement Hi - Res PDFDocument60 pagesCaptain Jack On FF Predict Price Movement Hi - Res PDFMushfiq FaysalNo ratings yet

- What Is An Injunction? When Can You Get One?Document2 pagesWhat Is An Injunction? When Can You Get One?FindLawNo ratings yet

- 2020 q3 Sportback ManualDocument38 pages2020 q3 Sportback Manualjose luis RamirezNo ratings yet

- Development of Atomic TheoryDocument28 pagesDevelopment of Atomic TheoryRenelynn SiloNo ratings yet

- Week 1&2-CPHM PDFDocument4 pagesWeek 1&2-CPHM PDFAziz AyobNo ratings yet

- Mail Merge Feature in Word 2010Document2 pagesMail Merge Feature in Word 2010Gitanjali NayakNo ratings yet

- USF Elementary Education Lesson Plan Template (S 2014) SchwarzDocument7 pagesUSF Elementary Education Lesson Plan Template (S 2014) Schwarzapi-309598345No ratings yet