Professional Documents

Culture Documents

Ds Te6002 en Co

Ds Te6002 en Co

Uploaded by

Muhammad Haroon AsgharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ds Te6002 en Co

Ds Te6002 en Co

Uploaded by

Muhammad Haroon AsgharCopyright:

Available Formats

Temperature

Resistance thermometer

For additional thermowell

Model TR10-B

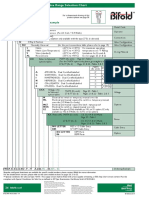

WIKA data sheet TE 60.02

for further Approvals,

see page 16

Applications

■ Machine building, plant and vessel construction

■ Energy and power plant technology

■ Chemical industry

■ Food and beverage industry

■ Sanitary, heating and air-conditioning technology

Special features

■ Sensor ranges from -196 ... +600 °C [-320 ... +1,112 °F]

■ For mounting in all standard thermowell designs

■ Spring-loaded measuring insert (replaceable)

■ Pt100 or Pt1000 sensors

■ Explosion-protected versions are available for many

approval types

Description

Resistance thermometers in this series can be combined

with a large number of thermowell designs. Operation without

thermowell is only recommended in certain applications.

A wide variety of possible combinations of Pt100 or

Pt1000 sensor, connection head, insertion length, neck

length, connection to thermowell etc. are available for the

thermometers; suitable for any thermowell dimension and

any application.

Fig. left: Model TR10-B with BSZ connection head

A large number of different explosion-protected approvals Fig. right: Model TR10-B with 1/4000 connection head

are available for the TR10-B.

Optionally we can fit analogue or digital transmitters from the

WIKA range into the connection head of the TR10-B.

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 1 von 21

Data sheets showing similar products:

Thermocouple for additional thermowell; model TC10-B; see data sheet TE 65.02

Threaded resistance thermometer; model TR10-C; see data sheet TE 60.03

Threaded thermocouple; model TC10-C; see data sheet TE 65.03

Representation of the components

3160645.08

Legend:

Connection head

Neck tube

Connection to thermowell

Measuring insert (TR10-A)

Terminal block/transmitter (option)

Transmitter (option)

Overview of approvals for explosion protection

Approval Explosion protection

Ex i (gas) Ex i (dust) Ex e (gas) Ex t (dust) Ex nA (gas)

Zone 0, 1, 2 Zone 20, 21, 22 Zone 1, 2 Zone 21, 22 Zone 2

ATEX x x x x x

IECEx x x x x x

EAC x x - - x

Ex Ukraine x x - - -

INMETRO x x - - -

CCC x x x - -

KCs x - - - -

PESO x - - - -

→ For detailed information, see page „Approvals“ on page 16

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 2 von 21

Measuring element

Measuring element

Type of measuring element Pt100, Pt1000 1)

Measuring current 0.1 ... 1.0 mA

Connection method

Single elements Dual elements

1 x 2-wire 2 x 2-wire

red red

white white

black

yellow

1 x 3-wire red 2 x 3-wire red

red red

white white

black

black

yellow

1 x 4-wire red 2 x 4-wire 2) red

red red

white white

white white

black

black

yellow

yellow

Validity limits of the class accuracy in accordance with IEC 60751

Class B Wire-wound ■ -196 ... +600 °C [-321 ...

± (0.30 + 0.0050 | t |) 4) +1112 °F]

■ -196 ... +450 °C [-321 ... +842

°F]

Thin film ■ -50 ... +500 °C [-58 ... +932 °F]

■ -50 ... +250 °C [-58 ... +482 °F]

Class A 3) Wire-wound -100 ... +450 °C [-148 ... +842 °F]

± (0.15 + 0.0020 | t |) 4)

Thin film -30 ... +300 °C [-22 ... +572 °F]

Class AA 3) Wire-wound -50 ... +250 °C [-58 ... +482 °F]

± (0.10 + 0.0017 | t |) 4)

Thin film 0 ... 150 °C [32 ... 302 °F]

1) Pt1000 only available as a thin-film measuring resistor ■ The combinations of a 2-wire connection with class A or

2) Not for 3 mm [0.118 in] diameter

3) Not for 2-wire connection method class AA are not permissible, since the lead resistance of

4) | t | is the numerical value of the temperature in °C without consideration of the sign

the MI cable and the connection lead negates the higher

sensor accuracy.

→ For detailed specifications for Pt100 sensors, see techni-

cal information IN 00.17 at www.wika.com. Maximum probe length including connection cable:

■ Class B, 3-wire connection: ~ 30 m [98 ft]

The table shows the temperature ranges listed in the respec- ■ Class A, 3-wire connection: ~ 10 m [33 ft]

tive standards, in which the tolerance values (class accura- ■ Class AA, 3-wire connection: ~ 3 m [10 ft]

cies) are valid.

■ Longer probe/cable lengths should be designed with a

4-wire connection, since this connection method has no

length effect on the accuracy.

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 3 von 21

Connection head

■ European designs per EN 50446 / DIN 43735

Model Material Cable inlet Ingress protec- Cap Surface Connec-

thread size tion (max.) 1) tion to

IEC/EN 60529 neck tube

BS Aluminium ■ M20 x 1.5 IP65 3) Flat cover with Blue, painted ■ M24 x 1.5

■ ½ NPT 2 screws (RAL 5022) ■ ½ NPT

JS BS BSZ BSZ, BSZ-K Aluminium

BSZ-H, BSZ-HK ■ M20 x 1.5

BSS IP65 3) BSS-H Spherical

BVS hinged BVS (NuG)

Blue, painted M24 x 1.5

■1/4000 5/6000

■ ½ NPT cover with cylinder (RAL 5022) ■ ½ NPT

head screw

BSZ-K Plastic ■ M20 x 1.5 IP65 Spherical hinged Black M24 x 1.5

BS BSZ, BSZ-K BSZ-H, BSZ-HK BSS ■ ½ NPT BSS-H BVS cover with cylinder

BVS (NuG) 1/4000 5/6000 7/8000 7

head screw

BSZ-H Aluminium ■ M20 x 1.5 IP65 3) Raised hinged Blue, painted ■ M24 x 1.5

■ ½ NPT cover with cylinder (RAL 5022) ■ ½ NPT

head screw

BSZ-H Aluminium ■ 2 x M20 x 1.5 IP65 3) Raised hinged Blue, painted M24 x 1.5

(2 x cable ■ 2 x ½ NPT cover with cylinder (RAL 5022)

BSZ, BSZ-K BSZ-H, BSZ-HK outlet) BSS BSS-H BVS BVS (NuG) head screw 5/6000

1/4000 7/8000 7/8000 DIH50 andere Anschlussge

BSZ-H / DIH10 2) Aluminium ■ M20 x 1.5 IP65 Raised hinged Blue, painted ■ M24 x 1.5

■ ½ NPT cover with cylinder (RAL 5022) ■ ½ NPT

head screw

BSZ-HK Plastic ■ M20 x 1.5 IP65 Raised hinged Black M24 x 1.5

■ ½ NPT cover with cylinder

head screw

BSS Aluminium ■ M20 x 1.5 IP65 Spherical hinged Blue, painted ■ M24 x 1.5

■ ½ NPT cover with clamp- (RAL 5022) ■ ½ NPT

ing lever

BSS-H Aluminium ■ M20 x 1.5 IP65 Raised hinged Blue, painted ■ M24 x 1.5

BSZ-H, BSZ-HK BSS BSS-H BVS BVS (NuG) 1/4000 5/6000 7/8000 7/8000 DIH50 andere Anschlussgehäuse KN4-P B

■ ½ NPT cover with clamp- (RAL 5022) ■ ½ NPT

ing lever

BVS Stainless M20 x 1.5 IP65 Precision-cast Natural finish, M24 x 1.5

BSS BSS-H BVS BVS (NuG) 1/4000 5/6000 7/8000 7/8000 DIH50 andere Anschlussgehäuse KN4-P BVC

steel screw-on lid electropol-

ished

BSS-H BVS BVS (NuG) 1/4000 5/6000 7/8000 7/8000 DIH50 andere Anschlussgehäuse KN4-P BVC

Further thread sizes on request

Model Explosion protection

Without Ex i (gas) Ex i (dust) Ex e (gas) Ex t (dust) Ex nA (gas)

Zone 0, 1, 2 Zone 20, 21, Zone 1, 2 Zone 21, 22 Zone 2

22

BS x x x - - -

BSZ x x x x 4) x 4) x 5)

BSZ-H x x x x 4) x 4) x 5)

BSZ-H (2 x cable outlet) x x x x 4) x 4) x 5)

BSZ-H / DIH10 2) x x - - - -

BSS x x - - - -

BSS-H x x - - - -

BVS x x - - - -

BSZ-K x x - - - -

BSZ-HK x x - - - -

1) IP ingress protection of the connection head. The IP ingress protection of the complete TR10-B instrument does not necessarily have to correspond to the connection head.

2) LED display DIH10

3) Ingress protections, describing temporary or permanent immersion, on request

4) Only ATEX

5) Only ATEX and EAC

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 4 von 21

■ International connection heads

Model Material Cable inlet Ingress Cap Surface Connection to

thread size protection neck tube

(max.) 1)

IEC/EN 60529

KN4-A Aluminium ■ ½ NPT IP65 3) Screw-on lid Blue, painted ■ M24 x 1.5

■ M20 x 1.5 (RAL 5022) ■ ½ NPT

KN4-P 2) Polypropylene ½ NPT IP65 3) Screw-on lid White ½ NPT

1/4000 F Aluminium ■ ½ NPT IP66 3) Screw-on lid Blue, painted ½ NPT

ndere Anschlussgehäuse KN4-P BVC

■ ¾ NPT (RAL 5022)

■ M20 x 1.5

1/4000 S Stainless steel ■ ½ NPT IP66 3) Screw-on lid Natural finish ½ NPT

VS (NuG) 1/4000 5/6000 7/8000 ■ ¾ NPT andere Anschlussgehäuse

7/8000 DIH50 KN4-P BVC

■ M20 x 1.5

7/8000 W Aluminium ■ ½ NPT IP66 3) Screw-on lid Blue, painted ½ NPT

■ ¾ NPT (RAL 5022)

■ M20 x 1.5

7/8000 S Stainless steel ■ ½ NPT IP66 3) Screw-on lid Natural finish ½ NPT

5/6000 7/8000 7/8000 DIH50 andere Anschlussgehäuse ■KN4-P¾ NPT BVC

■ M20 x 1.5

7/8000 W / Aluminium ■ ½ NPT IP66 3) Screw-on lid Blue, painted ½ NPT

DIH50 4) ■ ¾ NPT (RAL 5022)

■ M20 x 1.5

7/8000 S / Stainless steel ■ ½ NPT IP66 3) Screw-on lid Natural finish ½ NPT

7/8000 7/8000 DIH50 DIH50 4)

andere Anschlussgehäuse KN4-P ■BVC ¾ NPT

■ M20 x 1.5

PIH-L 5) Aluminium ■ 1/2 NPT / closed IP66 3) Screw-on lid, Blue upper ■ 1/2 NPT

■ M20 x 1.5 / flat body, painted ■ M20 x 1.5

closed (RAL 5022)

■ 2 x 1/2 NPT Grey lower

■ 2 x M20 x 1.5 body, painted

(RAL 7032)

PIH-H 5) Aluminium ■ 1/2 NPT IP66 3) Screw-on lid, Blue upper ■ 1/2 NPT

■ M20 x 1.5 high body, painted ■ M20 x 1.5

■ 2 x 1/2 NPT (RAL 5022)

■ 2 x M20 x 1.5 Grey lower

body, painted

(RAL 7032)

Model Explosion protection

Without Ex i (gas) Ex i (dust) Ex e (gas) Ex t (dust) Ex nA (gas)

Zone 0, 1, 2 Zone 20, 21, Zone 1, 2 Zone 21, 22 Zone 2

22

KN4-A x x - - - -

KN4-P 2) x - - - - -

1/4000 F x x x x x x

1/4000 S x x x x x x

7/8000 W x x x x x x

7/8000 S x x x x x x

7/8000 W / DIH50 4) x x x - - -

7/8000 S / DIH50 4) x x x - - -

PIH-L / PIH-H 5) x x x x x x

1) IP ingress protection of the connection head. The IP ingress protection of the complete TR10-B instrument does not necessarily have to correspond to the connection head.

2) On request

3) Suitable sealing/cable gland required

4) LC display DIH50

5) Available from Q2/2023

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 5 von 21

Connection head with digital indicator

Connection head BSZ-H with LED display model DIH10 Connection head 7/8000 W with LC display

→ see data sheet AC 80.11 model DIH50

→ see data sheet AC 80.10

To operate the digital displays, a transmitter with a 4 ... 20 mA output is always required.

Cable inlet

Cable inlet Colour Ingress Cable inlet Min./max. ambient

protection (max.) thread size temperature

IEC/EN 60529 1)

Standard cable inlet 2) Natural IP65 ■ M20 x 1.5 -40 ... +80 °C

finish ■ ½ NPT [-40 ... +176 °F]

Plastic cable gland ■ Black IP66 3) ■ M20 x 1.5 -40 ... +80 °C

(cable Ø 6 ... 10 mm) 2) ■ Grey ■ ½ NPT [-40 ... +176 °F]

Plastic cable gland ■ Light IP66 3) ■ M20 x 1.5 ■ -20 ... +80 °C

(cable Ø 6 ... 10 mm), Ex e 2) blue ■ ½ NPT [-4 ... +176 °F]

■ Black ■ -40 ... +70 °C

[-40 ... +158 °F]

Nickel-plated brass cable gland Natural IP66 3) ■ M20 x 1.5 -60 4) / -40 ... +80 °C

(cable Ø 6 ... 12 mm) finish ■ ½ NPT [-76 / -40 ... +176 °F]

Nickel-plated brass cable gland Natural IP66 3) ■ M20 x 1.5 -60 4) / -40 ... +80 °C

(cable Ø 6 ... 12 mm), Ex e finish ■ ½ NPT [-76 / -40 ... +176 °F]

Stainless steel cable gland Natural IP66 3) ■ M20 x 1.5 -60 4) / -40 ... +80 °C

(cable Ø 7 ... 12 mm) finish ■ ½ NPT [-76 / -40 ... +176 °F]

Stainless steel cable gland Natural IP66 3) ■ M20 x 1.5 -60 4) / -40 ... +80 °C

(cable Ø 7 ... 12 mm), Ex e finish ■ ½ NPT [-76 / -40 ... +176 °F]

Plain threaded - IP00 ■ M20 x 1.5 -

■ ½ NPT

2 x plain threaded 5) - IP00 ■ 2 x M20 x 1.5 -

■ 2 x ½ NPT

Junction box M12 x 1 (4-pin) 6) - IP65 M20 x 1.5 -40 ... +80 °C

[-40 ... +176 °F]

Sealing plugs for shipping Transparent - ■ M20 x 1.5 -40 ... +80 °C

■ ½ NPT [-40 ... +176 °F]

1) IP ingress protection of the cable gland. The IP protection of the complete TR10-B

instrument does not necessarily have to correspond to the cable gland.

2) Not available for BVS connection head

3) Ingress protections, describing temporary or permanent immersion, on request

4) Special version on request (explosion-protected versions only available with specific

approvals)

5) Only for BSZ-H connection head

6) Not available for ½ NPT thread size cable entry

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 6 von 21

Cable inlet Explosion protection

With- Ex i (gas) Ex i (dust) Ex e (gas) Ex t (dust) Ex nA (gas)

out Zone 0, 1, 2 Zone 20, 21, 22 Zone 1, 2 Zone 21, 22 Zone 2

Standard cable inlet 1) x x - - - -

Plastic cable gland 1) x x - - - -

Plastic cable gland (light blue), Ex e 1) x x x - - -

Plastic cable gland (black), Ex e 1) x x x x x x

Brass cable gland, nickel-plated x x x - - -

Brass cable gland, nickel-plated, Ex e x x x x x x

Stainless steel cable gland x x x - - -

Stainless steel cable gland, Ex e x x x x x x

Plain threaded x x x 5) x 5) x 5) x 5)

2 x plain threaded 2) x x x 5) x 5) x 5) x 5)

Junction box M12 x 1 (4-pin) 3) x x 4) x 4) - - -

Sealing plugs for shipping Not applicable, transport protection 5)

1) Not available for BVS connection head

2) Only for BSZ-H connection head

3) Not available for ½ NPT thread size cable entry

4) With appropriate mating connector connected

5) Suitable cable gland required for operation

Measuring insert

Measuring insert

Versions Vibration-resistant sheathed measuring cable (MI cable)

Standard Standard soldering lugs

Option Recessed soldering lugs

Optimal heat transfer Requirement ■ Correct measuring insert length

■ Correct measuring insert diameter

Bore diameter of the Max. 1 mm [0.039 in] larger than the measuring insert diameter

thermowell

Gap width With gap widths > 0.5 mm [> 0.020 in] between thermowell and measuring insert:

→ Negative impact on heat transfer

→ Unfavourable response behaviour of the thermometer

Insertion length When fitting the measuring insert into a thermowell, it is very important to determine the correct insertion

length (= thermowell length for tip thicknesses of ≤ 5.5 mm [≤ 0.217 in]). In order to ensure that the measur-

ing insert is firmly pressed down onto the bottom of the thermowell, the insert must be spring-loaded (spring

travel: max. 10 mm [0.394 in]).

Spring travel Max. 10 mm [0.394 in]

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 7 von 21

Dimensions in mm [in]

1 2 3 4 Design prepared

5 for trans- 6

Design

7

with 8

mitter mounting mounted

transmitter

[1.57]

40

3159796.09

Ø42* Measuring insert with

[1.65] sleeve in the sensor Ø33

area [1.30]

Ø6

[0.24]

Ød

l5

nichtbendable

biegbar

[1.38 -2.36]

Ø8

≈ 35 -60

[0.31]

not

* Ø 45 mm [1.77 in] for 2 x Pt100 in 4-wire connection

Legend

Connection terminal Insulation washer

Spring-loaded screw Terminal plate

Measuring insert diameter Ø d in mm Index per DIN 43735 Tolerance in mm Sheath material

3 [0.118 in] Standard 30 3 ±0.05 ■ 1.4571

■ 316L

0

6 [0.236 in] Standard 60 6 -0.1

8 [0.315 in] Standard - 8 0 ■ 1.4571

-0.1

(6 mm [0.236 in] with

sleeve)

8 [0.315 in] Standard 80 8 -0.10 ■ 1.4571

■ 316L

Legend:

l5 Measuring insert length

Ø d Measuring insert diameter

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 8 von 21

Transmitter

Transmitter models Model T15 Model T32

Transmitter data sheet TE 15.01 TE 32.04

Figure

Output

4 ... 20 mA x x

HART® protocol - x

Connection method ■ 1 x 2-wire ■ 1 x 2-wire

■ 1 x 3-wire ■ 1 x 3-wire

■ 1 x 4-wire ■ 1 x 4-wire

■ 2 x 2-wire

Measuring current < 0.2 mA < 0.3 mA

Explosion protection Option Option

Mounting types

Mounting onto the measuring insert With mounting on the measuring insert, the transmitter replaces the terminal block and

is fixed directly to the terminal plate of the measuring insert.

Mounted within the cover of the connection Mounting the transmitter in the cover of the connection head is preferable to mounting it

head on the measuring insert. With this mounting type, for one, a better thermal insulation is

ensured, and in addition, exchange and mounting for servicing is simplified.

Mounting types

Mounting onto the measuring insert Mounted within the cover of the connection head

Measuring insert with mounted Measuring insert prepared for

transmitter (here: Model T32) transmitter mounting

When using dual sensors in conjunction with a single trans-

mitter, sensor 1 is connected to the transmitter. The connec-

tion leads of sensor 2 (insulated against short-circuits)

protrude loosely into the connection head.

The exception is the combination of a 2 x 2-wire in conjunc-

tion with a T32 transmitter in the “redundancy” configuration.

In this case, both sensors are connected to the T32.

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 9 von 21

Possible mounting positions for trans- Model T15 Model T32

mitters

BS ○ -

BSZ ○ ○

BSZ-H ● ●

BSZ-H (2x cable outlet) ● ●

BSZ-H / DIH10 ○ ○

BSS ○ ○

BSS-H ● ●

BVS ○ ○

BSZ-K ○ ○

BSZ-HK ● ●

KN4-A ○ ○

KN4-P ○ ○

1/4000 ○ ○

7/8000 ○ ○

7/8000 / DIH50 ○ ○

PIH-L / PIH-H ○ ○

Legend:

○ Mounted instead of terminal block

● Mounted within the cover of the connection head

- Mounting not possible

The mounting of a transmitter on the measuring insert is possible with all the connection heads listed here. The fitting of a

transmitter in the (screw) cap of a connection head is not possible. Mounting of 2 transmitters on request.

For a correct determination of the overall measuring deviation, the sensor and transmitter measuring deviations must be

added.

Functional safety with model T32 temperature

transmitter (option)

SIL

IEC 61508 / IEC 61511

In safety-critical applications, the entire measuring chain

must be taken into consideration in terms of the safety

parameters. The SIL classification allows the assessment of

the risk reduction achieved by the safety installations.

Selected TR10-B resistance thermometers, in combination

with a suitable temperature transmitter (e.g. model T32.1S,

TÜV certified SIL version for protection systems developed

in accordance with IEC 61508), are suitable as sensors for

safety functions to SIL 2.

For SIL 3 applications, WIKA recommends the use of two

individual TR10-B with one SIL-certified T32 transmitter

connected to each.

→ For detailed specifications, see technical information

IN 00.19 at www.wika.com.

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 10 von 21

Neck tube

Versions

Neck tube design Diameter Connection to head Connection to thermowell Material

Neck tube per DIN 43772 ■ 12 x 1.5 mm M24 x 1.5 ■ Mounting thread 1.4571

[0.472 x 0.059 in] (swivel connection) ■ Compression fitting

■ 12 x 2.5 mm ■ Union nut

[0.472 x 0.098 in] ■ Male nut

■ Without threaded connection, plain

14 x 2.5 mm M24 x 1.5 ■ Mounting thread 1.4571

[0.551 x 0.098 in] (swivel connection) ■ Union nut

■ Male nut

Neck tube with counter nut to 14 x 2.5 mm M20 x 1.5 Mounting thread 1.4571

head [0.551 x 0.098 in] (with counter nut)

Double threaded hex bushing - M24 x 1.5, ½ NPT Mounting thread 1.4571

(with hexagonal spanner flats)

“Nipple-union-nipple” neck ~ 22 mm [~ 0.9 in] ½ NPT Mounting thread 316

tube

~ 27 mm [~ 1.1 in] ¾ NPT Mounting thread 316

(nipple-union-nipple)

Double threaded hex bushing ~ 22 mm [~ 0.9 in] ½ NPT Mounting thread 316

(tube section)

~ 27 mm [~ 1.1 in] ¾ NPT Mounting thread 316

Thread sizes

Neck tube design Diameter Thread to the thermowell

Neck tube per DIN 43772 ■ 12 x 1.5 mm ■ G½B

[0.472 x 0.059 in] ■ G¾B

■ 12 x 2.5 mm ■ G¼B

[0.472 x 0.098 in] ■ M20 x 1.5

■ M18 x 1.5

■ M14 x 1.5

■ ½ NPT

■ ¾ NPT

■ G ½ B compression fitting (metal

ferrule)

■ G ¾ B compression fitting (metal

ferrule)

■ M18 x 1.5 compression fitting (metal

ferrule)

■ M20 x 1.5 compression fitting (metal

ferrule)

■ G ½ B union nut

■ G ¾ B union nut

■ M20 x 1.5 union nut

■ G ½ B male nut

■ G ¾ B male nut

■ M20 x 1.5 male nut

■ Without threaded connection, plain

Neck tube per DIN 43772 14 x 2.5 mm ■ G½B

[0.551 x 0.098 in] ■ G¾B

■ G¼B

■ M20 x 1.5

■ M18 x 1.5

■ M14 x 1.5

■ ½ NPT

■ ¾ NPT

■ G ½ B union nut

■ G ¾ B union nut

■ M20 x 1.5 union nut

■ G ½ B male nut

■ G ¾ B male nut

■ M20 x 1.5 male nut

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 11 von 21

Neck tube design Diameter Thread to the thermowell

Neck tube with counter nut to head 14 x 2.5 mm ■ ½ NPT

[0.551 x 0.098 in] ■ ¾ NPT

■ G½B

■ G¾B

■ G¼B

■ M14 x 1.5

■ M18 x 1.5

■ M20 x 1.5

Double threaded hex bushing (with hexagonal - ■ G½B

spanner flats) ■ G¾B

■ G¼B

■ ½ NPT

■ ¾ NPT

■ M14 x 1.5

■ M18 x 1.5

■ M20 x 1.5

“Nipple-union-nipple” neck tube ~ 22 mm [~ 0.9 in] ½ NPT

~ 27 mm [~ 1.1 in] ¾ NPT

Double threaded hex bushing (tube section) ~ 22 mm [~ 0.9 in] ½ NPT

~ 27 mm [~ 1.1 in] ¾ NPT

Neck lengths

Neck tube design Neck length Min. / Max. neck length

Neck tube per DIN 43772 150 mm [~ 6 in] ■ 30 mm [~ 1.2 in]

■ 500 mm [~ 20 in]

Neck tube per DIN 43772, plain 150 mm [~ 6 in] ■ 75 mm [~ 3 in]

■ 900 mm [~ 35 in]

Neck tube with counter nut to head 150 mm [~ 6 in] ■ 75 mm [~ 3 in]

■ 250 mm [~ 10 in]

Double threaded hex bushing (with hexagonal spanner flats)

M24 x 1.5 to connection head, 13 mm [0.512 in] -

parallel thread to thermowell

1/2 NPT to connection head, ~ 25 mm [1 in] -

parallel thread to thermowell

M24 x 1.5 to connection head, ~ 25 mm [1 in] -

tapered thread to thermowell

1/2 NPT to connection head, ~ 25 mm [1 in] -

tapered thread to thermowell

“Nipple-union-nipple” neck tube ~ 150 mm [6 in] ■ ~ 75 mm [3 in]

■ ~ 250 mm [10 in]

Double threaded hex bushing (tube section) ~ 50 mm [2 in] ■ ~ 50 mm [2 in]

■ ~ 250 mm [10 in]

The neck tube is screwed into the connection head. The neck length depends on the intended use. Usually an isolation is

bridged by the neck tube. Also, in many cases, the neck tube serves as a cooling element between the connection head and

the medium, in order to protect a possible built-in transmitter from high medium temperatures.

Other versions on request.

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 12 von 21

Operating conditions

Operating conditions

Ambient and storage temperature ■ -40 ... +80 °C [-40 ... +176 °F]

■ -601) ... +80 °C [-76 ... +176 °F]

Vibration resistance The information on vibration resistance refers to the tip of the measuring insert.

→ For detailed specifications on the vibration resistance of Pt100 sensors, see techni-

cal information IN 00.17 at www.wika.com.

1) Special version on request (explosion-protected versions only available with specific approvals)

Examples of vibration resistance

Measuring insert Measuring insert

∅ 6 mm [0.236 in] ∅ 3 mm [0.118 in]

Sensor ■ 1 x Pt100 (thin film) ■ 1 x Pt100 (thin film)

■ 2 x Pt100 (thin film) ■ 2 x Pt100 (thin film)

Connection method ■ 3-wire ■ 3-wire

■ 4-wire ■ 4-wire (only 1 x Pt100)

Diameter ∅ 6 mm [0.236 in] ∅ 3 mm [0.118 in]

Insertion length (A) + neck length (N) 100 ... 1,100 mm [~ 4 … 43 in] 100 ... 1,100 mm [~ 4 … 43 in]

Material ■ Stainless steel 1.4571 ■ Stainless steel 1.4571

■ Stainless steel 316L ■ Stainless steel 316L

Vibration resistance

Standard probe tip, x x

(max. 3 g amplitude / 6 g peak-to-peak)

Vibration-resistant probe tip x x

(max. 10 g amplitude / 20 g peak-to-peak)

Highly vibration-resistant probe tip On request On request

(max. 25 g amplitude / 50 g peak-to-peak)

Extremely vibration-resistant probe tip On request -

(max. 50 g amplitude / 100 g peak-to-peak)

Vibration resistance of thermometers in other configurations as well as vibration resistance higher than 50 g amplitude /

100 g tip - tip on request.

The thermometer designs listed above describe instruments in standard designs.

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 13 von 21

IP ingress protection per IEC/EN 60529

First index number Degree of protection / Short de- Test parameters

scription

Degrees of protection against solid foreign bodies (defined by the 1st index number)

5 Dust-protected Per IEC/EN 60529

6 Dust-tight Per IEC/EN 60529

Degrees of protection against water (defined by the 2nd index number)

4 Protected against splash water Per IEC/EN 60529

5 Protected against water jets Per IEC/EN 60529

6 Protected against strong water jets Per IEC/EN 60529

7 1) Protected against the effects of temporary Per IEC/EN 60529

immersion in water

8 1) Protected against the effects of perma- As agreed upon

nent immersion in water

1) Ingress protections, describing temporary or permanent immersion, on request

Standard ingress protection of model TR10-B is IP65.

The specified degrees of protection apply under the following

conditions:

■ Use of a suitable thermowell

(without suitable thermowell: IP40)

■ Use of a suitable cable gland

■ Use of a cable cross-section appropriate for the gland or

select the appropriate cable gland for the available cable

■ Adhere to the tightening torques for all threaded connections

Examples of response time

Measuring insert Measuring insert

∅ 6 mm [0.236 in] ∅ 3 mm [0.118 in]

Sensor ■ 1 x Pt100 (thin film) ■ 1 x Pt100 (thin film)

■ 2 x Pt100 (thin film) ■ 2 x Pt100 (thin film)

Connection method ■ 3-wire ■ 3-wire

■ 4-wire ■ 4-wire (only 1 x Pt100)

Diameter ∅ 6 mm [0.236 in] ∅ 3 mm [0.118 in]

Insertion length (A) + neck length (N) 100 ... 1,100 mm [~ 4 … 43 in] 100 ... 1,100 mm [~ 4 … 43 in]

Material ■ Stainless steel 1.4571 ■ Stainless steel 1.4571

■ Stainless steel 316L ■ Stainless steel 316L

Response time in seconds (+/- 10 %)

t0.5 3.8 2.8

t0.63 4.8 3.5

t0.9 8.6 6.6

Fundamentals of measurements:

Directive VDI/VDE 3522 sheet 1: Dynamic behaviour of contact thermometers / Principles and characteristic values

Directive VDI/VDE 3522 sheet 2 Dynamic behaviour of contact thermometers / Experimental determination of time percentage

values

IEC 60751 Definition of thermal response time / Specification of measurement parameters

IEC 60751 Thermal response time

Medium to be measured: Water

Response times of thermometers in other dimensions, configurations or materials on request.

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 14 von 21

Thermowell (option)

Thermowell selection

Illustration Model Data sheet

TW10 ■ TW 95.10

■ TW 95.11

■ TW 95.12

TW15 TW 95.15

TW20 TW 95.20

TW25 TW 95.25

TW30 TW 95.30

TW45 TW 95.45

TW50 TW 95.50

TW55 TW 95.55

Special thermowells on request.

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 15 von 21

Approvals

Approvals included in the scope of delivery

Logo Description Country

EU declaration of conformity European Union

EMC directive 1)

EN 61326 emission (group 1, class B) and immunity (industrial application)

RoHS directive

1) Only for built-in transmitter

Optional approvals

Logo Description Country

EU declaration of conformity European Union

ATEX directive

Hazardous areas

- Ex i Zone 0 gas II 1G Ex ia IIC T1 ... T6 Ga

Zone 1 gas II 2G Ex ia IIC T1 ... T6 Gb

Zone 1 mounting to zone 0 gas II 1/2G Ex ia IIC T1 ... T6 Ga/Gb

Zone 20 dust II 1D Ex ia IIIC T125 ... T65 °C Da

Zone 21 dust II 2D Ex ia IIIC T125 ... T65 °C Db

Zone 21 mounting to zone 20 dust II 1/2D Ex ia IIIC T125 ... T65 °C Da/Db

- Ex e 1) Zone 1 gas II 2G Ex eb IIC T1 ... T6 Gb 3)

Zone 2 gas II 3G Ex ec IIC T1 ... T6 Gc X

Zone 21 dust II 2D Ex tb IIIC TX °C Db 3)

Zone 22 dust II 3D Ex tc IIIC TX °C Dc X

- Ex n 1) Zone 2 gas II 3G Ex nA IIC T1 ... T6 Gc X

- Ex t 1) Zone 22 dust II 3D Ex tc IIIC TX °C Dc X

IECEx International

Hazardous areas

- Ex i Zone 0 gas Ex ia IIC T1 ... T6 Ga

Zone 1 gas Ex ia IIC T1 ... T6 Gb

Zone 1 mounting to zone 0 gas Ex ia IIC T1 ... T6 Ga/Gb

Zone 20 dust Ex ia IIIC T125 ... T65 °C Da

Zone 21 dust Ex ia IIIC T125 ... T65 °C Db

Zone 21 mounting to zone 20 dust Ex ia IIIC T125 ... T65 °C Da/Db

- Ex e 2) Zone 1 gas Ex eb IIC T1 ... T6 Gb 3)

Zone 2 gas Ex ec IIC T1 ... T6 Gc

Zone 21 dust Ex tb IIIC TX °C Db 3)

Zone 22 dust Ex tc IIIC TX °C Dc

- Ex n 2) Zone 2 gas Ex nA IIC T1 ... T6 Gc

- Ex t 2) Zone 22 dust Ex tc IIIC TX °C Dc

Ex Ukraine Ukraine

Hazardous areas

- Ex i Zone 0 gas II 1G Ex ia IIC T1 ... T6 Ga

Zone 1 gas II 2G Ex ia IIC T1 ... T6 Gb

Zone 1 mounting to zone 0 gas II 1/2G Ex ia IIC T1 ... T6 Ga/Gb

Zone 20 dust II 1D Ex ia IIIC T65°C Da

Zone 21 dust II 2D Ex ia IIIC T65°C Db

Zone 21 mounting to zone 20 dust II 1/2D Ex ia IIIC T65°C Da/Db

INMETRO Brazil

Hazardous areas

- Ex i Zone 0 gas Ex ia IIC T3 ... T6 Ga

Zone 1 mounting to zone 0 gas Ex ia IIC T3 ... T6 Ga/Gb

Zone 20 dust Ex ia IIIC T125 ... T65 °C Da

Zone 21 mounting to zone 20 dust Ex ia IIIC T125 ... T65 °C Da/Db

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 16 von 21

Logo Description Country

CCC 3) China

Hazardous areas

- Ex i Zone 0 gas Ex ia IIC T1 ... T6 Ga

Zone 1 gas Ex ia IIC T1 ... T6 Gb

Zone 1 mounting to zone 0 gas Ex ia IIC T1 ... T6 Ga/Gb

Zone 20 dust Ex ia IIIC T20065°C/T20095°C/T200125°C Da

Zone 21 dust Ex ia IIIC T65°C/T95°C/T125°C Db

Zone 21 mounting to zone 20 dust Ex ia IIIC T20065°C/T20095°C/T200125°C Da/Db

Zone 21 dust Ex ib IIIC T65°C/T95°C/T125°C Db

- Ex e 2) Zone 1 gas Ex eb IIC T1 ... T6 Gb

Zone 2 gas Ex ec IIC T1 ... T6 Gc

NEPSI 4) China

Hazardous areas

- Ex i Zone 0 gas

Zone 1 gas Ex ia IIC T1 ~ T6 Gb

Zone 1 mounting to zone 0 gas Ex ia IIC T1 ~ T6 Ga/Gb

Zone 20 dust Ex iaD 20 T65/T95/T125°C

Zone 21 dust Ex iaD 21 T65/T95/T125°C

Zone 21 mounting to zone 20 dust Ex iaD 20/21 T65/T95/T125°C

- Ex n 2) Zone 2 gas Ex nA IIC T1 ~ T6 Gc

KCs South Korea

Hazardous areas

- Ex i Zone 0 gas Ex ia IIC T4 ... T6

Zone 1 gas Ex ib IIC T4 ... T6

- PESO India

Hazardous areas

- Ex i Zone 0 gas Ex ia IIC T1 ... T6 Ga

Zone 1 gas Ex ia IIC T1 ... T6 Gb

Zone 1 mounting to zone 0 gas Ex ia IIC T1 ... T6 Ga/Gb

EAC Eurasian Economic

Hazardous areas Community

- Ex i Zone 0 gas 0 Ex ia IIC T6 ... T1 Ga X

Zone 1 gas 1 Ex ia IIC T6 ... T1 Gb X

Zone 20 dust Ex ia IIIC T80 …T440 °C Da X

Zone 21 dust Ex ia IIIC T80…T440 °C Db X

- Ex n 1) Zone 2 gas 2 Ex nA IIC T6 ... T1 Gc X

PAC Ukraine Ukraine

Metrology, measurement technology

PAC Kazakhstan Kazakhstan

Metrology, measurement technology

- MchS Kazakhstan

Permission for commissioning

PAC Uzbekistan Uzbekistan

Metrology, measurement technology

DNV GL International

Type approval for the shipbuilding industry

- Maximum insertion length l1: 435 mm

- Connection head: Model BSZ

- Neck tube: ∅ 11 x 2 mm or ∅ 12 x 2.5 mm, max. 150 mm long

- Measuring insert: ∅ 6 mm

- Optional with TW10-P (see data sheets TW 95.10, TW 95.12)

Location classification:

Tempera-

D (ambient temperature: -25 ... +70 °C)

ture

Humidity B (relative humidity: up to 100 %)

Vibration B (frequency: 3 ... 25 Hz; amplitude: 1.6 mm peak; frequency: 25 ... 100 Hz; amplitude: 4 g)

EMC Not relevant

Case Required protection according to DNV rules shall be provided upon installation on board. For

use on open deck a connection head IP68 is required. 5)

(for “open deck”)

1) Only for connection head model BSZ, BSZ-H, 1/4000, 5/6000 or 7/8000 (see “Connection head”)

2) Only with connection head, model 1/4000, 5/6000 or 7/8000 (see “Connection head”)

3) Only without transmitter

4) Only with transmitter

5) Suitable cable gland required

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 17 von 21

Instruments marked with “ia” may also be used in areas only

requiring instruments marked with “ib” or “ic”. If an instrument

with “ia” marking has been used in an area with requirements

in accordance with “ib” or “ic”, it can no longer be operated in

areas with requirements in accordance with “ia” afterwards.

Explosion protection (option)

The permissible power, Pmax, as well as the permissible

ambient temperature, for the respective category can be

seen on the Ex certificate or the operating instructions.

The transmitter have their own certificates for hazardous

areas. The permissible ambient temperature ranges of the built-in transmitters can be taken from the corresponding transmitter

operating instructions and approvals.

Manufacturer's information and certificates

Logo Description

SIL SIL 2, SIL 3 see page 10

Functional safety

IEC 61508 / IEC 61511

NAMUR NAMUR NE 024

Hazardous areas (Ex i)

Certificates (option)

Certification type Measurement accuracy Material certificate 1)

2.2 test report x x

3.1 inspection certificate x x

DAkkS calibration certificate x -

1) Thermowells have their own material certificates for selected components

For calibration, the measuring insert is removed from the thermometer. The minimum length (metal part of the probe) for carry-

ing out a 3.1 measurement accuracy test or DAkkS is 100 mm [~ 4 in].

Calibration of shorter lengths as well as calibration of versions in 2-wire connection possible on request.

The different certifications can be combined with each other.

→ For approvals and certificates, see website

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 18 von 21

Dimensions

Neck tube per DIN 43772

3160670.07

parallel thread tapered thread

Neck tube per DIN 43772, straight, with/without compression fitting

3160688.06

without thread (plain) parallel thread tapered thread

Legend:

A (l1) Insertion length (parallel threads) CT Thread cable inlet

A (U2) Insertion length (tapered threads) Ø F1 Neck tube diameter

l5 Measuring insert length P Thread to the thermowell

N (MH) Neck length Ød Measuring insert diameter

KE 1/2 NPT: 8.13 mm [0.320 in]

3/4 NPT: 8.61 mm [0.339 in]

The figures show examples of connection heads.

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 19 von 21

Neck tube, with counter nut to head Double threaded hex bushing (with hexagonal spanner

14111586.01

14111667.02

flats)

parallel thread tapered thread parallel thread tapered thread

“Nipple-union-nipple” neck tube Double threaded hex bushing Without neck tube

(tube)

14111563.02

14111563.02

3160670.07

tapered thread tapered thread

Legend:

A (l1) Insertion length (parallel threads) CT Thread cable inlet

A (U2) Insertion length (tapered threads) Ø F1 Neck tube diameter

l5 Measuring insert length P Thread to the thermowell

N (MH) Neck length Ød Measuring insert diameter

KE 1/2 NPT: 8.13 mm [0.320 in]

3/4 NPT: 8.61 mm [0.339 in]

The figures show examples of connection heads.

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 20 von 21

Ordering information

Model / Explosion protection / Further approvals, certificates / Sensor / Accuracy class, range of use of the sensor / Connec-

tion housing / Cable inlet / Transmitter / Connection to neck tube / Neck tube / Thread size / Neck length N (MH) / Insertion

length A (l1), A (U2) / Measuring insert diameter Ø d / Measuring insert sheath material / Certificates / Options

© 04/2003 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

02/2023 EN

WIKA data sheet TE 60.02 ∙ 02/2023 Seite 21 von 21

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

info@wika.de

www.wika.de

You might also like

- Tda 18273 HNDocument52 pagesTda 18273 HNSheraz Shaikh100% (2)

- 28 Points You Need To Know About SAP WM ImplementationDocument5 pages28 Points You Need To Know About SAP WM ImplementationeddiemedNo ratings yet

- 299 - Sfere Manual (EN)Document36 pages299 - Sfere Manual (EN)Minh NguyễnNo ratings yet

- ADZ - SMH DatasheetDocument4 pagesADZ - SMH DatasheettamanogNo ratings yet

- Digital Load Cell: Special FeaturesDocument2 pagesDigital Load Cell: Special FeaturesCristhian TaipeNo ratings yet

- Characteristics: Serial Communication SystemsDocument2 pagesCharacteristics: Serial Communication SystemsDiego BenitezNo ratings yet

- P T S 21 R S 21 SR / MR: Iezoresistive Ransmitters / Eries EriesDocument2 pagesP T S 21 R S 21 SR / MR: Iezoresistive Ransmitters / Eries EriesBinh Thai HYNo ratings yet

- Pg053 U Liy (ST) Y-TpDocument1 pagePg053 U Liy (ST) Y-TpDolyNo ratings yet

- Experiment 3 - Introduction To Oscilloscopes PDFDocument2 pagesExperiment 3 - Introduction To Oscilloscopes PDFJÜnn BatacNo ratings yet

- Piezorresistive Transmitters: Model: 21R - 21 SR / MRDocument2 pagesPiezorresistive Transmitters: Model: 21R - 21 SR / MRMarcelo PellizzaNo ratings yet

- Sub Sensors 02SDocument44 pagesSub Sensors 02SArturo David Ubaldo HerreraNo ratings yet

- Tm-RS485-MB / Tm-RS485-MT: Module Temperature Sensor With RS485 InterfaceDocument2 pagesTm-RS485-MB / Tm-RS485-MT: Module Temperature Sensor With RS485 InterfaceGabrielNo ratings yet

- RADIX All ProductsDocument24 pagesRADIX All ProductsAprian Dwi Rahmanu100% (1)

- MA8692 Supplement EU MLDocument4 pagesMA8692 Supplement EU MLMaxsilva85No ratings yet

- DSP15EExmNT IECex 15WDocument1 pageDSP15EExmNT IECex 15WIqbal MatondangNo ratings yet

- ET-4D A 2 eDocument4 pagesET-4D A 2 emanufesiNo ratings yet

- Transformer Monitor Comparison IEDVSITMDocument3 pagesTransformer Monitor Comparison IEDVSITMjuan david garciaNo ratings yet

- Declaração VarixxDocument2 pagesDeclaração VarixxGabrielNo ratings yet

- Handbuch 2013Document229 pagesHandbuch 2013tolomeo10No ratings yet

- List of Materials and Equipments For IncubatorDocument8 pagesList of Materials and Equipments For IncubatorJoshua CooperNo ratings yet

- Kde en 923 0862Document32 pagesKde en 923 0862joseloaiza378No ratings yet

- CentspotDocument2 pagesCentspotvicky khanNo ratings yet

- Electronic Vacuum Switch: Specifi Cations AdvantagesDocument1 pageElectronic Vacuum Switch: Specifi Cations AdvantagesYasin ElaswadNo ratings yet

- Paa21sr/80444.3 - 1 Paa21sr/80444.3 - 14-20ma Paa21sr/80444.3 - 2.5 PR21S/80549.3-2. 5 4-20ma PR21SR/80444.3-2.5Document5 pagesPaa21sr/80444.3 - 1 Paa21sr/80444.3 - 14-20ma Paa21sr/80444.3 - 2.5 PR21S/80549.3-2. 5 4-20ma PR21SR/80444.3-2.5Jose MadrizNo ratings yet

- DRAMs ProDocument2 pagesDRAMs ProzokiNo ratings yet

- Technical Data Sheet: Designation Dry Conïact Receiver Reference 5014328 RangeDocument2 pagesTechnical Data Sheet: Designation Dry Conïact Receiver Reference 5014328 RangeMehmet Emin EraslanNo ratings yet

- Gnexs2H Alarm Horn Sounder: 1-22-025 / Explo S Io N/Flame Pro O F S Ignals 1-22-025 / Explo S Io N/Flame Pro O F S IgnalsDocument4 pagesGnexs2H Alarm Horn Sounder: 1-22-025 / Explo S Io N/Flame Pro O F S Ignals 1-22-025 / Explo S Io N/Flame Pro O F S IgnalsbondsivamaniNo ratings yet

- Progress Kedatangan Dan Kekurangan Material Per 30 Apr 2023Document11 pagesProgress Kedatangan Dan Kekurangan Material Per 30 Apr 2023Saiful RochmanNo ratings yet

- SFERE Energy Meter3706581013667435464Document2 pagesSFERE Energy Meter3706581013667435464Cho Cho MyintNo ratings yet

- HPT200 Pressure Datasheet.Document6 pagesHPT200 Pressure Datasheet.Mai Vạn HậuNo ratings yet

- H73317n Instructions 8283 8287 8288 EPR EPI EPN Pressure TransmitterDocument2 pagesH73317n Instructions 8283 8287 8288 EPR EPI EPN Pressure Transmitteroca.carlos14No ratings yet

- RedBin-D_enDocument6 pagesRedBin-D_enTareq JildehNo ratings yet

- 3000 Series Electronic Quick Install Guide: Important Safety InstructionsDocument18 pages3000 Series Electronic Quick Install Guide: Important Safety InstructionsPepe Queño MtzNo ratings yet

- Junction Box Ro-X-Ex Ia: Description, ApplicationDocument2 pagesJunction Box Ro-X-Ex Ia: Description, ApplicationKenan KuloglijaNo ratings yet

- Model No.: T1-K, T2-K, T3-K: Wall Mounted Rotar y PanelDocument2 pagesModel No.: T1-K, T2-K, T3-K: Wall Mounted Rotar y PanelgoogleNo ratings yet

- Sensor de Presion TecSis 1barDocument4 pagesSensor de Presion TecSis 1barMarco ColomaNo ratings yet

- Push&SwitchDocument12 pagesPush&SwitchbigopostNo ratings yet

- KT Temperature ControllerDocument16 pagesKT Temperature ControllerAde SpiesNo ratings yet

- 8EI8X8HWT10.XXXX-1: 1 Order DataDocument13 pages8EI8X8HWT10.XXXX-1: 1 Order DataLaerte MeloNo ratings yet

- FP06P Selection Chart - Ordering Example: FP06P S1 S2 04 A04 32 NU S SA V ALDocument1 pageFP06P Selection Chart - Ordering Example: FP06P S1 S2 04 A04 32 NU S SA V ALGabby LatupeirissaNo ratings yet

- Grid Connected Inverter SpcificationDocument2 pagesGrid Connected Inverter Spcificationdh24992499No ratings yet

- Манометры ТМ (ТВ,ТМВ) Серия10 РОСМАDocument4 pagesМанометры ТМ (ТВ,ТМВ) Серия10 РОСМАSergNo ratings yet

- TD5613687-00 en Trasy2 CompactDocument12 pagesTD5613687-00 en Trasy2 CompactIvan SalapićNo ratings yet

- Td5613687-00 en Trasy2 CompactDocument12 pagesTd5613687-00 en Trasy2 CompactRodrigoNo ratings yet

- TD5613687-00 en Trasy2 Compact PDFDocument12 pagesTD5613687-00 en Trasy2 Compact PDFRenato Almache FloresNo ratings yet

- Eng DG Progr Multi A.C DH em DP emDocument6 pagesEng DG Progr Multi A.C DH em DP emRanda solimanNo ratings yet

- Technical DataDocument12 pagesTechnical DataYaser SeminarioNo ratings yet

- PDFDocument28 pagesPDFMiraNo ratings yet

- Diz G Dab e 130Document2 pagesDiz G Dab e 130HernanMillaMendozaNo ratings yet

- AD82587D EliteSemiconductorDocument45 pagesAD82587D EliteSemiconductorMed SamiNo ratings yet

- Generation G: EMH MeteringDocument2 pagesGeneration G: EMH MeteringJamier Chafloque SilvaNo ratings yet

- Bas 04 Atex 0220Document9 pagesBas 04 Atex 0220Rafael MarçalNo ratings yet

- Gnexs2F Alarm Horn Sounder: 1-22-020 / Explo S Io N/Flame Pro O F S Ignals 1-22-020 / Explo S Io N/Flame Pro O F S IgnalsDocument4 pagesGnexs2F Alarm Horn Sounder: 1-22-020 / Explo S Io N/Flame Pro O F S Ignals 1-22-020 / Explo S Io N/Flame Pro O F S IgnalsbondsivamaniNo ratings yet

- MH SFERE Dseries KWH Meter (Catalog) v4Document2 pagesMH SFERE Dseries KWH Meter (Catalog) v4Dodi RivaldiNo ratings yet

- Medical Adapter: Rated 30W SNP-A03x-M SeriesDocument4 pagesMedical Adapter: Rated 30W SNP-A03x-M SeriesJesus PerezNo ratings yet

- SM SZ Ducted Outdoor Ducted Cassette VAHU MFL68082948Document18 pagesSM SZ Ducted Outdoor Ducted Cassette VAHU MFL68082948phamduckien80No ratings yet

- Enraf-Nonius Endomed 182 enDocument7 pagesEnraf-Nonius Endomed 182 enDoni XtreemNo ratings yet

- Datenblatt Serie-41X-Ei eDocument2 pagesDatenblatt Serie-41X-Ei eBoody CNo ratings yet

- The Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsFrom EverandThe Fourth Terminal: Benefits of Body-Biasing Techniques for FDSOI Circuits and SystemsSylvain ClercNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Ds tr10 4 en UsDocument2 pagesDs tr10 4 en UsMuhammad Haroon AsgharNo ratings yet

- 2009 - 03 - 06 Hochschulzugang Berufl Qualifizierte BewerberDocument3 pages2009 - 03 - 06 Hochschulzugang Berufl Qualifizierte BewerberMuhammad Haroon AsgharNo ratings yet

- 1997 - 06 - 05 Fachoberschulreife Berufliche BildungDocument10 pages1997 - 06 - 05 Fachoberschulreife Berufliche BildungMuhammad Haroon AsgharNo ratings yet

- 1976 11 25-RV-BerufsoberschuleDocument10 pages1976 11 25-RV-BerufsoberschuleMuhammad Haroon AsgharNo ratings yet

- PublisherDocument11 pagesPublisherJen FloresNo ratings yet

- Form 1-A (To Claim 1st Instalment Under PMMVYDocument6 pagesForm 1-A (To Claim 1st Instalment Under PMMVYDanish MushtaqNo ratings yet

- What Is EHealthDocument64 pagesWhat Is EHealthAshvini GoelNo ratings yet

- Marketing Research - Advantages, Disadvantages & LimitationsDocument5 pagesMarketing Research - Advantages, Disadvantages & LimitationsShazNo ratings yet

- Stanley C Harris JR Bank StatementDocument3 pagesStanley C Harris JR Bank StatementDamion HollisNo ratings yet

- Live Build A Custom Kali ISODocument3 pagesLive Build A Custom Kali ISOUkihana SamuraiNo ratings yet

- Sujit Kumar LGF34-92Document3 pagesSujit Kumar LGF34-92doc purushottamNo ratings yet

- 30GX and 30HXC SeriesDocument57 pages30GX and 30HXC SeriesnansusanNo ratings yet

- Lista Aspectelor de Mediu IdentificateDocument7 pagesLista Aspectelor de Mediu IdentificateLuminita GrecuNo ratings yet

- 25% 50% 33% 100% Solution: Efficiency of Modulation Is Given byDocument5 pages25% 50% 33% 100% Solution: Efficiency of Modulation Is Given byAkashdeep BhattacharjeeNo ratings yet

- Flow Chart BasicsDocument1 pageFlow Chart BasicsDinar TogatoropNo ratings yet

- Dinorah DinorahDocument5 pagesDinorah DinorahMartinNo ratings yet

- Microfluidic For Supporting Fiber-Optic-Based Surface Plasmon Resonance SensorDocument10 pagesMicrofluidic For Supporting Fiber-Optic-Based Surface Plasmon Resonance SensorAsih SetiariniNo ratings yet

- N Adaptive PID Controller Based On Genetic Algorithm ProcessorDocument6 pagesN Adaptive PID Controller Based On Genetic Algorithm ProcessorEngr Nayyer Nayyab MalikNo ratings yet

- Benefits of SFRCDocument17 pagesBenefits of SFRCShubhayu_duttaNo ratings yet

- Technical Specifications: 12 V 18ah AGM 5 YearsDocument2 pagesTechnical Specifications: 12 V 18ah AGM 5 YearsDaniel EspinozaNo ratings yet

- Protect Fuse Switch Disconnector, XLBM 160-630ADocument32 pagesProtect Fuse Switch Disconnector, XLBM 160-630Azg828No ratings yet

- PST Roll - NoDocument1 pagePST Roll - NoChangez OfficialNo ratings yet

- 00 Atomic Habits Resources - James ClearDocument6 pages00 Atomic Habits Resources - James Clearlili luluNo ratings yet

- SHS Applied Empowerment Technologies For The StrandDocument2 pagesSHS Applied Empowerment Technologies For The StrandEdgar Allan De Guia100% (1)

- Products Standardization in Oil & Gas Sector in IndiaDocument39 pagesProducts Standardization in Oil & Gas Sector in Indiakingking21177No ratings yet

- AGL Controlbox 312Document8 pagesAGL Controlbox 312World Digital GraphicsNo ratings yet

- Reviewers: Project Transition ChecklistDocument6 pagesReviewers: Project Transition Checklistnsadnan100% (2)

- Kuangchi Science - Calvin Jiang 75c00848abDocument34 pagesKuangchi Science - Calvin Jiang 75c00848abBen Smith100% (1)

- Impact of Tehri Dam Lessons LearntDocument45 pagesImpact of Tehri Dam Lessons Learntjamjam75No ratings yet

- Titles Pages 2 Safety and Health Procedures 3 Objective 4 Apparatus 5 Procedures 6 Result 7 Discussion 8 Questions 9 Conclusion 10Document10 pagesTitles Pages 2 Safety and Health Procedures 3 Objective 4 Apparatus 5 Procedures 6 Result 7 Discussion 8 Questions 9 Conclusion 10Iqi IqahNo ratings yet

- Tips Sort - JCLDocument16 pagesTips Sort - JCLtiziphoraNo ratings yet

- Material Selection Lecture-1Document50 pagesMaterial Selection Lecture-1Hassan HabibNo ratings yet

- Waterco FPI Valves: Engineered For Optimal PerformanceDocument2 pagesWaterco FPI Valves: Engineered For Optimal Performanceethan8888No ratings yet