Professional Documents

Culture Documents

MSH - AuditTemplate - ExplSf - TransUseDisposal 2

MSH - AuditTemplate - ExplSf - TransUseDisposal 2

Uploaded by

yq9vxy8h9w0 ratings0% found this document useful (0 votes)

4 views9 pagesAudit bladting contoh untuk download artikel

Original Title

MSH_AuditTemplate_ExplSf_TransUseDisposal 2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAudit bladting contoh untuk download artikel

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

4 views9 pagesMSH - AuditTemplate - ExplSf - TransUseDisposal 2

MSH - AuditTemplate - ExplSf - TransUseDisposal 2

Uploaded by

yq9vxy8h9wAudit bladting contoh untuk download artikel

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 9

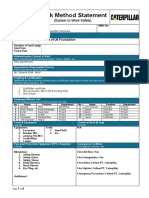

Department of Mines, Industry Regulation and Safety Resources Safety

EXPLOSIVES: SURFACE TRANSPORT, USE AND DISPOSAL AUDIT Site: _________________________________

Date conducted:_______________________

1 TRANSPORT

Point Standard Standard met Comments

1.1 There are suitably modified explosives

vehicles designed to transport explosives on

site.

1.2 There are suitably modified explosives

vehicles designed to transport explosives on

site and public roads.

1.3 The explosives vehicles are fitted with lockable

wooden boxes to transport the explosives.

1.4 The explosives vehicles are correctly

placarded.

1.5 The explosives vehicle is fitted with a suitable

fire extinguisher.

1.6 Where the explosives vehicle is used to

transport incompatible explosives (detonators

and blasting explosives) that it is fitted with an

appropriate blast barrier segregating the two.

1.7 There are systems in place to ensure that only

authorised secure nominees drive the

explosives vehicle.

1.8 The secure nominees authorised to transport

the explosives are adequately trained for the

task.

1.9 The explosives vehicles are adequately

serviced and well maintained.

Explosives: Surface transport, use and disposal audit

Page 1 of 9

Department of Mines, Industry Regulation and Safety Resources Safety

1.10 There are systems in place to prevent

explosives vehicles loaded with explosives

from being left unattended (e.g. at crib rooms,

magazine compounds, blast sites, etc.).

1.11 Adequate security is provided for the keys of

the explosives vehicles.

2 RECORDS

Point Standard Standard met Comments

2.1 Blasts are planned and designed to ensure

required blast results e.g. good fragmentation,

displacement of muck pile etc.

2.2 A blast plan is prepared prior to each blast.

2.3 Blast plans comply with AS 2187.2 Appendix A

section A2

2.4 Drilling patterns are laid out in accordance with

the design.

2.5 Survey records of blast are kept.

2.6 Records of every blast are kept including key

blasting parameters.

2.7 There is a system in place to assess and deal

with dangers from fly rock to any person,

property and public property

2.8 Any dangerous goods incident that involves an

explosive such as fly rock causing damage to

property or injuries to personnel, undetected

misfires in broken rock, etc. are reported to the

department.

2.9 Where air blast overpressure or ground

vibration could be a problem, records are kept

Explosives: Surface transport, use and disposal audit

Page 2 of 9

Department of Mines, Industry Regulation and Safety Resources Safety

including complaints.

3 DRILLING PRECAUTIONS

Point Standard Standard met Comments

3.1 Drilling is not carried out on a face or bench

until it has been checked for misfires.

3.2 Drilling is not carried out in a quarry operation

where a portion of the hole is closer than 6

metres to a hole containing explosives except

for clearing a misfire as per the written

instructions of the quarry manager.

4 CHARGING OPERATIONS

Point Standard Standard met Comments

4.1 Before charging commences personnel and

machinery not required for charging operations

are removed from the area.

4.2 Warning signs that charging operations are in

progress are displayed and the area is clearly

delineated and demarcated to prevent

unauthorised personnel from entering the blast

site.

4.3 That a minimum of two people are involved in

the charging process.

4.4 Cartridges of explosives are not forced into

holes.

4.5 Only those holes that are intended to be

blasted (in that blast) are charged.

Explosives: Surface transport, use and disposal audit

Page 3 of 9

Department of Mines, Industry Regulation and Safety Resources Safety

4.6 Polythene lay flat blasthole liners are not used

where loose ANFO is poured on top of a

primer.

4.7 The depth and condition of blastholes are

checked prior to charging.

4.8 No persons smoke while handling explosives

or charging.

4.9 Any blasthole that is hot from previous

blasting, drilling or any other cause is not

charged until sufficiently cool.

4.10 A sufficient depth of each blasthole is left

uncharged to permit adequate stemming.

4.11 Care is taken in charging and stemming

operations to avoid damaging down lines or

allowing them to be pulled down in hole.

4.12 Stemming is completed as soon as possible

after charging.

4.13 Explosive in cartridge form is not dropped into

any blasthole.

4.14 No rockdrill, shovel, machine or vehicle

(except the vehicle or machine used for

charging operations) is operated within 6

metres from any hole containing a charge.

4.15 Any charge in a designated blast which has

not been fired or has not exploded is treated

as misfire.

4.16 A secure nominee is present at all times during

the charging operations.

4.17 The explosives loaded into the blast holes are

reconciled with what is recorded on the blast

plan.

4.18 Blast holes that are slept for a period of time

are stemmed and not tied in until they are to

Explosives: Surface transport, use and disposal audit

Page 4 of 9

Department of Mines, Industry Regulation and Safety Resources Safety

be fired.

4.19 Adequate security is provided for explosives

that are slept for a period of time.

5 BLAST WARNING AND GUARDING

Point Standard Standard met Comments

5.1 The manager/ blast design team determines

the size of blast exclusion zone. This is also to

include out of the ordinary blasting such as

secondary blasting.

5.2 The blast plan map shall show the blast

exclusion zone and include details of where

the blast guards and shotfirer are located.

5.3 All persons in the vicinity of the blasting area

are warned and moved to a safe place before

the shot is fired.

5.4 There are procedures in place for clearing the

blast exclusion zone prior to the blast.

5.5 All means of entry to the place of blasting are

securely guarded against entry by persons, or

warning notices are erected to prevent entry.

5.6 Blast guards and blast controllers are

competent in their roles.

5.7 There is a register of personnel who are

authorised in the roles of blast guard and blast

controller.

5.8 There is a list of equipment available for

establishing the blast exclusion zone.

5.9 An audible warning device (a modulated

frequency siren) is installed and used at the

Explosives: Surface transport, use and disposal audit

Page 5 of 9

Department of Mines, Industry Regulation and Safety Resources Safety

mine site.

5.10 Notices are erected warning that the noise

from the audible warning device is a signal that

blasting is taking place.

5.11 All persons on a mine are notified at least 24

hours prior to the scheduled blast of the

blasting time.

6 FIRING TIMES AND PROCEDURES

Point Standard Standard met Comments

6.1 Firing times are authorised by the Registered

Manager.

6.2 Blasting does not occur at night except for

blasting to remove obstructions in crushers,

making workings safe, or firing misfired holes if

permission is received from the Quarry

Manager or his representative in every case.

6.3 The manager determines blasting times and

any other controls necessary where blasting is

likely to constitute a public nuisance in a built

up area.

6.4 There is a procedure for firing the shot.

6.5 A pre-blast meeting is held between the

shotfirer, blast guards and the blast controller.

6.6 The shotfirer cannot proceed with the blast

without the consent of the blast controller.

6.7 Personnel cannot re-enter the blast exclusion

zone until the “All Clear” is given by the

shotfirer.

Explosives: Surface transport, use and disposal audit

Page 6 of 9

Department of Mines, Industry Regulation and Safety Resources Safety

7 HANDLING MISFIRES

Point Standard Standard met Comments

7.1 There is a written procedure that provides a

safe system of entry and inspection for misfires

before resuming normal work in an area that

has just been blasted.

7.2 There is a procedure in place for dealing with

misfires.

7.3 Inspections carried out for misfires and any

actions taken as a result of misfires are

recorded in the record book.

7.4 Misfires not detected when the "All Clear" is

given are reported to the Chief Officer (for

Dangerous Goods).

8 ELECTRIC, ELECTRONIC BLASTING AND SIGNAL TUBE FIRING

Point Standard Standard met Comments

8.1 Only suitable exploders complying with

AS2187.2 are used when firing electrically or

electronically.

8.2 A system is in place that ensures that

exploders are tested and maintained in good

working order.

8.3 Only suitable circuit testers complying with

AS2187.2 are used when firing electrically or

electronically.

8.4 A system is in place that ensures that circuit

testers are maintained in good and efficient

condition.

Explosives: Surface transport, use and disposal audit

Page 7 of 9

Department of Mines, Industry Regulation and Safety Resources Safety

8.5 There is a written procedure in place that

provides a safe system of connection, testing

and initiation.

9 EXTERNAL ELECTRICAL HAZARDS

Point Standard Standard met Comments

9.1 There is a system in place for the ceasing of

charging and firing and withdrawal of

personnel in the event of a threat from an

electrical storm.

9.2 There is a system in place to eliminate hazards

caused by premature initiation of detonators by

electro-magnetic radiation, static electricity or

any other electrical apparatus.

10 BLASTING IN REACTIVE GROUND

Point Standard Standard met Comments

10.1 The procedures used for charging and firing in

oxidising or reactive ground and the

precautions taken are in accordance with the

manufacturer's or supplier's recommendations.

10.2 Tests are conducted on the reactive ground to

determine the level of reactivity in accordance

with AEISG code on Elevated temperature and

reactive ground.

10.3 The District Inspector is notified of any blasting

that is to be done in oxidising or reactive

ground.

Explosives: Surface transport, use and disposal audit

Page 8 of 9

Department of Mines, Industry Regulation and Safety Resources Safety

11 DISPOSAL

Point Standard Standard met Comments

11.1 There is a procedure for the disposal of old or

damaged explosives.

11.2 The procedure for disposing explosives

complies with AS 2187.2.

Explosives: Surface transport, use and disposal audit

Page 9 of 9

You might also like

- 5 JHA On Rock BlastingDocument6 pages5 JHA On Rock Blastingarylananyla100% (1)

- Accounting Cycle of A Merchandising BusinessDocument54 pagesAccounting Cycle of A Merchandising BusinessKim Flores100% (1)

- Manual 13-026Document10 pagesManual 13-026lipNo ratings yet

- 12-JSA Pipe Erection Work - Existing Pipe RackDocument4 pages12-JSA Pipe Erection Work - Existing Pipe RackSwaminathan ThayumanavanNo ratings yet

- Battle Area Clearance PDFDocument0 pagesBattle Area Clearance PDFZelwisNo ratings yet

- Guidance On The Safe Use of Explosives in QuarriesDocument9 pagesGuidance On The Safe Use of Explosives in QuarriesRisantoNo ratings yet

- MRTS55Document11 pagesMRTS55pabulumzengNo ratings yet

- Al-WAREED Engineering (PVT) LTD Sand Blasting - ManualDocument9 pagesAl-WAREED Engineering (PVT) LTD Sand Blasting - ManualMalik RiazNo ratings yet

- Surface Blasting Safety Procedures: I PurposeDocument21 pagesSurface Blasting Safety Procedures: I PurposeFuzail AyazNo ratings yet

- 02sop eDocument2 pages02sop ewingwidiatmokoNo ratings yet

- Del 861117751920793Document9 pagesDel 861117751920793Varahi VigneshNo ratings yet

- Site Law Application - Final - 9.27.17 - Chapter 20 - BlastingDocument7 pagesSite Law Application - Final - 9.27.17 - Chapter 20 - BlastingJaya SuriyaNo ratings yet

- Placard ExplosivesDocument1 pagePlacard ExplosivesAdrian MartínezNo ratings yet

- Lndialz: Excavation Work - Code of Safety (Document15 pagesLndialz: Excavation Work - Code of Safety (abhisk04gmailcomNo ratings yet

- SQA Blast Management Plan - Alafua QuarryDocument7 pagesSQA Blast Management Plan - Alafua Quarryjadan tupuaNo ratings yet

- Attachment 8 - Mohave BLASTING PLAN Draft - 508Document9 pagesAttachment 8 - Mohave BLASTING PLAN Draft - 508Willie Tumoe100% (1)

- JSA For Crane Columan Foundation - AB.1Document9 pagesJSA For Crane Columan Foundation - AB.1hse2No ratings yet

- Group 3 Excavation SafetyDocument72 pagesGroup 3 Excavation SafetyRohadzma N. NajebNo ratings yet

- Training Manual For Risk Assessment in Cement Plants - Part2Document10 pagesTraining Manual For Risk Assessment in Cement Plants - Part2Kamran ZafarNo ratings yet

- Codes of Practice For BMDDocument8 pagesCodes of Practice For BMDKuldeep Singh100% (1)

- POTCTE5 NRiskasessmentDocument27 pagesPOTCTE5 NRiskasessmentvidhya sagarNo ratings yet

- SOP-Charging, Stemming & BlastingDocument11 pagesSOP-Charging, Stemming & BlastingtrilokNo ratings yet

- Blasting AwarenessDocument74 pagesBlasting AwarenessSaurav ChhabraNo ratings yet

- Safety Procedure For Pile TestDocument2 pagesSafety Procedure For Pile TestIsna MuthoharohNo ratings yet

- Management Health and Safety Risk Assessment: ClientDocument3 pagesManagement Health and Safety Risk Assessment: ClientMohammed MuneebNo ratings yet

- OUI87 C2 DRisk Assessment PlanDocument12 pagesOUI87 C2 DRisk Assessment PlanMarianne JardinianoNo ratings yet

- Preventive Measures Against Hazards in Work Places 5Document7 pagesPreventive Measures Against Hazards in Work Places 5Tinku ChakrabartyNo ratings yet

- Safe Working Procedure ExcavationsDocument4 pagesSafe Working Procedure ExcavationsMunaku TafadzwaNo ratings yet

- Part 4 ExcavationDocument6 pagesPart 4 ExcavationHana Seiadi100% (1)

- Kuwait Ordnance ManualDocument204 pagesKuwait Ordnance ManualProjection NisteNo ratings yet

- Action Plan and Control MeasuresDocument2 pagesAction Plan and Control MeasuresMalik Aamir XohailNo ratings yet

- Excavation Safety - Hazards and Precautions - Safety NotesDocument5 pagesExcavation Safety - Hazards and Precautions - Safety Notesaneethavils100% (1)

- Jsa PCC & RCCDocument2 pagesJsa PCC & RCCNilesh koliNo ratings yet

- CPA STIG 0403 Risk Assessment For Shoring Equipment 040901Document11 pagesCPA STIG 0403 Risk Assessment For Shoring Equipment 040901Budiraharjo SoepangatNo ratings yet

- 472415886 Jsa for Pipe Laying Water and Sewer 1Document1 page472415886 Jsa for Pipe Laying Water and Sewer 1nagavijayababu108No ratings yet

- Rock Blasting ProceduresDocument21 pagesRock Blasting ProceduresRajanbabu100% (1)

- D422 PDFDocument27 pagesD422 PDFpyiphyo peNo ratings yet

- Explosive Safety PR89POGC001Document10 pagesExplosive Safety PR89POGC001Nizar KhalidNo ratings yet

- 11.06 Task Risk Assessment (Tra) - ExampleDocument2 pages11.06 Task Risk Assessment (Tra) - ExampleAswad AzizNo ratings yet

- Work Method StatamentDocument4 pagesWork Method StatamentAmril Al RizaNo ratings yet

- 28032016NZPM1NAPAnnexure documentofRiskAssessmentDocument12 pages28032016NZPM1NAPAnnexure documentofRiskAssessmentMichaelNo ratings yet

- Handling of Misfires in MinesDocument4 pagesHandling of Misfires in Mineskanica maryNo ratings yet

- Job Procedure For Rock Blasting: Site Grading and Enabling Works For 5 Stream Alumina RefineryDocument9 pagesJob Procedure For Rock Blasting: Site Grading and Enabling Works For 5 Stream Alumina RefineryRishi RajNo ratings yet

- Section 1 - Simultaneous Operations: Madison Oil Turkey Policy and ProceduresDocument4 pagesSection 1 - Simultaneous Operations: Madison Oil Turkey Policy and ProceduresPark placeNo ratings yet

- Https Rdso - Indianrailways.gov - in Uploads Files GE-G-0016Document38 pagesHttps Rdso - Indianrailways.gov - in Uploads Files GE-G-0016vinodshukla25No ratings yet

- Risk Assessment For Shoring & Piling Operations - Aldridge Piling ...Document11 pagesRisk Assessment For Shoring & Piling Operations - Aldridge Piling ...محمود سعيدNo ratings yet

- Raft - MSDocument10 pagesRaft - MSabson pongNo ratings yet

- Annexure 2-2 Safety in Blasting:: 1. SupervisionDocument2 pagesAnnexure 2-2 Safety in Blasting:: 1. SupervisionManoj BishtNo ratings yet

- Safe Lifting Operating ProcedureDocument12 pagesSafe Lifting Operating ProcedureRafiullah KhanNo ratings yet

- JSA FOR WELDING, GRINDING, GAS CUTTINGDocument2 pagesJSA FOR WELDING, GRINDING, GAS CUTTINGm.rehanhseNo ratings yet

- Excavation For Interconnecting Pipe LineDocument7 pagesExcavation For Interconnecting Pipe LineKhyle Laurenz DuroNo ratings yet

- ExcavationDocument7 pagesExcavationAnandha BharathiNo ratings yet

- Jsa For Welding, Grinding, Gas CuttingDocument2 pagesJsa For Welding, Grinding, Gas Cuttingwahyu nugroho67% (3)

- OCEs and The Law - 221022Document7 pagesOCEs and The Law - 221022Darryl PriceNo ratings yet

- 619 Confined Space Rescue OperationsDocument9 pages619 Confined Space Rescue Operationstabish_khattakNo ratings yet

- Raft MSDocument9 pagesRaft MSSoe Moe AungNo ratings yet

- 733.learner No - IG2. 20.08.2020.OBE, DL, SaudiArabiaDocument11 pages733.learner No - IG2. 20.08.2020.OBE, DL, SaudiArabiaMominul hoqueNo ratings yet

- JOSOP 607 - Repair Procedure For Flowlines, Pipelines, Vessels, Tanks, Separators and Other EquipmentDocument7 pagesJOSOP 607 - Repair Procedure For Flowlines, Pipelines, Vessels, Tanks, Separators and Other EquipmentOrdu Henry Onyebuchukwu100% (1)

- Hse Manual: Entry Into Vessels and Confined SpacesDocument14 pagesHse Manual: Entry Into Vessels and Confined SpacesAmirNo ratings yet

- Method Statements For Construction of Masonry Lined Drains Rev 0Document13 pagesMethod Statements For Construction of Masonry Lined Drains Rev 0McDonald WesleyNo ratings yet

- Bombers' Training, and Application of Same in Trench WarfareFrom EverandBombers' Training, and Application of Same in Trench WarfareNo ratings yet

- Food Safety Culture Module BrochureDocument8 pagesFood Safety Culture Module Brochurejamil voraNo ratings yet

- 1MRK511313-BEN C en Product Guide Bay Control REC670 2.0Document107 pages1MRK511313-BEN C en Product Guide Bay Control REC670 2.0A1410 15No ratings yet

- Ur19017 Ur19093 CaseStudyDocument10 pagesUr19017 Ur19093 CaseStudyanon_980855279No ratings yet

- TSWDocument23 pagesTSWKiran Kagitapu100% (1)

- Fast Frequency Response From Smart Induction Motor Variable Speed DrivesDocument11 pagesFast Frequency Response From Smart Induction Motor Variable Speed DrivesAravind SNo ratings yet

- CH 02 Principle of ManagementDocument18 pagesCH 02 Principle of ManagementBhunesh Kumar100% (1)

- Assessment & Development Centre Workshop: Psyasia International'SDocument5 pagesAssessment & Development Centre Workshop: Psyasia International'SAditya BagaswaraNo ratings yet

- Derval Energy GB LowDocument6 pagesDerval Energy GB LowTahasinor TabrazNo ratings yet

- Function ModulesDocument2 pagesFunction ModulesMazin MahmoodNo ratings yet

- Gas Sweetening Processes: (1) 73000 Nm3/H (2) 139000 Nm3/H Peak (3) 1.57 Mnm3/D PeakDocument1 pageGas Sweetening Processes: (1) 73000 Nm3/H (2) 139000 Nm3/H Peak (3) 1.57 Mnm3/D PeakAjaykumarNo ratings yet

- Public Health Surveillance: Preparing For The FutureDocument40 pagesPublic Health Surveillance: Preparing For The FutureSusan BeachyNo ratings yet

- Final Business PlanDocument21 pagesFinal Business PlanJulie Mae BusarangNo ratings yet

- Brand Image: Peer InfluenceDocument3 pagesBrand Image: Peer InfluencePaula Vaness PangilinanNo ratings yet

- GearBoxes E DOC00071Document48 pagesGearBoxes E DOC00071Manikanta SwamyNo ratings yet

- 陶瓷柜子智能Document30 pages陶瓷柜子智能David SunNo ratings yet

- Ideas and Not Solution - Enabling Innovatoin Through Internal Crowsourcing in The Tata GroupDocument9 pagesIdeas and Not Solution - Enabling Innovatoin Through Internal Crowsourcing in The Tata GroupfarrelnaufalrahmanNo ratings yet

- Secretary of Justice Cuevas Vs Bacal Case DigestDocument2 pagesSecretary of Justice Cuevas Vs Bacal Case DigestRyanNo ratings yet

- Advantages and Uses of Annual WorthII)Document46 pagesAdvantages and Uses of Annual WorthII)my.nafi.pmp5283100% (1)

- SYLLDocument1 pageSYLLJ Madhansharma JeyarajNo ratings yet

- Colpitts OscillatorDocument4 pagesColpitts OscillatorAnimesh Bhanja100% (1)

- H. Aronson & Co., Inc. v. Associated Labor UnionDocument4 pagesH. Aronson & Co., Inc. v. Associated Labor UnionChing ApostolNo ratings yet

- MelanieresumeDocument1 pageMelanieresumeapi-253574700No ratings yet

- MCi Guardrail E-Catalog (Upp)Document6 pagesMCi Guardrail E-Catalog (Upp)Nusaibah YusofNo ratings yet

- Bhel My Question PaperDocument72 pagesBhel My Question PaperNITHYAPREMININo ratings yet

- Owner'S Manual: F50D T50D F60D T60DDocument80 pagesOwner'S Manual: F50D T50D F60D T60Deduardo garciaNo ratings yet

- A Presentation On PEDocument28 pagesA Presentation On PEanishNo ratings yet

- Case Study On Sab Miller IndiaDocument163 pagesCase Study On Sab Miller Indiaசக்தி தாசன்No ratings yet

- Unit3 Images&GraphicsDocument23 pagesUnit3 Images&GraphicsNec'x RoseteNo ratings yet

- German DWA Worksheet A 143, Part 2 What S New in Structural Design of CIPP?Document16 pagesGerman DWA Worksheet A 143, Part 2 What S New in Structural Design of CIPP?jeovanNo ratings yet