Professional Documents

Culture Documents

Sop Sorting

Sop Sorting

Uploaded by

Surya GoyalCopyright:

Available Formats

You might also like

- Standard Operating Procedure General Rework Procedure: Pranjal Projects (P) LTDDocument1 pageStandard Operating Procedure General Rework Procedure: Pranjal Projects (P) LTDvekas bhatia100% (3)

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationFrom EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationRating: 5 out of 5 stars5/5 (1)

- IQA IATF ChecksheetDocument37 pagesIQA IATF ChecksheetSumeet Rathee100% (6)

- 8D Problem Solving Worksheet - Long FormDocument7 pages8D Problem Solving Worksheet - Long FormdanielonnarNo ratings yet

- 12 Fat Sat PDFDocument18 pages12 Fat Sat PDFFirdaus Mohd100% (1)

- 023-SOP For Conducting Hold Time StudyDocument3 pages023-SOP For Conducting Hold Time StudyAshok Lenka67% (3)

- Supplier QuestionnaireDocument5 pagesSupplier QuestionnaireNikhil Bhat InanjaiNo ratings yet

- Reference Format No.: SOP/QA/001-F01-00Document4 pagesReference Format No.: SOP/QA/001-F01-00Rahul67% (3)

- Sop Qa 050Document2 pagesSop Qa 050chalicevitalchemNo ratings yet

- Hold Time Study SOP Indian Pharma 1Document3 pagesHold Time Study SOP Indian Pharma 1ziadddNo ratings yet

- FS - MM-RP-077 - Physical Verification Report - V0.2Document8 pagesFS - MM-RP-077 - Physical Verification Report - V0.2SUBHOJIT BANERJEENo ratings yet

- Celebrity Biopharma LimitedDocument10 pagesCelebrity Biopharma LimitedchalicevitalchemNo ratings yet

- 5S and Lean ManufacturingDocument55 pages5S and Lean ManufacturingMarie TemploNo ratings yet

- Answer For Finding Sorting OD Height (291121)Document16 pagesAnswer For Finding Sorting OD Height (291121)Azlan MustaphaNo ratings yet

- SOP065.3 - 01 Raw Materials and Development of Spec For Cat ODocument7 pagesSOP065.3 - 01 Raw Materials and Development of Spec For Cat OGrace Chen100% (1)

- Eddy Current RFT ProcedureDocument12 pagesEddy Current RFT ProcedureJeganeswaran100% (1)

- Department: HOT SHOP Auditee: AuditorDocument52 pagesDepartment: HOT SHOP Auditee: AuditorSead ZejnilovicNo ratings yet

- ReprocessingDocument3 pagesReprocessingswanandkul86% (7)

- ISO ChecklistDocument36 pagesISO ChecklistDhinakaran100% (1)

- SOP For SOPDocument3 pagesSOP For SOPtridentindiacompanyNo ratings yet

- SOP For Preparation and Handling of Working StandardsDocument5 pagesSOP For Preparation and Handling of Working StandardsSolomon100% (2)

- IATF ChecksheetDocument37 pagesIATF ChecksheetDhinakaran67% (3)

- Sop Paper ManufacturingDocument3 pagesSop Paper Manufacturingkesavan siwanathanNo ratings yet

- Standard Operating Procedure: Darsh Pharmachem Pvt. LTDDocument4 pagesStandard Operating Procedure: Darsh Pharmachem Pvt. LTDNishit SuvaNo ratings yet

- Quality Record Procedure Rev-JDocument4 pagesQuality Record Procedure Rev-JherminNo ratings yet

- OOT Investigation FormDocument7 pagesOOT Investigation FormAnkur Choudhary100% (2)

- Audit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50Document1 pageAudit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50BALACHANDAR SNo ratings yet

- Oos Out of SpecificationDocument12 pagesOos Out of SpecificationShumaila Iftikhar100% (1)

- QSP-19. Procedure for ReworkDocument5 pagesQSP-19. Procedure for Reworksigmaqcs02No ratings yet

- GLC - 5 S Presentation PDFDocument118 pagesGLC - 5 S Presentation PDFVenkatesanNo ratings yet

- 5) Control of Quality RecordsDocument4 pages5) Control of Quality RecordsSagar DaundNo ratings yet

- 007 Out of SpecificationDocument12 pages007 Out of Specificationmarkandey gupta67% (3)

- MVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014Document5 pagesMVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014BALACHANDAR SNo ratings yet

- (QSP-QA-08) Process For Internal Rejection HandelingDocument4 pages(QSP-QA-08) Process For Internal Rejection HandelingMUNENDRA SHAKYANo ratings yet

- APQP ProcedureDocument6 pagesAPQP ProcedureluckydaysNo ratings yet

- March Week 2Document73 pagesMarch Week 2Agnes AnggitNo ratings yet

- MSIL Audit Cheklist 16Document90 pagesMSIL Audit Cheklist 16mallarjun0010No ratings yet

- QP-QA-03-Final InspectionDocument2 pagesQP-QA-03-Final InspectionDebkanta Das100% (1)

- 001entering in and Exiting From Production AreaDocument3 pages001entering in and Exiting From Production AreaMuhammad HanifNo ratings yet

- 5S TrainingDocument31 pages5S Trainingedward contreras100% (1)

- Batch Releas ProcedureDocument4 pagesBatch Releas ProcedureSolomon Gamanuel100% (1)

- Saif Powertec Limited Battery Division: Awarness SessionDocument47 pagesSaif Powertec Limited Battery Division: Awarness SessionNadeem NafisNo ratings yet

- SMART LOGISTICS AND FACILITY MANAGEMENT PROCEDURE FOR CONTROL OF NONDocument6 pagesSMART LOGISTICS AND FACILITY MANAGEMENT PROCEDURE FOR CONTROL OF NONJustin B NickafNo ratings yet

- Finished Product Reference SamplesDocument4 pagesFinished Product Reference SamplesTifah InternationalNo ratings yet

- Audit GuidexlsxDocument4 pagesAudit GuidexlsxMuhammad Javed IqbalNo ratings yet

- Hazard Study 4 - BuildingDocument12 pagesHazard Study 4 - BuildingSaran rasayaNo ratings yet

- Implementation & Monitoring: (Work Place Improvement)Document112 pagesImplementation & Monitoring: (Work Place Improvement)Sonika SinghNo ratings yet

- Hold-Time-Study-of-GarmentsDocument7 pagesHold-Time-Study-of-GarmentsAKKAD PHARMANo ratings yet

- 10.2 Internal Audit ReportDocument9 pages10.2 Internal Audit ReportDhananjay Patil100% (1)

- RR Plast Extrusions Pvt. LTD - Internal Audit Report September 2021 (MY)Document16 pagesRR Plast Extrusions Pvt. LTD - Internal Audit Report September 2021 (MY)Chetan ChoudhariNo ratings yet

- F 392 0 r01 Supplier Quality AssessmentDocument12 pagesF 392 0 r01 Supplier Quality AssessmentSiddheshwarr JabagoudarNo ratings yet

- Hazard Study 4 - Compress AirDocument12 pagesHazard Study 4 - Compress AirSaran rasayaNo ratings yet

- 1.1 Signing Off The ProductDocument3 pages1.1 Signing Off The ProductJSG GroupNo ratings yet

- Sop For Destruction of Sample After Analysis.Document5 pagesSop For Destruction of Sample After Analysis.vasant ugale100% (1)

- PPEPL-SOP-03 Procedure For Control of NCDocument7 pagesPPEPL-SOP-03 Procedure For Control of NCRaja RehaNo ratings yet

- SortingDocument2 pagesSortingqcNo ratings yet

- Sop Qa 066Document2 pagesSop Qa 066chalicevitalchemNo ratings yet

- Regent Garment - IED-SOP 020 Scan & PackDocument3 pagesRegent Garment - IED-SOP 020 Scan & Packie.madeups.ktml1No ratings yet

- 13.1 PURCHASE PROCEDURE - Updated 07.01.2021Document7 pages13.1 PURCHASE PROCEDURE - Updated 07.01.2021cghodake1No ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

Sop Sorting

Sop Sorting

Uploaded by

Surya GoyalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop Sorting

Sop Sorting

Uploaded by

Surya GoyalCopyright:

Available Formats

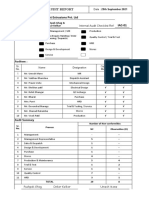

Sop for sorting

1.0 Purpose

To lay down the procedure for Sorting of Finished Materials for Visual Defects before

Pasting/Packing and Despatch so that No defective Materials reaches Custmer.

2.0 Scope

Sorting of all Printed Material before Pasting/Packing.

3.0 Responsibilities

Sorter/Supervisor-Pasting

4.0 Procedure

4.1 Clean the Sorting Area properly.

4.2 Ensure that no cartons of the previous/any other Job is in sorting area.

4.3 Get the Approved Shade Card from the Supervisor and review the same.

4.4 Start sorting the material w.r.t. the Shade Card.

4.5 Check for any type of Printing/Coating/Lamination/Die Cutting Defects and color Variation in the

cartons and take such cartons out and keep it in Hold (Having Minor Defects, Which can be

Reviewed Later on) and Rejection Area (Having Major Defects).

4.6 Send the OK Cartons for Pasting/Next Operation.

4.7 After Sorting of the material is finished, inform the Supervisor

4.8 Count the Defective Cartons and inform Supervisor to note down the Rejected Qty.

4.9 Sheets marked for 100% sorting should be sorted separately and carefully and defective cartons

should be removed.

4.10 In case any tag is attached for identification of defects, inform to concern Supervisor.

5.0 Corrective Action

Arrange segregation of the Printed Sheets if found defective during in-process check. Keep the

rejected sheets in Rejection area and note down the qty

6.0 Reference to Other Documents

--

7.0 Records

Line Clearance Record QA/FM/06

No Date

Description of Revision Reason for Revision

Revision

REVISION RECORD SHEET

1 of 1

Mr. Rahul Singh (Q.A Executive) Mr. Tikkam Dutt Sharma ( H.O.D QA) Mr. Vijay Sharma (Plant Head)

Prep. By Reviewed By Approved By Page

You might also like

- Standard Operating Procedure General Rework Procedure: Pranjal Projects (P) LTDDocument1 pageStandard Operating Procedure General Rework Procedure: Pranjal Projects (P) LTDvekas bhatia100% (3)

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationFrom EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationRating: 5 out of 5 stars5/5 (1)

- IQA IATF ChecksheetDocument37 pagesIQA IATF ChecksheetSumeet Rathee100% (6)

- 8D Problem Solving Worksheet - Long FormDocument7 pages8D Problem Solving Worksheet - Long FormdanielonnarNo ratings yet

- 12 Fat Sat PDFDocument18 pages12 Fat Sat PDFFirdaus Mohd100% (1)

- 023-SOP For Conducting Hold Time StudyDocument3 pages023-SOP For Conducting Hold Time StudyAshok Lenka67% (3)

- Supplier QuestionnaireDocument5 pagesSupplier QuestionnaireNikhil Bhat InanjaiNo ratings yet

- Reference Format No.: SOP/QA/001-F01-00Document4 pagesReference Format No.: SOP/QA/001-F01-00Rahul67% (3)

- Sop Qa 050Document2 pagesSop Qa 050chalicevitalchemNo ratings yet

- Hold Time Study SOP Indian Pharma 1Document3 pagesHold Time Study SOP Indian Pharma 1ziadddNo ratings yet

- FS - MM-RP-077 - Physical Verification Report - V0.2Document8 pagesFS - MM-RP-077 - Physical Verification Report - V0.2SUBHOJIT BANERJEENo ratings yet

- Celebrity Biopharma LimitedDocument10 pagesCelebrity Biopharma LimitedchalicevitalchemNo ratings yet

- 5S and Lean ManufacturingDocument55 pages5S and Lean ManufacturingMarie TemploNo ratings yet

- Answer For Finding Sorting OD Height (291121)Document16 pagesAnswer For Finding Sorting OD Height (291121)Azlan MustaphaNo ratings yet

- SOP065.3 - 01 Raw Materials and Development of Spec For Cat ODocument7 pagesSOP065.3 - 01 Raw Materials and Development of Spec For Cat OGrace Chen100% (1)

- Eddy Current RFT ProcedureDocument12 pagesEddy Current RFT ProcedureJeganeswaran100% (1)

- Department: HOT SHOP Auditee: AuditorDocument52 pagesDepartment: HOT SHOP Auditee: AuditorSead ZejnilovicNo ratings yet

- ReprocessingDocument3 pagesReprocessingswanandkul86% (7)

- ISO ChecklistDocument36 pagesISO ChecklistDhinakaran100% (1)

- SOP For SOPDocument3 pagesSOP For SOPtridentindiacompanyNo ratings yet

- SOP For Preparation and Handling of Working StandardsDocument5 pagesSOP For Preparation and Handling of Working StandardsSolomon100% (2)

- IATF ChecksheetDocument37 pagesIATF ChecksheetDhinakaran67% (3)

- Sop Paper ManufacturingDocument3 pagesSop Paper Manufacturingkesavan siwanathanNo ratings yet

- Standard Operating Procedure: Darsh Pharmachem Pvt. LTDDocument4 pagesStandard Operating Procedure: Darsh Pharmachem Pvt. LTDNishit SuvaNo ratings yet

- Quality Record Procedure Rev-JDocument4 pagesQuality Record Procedure Rev-JherminNo ratings yet

- OOT Investigation FormDocument7 pagesOOT Investigation FormAnkur Choudhary100% (2)

- Audit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50Document1 pageAudit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50BALACHANDAR SNo ratings yet

- Oos Out of SpecificationDocument12 pagesOos Out of SpecificationShumaila Iftikhar100% (1)

- QSP-19. Procedure for ReworkDocument5 pagesQSP-19. Procedure for Reworksigmaqcs02No ratings yet

- GLC - 5 S Presentation PDFDocument118 pagesGLC - 5 S Presentation PDFVenkatesanNo ratings yet

- 5) Control of Quality RecordsDocument4 pages5) Control of Quality RecordsSagar DaundNo ratings yet

- 007 Out of SpecificationDocument12 pages007 Out of Specificationmarkandey gupta67% (3)

- MVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014Document5 pagesMVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014BALACHANDAR SNo ratings yet

- (QSP-QA-08) Process For Internal Rejection HandelingDocument4 pages(QSP-QA-08) Process For Internal Rejection HandelingMUNENDRA SHAKYANo ratings yet

- APQP ProcedureDocument6 pagesAPQP ProcedureluckydaysNo ratings yet

- March Week 2Document73 pagesMarch Week 2Agnes AnggitNo ratings yet

- MSIL Audit Cheklist 16Document90 pagesMSIL Audit Cheklist 16mallarjun0010No ratings yet

- QP-QA-03-Final InspectionDocument2 pagesQP-QA-03-Final InspectionDebkanta Das100% (1)

- 001entering in and Exiting From Production AreaDocument3 pages001entering in and Exiting From Production AreaMuhammad HanifNo ratings yet

- 5S TrainingDocument31 pages5S Trainingedward contreras100% (1)

- Batch Releas ProcedureDocument4 pagesBatch Releas ProcedureSolomon Gamanuel100% (1)

- Saif Powertec Limited Battery Division: Awarness SessionDocument47 pagesSaif Powertec Limited Battery Division: Awarness SessionNadeem NafisNo ratings yet

- SMART LOGISTICS AND FACILITY MANAGEMENT PROCEDURE FOR CONTROL OF NONDocument6 pagesSMART LOGISTICS AND FACILITY MANAGEMENT PROCEDURE FOR CONTROL OF NONJustin B NickafNo ratings yet

- Finished Product Reference SamplesDocument4 pagesFinished Product Reference SamplesTifah InternationalNo ratings yet

- Audit GuidexlsxDocument4 pagesAudit GuidexlsxMuhammad Javed IqbalNo ratings yet

- Hazard Study 4 - BuildingDocument12 pagesHazard Study 4 - BuildingSaran rasayaNo ratings yet

- Implementation & Monitoring: (Work Place Improvement)Document112 pagesImplementation & Monitoring: (Work Place Improvement)Sonika SinghNo ratings yet

- Hold-Time-Study-of-GarmentsDocument7 pagesHold-Time-Study-of-GarmentsAKKAD PHARMANo ratings yet

- 10.2 Internal Audit ReportDocument9 pages10.2 Internal Audit ReportDhananjay Patil100% (1)

- RR Plast Extrusions Pvt. LTD - Internal Audit Report September 2021 (MY)Document16 pagesRR Plast Extrusions Pvt. LTD - Internal Audit Report September 2021 (MY)Chetan ChoudhariNo ratings yet

- F 392 0 r01 Supplier Quality AssessmentDocument12 pagesF 392 0 r01 Supplier Quality AssessmentSiddheshwarr JabagoudarNo ratings yet

- Hazard Study 4 - Compress AirDocument12 pagesHazard Study 4 - Compress AirSaran rasayaNo ratings yet

- 1.1 Signing Off The ProductDocument3 pages1.1 Signing Off The ProductJSG GroupNo ratings yet

- Sop For Destruction of Sample After Analysis.Document5 pagesSop For Destruction of Sample After Analysis.vasant ugale100% (1)

- PPEPL-SOP-03 Procedure For Control of NCDocument7 pagesPPEPL-SOP-03 Procedure For Control of NCRaja RehaNo ratings yet

- SortingDocument2 pagesSortingqcNo ratings yet

- Sop Qa 066Document2 pagesSop Qa 066chalicevitalchemNo ratings yet

- Regent Garment - IED-SOP 020 Scan & PackDocument3 pagesRegent Garment - IED-SOP 020 Scan & Packie.madeups.ktml1No ratings yet

- 13.1 PURCHASE PROCEDURE - Updated 07.01.2021Document7 pages13.1 PURCHASE PROCEDURE - Updated 07.01.2021cghodake1No ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)