Professional Documents

Culture Documents

Strict Hygiene Practices During The Processing of Scallops

Strict Hygiene Practices During The Processing of Scallops

Uploaded by

Rastha RomaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strict Hygiene Practices During The Processing of Scallops

Strict Hygiene Practices During The Processing of Scallops

Uploaded by

Rastha RomaCopyright:

Available Formats

Implementing strict hygiene practices during the processing of scallops or any seafood is crucial to ensure

food safety and prevent contamination. Here are some key steps and practices to consider:

1. Personal Hygiene: Proper personal hygiene is essential for all workers involved in the processing of scallops.

This includes regular hand washing with soap and water before and after handling the seafood. Additionally,

employees should wear clean protective clothing, including aprons, gloves, hairnets, and appropriate footwear to

prevent contamination.

2. Sanitation of Equipment and Facilities: All processing equipment, work surfaces, and facilities should be

regularly cleaned and sanitized to prevent the growth and spread of harmful bacteria. This includes using approved

cleaning agents and ensuring that all surfaces are thoroughly cleaned to remove any potential contaminants.

3. Temperature Control: Maintain proper temperature control throughout the processing facility to ensure that the

scallops are kept at safe temperatures to prevent bacterial growth. This includes refrigeration and proper storage

practices to maintain the freshness and quality of the seafood.

4. Pest Control: Implement measures to prevent pests, such as insects and rodents, from entering the processing

facility. This may involve regular inspections, sealing of entry points, and the use of traps or baits to control pests.

5. Water Quality: If water is used in any part of the processing, it is essential to ensure that it is of high quality and

free from contaminants. Regular testing of water quality and maintenance of water treatment systems are crucial to

prevent the risk of contamination.

6. Controls for Cross-Contamination: Implement measures to prevent cross-contamination between different

batches of scallops or other seafood products. This includes using separate equipment for handling different

products, as well as ensuring that work areas are adequately cleaned and sanitized between processing tasks.

7. Employee Training: Provide thorough training for all employees on the importance of hygiene practices and the

specific protocols to follow within the processing facility. Ensure that workers are aware of proper handwashing,

sanitation, and food handling procedures.

8. Regular Inspections and Audits: Conduct regular inspections and audits of the processing facility to ensure that

hygiene practices are being adhered to. This may include internal inspections as well as third-party audits to verify

compliance with industry standards and regulations.

9. Compliance with Regulatory Standards: Stay updated with the latest food safety regulations and ensure that the

processing facility complies with all relevant standards and requirements set forth by regulatory authorities.

10. Record-Keeping: Maintain detailed records of sanitation procedures, cleaning schedules, employee training, and

any corrective actions taken to address potential hygiene issues. Proper documentation is essential to demonstrate

compliance with food safety standards.

By implementing and maintaining strict hygiene practices throughout the processing of scallops, fish

processing plants can minimize the risk of foodborne illness, ensure the safety and quality of their products,

and build trust with consumers and regulatory agencies.

You might also like

- CAC Codex HACCP Check ListDocument14 pagesCAC Codex HACCP Check ListEdward Danish83% (6)

- Good Manufacturing Practices in Food IndustryDocument18 pagesGood Manufacturing Practices in Food IndustryShahida Hussain100% (7)

- Enhance Customer Service Experience PDFDocument61 pagesEnhance Customer Service Experience PDFkripa sunuwar67% (3)

- Good Hygiene and Manufacturing PracticesDocument15 pagesGood Hygiene and Manufacturing PracticesMihai BejanNo ratings yet

- Industrial Tour For Manufacturing Company SILVER SWANDocument5 pagesIndustrial Tour For Manufacturing Company SILVER SWANjaredjoeNo ratings yet

- Basic Elements of A Sanitation Program For Food ProcessingDocument5 pagesBasic Elements of A Sanitation Program For Food ProcessingJohn Henry Wells100% (2)

- Strategies For Overcoming Hazards in Fish ProcessingDocument1 pageStrategies For Overcoming Hazards in Fish ProcessingRastha RomaNo ratings yet

- Major SubjectDocument7 pagesMajor SubjectJames SachznaNo ratings yet

- Mod2 Food Processing LO1.3 LO1.4 LO1.5Document29 pagesMod2 Food Processing LO1.3 LO1.4 LO1.5Roma Diane AvigueteroNo ratings yet

- Food HygieneDocument4 pagesFood HygieneGraciela Woolman AubNo ratings yet

- SCRIPTTTTDocument6 pagesSCRIPTTTTdumamag.sandarahkylahNo ratings yet

- SITXFSA002 A01 Participate in Safe Food Handling PracticesDocument19 pagesSITXFSA002 A01 Participate in Safe Food Handling PracticesPardeep Kumar100% (1)

- Chapter 24 Hygiene in Processing and ManufacturingDocument25 pagesChapter 24 Hygiene in Processing and Manufacturingaq3398237No ratings yet

- Unit Code: - SITXFSA002 Unit Name: - Participate in Safe Food Handling PracticeDocument40 pagesUnit Code: - SITXFSA002 Unit Name: - Participate in Safe Food Handling Practicesandeep kesar0% (1)

- Part 5 - t11 Good Production Processing Practices (GMP, GAP, GHP, GLP, BAP, Etc)Document38 pagesPart 5 - t11 Good Production Processing Practices (GMP, GAP, GHP, GLP, BAP, Etc)namitaNo ratings yet

- Food Storage Warehouses GuidelinesDocument16 pagesFood Storage Warehouses GuidelinesThuyền TháiNo ratings yet

- GHP UDocument2 pagesGHP USadam HussainNo ratings yet

- Food HandlingDocument10 pagesFood HandlingveeraNo ratings yet

- Regular Inspection and Sanitation of Processing EquipmentDocument1 pageRegular Inspection and Sanitation of Processing EquipmentRastha RomaNo ratings yet

- Standard Operational Sanitation Procedure - Equipment and Facility CleaningDocument1 pageStandard Operational Sanitation Procedure - Equipment and Facility CleaningSyarmine Aqila IsaNo ratings yet

- General Principles of Food Sanitation and Hygiene: A.P.GandhiDocument17 pagesGeneral Principles of Food Sanitation and Hygiene: A.P.GandhiAdapa Prabhakara GandhiNo ratings yet

- Pre Requisite Program in Food SafetyDocument61 pagesPre Requisite Program in Food Safetyaq3398237No ratings yet

- 4.9.1 Personnel TrainingDocument8 pages4.9.1 Personnel TrainingTylerNo ratings yet

- Practicals Fe503Document19 pagesPracticals Fe503basmaranaaNo ratings yet

- Participate in Safe Food Handling Practices ASSIGNMENTDocument14 pagesParticipate in Safe Food Handling Practices ASSIGNMENTPardeep KumarNo ratings yet

- Food Safety and SanitationDocument1 pageFood Safety and SanitationJoddie LoplopNo ratings yet

- Write Up PDFDocument17 pagesWrite Up PDFFrancine Dawn MoloNo ratings yet

- Safety Semis Compilation 01Document11 pagesSafety Semis Compilation 01Jazer Mari CantosNo ratings yet

- Worker Health, Hygiene and Sanitary Facilities: Fatemeh Malekian, ProfessorDocument32 pagesWorker Health, Hygiene and Sanitary Facilities: Fatemeh Malekian, ProfessorelizaviraniNo ratings yet

- Fish ProcessingDocument226 pagesFish ProcessingReymond Saragena PapaNo ratings yet

- CSSD ManagementDocument5 pagesCSSD ManagementShafqat UllahNo ratings yet

- Food Safety Manual For Restaurants and KitchensDocument4 pagesFood Safety Manual For Restaurants and Kitchensgetaneh abebeNo ratings yet

- Principles of Safety, Hygiene and Satination Powerpoint-1Document39 pagesPrinciples of Safety, Hygiene and Satination Powerpoint-1Rochelle Bautista100% (1)

- SOP Guideline For BEAN Factory - 29.05.23Document11 pagesSOP Guideline For BEAN Factory - 29.05.23Ashraf AlamNo ratings yet

- Module 11 Current Good Manufacturing PracticesDocument13 pagesModule 11 Current Good Manufacturing Practicesemiones17No ratings yet

- Sanitary Design and Role of HACCP in SanitationDocument12 pagesSanitary Design and Role of HACCP in SanitationBhupen HajongNo ratings yet

- Guidelines Good Hygiene Practices For Small and Medium Scale Food Industries Towards HaccpDocument14 pagesGuidelines Good Hygiene Practices For Small and Medium Scale Food Industries Towards HaccpSally Salina FarahNo ratings yet

- Detailed Learning Plan in TLE 7-Week 5Document13 pagesDetailed Learning Plan in TLE 7-Week 5shine davidNo ratings yet

- Workers Health and Hygiene FatemehDocument32 pagesWorkers Health and Hygiene FatemehAnonymous JtY0EB2ONo ratings yet

- Primary ProductionDocument32 pagesPrimary Productionanjalidhanala45No ratings yet

- Aman KiDocument9 pagesAman KiAshish JaatNo ratings yet

- Workers Health and Hygiene FatemehDocument31 pagesWorkers Health and Hygiene FatemehAbdullah AtherNo ratings yet

- Sterility Assurance TrainingDocument28 pagesSterility Assurance TrainingVasanthNo ratings yet

- Good Manufacturing Practices.Document123 pagesGood Manufacturing Practices.anandhra2010100% (2)

- FSMS - PRPsDocument207 pagesFSMS - PRPsSidNo ratings yet

- 77 Food Production GMP Audit ChecklistDocument5 pages77 Food Production GMP Audit Checklistgarry.scrivens1ntlworld.comNo ratings yet

- Doc-20240113-Wa0019. 20240113 204609 0000Document41 pagesDoc-20240113-Wa0019. 20240113 204609 0000Syaidan ZulmizanNo ratings yet

- New Microsoft Word DocumentDocument5 pagesNew Microsoft Word DocumentWasim ArshadNo ratings yet

- Module 5: Implement Good Manufacturing Practice ProcedureDocument7 pagesModule 5: Implement Good Manufacturing Practice ProcedureStevenNo ratings yet

- Assignment2 - Research On Restraurant - EditedDocument16 pagesAssignment2 - Research On Restraurant - EditedSwarnali Dutta ChatterjeeNo ratings yet

- Food Safety IssuesDocument144 pagesFood Safety IssuesVishal MeenaNo ratings yet

- Water and End Products VerificationDocument3 pagesWater and End Products VerificationMahayu Mohd IsaNo ratings yet

- LO2. Implement Food Safety PracticesDocument12 pagesLO2. Implement Food Safety PracticesRENATO NATORNo ratings yet

- Sanitary Design and Role of HACCP in SANITATION - HABUNGDocument13 pagesSanitary Design and Role of HACCP in SANITATION - HABUNGBhupen Hajong100% (1)

- (PRPS) ListDocument9 pages(PRPS) ListDeepak MoreNo ratings yet

- Food SanitationDocument21 pagesFood SanitationHeyy NaNo ratings yet

- GMP GHP SopDocument64 pagesGMP GHP SopPrasad Mg100% (3)

- GMP GHP SopDocument64 pagesGMP GHP SopPrasad MgNo ratings yet

- Activity No. 1 SOP Making: Answer: Hairnet, Hand Towel, Gloves, ApronDocument4 pagesActivity No. 1 SOP Making: Answer: Hairnet, Hand Towel, Gloves, ApronEsparrago RandolfNo ratings yet

- Chapter 3. Safety Sanitation and BeautificationDocument50 pagesChapter 3. Safety Sanitation and BeautificationJia Mae Sapico ApantiNo ratings yet

- Fish Preservation and ProcessingDocument32 pagesFish Preservation and ProcessingRastha RomaNo ratings yet

- Proper Cleaning ProceduresDocument1 pageProper Cleaning ProceduresRastha RomaNo ratings yet

- Regular Inspection and Sanitation of Processing EquipmentDocument1 pageRegular Inspection and Sanitation of Processing EquipmentRastha RomaNo ratings yet

- Hazards of in The Fish Processing PlantDocument1 pageHazards of in The Fish Processing PlantRastha RomaNo ratings yet

- CoconutsDocument2 pagesCoconutsAthaNo ratings yet

- Shailendra Yadav (Etah) Particulars Inwards Outwards Opening BalanceDocument48 pagesShailendra Yadav (Etah) Particulars Inwards Outwards Opening Balancekush mishraNo ratings yet

- Chicken Tikka Masala RecipeDocument2 pagesChicken Tikka Masala Recipeapi-359588776No ratings yet

- Coffee Brewing CheatsheetDocument1 pageCoffee Brewing CheatsheetAlNo ratings yet

- PEX Ingredients List AutumnWinter 2023 V12Document71 pagesPEX Ingredients List AutumnWinter 2023 V12hqkx78xyfmNo ratings yet

- Islamic Microfinance Help DeskDocument6 pagesIslamic Microfinance Help DeskAlHuda Centre of Islamic Banking & Economics (CIBE)No ratings yet

- Pulses2016 PDFDocument317 pagesPulses2016 PDFGanpat Lal SharmaNo ratings yet

- Natalie Resume Di Ms EditedDocument1 pageNatalie Resume Di Ms Editedapi-270994771No ratings yet

- Matrikulasi Hospitality ManagementDocument48 pagesMatrikulasi Hospitality Managementamzie_jr3616No ratings yet

- FNCP Final EditedDocument10 pagesFNCP Final EditedMrLarry DolorNo ratings yet

- Tapey (Feature Article)Document2 pagesTapey (Feature Article)Fredie Dalay-on Unggay100% (1)

- 1 Week Gastritis Diet Plan (My Personal Experience) - NatureWordDocument1 page1 Week Gastritis Diet Plan (My Personal Experience) - NatureWordÖmerin DefnesiNo ratings yet

- Welcome AboardDocument47 pagesWelcome AboardKim SmithNo ratings yet

- Mind Control Cult - Issue #2Document2 pagesMind Control Cult - Issue #2Michael MaleedyNo ratings yet

- CBSE Class 10 Chemistry Worksheet - Acids, Bases and SaltsDocument2 pagesCBSE Class 10 Chemistry Worksheet - Acids, Bases and Saltsvermajiya979No ratings yet

- BRM Project FinalDocument45 pagesBRM Project FinalLalit TradaNo ratings yet

- Ediware: Edible Cutlery and CrockeryDocument11 pagesEdiware: Edible Cutlery and CrockerykavindriNo ratings yet

- Wedding ChecklistDocument8 pagesWedding ChecklistRoy Benedict BautistaNo ratings yet

- General Comparison of Health Claims With Regards To Food and Supplement Legislation in Europe, US, and CanadaDocument4 pagesGeneral Comparison of Health Claims With Regards To Food and Supplement Legislation in Europe, US, and CanadaBudi Utami WibawaniNo ratings yet

- Kitchen Expenses May 2015Document180 pagesKitchen Expenses May 2015Bong Urbano AIcantaraNo ratings yet

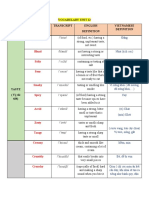

- Bitter: Vocabulary Unit 12 Vocabulary Transcript English VietnameseDocument4 pagesBitter: Vocabulary Unit 12 Vocabulary Transcript English VietnamesePan PerterNo ratings yet

- The Purple Worm GraveyardDocument5 pagesThe Purple Worm Graveyardh0% (1)

- Gastroenteritis Leaflet FinalDocument2 pagesGastroenteritis Leaflet FinalRiony GusbaniansyahNo ratings yet

- Intermediate MOCK2020Document6 pagesIntermediate MOCK2020villoldopaulaNo ratings yet

- Attitudes and Household Characteristics Influencing Solid Waste Generation: A Household Garbage AnalysisDocument6 pagesAttitudes and Household Characteristics Influencing Solid Waste Generation: A Household Garbage AnalysisjovilleNo ratings yet

- Resume 2Document1 pageResume 2api-491898211No ratings yet

- Food Security NotesDocument5 pagesFood Security NotesChethanaNo ratings yet

- SJK (C) Pei Hwa JB English Language Assessment (3) Paper 1 50 MinutesDocument9 pagesSJK (C) Pei Hwa JB English Language Assessment (3) Paper 1 50 MinutesFasihah LiewNo ratings yet

- Wish ClausesDocument16 pagesWish ClausestepeparkNo ratings yet