Professional Documents

Culture Documents

Egrvalve

Egrvalve

Uploaded by

swap2gz0 ratings0% found this document useful (0 votes)

3 views1 pageАнрргг

Original Title

egrvalve

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentАнрргг

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views1 pageEgrvalve

Egrvalve

Uploaded by

swap2gzАнрргг

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

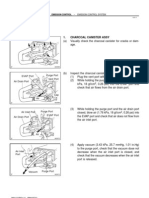

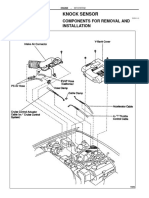

EG–194

ENGINE – SFI SYSTEM

(c) Remove the bolt and VSV.

3. INSPECT VSV

A. Inspect VSV for open circuit

Using an ohmmeter, check that there is continuity between

the terminals.

Resistance:

At 20°C (68°F): 37 – 44 W

If there is no continuity, replace the VSV.

B. Inspect VSV for ground

Using an ohmmeter, check that there is no continuity be-

tween each terminal and the body.

If there is continuity, replace the VSV.

C. Inspect VSV operation

(a) Check that air flows from ports E to G.

(b) Apply battery voltage across the terminals.

(c) Check that air flows from port E to the filter.

If operation is not as specified, replace the VSV.

4. REINSTALL VSV

(a) Install the VSV with the bolt.

Torque: 18 N⋅m (185 kgf⋅cm, 13 ft⋅lbf)

(b) Connect these hoses to the VSV:

• Vacuum hose from fuel pressure regulator

• Vacuum hose from air intake chamber

(c) Connect the VSV connector.

5. REINSTALL V–BANK COVER

EG1PF–04

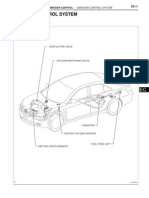

VSV FOR EVAP

(See VSV inspection in evaporative emission control

system in Emission Control Systems)

EG1PJ–04

EGR VALVE

(See EGR valve inspection in Emission Control Systems)

You might also like

- Emission Control System: PurposeDocument27 pagesEmission Control System: PurposeclergeonNo ratings yet

- 2uz-Fe SfiDocument84 pages2uz-Fe SfiAe Manual100% (1)

- Engine Control SystemDocument73 pagesEngine Control SystemJuan Sánchez López90% (10)

- VSV TestDocument1 pageVSV Testpuma384No ratings yet

- Vacuum Switching Valve (VSV)Document2 pagesVacuum Switching Valve (VSV)Enrique Villamizar LaguadoNo ratings yet

- Vacuum Switching Valve VSVDocument2 pagesVacuum Switching Valve VSVindrajith.meNo ratings yet

- Yaris Electrical Wiring Diagram 0Document2 pagesYaris Electrical Wiring Diagram 0Nina FloydNo ratings yet

- Emission ControlDocument19 pagesEmission ControlMusat Catalin-Marian0% (1)

- Inspection: 1. Inspect Intake Air Control Valve Assy No.2Document5 pagesInspection: 1. Inspect Intake Air Control Valve Assy No.2Dean BNo ratings yet

- Inspection: 1. Charcoal Canister AssyDocument5 pagesInspection: 1. Charcoal Canister AssyNoir HamannNo ratings yet

- Exhaust Gas Recirculation (Egr) System (4A FE)Document6 pagesExhaust Gas Recirculation (Egr) System (4A FE)Hongda Zhuo100% (1)

- InspDocument5 pagesInspIfex SalemNo ratings yet

- 1gr-Fe SfiDocument68 pages1gr-Fe SfiByron GómezNo ratings yet

- 05 Emission ControlsDocument16 pages05 Emission ControlsvixentdNo ratings yet

- (Others) : Downloaded From Manuals Search EngineDocument10 pages(Others) : Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- M Di 0038Document7 pagesM Di 0038Dayro Jose Geney OrtizNo ratings yet

- Avensis Intake System PDFDocument19 pagesAvensis Intake System PDFMladen VidovićNo ratings yet

- Exhaust Gas Recirculation EGRDocument4 pagesExhaust Gas Recirculation EGRCesar Alarcón SolisNo ratings yet

- VAV T&C - MugunthanDocument27 pagesVAV T&C - MugunthanlongNo ratings yet

- MAF Tpyota 4runer Mod. 93Document3 pagesMAF Tpyota 4runer Mod. 93Hugo Armando Garcia LepeNo ratings yet

- Charging SystemDocument18 pagesCharging SystemChristian Linares AbreuNo ratings yet

- Pajero Full 2008 15Document81 pagesPajero Full 2008 15Antonio Gaspar100% (1)

- Circuit Breaker MaintDocument4 pagesCircuit Breaker MaintSelvn SubramanianNo ratings yet

- Etp-03 Test Procedure For Oil Filled TransformerDocument2 pagesEtp-03 Test Procedure For Oil Filled TransformeralekyaNo ratings yet

- 2GR FE ChargingDocument25 pages2GR FE Chargingmink4uNo ratings yet

- Air Circuit Breaker-2Document9 pagesAir Circuit Breaker-2ssvasavaongcNo ratings yet

- Group 4 Mechatronics System: 1. All Actuators Speed Are SlowDocument17 pagesGroup 4 Mechatronics System: 1. All Actuators Speed Are SlowTaha RdmanNo ratings yet

- Ec (2jz-Gte) PDFDocument12 pagesEc (2jz-Gte) PDFAshokNo ratings yet

- Idle Air Control Iac ValveDocument2 pagesIdle Air Control Iac ValveHugo Armando Garcia Lepe0% (1)

- Emissions Control SystemsDocument15 pagesEmissions Control SystemsTharsikan singamNo ratings yet

- Test Procedure of Oil TransformerDocument2 pagesTest Procedure of Oil TransformeralekyaNo ratings yet

- ENG 046 CVVT OCV InspectionDocument5 pagesENG 046 CVVT OCV Inspectionpacosworld100% (1)

- 2AZ-FE Emission ControlDocument25 pages2AZ-FE Emission ControlLuks FernandezNo ratings yet

- Inspection: E2 THA OhmmeterDocument3 pagesInspection: E2 THA OhmmeterPhang KumwingNo ratings yet

- EC (STi) 02 Emission ControlDocument18 pagesEC (STi) 02 Emission ControlGustavo RivasNo ratings yet

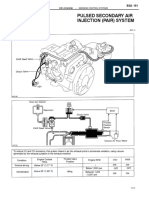

- Pulsed Secondary Air InjectionDocument3 pagesPulsed Secondary Air InjectionHugo Armando Garcia LepeNo ratings yet

- HV Pressure Tests - 3 PDFDocument4 pagesHV Pressure Tests - 3 PDFssNo ratings yet

- HV Pressure Tests - 3Document4 pagesHV Pressure Tests - 3ssNo ratings yet

- 98 Dodge Ram Truck SM SCSDocument1 page98 Dodge Ram Truck SM SCSEduardo MacMasterNo ratings yet

- KIA Carnival 04-Emission Control SystemDocument10 pagesKIA Carnival 04-Emission Control SystemHenryHutabarat100% (1)

- Maintenance Operations: Engine Cold Engine OperationsDocument18 pagesMaintenance Operations: Engine Cold Engine OperationsJorgeAlbuquerqueNo ratings yet

- GAC-12-VX-RMH-LAH-001 - Attachments - 1 To 7Document17 pagesGAC-12-VX-RMH-LAH-001 - Attachments - 1 To 7Dipayan DasNo ratings yet

- Ahu SelectionDocument52 pagesAhu SelectionFaquruddinNo ratings yet

- Inspec 40Document3 pagesInspec 40Rodrigo VillagraNo ratings yet

- AGV50 Manual, Version 4 - 1Document53 pagesAGV50 Manual, Version 4 - 1Luis Jonathan Bahamaca FernandezNo ratings yet

- Commissioning of TransformerDocument8 pagesCommissioning of TransformeranilsinghteslaNo ratings yet

- Venturi ManualDocument8 pagesVenturi ManualStavros DorisNo ratings yet

- ROIVsDocument8 pagesROIVshamza shafiqNo ratings yet

- 2007 Toyota Prius 1.5L MFI HEV DOHC 4cyl - Repair Guides - Components & Systems - Idle Air Control ValveDocument11 pages2007 Toyota Prius 1.5L MFI HEV DOHC 4cyl - Repair Guides - Components & Systems - Idle Air Control ValvePrivate LaneNo ratings yet

- GAC-12-VX-RMH-LAH-006 - Rev 1 - Attachments - 1 To 9Document15 pagesGAC-12-VX-RMH-LAH-006 - Rev 1 - Attachments - 1 To 9Dipayan DasNo ratings yet

- Damcos VPI Valve Position IndicationDocument4 pagesDamcos VPI Valve Position IndicationSR CUPSNo ratings yet

- PVG32 Assembly TestingDocument15 pagesPVG32 Assembly Testingjose manuel barroso pantojaNo ratings yet

- EC (H4SO) Emission ControlDocument18 pagesEC (H4SO) Emission ControlHMs SamuelNo ratings yet

- Exhaust Gas Recirculation (Egr) System: EngineDocument4 pagesExhaust Gas Recirculation (Egr) System: EnginemangyanNo ratings yet

- 1GR FE ChargingDocument15 pages1GR FE ChargingDemosthenes QuintanaNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- DTCP 0420Document2 pagesDTCP 0420swap2gzNo ratings yet

- FrontshoDocument4 pagesFrontshoswap2gzNo ratings yet

- KnocksenDocument4 pagesKnocksenswap2gzNo ratings yet

- HowtoproDocument3 pagesHowtoproswap2gzNo ratings yet

- UppersusDocument2 pagesUppersusswap2gzNo ratings yet

- SteeringDocument10 pagesSteeringswap2gzNo ratings yet

- GeneraldDocument2 pagesGeneraldswap2gzNo ratings yet