Professional Documents

Culture Documents

1 s2.0 0143749695987425 Main

1 s2.0 0143749695987425 Main

Uploaded by

Şebnem İlarslanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 0143749695987425 Main

1 s2.0 0143749695987425 Main

Uploaded by

Şebnem İlarslanCopyright:

Available Formats

I~UTTERWQRTH &t. J.

Adhesion and Adhesives 15 (1995) 87 90

I~E I N E M A N N Elsevier Science Limited

Printed in Great Britain

0143-7496/95/$10.00

Treatment of low energy surfaces for adhesive

bonding

D.M. Brewis*, I. Mathieson and M. Wolfensberger*

Institute of Surface Science and Technology, University of Technology,

Loughborough, Leicestershire LE11 3TU, UK

Surface pretreatment methods to enhance adhesion to polymers with low surface energies generally either

remove a region of low strength from the surface or introduce new surface functional groups. The

relative importance of these two mechanisms is examined in the present paper for various combinations

of pretreatment and polymer.

(Keywords: adhesive bonding; polymers; surface pretreatment)

INTRODUCTION transferred at low loads to an epoxide adhesive 1. Some

improvements in adhesion to chemically unmodified

Organic molecules including polymers possess low P T F E have been achieved. In multiple bonding experi-

surface energies. The poor adhesion to some polymers ments where an epoxide was bonded many times to the

has often been ascribed to this low surface energy, but same piece of PTFE, a 2.2 fold increase in bond

an alternative reason has also been proposed, namely strength occurred2; this may have been due in part to

the existence of weak boundary layers - i.e. a region of an increase in roughness. Plasma treatment (Table 1)

low cohesive strength between the polymer and the resulted in a fourfold increase in joint strength without

adhesive. Many pretreatments are available to enhance significant change in surface chemistry as determined

the adhesion to polymers. These pretreatments range by X-ray photoelectron spectroscopy (XPS) 3.

from a solvent wipe for poly(vinyl chloride) (PVC), to To achieve high adhesion levels with PTFE, it may

grit blasting for composites, and to flame treatment for be that substantial chemical modification is required as

polyolefins. In the first case the pretreatment removes a is achieved with the commercial sodium complex

region of low strength from the surfaces. In other cases treatment Tetra-Etch (Table 2).

a pretreatment may be effective by introducing new

functional groups into a surface or by a combination

of the two mechanisms.

In the present paper, the relative importance of these Cls

two mechanisms is examined for various combinations Fls

of pretreatment and polymer. These combinations are

the sodium complex and plasma treatments of fluori-

nated polymers, the reversible bromination of polyethyl-

C KLL

enes, and the treatment of poly(ether ether ketone)

(PEEK) with a flame and also with chromic acid. The g F 2s

KLL O ls I I

epoxide adhesive used in all experiments was Araldite ,-n

AV100 with HVI00 hardener.

FLUOROPOLYMERS

The existence of a weak boundary layer has been I I I I I I I I '2 o o

1000 800 600 400

demonstrated in the case of polytetrafluoroethylene

4 Bindingenergy (eV)

(PTFE). Figure 1 shows that fluorinated material was

Figure I XPS broad scan of the surface of an epoxide adhesive

* To whom correspondence should be addressed which had been cured in contact with PTFE. The PTFE was

~Visiting scientist from the Swiss Federal Laboratories for Materials detached from the epoxide at a low failure load but transfer of fluori-

Testing and Research (EMPA), Switzerland nated material has clearly taken place (ref. 1, with permission)

INT. J. ADHESION AND ADHESIVES Volume 15 Number 2 1995 87

Treatment of low energy surfaces: D.M. Brewis et al.

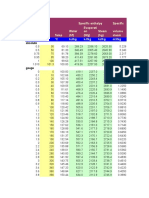

Table I Surfaceanalysis and bond strengths of poly(vinyl fluoride) (PVF) and PTFE after plasma treatments

XPS (atom%)

Polymer Plasma C O F Failure load (N)

PVF None 70.4 0.8 28.8 360

Ar, I rain 71.3 11.0 17.7 4060

Ar, 30min 78.0 11.9 10.1 4540

02, I rain 66.3 12.4 21.3 3420

Air, I rain 66.8 8.0 25.2 3080

N2, I rain 66.5 5.8 27.7 2720

PTFE None 34.6 65.4 420

Ar, I min 42.1 4.5 53.4 1340

Ar, 5 rain 33.1 1.6 65.3 1400

Ar, 30 min 33.5 0.9 65.6 1860

Ar, 60 min 32.8 0.2 67.0 1660

02, I rain 34.4 65.6 1080

O~, 10min 33.6 0.2 66.2 1440

02, 30min 34.0 0.5 65.5 640

Table 2 Effect of Tetra-Etch treatment on PTFE, PVF and poly(vinylidenefluoride) (PVdF)

Polymer, XPS (atom%)

treatment time Colour C F O Failure load (N)

PTFE, none white 38.4 61.6 0 420

PTFE, 10 s brown 87.6 0.8 I 1.6 4280

PTFE, 1 rain black 82.2 0.9 16.9 4260

PVF, none colourless 70.4 28.8 0.8 360

PVF, 10 s colourless 72.4 26.7 0.9 8O0

PVF, 1rain colourless 75.4 23.0 1.6 2080

PVF, 60 min colourless 87.3 11.4 1.3 3020

(i

PVdF, none colourless 51.4 47.9 0.7

PVdF, 1min faint brown 77.4 12.9 9.7 ¢1

PVdF, 60 min faint brown 79.5 9.2 11.3

"Not measured

There is an interesting contrast in the T e t r a - E t c h substantial changes occur to the surface chemistry v 9. It

t r e a t m e n t s of P T F E a n d poly(vinyl fluoride) (PVF). has been argued that good adhesion can be o b t a i n e d to

The chemical modifications at a given t r e a t m e n t time chemically u n m o d i f i e d polyolefins l°'tl but there is no

are m u c h more p r o n o u n c e d with P T F E . In the case of clear evidence to s u p p o r t this ~2. However, there is good

PVF, large increases in j o i n t strength are o b t a i n e d evidence to show that the p o o r adhesion o b t a i n e d with

w i t h o u t i n t r o d u c i n g a s u b s t a n t i a l q u a n t i t y of oxygen- u n t r e a t e d polyolefins is due to a lack of f u n c t i o n a l

c o n t a i n i n g f u n c t i o n a l groups. This indicates that groups. F o r example, work by Chew et al. 13 showed

i m p r o v e m e n t in adhesion is m a i n l y due to the elimina- that large increases in j o i n t strength were o b t a i n e d

tion of a potential weak b o u n d a r y layer. This is when low density polyethylene ( L D P E ) a n d high

supported by the fact that a n o t h e r batch of P V F gave density polyethylene ( H D P E ) were b r o m i n a t e d (Figure

good adhesion to the same epoxide adhesive w i t h o u t a 2). However, the j o i n t strengths returned to very low

p r e t r e a t m e n t 4, A l t h o u g h the surface energies of P V F

a n d poly(vinylidene fluoride) (PVdF) are similar to

that of polyethylene, the former two polymers are

B r 2 / hv

polar ~ a n d therefore relatively strong interactions can

be achieved to an epoxide. In some cases chemical

b o n d i n g m a y occur between the f l u o r o p o l y m e r a n d the

epoxide adhesive 6,

--CH2--CH2-- CH2--CHBr--

POLYOLEFINS

C o r o n a t r e a t m e n t is the most c o m m o n l y used pretreat-

m e n t for polyolefin films whereas flame t r e a t m e n t is

usually used for thicker sections of polyolefin such as

bottles. C h r o m i c acid is sometimes used where the TBTH

p o l y m e r has a complex shape. In all these cases Figure 2 The reversible bromination of polyethylene13

88 INT. J. ADHESION AND ADHESIVES Volume 15 Number 2 1995

Treatment of low energy surfaces: D.M. Brewis et al.

Table 3 Effect of bromination and subsequent reduction of Table 5 Joint strengths obtained with untreated and treated PEEK

polyethylene on joint strength

Failure load (kN)"

Joint strength XPS data

Polymer (MPa) Br:C (atom%) Treatment Batch 1 Batch 2

Untreated LDPE 1.4 0 None 2.8 0.7

Brominated LDPE (A) 12.7 11 Flamet' 4.9 0.9

Reduction of (A) 1.8 0 Chromic acid" (1 min, 60C) 4.0

Chromic acid (5 min, 35"C) 3.2

Untreated HDPE 0.7 0 Chromic acid (1 min, 33°C) 3.1

Brominated HDPE (B) 11.5 5.9

Reduction of (B) 0.8 0 ~Film of PEEK bonded with an epoxide to two mild steel strips

(60mm long × 20mm wide) so the overlap area is 20mm × 10mm

hFlame treatment was for 0.012 s

'The chromic acid comprised potassium dichromate, water and

levels when the brominated polyethylenes were reduced concentrated sulfuric acid in the ratio 7:12:150 by weight

back to polyethylene with tributyltinhydride (TBTH) in

m e t h y l t e t r a h y d r o f u r a n as shown in Table 3.

Further evidence to support the view that p o o r differences between the two untreated materials. The

adhesion with polyolefins is due to a lack o f functional- likely cause o f the p o o r adhesion with batch 2 is an

ity rather than weak b o u n d a r y layers is given by the inadequate degree o f polymerization. Flame treatment

work o f Brewis j4 in which he deliberately added a layer m a y chemically modify the surface o f batch 2 but if a

o f low cohesive strength ( h y d r o c a r b o n grease) to a region o f low cohesive strength which cannot be

chromic acid treated H D P E . The results are given in absorbed by the adhesive remains, then p o o r adhesion

Table 4. Addition o f the h y d r o c a r b o n grease caused will result. The success o f the chromic acid treatment is

some reduction in joint strength but the value remained presumably due to dissolution o f the relatively low

much higher than that o f the untreated polymer. This molecular weight material on the surface o f the P E E K

means that the grease layer, which was about 1 #m (batch 2).

thick, was absorbed by the epoxide adhesive. The

implication o f this work is that even if there is a region

of low cohesive strength on a polymer surface, due to CONCLUSIONS

low molecular weight polymer or additives, it need not

necessarily behave as a weak b o u n d a r y layer. Whether l) To obtain high adhesion levels to fully fluorinated

the layer is absorbed will depend on various factors polymers such as P T F E and to polyolefins, it is

including the thickness o f the layer, the compatibility p r o b a b l y necessary to significantly modify their

between the layer and the adhesive, the temperature surface chemistry.

and the time the adhesive takes to harden. 2) Most other polymers contain sufficient functionality

to achieve at least reasonable joint strengths. If

p o o r adhesion is obtained with these polymers, it is

POLY(ETHER ETHER KETONE) probably due to a weak b o u n d a r y layer.

3) With partially fluorinated polymers such as P V F

P E E K possesses a reasonable degree o f functionality, and P V d F g o o d adhesion can be achieved without a

i.e. pretreatment. However, some batches o f these

polymers may have regions o f low cohesive strength

on their surfaces and thus require a pretreatment.

O

4) There is sufficient functionality in untreated P E E K

-o-@-o-©-c- II

to achieve g o o d adhesion but regions o f low

cohesive strength on the surface m a y lead to p o o r

adhesion with a given batch o f polymer.

and p o o r adhesion to untreated P E E K would not be

expected from its structure. In a recent study ~5 g o o d

adhesion was obtained to one batch o f P E E K but p o o r

adhesion was obtained to another (Table 5). REFERENCES

Flame treatment caused a substantial improvement

1 Briggs,D. in 'Industrial Adhesion Problems' (Eds D.M, Brewis

in adhesion to batch 1. XPS indicated no significant and D. Briggs), Orbital Press, Oxford, 1985, p. 15

2 Brewis, D.M., Mathieson, I., Sutherland, 1. and Cayless, R.A.J.

Adhes. 1993, 41, 113

Table 4 Effect of added layer of hydrocarbon grease to joint 3 Mathieson, I., Brewis, D.M., Sutherland, I., Cayless, R.A.J.

strength with chromic acid treated HDPE Adhes. 1994, 46, 49

4 Brewis, D.M. Prog. Rubber Plast. Technol. 1985, 1(4), 1

Lap shear 5 Rance, D.G. in 'Industrial Adhesion Problems' (Eds D.M.

Treatment strength (MPa) Brewis and D. Briggs), Orbital Press, Oxford, 1985, p. 121

6 Schonhorn, H. and Luongo, J.P.J. Adhes. Sci. Technol. 1989,

None 1.8 3(4), 2277

Chromic acid (C) 17.6 7 Briggs,D. and Kendall, C.R. Int. J. Adhes. Adhes. 1982, 2, 13

As (C) but layer of hydrocarbon added 12.7 8 Briggs D., Brewis, D.M. and Konieczko, M.B.J. Mater. Sci

1979, 14, 1344

INT. J. ADHESION AND ADHESIVES Volume 15 Number 2 1995 89

Treatment of low energy surfaces: D.M. Brewis et al.

9 Briggs D., Brewis, D.M. and Konieczko, M.B.J. Mater. Sci 12 Brewis, D.M. Int. J. Adhes. Adhes. 1993, 13(4), 251

1976, 11, 1270 13 Chew, A., Dahm, R.H., Brewis, D.M., Briggs, D. and Rance,

10 Schonhorn, H. and Hansen, R.H.J. Appl. Polym. Sci. 1967, 11, D.G.J. Colloid Interf. Sci, 1986, 110(1), 88

1461 14 Brewis, D.M.J. Mater. Sci. 1968, 3(3), 262

11 Blais, P., Carlsson, DJ., Csullog, G.W. and Wiles, D . M . J . 15 Brewis, D.M., Mathieson, I. and Wolfensberger, M. unpub-

Colloid InterJ~ Sci. 1974, 47, 610 lished work

90 INT. J. ADHESION AND ADHESIVES Volume 15 Number 2 1995

You might also like

- наполнители PTFEDocument4 pagesнаполнители PTFEAndreyNo ratings yet

- Graded Ni-P-PTFE Coatings and Their Potential ApplicationsDocument6 pagesGraded Ni-P-PTFE Coatings and Their Potential ApplicationsJosé Emilio Román de AndaNo ratings yet

- Surface & Coatings Technology: Emerson Escobar Nunez, Seung Min Yeo, Kyriaki Polychronopoulou, Andreas A. PolycarpouDocument12 pagesSurface & Coatings Technology: Emerson Escobar Nunez, Seung Min Yeo, Kyriaki Polychronopoulou, Andreas A. PolycarpouJon KiNo ratings yet

- Slimming World, Feb 2011Document5 pagesSlimming World, Feb 2011emediageNo ratings yet

- HMSPPDocument3 pagesHMSPPMarian AmayaNo ratings yet

- Protective Performance of Epoxy Resin Modified With Coal Tar Coating Studied by Electrochemical Impedance SpectrosDocument4 pagesProtective Performance of Epoxy Resin Modified With Coal Tar Coating Studied by Electrochemical Impedance SpectrosLê Tuấn HùngNo ratings yet

- Partial Discharge Resistant Characteristics of Epoxy Nanocomposites PDFDocument11 pagesPartial Discharge Resistant Characteristics of Epoxy Nanocomposites PDFMOHD HAFIZI BIN AHMAD FKENo ratings yet

- Radiation Processing of FluoropolymersDocument7 pagesRadiation Processing of FluoropolymerscgeategcNo ratings yet

- Agentes Dispersante para Negro de HumoDocument11 pagesAgentes Dispersante para Negro de HumoMauricio LombanaNo ratings yet

- Interface Engineering of Perovskite Solar Cells With PEO For Improved PerformanceDocument6 pagesInterface Engineering of Perovskite Solar Cells With PEO For Improved PerformanceHuckkey HuNo ratings yet

- Nature: Chemistry Two New Complex Calcium Ferrite PhasesDocument1 pageNature: Chemistry Two New Complex Calcium Ferrite PhasesSatadal GhoraiNo ratings yet

- 1 s2.0 S0378775315006539 MainDocument6 pages1 s2.0 S0378775315006539 MainwangyimingNo ratings yet

- JPC2006Document5 pagesJPC2006vumar83No ratings yet

- Artikel 2Document12 pagesArtikel 2Carolina TambaNo ratings yet

- The Effect of Carbon Aspect Ratio On The Friction and Wear of PtfeDocument9 pagesThe Effect of Carbon Aspect Ratio On The Friction and Wear of PtfeHenk van GansenNo ratings yet

- The Corrosion Behaviour of Polypyrrole Coating Synthesized in Phenylphosphonic Acid SolutionDocument8 pagesThe Corrosion Behaviour of Polypyrrole Coating Synthesized in Phenylphosphonic Acid SolutionMarly Blanco VeraNo ratings yet

- Interface Phenomena On Conducting Polymer Films Investigated With Atomic Force SpectrosDocument5 pagesInterface Phenomena On Conducting Polymer Films Investigated With Atomic Force SpectroslluettaNo ratings yet

- 10 MeV Electron Beam Cross-Linking of Plasticized PVCDocument6 pages10 MeV Electron Beam Cross-Linking of Plasticized PVCDuc Nguyen HuuNo ratings yet

- Pola 1988 080260604Document9 pagesPola 1988 080260604Samara SuellenNo ratings yet

- 2011 APL C60 CuPc OSC HiramotoDocument4 pages2011 APL C60 CuPc OSC HiramotoAftab FarrukhNo ratings yet

- Zeus FocusPTFEDocument6 pagesZeus FocusPTFESelva BabuNo ratings yet

- PTFE SiO2ThinFilmsDocument7 pagesPTFE SiO2ThinFilms陳信辰No ratings yet

- J Jdent 2011 10 018Document8 pagesJ Jdent 2011 10 018kr7wyddmw2No ratings yet

- Antistatic Performance and Morphological Observation of Ternary Blends of Poly (Ethylene Terephthalate), Poly (Ether Esteramide), and Na-Neutralized Poly (Ethylene-Co-Methacrylic Acid) CopolymersDocument9 pagesAntistatic Performance and Morphological Observation of Ternary Blends of Poly (Ethylene Terephthalate), Poly (Ether Esteramide), and Na-Neutralized Poly (Ethylene-Co-Methacrylic Acid) CopolymersEliton Medeiros Candido de MacêdoNo ratings yet

- Applied Catalysis A: General: Laura Suárez, Huiyu Dong, Cesar Pulgarin, Rosendo Sanjines, Zhimin Qiang, John KiwiDocument10 pagesApplied Catalysis A: General: Laura Suárez, Huiyu Dong, Cesar Pulgarin, Rosendo Sanjines, Zhimin Qiang, John KiwiAlvin Rahmad WidyantoNo ratings yet

- Communications To The Editor: ModelDocument3 pagesCommunications To The Editor: ModelLaboratorio de TermohigrometríaNo ratings yet

- 791 PDFDocument4 pages791 PDFKarolina KaczmarskaNo ratings yet

- Preparation and Optical Properties of Barium Titanate Thin Films.Document5 pagesPreparation and Optical Properties of Barium Titanate Thin Films.Farhan Naufal Firdaus Al-FathNo ratings yet

- Applied Surface Science: Leticia F. Velasco, Jose B. Parra, Conchi O. AniaDocument5 pagesApplied Surface Science: Leticia F. Velasco, Jose B. Parra, Conchi O. AniaA. M. SHAREQUENo ratings yet

- PVDFDocument9 pagesPVDFAnish KumarNo ratings yet

- LDPE CB TiDocument10 pagesLDPE CB TianthonyNo ratings yet

- Studies On The Dynamic Mechanical and Vibration Damping Properties of Yether Urethane and Epoxy CompositesDocument7 pagesStudies On The Dynamic Mechanical and Vibration Damping Properties of Yether Urethane and Epoxy Compositesravi kumar B v ANo ratings yet

- Ja8005918 BaozhenanDocument2 pagesJa8005918 BaozhenanYonggang ZhenNo ratings yet

- Study of A New Polymer Electrolyte Poly (Ethylene Oxide) : Naclo With Several Plasticizers For Battery ApplicationDocument6 pagesStudy of A New Polymer Electrolyte Poly (Ethylene Oxide) : Naclo With Several Plasticizers For Battery ApplicationKRUNAL ParmarNo ratings yet

- Accepted Manuscript: Journal of Photochemistry and Photobiology A: ChemistryDocument37 pagesAccepted Manuscript: Journal of Photochemistry and Photobiology A: ChemistryAudry AriasNo ratings yet

- Compatibility Behaviour of Blends of Poly (Ethylene Terephthalate) With An Amorphous CopolyesterDocument7 pagesCompatibility Behaviour of Blends of Poly (Ethylene Terephthalate) With An Amorphous CopolyesterJosé Roberto LazoNo ratings yet

- Xie Et Al. - 2015 - Effective Protection of Sequential Solution-Processed Polymerfullerene Bilayer Solar Cell Against Charge RecombinDocument7 pagesXie Et Al. - 2015 - Effective Protection of Sequential Solution-Processed Polymerfullerene Bilayer Solar Cell Against Charge RecombinLIN XIENo ratings yet

- A Mechanistic Study Explaining the Synergistic Viscosity Increase Obtained From Polyethylene Oxide (PEO) and Β-naphthalene Sulfonate (BNS) in ShotcreteDocument8 pagesA Mechanistic Study Explaining the Synergistic Viscosity Increase Obtained From Polyethylene Oxide (PEO) and Β-naphthalene Sulfonate (BNS) in Shotcrete胡家兵No ratings yet

- Effects of The Composition of Hot-Melt Adhesives On Their Bulk and Interfacial PropertiesDocument7 pagesEffects of The Composition of Hot-Melt Adhesives On Their Bulk and Interfacial PropertieskübraNo ratings yet

- Poly (Vinyl Methyl Ether) Poly (Methyl Methacrylate) Blends Using Diblock CopolymerDocument5 pagesPoly (Vinyl Methyl Ether) Poly (Methyl Methacrylate) Blends Using Diblock Copolymerfadhillah ivanNo ratings yet

- Optical Materials: SciencedirectDocument3 pagesOptical Materials: SciencedirectBlue StarNo ratings yet

- Polymer: Gung-Pei Chang, Ching-Nan Chuang, Jong-Yih Lee, Yung-Shen Chang, Man-Kit Leung, Kuo-Huang HsiehDocument8 pagesPolymer: Gung-Pei Chang, Ching-Nan Chuang, Jong-Yih Lee, Yung-Shen Chang, Man-Kit Leung, Kuo-Huang Hsieh張大帥No ratings yet

- Hydrogen Bonding Effects in Perfluorinated Polyamides: An Investigation Based On Infrared Spectroscopy and Density Functional Theory CalculationsDocument14 pagesHydrogen Bonding Effects in Perfluorinated Polyamides: An Investigation Based On Infrared Spectroscopy and Density Functional Theory CalculationsGiorgio CanilNo ratings yet

- Irdham Kusumawardhana 1Document8 pagesIrdham Kusumawardhana 1PRIMA100% (2)

- 1 s2.0 S0969806X21005181 MainDocument9 pages1 s2.0 S0969806X21005181 MainJessica GattiNo ratings yet

- Naddeo 2004Document5 pagesNaddeo 2004Roshni PattanayakNo ratings yet

- Using Triple-Layer Remote Phosphor Structures LaVO4:Eu3+ and ZnS:Cu, SN To Improve The Chromatic Uniformity and Luminous Quality of WLEDsDocument7 pagesUsing Triple-Layer Remote Phosphor Structures LaVO4:Eu3+ and ZnS:Cu, SN To Improve The Chromatic Uniformity and Luminous Quality of WLEDsTELKOMNIKANo ratings yet

- Ac Impedance X Ray Photoelectron SpectroDocument12 pagesAc Impedance X Ray Photoelectron Spectrochérifa boulechfarNo ratings yet

- Meysam Najafi, Kaveh Haghighi Mood, Mansour Zahedi, Erik KleinDocument12 pagesMeysam Najafi, Kaveh Haghighi Mood, Mansour Zahedi, Erik KleinJesus MF JMFNo ratings yet

- The Function of A TiO2 Compact Layer in Dye-Sensitized Solar Cells Incorporating "Planar" Organic DyesDocument5 pagesThe Function of A TiO2 Compact Layer in Dye-Sensitized Solar Cells Incorporating "Planar" Organic DyesTiến NguyễnNo ratings yet

- 1-s2.0-S092702481000098X-main - For PresentationDocument5 pages1-s2.0-S092702481000098X-main - For PresentationFlorentin DumitruNo ratings yet

- XA9642868 G. Marinello Departement Inter-Hospitalier de Cancerologie, Service de Radiotherapie. Centre Hospitalo-Universitaire, Creteil, FranceDocument14 pagesXA9642868 G. Marinello Departement Inter-Hospitalier de Cancerologie, Service de Radiotherapie. Centre Hospitalo-Universitaire, Creteil, FranceGourav ChauhanNo ratings yet

- Continuous Modification Treatment of Polyester Fabric by Dielectric Barrier DischargeDocument5 pagesContinuous Modification Treatment of Polyester Fabric by Dielectric Barrier DischargeKasra GolbanNo ratings yet

- Bordi 2004Document42 pagesBordi 2004brouuorbNo ratings yet

- Understanding The Difference of Photocatalytic Activity Amongst Anatase Vs Rutile - May14Document5 pagesUnderstanding The Difference of Photocatalytic Activity Amongst Anatase Vs Rutile - May14srowbothamNo ratings yet

- 0 Unknown Upload 24363416 sdn03r SCDocument42 pages0 Unknown Upload 24363416 sdn03r SCrajanadarajanNo ratings yet

- Relative Photonic Efficiencies and Quantum Yields in Heterogeneous PhotocatalysisDocument12 pagesRelative Photonic Efficiencies and Quantum Yields in Heterogeneous PhotocatalysisPaula TrindadeNo ratings yet

- 1991 - Defect Chemistry of BaTiO3Document20 pages1991 - Defect Chemistry of BaTiO3Beh NaatNo ratings yet

- mero2005Document7 pagesmero2005liviu9nanoNo ratings yet

- The Chemistry of Membranes Used in Fuel Cells: Degradation and StabilizationFrom EverandThe Chemistry of Membranes Used in Fuel Cells: Degradation and StabilizationShulamith SchlickNo ratings yet

- 1 s2.0 S000862231200111X MainDocument10 pages1 s2.0 S000862231200111X MainŞebnem İlarslanNo ratings yet

- 1 s2.0 S0926860X05003054 MainDocument11 pages1 s2.0 S0926860X05003054 MainŞebnem İlarslanNo ratings yet

- Adv Mat13, 677Document5 pagesAdv Mat13, 677Şebnem İlarslanNo ratings yet

- Biesinger 2017Document10 pagesBiesinger 2017Şebnem İlarslanNo ratings yet

- Ashby, 1988Document9 pagesAshby, 1988Şebnem İlarslanNo ratings yet

- Graphene Materials With Different Structures Prepared From The Same Graphite by The Hummers and Brodie MethodsDocument26 pagesGraphene Materials With Different Structures Prepared From The Same Graphite by The Hummers and Brodie MethodsŞebnem İlarslanNo ratings yet

- Sensors: Determination of Trace Antimony (III) by Adsorption Voltammetry at Carbon Paste ElectrodeDocument9 pagesSensors: Determination of Trace Antimony (III) by Adsorption Voltammetry at Carbon Paste ElectrodeŞebnem İlarslanNo ratings yet

- Inorganic: ChemistryDocument8 pagesInorganic: ChemistryŞebnem İlarslanNo ratings yet

- Food Chemistry: S. Carneado, E. Hernández-Nataren, J.F. López-Sánchez, A. SahuquilloDocument7 pagesFood Chemistry: S. Carneado, E. Hernández-Nataren, J.F. López-Sánchez, A. SahuquilloŞebnem İlarslanNo ratings yet

- Talanta: Carlos Rojas-Romo, Núria Serrano, Cristina Ariño, Verónica Arancibia, José Manuel Díaz-Cruz, Miquel EstebanDocument7 pagesTalanta: Carlos Rojas-Romo, Núria Serrano, Cristina Ariño, Verónica Arancibia, José Manuel Díaz-Cruz, Miquel EstebanŞebnem İlarslanNo ratings yet

- Science of The Total EnvironmentDocument5 pagesScience of The Total EnvironmentŞebnem İlarslanNo ratings yet

- Journal of Food Composition and Analysis: Cu Neyt Gu Ler, Musa AlpaslanDocument10 pagesJournal of Food Composition and Analysis: Cu Neyt Gu Ler, Musa AlpaslanŞebnem İlarslanNo ratings yet

- Entropy Change For Chemical ReactionDocument11 pagesEntropy Change For Chemical ReactiongtdomboNo ratings yet

- Investigation of tungsten/EUROFER97 Diffusion Bonding Using NB InterlayerDocument4 pagesInvestigation of tungsten/EUROFER97 Diffusion Bonding Using NB InterlayerHARIMETLYNo ratings yet

- Arka BrochureDocument12 pagesArka BrochureQOQO TEAMNo ratings yet

- Onion ReviewDocument13 pagesOnion ReviewSathish D.No ratings yet

- BWT CS-1001 enDocument1 pageBWT CS-1001 enMehdi AcilNo ratings yet

- 28b. IS 3600 - 2 - 1985 PDFDocument2 pages28b. IS 3600 - 2 - 1985 PDFhhr2412No ratings yet

- 02-04-2023 SR - Super60 Nucleus & All BT Jee-Main-Gtm-33 Key & Sol'sDocument14 pages02-04-2023 SR - Super60 Nucleus & All BT Jee-Main-Gtm-33 Key & Sol'sK R I S HNo ratings yet

- Basic Mineralogy: Introduction To Mineralogy and Petrology (Second Edition)Document16 pagesBasic Mineralogy: Introduction To Mineralogy and Petrology (Second Edition)DanaNo ratings yet

- FINAL SMAW-12-Quarter-3-module 3 PDFDocument20 pagesFINAL SMAW-12-Quarter-3-module 3 PDFRandy Sacatani100% (1)

- CHAPTER 6 Flow in Pipes FinalDocument22 pagesCHAPTER 6 Flow in Pipes FinalSyaiful Akmal AzizNo ratings yet

- B 2648 PDFDocument6 pagesB 2648 PDFbcanilkumar007No ratings yet

- Final Leed RheedDocument28 pagesFinal Leed RheedAngshuman SarkarNo ratings yet

- Sad PDFDocument1 pageSad PDFrisrizNo ratings yet

- Prob11 25Document1 pageProb11 25ozi125_2No ratings yet

- COG Broschuere O-Ring 1x1 enDocument52 pagesCOG Broschuere O-Ring 1x1 entehnoNo ratings yet

- Ohayon Biodiesel PowerpointDocument15 pagesOhayon Biodiesel PowerpointnapinnvoNo ratings yet

- Voluntary Estuary Monitoring Manual Chapter 11: PH and AlkalinityDocument13 pagesVoluntary Estuary Monitoring Manual Chapter 11: PH and AlkalinityManeet SharmaNo ratings yet

- 1MC06 CEK GT REP C002 000154 Soil Classification of Backfill SoilDocument83 pages1MC06 CEK GT REP C002 000154 Soil Classification of Backfill SoilAnilNo ratings yet

- Reinforce Plastics: Ro Membrane Housing and Pressure VesselsDocument2 pagesReinforce Plastics: Ro Membrane Housing and Pressure VesselsSunriseNo ratings yet

- Steam Tracing and Relevant UsageDocument3 pagesSteam Tracing and Relevant UsageKalpeshNo ratings yet

- Design Analysis of A Refrigerated Warehouse Using LNG Cold EnergyDocument10 pagesDesign Analysis of A Refrigerated Warehouse Using LNG Cold EnergyJSK1 JSK11No ratings yet

- GME Question Paper 2015 (New)Document4 pagesGME Question Paper 2015 (New)Ekantha MoorthyNo ratings yet

- Cast Steel 2017 1 0Document100 pagesCast Steel 2017 1 0geovanny sinahi santos avelinoNo ratings yet

- Modul Chemistry Form 5Document101 pagesModul Chemistry Form 5cikgufiezaNo ratings yet

- Modelling and Simulation of A Direct Contact Rotary DryerDocument16 pagesModelling and Simulation of A Direct Contact Rotary DryerVinh Do ThanhNo ratings yet

- Fu 2009Document11 pagesFu 2009Kim Anh NguyễnNo ratings yet

- Steam Tables - MetricDocument4 pagesSteam Tables - MetricUdhayakumar VenkataramanNo ratings yet

- Smart Supercapacitors From Materials To DevicesDocument13 pagesSmart Supercapacitors From Materials To DevicesRavi SuryaNo ratings yet

- 13 Water Treatment Training Pretreatment FiltrationDocument32 pages13 Water Treatment Training Pretreatment Filtrationsantoshkumar gurmeNo ratings yet

- Determination of C Through C Hydrocarbons in Gasolines by Gas ChromatographyDocument7 pagesDetermination of C Through C Hydrocarbons in Gasolines by Gas Chromatographyrimi7alNo ratings yet