Professional Documents

Culture Documents

General Notes 1

General Notes 1

Uploaded by

محمد ابراهيمCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes 1

General Notes 1

Uploaded by

محمد ابراهيمCopyright:

Available Formats

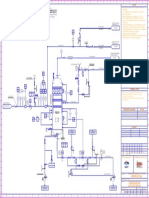

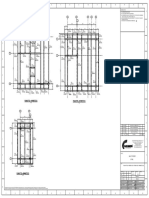

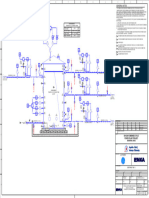

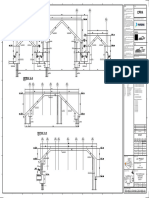

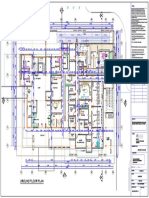

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

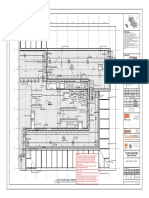

NOTES

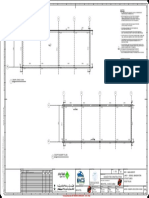

1. DIMENSIONS

A 1.1 All dimensions are in millimeter unless otherwise mentioned in

the drawings. A

STRUCTURAL NOTES 1.2 All dimensions should be checked with the road planning

and arch drawings.

2. CODES

2.1 The bridge has been designed according to the Egyptian

REINFORCEMENT DETAILS Code for the Design and Construction of R.C structures

DESIGN SPECIFICATIONS AND REFERENCE 7. SHRINKAGE (2018) Edition.

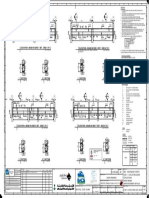

REINFORCING STEEL CALLOUTS SHALL BE READ AS SHOWN BELOW: 3. DRAWINGS

THE DESIGN OF THE BRIDGEWORKS IS IN ACCOORDANCE WITH ECP 207-2015. REFER TO ECP-203-2007 CLAUSE 2-3-3-4 3.1 All structural drawings should be revised with Road planning

THE LOADS ON THE BRIDGS IS IN ACCOORDANCE WITH THE EGYPTIAN CODE FOR LOADS, 2015. NUMBER OF BARS drawings.

GRADE OF CONCRETE 3.2 Do not measure from drawings. All dimension should be read

Ø - FOR TOR STEEL DEFORMED BAR or computed.

THE GRADE OF CONCRETE FOR THIS WORK ARE BASED ON 28 DAYS 4. DETAILED STRUCTURAL NOTES

COMPRESSIVE CUBIC STRENGTH AND AS PER ASTM C31/39 ARE AS FOLLOWS: 4.1 Fcu for pile & pile cap = 35 Mpa

B (MAX. SIZE AGGREGATE SHALL BE 20mm).

BAR DIAMETER(MM)

4.2 Concrete cover for pile & pile cap = 70 mm B

DESIGN LOADS BAR CENTER SPACING (MM) 4.3 Concrete cover for columns = 50 mm

REINFORCE CONCRETE DECK SLABS AND BOX GIRDER 50 MPa 4.4 For other detailed structural refer to general notes drawing.

LAYOUT/LOCATION

1. DEAD LOAD AND MATERIAL OWN WEIGHT REINFORCE CONCRETE PRESTRESSED BEAMS AND DIAPHRAGMS 55 MPa

T - TOP E. GENERAL ABBREVIATIONS AND SYMBOLS

3 PIERS , PIER CAPS AND PILE COLUMNS 45 MPa

CONCRETE OWN WEIGHT (REINFORCED AND PRESTRESSED) 25 kN/m B - BOTTOM S.O.L

S.O.P

Setting-Out Line

Setting-Out Point

PILES , PILE CAPS AND FOUNDATION OF RETAINING WALL 35 MPa 20 - Ø 16 - 200 - T

WEARING SURFACE 22 kN/m 3 EF - EXTERNAL FACE H.S.L

STA

Highway Stationing Line

Station along H.S.L

APPROACH SLAB AND BARRIER 35 MPa I.F - INNER FACE W.C.B Whole Circle Bearing

BLINDING AND MASS CONCRETE 24 kN/m 3 E.G.L Existing Ground Level

BLINDING AND MASS CONCRETE 20 MPa NF - NEAR FACE D.G.L Design Ground Level

STRUCTURAL STEEL WORK 78.5 kN/m 3 FF - FAR FACE F.G.L Finished Ground Level

c/c Center to Center

C SOIL ABOVE GROUND WATER TABLE 16 kN/m 3

ALL STRUCTURAL COMPONENTS SHALL BE CONSTRUCTED OF CEM I CEMENT AND WITH ALT - ALTERNATE C.J

dim

Construction Joint

dimension C

CEMENT (OPC) WITH THE APPROPRIATE PROPORTIONS OF CEMENT REPLACEMENTS. STAG - STAGGERED o.s.a or similar approved

SOIL BELOW GROUND WATER TABLE mm millimeters

6 kN/m 3 ADDITION SILICA FUME MATERIAL ADMIXTURE WITH RATE UP TO 8% OF CEMENT WEIGHT , WITH B.F - BOTH FACE m meters

MAXIMUM WATER PERCENTAGE FOR CEMENT 0.4. USING IN ADDITION FOR SELF-COMPACTION L Length

No. Number

2. LIVE LOAD CONCRETE, HIGH PERFORMANCE POLYCARBOXYLATE ETHER (PCE) ADMIXTURE. dia. diameter

c centre line

AND FOR PILES AND PILE CAPS USE SAME ADMIXTURE IN ADDITION TO PROTECT THE REBAR FROM N.T.S not to scale

THE DESIGN LIVE LOAD IS AS FOLLOWING: kN kilonewton

RUST BY USING AN ANTI-RUST MATERIAL FOR REBAR, AMINO ESTER MATERIAL WITH RATE 5 Lit./m3. CONCRETE GRADE kg kilogram

DEFORMED BAR fy = 400 MPA N Newton

I - 1ST LANE : CONSISTS OF TRUCK WEIGHTED 60 TON DISTRIBUTED ON FOUR POINTS (15 TON EACH) DEEP FOUNDATION P.G.L Profile Grade Level

IN ADDITION TO UNIFORMLY DISTRIBUTED LOAD 0.9 T/m2 APPLIED OVER THE LANE AREA. Fcu (N/mm2) In tension In compression N.G.L. Naturel Ground Level

THE CONTRACTOR SHALL BE RESPONSIBLE FOR CONDUCTING NECESSARY PILE TESTS.

D D

sea level

LAP SPLICES

datum

DISTRIBUTED LOAD SHOULD BE ARRANGEMENT TO INTRODUCE THE MOST UN-FAVORITE EFFECT. TESTING ACCORDING TO TECHNICAL SPECIFICATION. 35 45 d 40 d

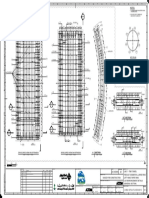

Key Plan:

N

PILE LENGTH SHOULD BE DEFINED BASED ON ACTUAL SUBSURFACE STRATIFICATION AND SCOUR DEPTH.

II- 2ND LANE : CONSISTS OF TRUCK WEIGHTED 40 TON DISTRIBUTED ON FOUR POINTS (10 TON EACH) 40 42 d 40 d

FOR SOIL PARAMETERS , REFER TO CALCULATION NOTES , CHAPTER (7).

IN ADDITION TO UNIFORMLY DISTRIBUTED LOAD 0.25 T/m2 APPLIED OVER THE LANE AREA.

> 45 40 d 40 d

DISTRIBUTED LOAD SHOULD BE ARRANGEMENT TO INTRODUCE THE MOST UN-FAVORITE EFFECT. BH-A3

BH-A2

A2

BH-A1

A1

TYPE OF REINFORCEMENT

BH-A4

A3

BH-A5

A4

BH-A6 A5

A8 BH-A7 A6

A9

BH-A8

III - 3RD LANE : CONSISTS OF TRUCK WEIGHTED 20 TON DISTRIBUTED ON FOUR POINTS (5 TON EACH)

BH-C1

A7

A10

BH-B1 BH-A9

BH-C2

A11

BH-B2

ALL REINFORCEMENT BARS ARE TO BE DEFORMED ROUND STEEL BARS

BH-A10

B3

C2

BH-B3 BH-C3

A17 BH-A11

B4

A18 BH-B4

BH-B4C B1

BH-C4

BH-A12

A19

BH-B4D

BH-C5 B2

BH-B4E BH-A13

A20

A12

BH-A14

*LAP SIZE IS ACCORDING TO EGYPTIAN CODE ECP 207-2015.

BH-B4F

BH-A15

B5

BH-B5 A13

B6 BH-A16

A14

BH-B6

BH-A17

IN ADDITION TO UNIFORMLY DISTRIBUTED LOAD 0.25 T/m2 APPLIED OVER THE LANE AREA.

A15

B7 A16

BH-A18

BH-B7

B8 BH-A19 A17

OF GRADE 40 / 60 COMPLYING WITH THE REQUIREMENT OF EGYPTIAN STANDARD 262

BH-B8

A18

BH-A20

B9

A19

BH-B9 BH-A21

A20

B10

BH-A22

BH-B10 A21

B11

BH-A23

A22

BH-B11

B12

BH-A24 A23

BH-B12

* d : IS THE DIAMETER OF STEEL BAR.

E E

B13

BH-B13 A24

BH-A25

B14

DISTRIBUTED LOAD SHOULD BE ARRANGEMENT TO INTRODUCE THE MOST UN-FAVORITE EFFECT.

BH-B14

A25

BH-A26

B15

SPECIFICATION .

BH-B15

B16

A26

BH-B16 BH-A27

B17

BH-B17

B18 A27

BH-A28

B19 BH-B18

B20 BH-B19

B22 B21

A28

BH-B20 BH-A29

BH-B21

BH-B22

BH-A30 A29

BH-A31

A30

BH-A32

BH-A33 A31

BH-A34

A32

BH-A35

BH-A36 A33

SPIRAL REINFORCEMENT PLAIN ROUND STEEL BARS GRADE 400

A34

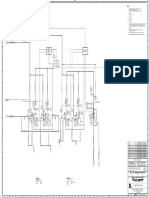

PRSTRESSING REINFORCEMENT :-

A36

A35

VI- OTHER LANE CONSISTS OF UNIFORMLY DISTRIBUTED LOAD 0.25 T/m2 APPLIED OVER THE REST TRAFFIC BRIDGE AREA.

COMPLYING WITH THE REQUIREMENT OF EGYPTIAN STANDARD 262. 1. PRESTRESSING TENDONS ARE.(Ø0.6"-AS PER TABLE WIRES STRAND) .

DISTRIBUTED LOAD SHOULD BE ARRANGEMENT TO INTRODUCE THE MOST UN-FAVORITE EFFECT.

WIRE MESH TO BE WELDED WIRE FABRIC REINFORCEMENT SMOOTH CONFORMING TO ASTM416-06 GRADE 270 WITH:

VII- UNIFORMLY DISTRIBUTED LOAD 0.5T/m2 APPLIED OVER THE PEDESTAL AREA DISTRIBUTED LOAD SHOULD BE ROUND BARS COMPLYING WITH THE REQUIREMENT OF EGYPTIAN STANDARD 262 - NOMINAL DIAMETER = 15.24mm

ARRANGEMENT TO INTRODUCE THE MOST UN-FAVORITE EFFECT. SPECIFICATION. - ULTIMATE STRENGHT = 1860 MPa

WHERE REINFORCING BARS ARE TO BE SPLICED-ALL BAR LAP LENGTH - YIELD STRENGTH = 1640 MPa

2. RADIUS OF CURVATURES FOR LONGITUDINAL PRESTRESSING

SHALL CONFORM TO THE REQUIREMENT OF THE DESIGN SPECIFICATION

SPLICE SHALL BE STAGGERED AT POINTS OF MAXIMUM STRESS AND TENDONS SHOULD NOT BE LESS THAN 5.0M .

3. THE DESIGN IS BASED ON JACKING FROM ONE END ONLY.

F SPLICEDBARS SHALL BE STAGGERED. F

the rest part to shoulder 0.25 t/m 2 GROUTING

4. FRICTION WOBBLE COEFFICIENT PER METER IS TAKEN AS (0.0015)

AND THE FRICTION CURVATURE COEFFICIENT IS TAKEN AS (0.25).

(15t) (15t) GROUT USED SHALL BE NON-SHRINKAGE STRUCTURAL GROUT WITH A MINIMUM

1.2 m STEEL STRUCTURES

2.0 m

CUBIC COMPRESSIVE STRENGTH OF 21MPa AT 7 DAYS AND 45 MPa AT 28 DAYS.

0.9 t/m 2

WL

OWNER :

Truck 60 t

CONCRETE COVER 1-THE STRUCTURE SHALL BE ARRANGED TO ENSURE THAT PAINT CAN BE

(15t) (15t) APPLIED WITH EASE AND EFFICIENCY SO THAT CONTINUOUS UNIFORM

(10t) (10t) MINIMUM COVER TO ENDS AND SIDES OF REINFORCEMENT UNLESS OTHERWISE COATING WILL BE ACHIEVED. DETAILS SUCH AS DEEP

1.2 m INDICATED ON DRAWINGS SHALL BE AS FOLLOWS:

2.0 m

0.25 t/m2 CORNERS, RECESSES, ETC., WHICH MAKE THE APPLICATION AND

WL

G Truck 40 t BARRIER 30 mm MAINTENANCE OF PROTECTIVE TREATMENT, OR PERMIT THE G

(10t) (10t) REINFORCED CONCRETE BEAMS 30 mm ACCUMULATIONOF DIRT, DUST, OR CONDENSED MOISTURE, SHALL

(5t) (5t) SLABS 30 mm BE AVOIDED WHEREVER POSSIBLE.

1.2 m

2.0 m

PIERS 50 mm 2-THE REQUIREMENTS OF CORROSION RESISTANCE AND PROTECTION)

0.25 t/m 2

WL

Truck 20 t ABUTMENTS 70 mm OF AASHTO SHALL BE FULLY COMPLIED WITH.

(5t) (5t) RETAINING WALL 70 mm 3-UNAVOIDABLE SMALL RECESSES OR CAVITIES WHICH WOULD

the rest part to shoulder 0.25 t/m 2 PILES, PILE CAPS 70 mm OTHERWISE ACCUMULATE DIRT AND MOISTURE SHALL BE FILLED WITH OWNER CONSULTANT :

AN APPROVED FILLER OR SEALANT.

H 3. WIND LOAD

4-DRAINAGE HOLES OF NOT LESS THAN 150 MM DIAMETER SHALL BE

H

REFER TO WIND LOADS IN ECP 207 - 2015 AND DESIGN CRITERIA CONCRETE CONSTRUCTION

PROVIDED AT ALL POINTS IN THE BOTTOM FLANGE OF BOX GIRDER

4. DIFFERENTIAL SETTLEMENT CHAMFERS:

IF NEEDED, EXPOSED CONCRETE CORNERS SHALL BE CHAMFERED STRUCTURES WHERE LEAKING WATER OR CONDENSATION MIGHT

DIFFERENTIAL SETTLEMENT BETWEEN TWO ADJACENT VIADUCT PIERS WILL BE CALCULATED ACCORDING TO

THE GROUND AND LOADING CONDITION. AND SHOULD BE TAKEN FROM GEOTECHNICAL REPORT . 20 MILLIMETERS UNLESS OTHERWISE NOTED ON THE DRAWINGS OTHERWISE ACCUMULATE. THESE SHALL HAVE GALVANISED MESH

CONSTRUCTION AND EXPANSION JOINTS: COVERS TO EXCLUDE BIRDS.

5. SIESMIC LOAD

ALL CONSTRUCTION AND EXPANSION JOINTS SHALL BE PLACED AS 5-STRUCTURES SHALL NOT RELY ON THE USE OF WEATHERING STEEL

REFER TO ECP-203-2007 SHOWNON IN THE DRAWINGS AS PROVIDED IN THE SPECIFICATIONS AND AS FOR CORROSION PREVENTION. PROJECT NAME :

- Peak ground acceleration ag = 0.15 g (for seismic zone 3) DIRECTED BY THE ENGINEER. 6- STEEL USED FOR MAIN GIRDERS, CROSS GIRDERS AND BRACING

I - Subsoil class is B According To Soil Report. IS ST 52-3 But Steel USED FOR SHEAR CONNECTORS IS ST 37

I

DIMENSIONS

- Importance factor γ = 1.3 (for main bridges)

UNLESS OTHERWISE NOTED, ALL DIMENSIONS SHOWN ON THE STRUCTURAL 7- MIN. FILLET WELD SIZE IS 8.0 mm OR MIN. THICKNESS OF PLATE WHICH

- Response reduction factor R = 1 BE WELDED & WELD OF WEB TO FLANGES OF MG ARE 10 mm U.N.O. ACCORDING DRAWING TITLE :

DRAWINGS ARE IN MILLIMETRES AND STATIONS AND ELEVATIONS SHOWN

6. CREEP TO REQUIREMENTS AND PRE-QUALIFICATIONS OF AWS D1.1 AND AWS D1.5.

ARE IN METRE.

REFER TO ECP-203-2007 CLAUSE 2-3-3-5 NO DIMENSIONS ARE TO BE OBTAINED BY SCALING DRAWING. 8- WELDS OF SHEAR CONNECTORS IS 6.0 mm. GENERAL NOTES

ALL REINFORCING BAR SIZES AND WELD SIZES (FOR STRUCTURAL STEEL) 9- BOLTS USED ARE GRADE 10.9 FRICTION TYPE CLASS A SURFACES OF

ARE GIVEN IN MILLIMETRES. COEFFICIENT = 0.5

THE CONTRACTOR SHALL CHECK ALL DRAWINGS TO VERIFY LEVELS AND DIMENSIONS DESIGN CHECK DATE

10- TOLERANCE FOR H.S.B ARE AS PER E.C.P. FOR STEEL CONSTRUCTION

J PRIOR TO CONSTRUCTION AND REPORT ANY DISCREPANCIES TO THE ENGINEER. AND BRIDGES - CODE NO. E.C.P.205. U.A. A.A. JAN. 2023

J

SCALE PROJECT NO. DWG NO. REV.

AS SHOWN C.S.100 00

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

You might also like

- Boq Construction of Kadengoi Water PanDocument22 pagesBoq Construction of Kadengoi Water Pansateja100% (1)

- S-21 - WH03-C-138 - COLUMN - Rev 1Document1 pageS-21 - WH03-C-138 - COLUMN - Rev 1TAMILarasuNo ratings yet

- VVVVDocument1 pageVVVVSanjoy SanyalNo ratings yet

- Typcal First Floor PlanDocument1 pageTypcal First Floor Plansatheb319429No ratings yet

- M BD2 100tu0 Ctli Edr 000112Document1 pageM BD2 100tu0 Ctli Edr 000112Sanjoy SanyalNo ratings yet

- Admission TextDocument1 pageAdmission TextSwati DhurpateNo ratings yet

- CB 1655 CombinedDocument3 pagesCB 1655 CombinedQuerubin RamirezNo ratings yet

- Box Culvert 2X2Document6 pagesBox Culvert 2X2abhishek singhNo ratings yet

- Detail of Locking Rrangement of The Main Gate From Both SidesDocument1 pageDetail of Locking Rrangement of The Main Gate From Both Sidesmohammed amir aliNo ratings yet

- M BD2 100tu0 Ctli Edr 000116Document1 pageM BD2 100tu0 Ctli Edr 000116Sanjoy SanyalNo ratings yet

- XXXXXDocument1 pageXXXXXSanjoy SanyalNo ratings yet

- 9205-BP12B-MMJV-IFCD-ME-P1-L01-00300-REV.000Document1 page9205-BP12B-MMJV-IFCD-ME-P1-L01-00300-REV.000Abdulhamit KAYYALINo ratings yet

- Terminal 2: Level 4 - Retail Mezzanine - Part Plan - 53Document1 pageTerminal 2: Level 4 - Retail Mezzanine - Part Plan - 53waz ahmedNo ratings yet

- 13 Domestic SC BLK-STRDocument1 page13 Domestic SC BLK-STRzulunchakweNo ratings yet

- D F PlanDocument1 pageD F PlanstanleyNo ratings yet

- Gridshell - Edge Truss Steel Size Legeccd: CC11 CC12 CC13 CC14 CC15 CC16 CC17 CC18 CC19 CC20 CC21 CC22 CC23Document1 pageGridshell - Edge Truss Steel Size Legeccd: CC11 CC12 CC13 CC14 CC15 CC16 CC17 CC18 CC19 CC20 CC21 CC22 CC23Faisal MuhammadNo ratings yet

- 00-A-01i-00007 - Overall Interior Details Sheet 1 - Doors - Rev No - 1Document1 page00-A-01i-00007 - Overall Interior Details Sheet 1 - Doors - Rev No - 1Forhad HossainNo ratings yet

- Detail - B1: Section - A Elevations Elevations Section - ADocument1 pageDetail - B1: Section - A Elevations Elevations Section - AKumudu PereraNo ratings yet

- DHQC Cecb MB Ti Ar DW ML 02 80513Document1 pageDHQC Cecb MB Ti Ar DW ML 02 80513Kumudu PereraNo ratings yet

- Terminal 2: E36 E38 E40 E33 E35 E37 E39 H34Document1 pageTerminal 2: E36 E38 E40 E33 E35 E37 E39 H34waz ahmedNo ratings yet

- 26221-100-V206651-EKL0-00283-003 Base Frame Layout-Updated 06.08.2022Document1 page26221-100-V206651-EKL0-00283-003 Base Frame Layout-Updated 06.08.2022Wison YangNo ratings yet

- A7120 94 A10 S XXX9400Document1 pageA7120 94 A10 S XXX9400Faisal MuhammadNo ratings yet

- 00251034badm12144 Cdfe03 01 02Document1 page00251034badm12144 Cdfe03 01 02prasadcspNo ratings yet

- Attachement-1 RFC-29-18Document14 pagesAttachement-1 RFC-29-18Mohamed ArafaNo ratings yet

- Ed 0100 PRS Pid 000 01005uDocument1 pageEd 0100 PRS Pid 000 01005uMohamed ArafaNo ratings yet

- M BD3 1F8000 Cutl Edr 000301Document1 pageM BD3 1F8000 Cutl Edr 000301ahmed.abdelmegeed78No ratings yet

- Neralized WaterDocument1 pageNeralized Watermohamed abourayaNo ratings yet

- WH03-JC-102 - JACK COLUMN - Rev 0Document1 pageWH03-JC-102 - JACK COLUMN - Rev 0TAMILarasuNo ratings yet

- WH03-JC-101 - JACK COLUMN - Rev 0Document1 pageWH03-JC-101 - JACK COLUMN - Rev 0TAMILarasuNo ratings yet

- Bridge No.169Document1 pageBridge No.169RajeshNo ratings yet

- Terminal 2: Level 4 - Retail Mezzanine - Part Plan - 54Document1 pageTerminal 2: Level 4 - Retail Mezzanine - Part Plan - 54waz ahmedNo ratings yet

- Pdch14-Gaj-Dwg-000-Xxx-Arc-31111-Pdf (T01) - Window Locations - Apartments Upper LevelsDocument1 pagePdch14-Gaj-Dwg-000-Xxx-Arc-31111-Pdf (T01) - Window Locations - Apartments Upper LevelsZaido Al HalabiNo ratings yet

- Refer To Drawing No.: 620620 SH-002 Refer To Drawing No.: 620620 SH-003Document1 pageRefer To Drawing No.: 620620 SH-002 Refer To Drawing No.: 620620 SH-003muthuvelaaNo ratings yet

- Site LayoutDocument1 pageSite Layoutvenkat rajuNo ratings yet

- Notes: Investor/Operator Engineering ContractorDocument1 pageNotes: Investor/Operator Engineering ContractorPerviz BabazadeNo ratings yet

- DCRJ-JED3-Inspection Request For Formwork Installation & AlignmentDocument3 pagesDCRJ-JED3-Inspection Request For Formwork Installation & AlignmentAlvin BadzNo ratings yet

- S-14 - Roof Framing PlanDocument1 pageS-14 - Roof Framing PlanJames PittsNo ratings yet

- Ndwiga 2 Bedroom Apartments in Chokaa PDFDocument1 pageNdwiga 2 Bedroom Apartments in Chokaa PDFRooney mutetiNo ratings yet

- Plan at El + 103950 (T.o.s) Plan at El +107309 (T.o.s) : A B C D e FDocument1 pagePlan at El + 103950 (T.o.s) Plan at El +107309 (T.o.s) : A B C D e FVineeth PvNo ratings yet

- BTGM - 1Document6 pagesBTGM - 1Eng Clive KabelengaNo ratings yet

- Lobby Floor Plan (Ground)Document1 pageLobby Floor Plan (Ground)Ma. Isabel RodriguezNo ratings yet

- KATEDAN, COLUMNS, PLINTH, ROOF LAYOUTS Throug Mail On 30.07.18Document1 pageKATEDAN, COLUMNS, PLINTH, ROOF LAYOUTS Throug Mail On 30.07.18nikita meshramNo ratings yet

- First FloorDocument1 pageFirst Flooryash ayreNo ratings yet

- Sec Deck and Infill 2 PDFDocument1 pageSec Deck and Infill 2 PDFKhaled WaelNo ratings yet

- General Notes:: 00ENB20BB003 Treated Co Storage TankDocument1 pageGeneral Notes:: 00ENB20BB003 Treated Co Storage Tankmustafa1989ocNo ratings yet

- Scale: 1:20 (1:2) (1:10) (1:5) : Original Drawing Size A1Document1 pageScale: 1:20 (1:2) (1:10) (1:5) : Original Drawing Size A1Shivendra Vikram SinghNo ratings yet

- z3 Macc SV Con Abl ST SSC 020031 00Document1 pagez3 Macc SV Con Abl ST SSC 020031 00jafarNo ratings yet

- Notes:: Details: 2 Details: 1Document1 pageNotes:: Details: 2 Details: 1Hitesh DabhiNo ratings yet

- DWARAKA TIRUMALA Q-LINES Base Plate & Truss MarkingDocument1 pageDWARAKA TIRUMALA Q-LINES Base Plate & Truss MarkingVenkata Bhaskar DameraNo ratings yet

- M BD3 1F8000 Cutl Edr 000202Document1 pageM BD3 1F8000 Cutl Edr 000202ahmed.abdelmegeed78No ratings yet

- Tender For Construction Equipping Training and Operationalization of Imic at Kutrrh 2Document1 pageTender For Construction Equipping Training and Operationalization of Imic at Kutrrh 2IANNo ratings yet

- MR - Sumit DUSSA JI (Panchsati Circle)Document1 pageMR - Sumit DUSSA JI (Panchsati Circle)Narender Singh RawatNo ratings yet

- M BD3 1F8000 Cutl Edr 000302Document1 pageM BD3 1F8000 Cutl Edr 000302ahmed.abdelmegeed78No ratings yet

- 4.plinth & Roof Details (With Diensions)Document1 page4.plinth & Roof Details (With Diensions)barathshyamNo ratings yet

- R03 C07B01 IKP 01 RF SDW AR 10024 - CommentsDocument1 pageR03 C07B01 IKP 01 RF SDW AR 10024 - CommentsEleazar SacloloNo ratings yet

- Attachment - 2 - GA For Shop Fabricated Tanks PDFDocument3 pagesAttachment - 2 - GA For Shop Fabricated Tanks PDFShah Newaz KabirNo ratings yet

- Stairs 1Document1 pageStairs 1anandit sharmaNo ratings yet

- Ep 101Document1 pageEp 101marwazaydoonNo ratings yet

- New IMportant StandardsDocument1 pageNew IMportant StandardsfacadeNo ratings yet

- Notes:: For ConstructionDocument1 pageNotes:: For ConstructionDAVID SOTONo ratings yet

- CamScanner ٠٢-٠٤-٢٠٢٤ ٠٩.١٧Document1 pageCamScanner ٠٢-٠٤-٢٠٢٤ ٠٩.١٧محمد ابراهيمNo ratings yet

- 06. دليل تأهيل و اعتماد مصانع الخرسانةDocument74 pages06. دليل تأهيل و اعتماد مصانع الخرسانةمحمد ابراهيمNo ratings yet

- Unyielding SupportDocument15 pagesUnyielding Supportمحمد ابراهيمNo ratings yet

- Managing Temporary Works: Andrea Robbins HM Inspector of Health and SafetyDocument47 pagesManaging Temporary Works: Andrea Robbins HM Inspector of Health and Safetyمحمد ابراهيم100% (1)

- Durability of Reinforced Concrete Structures, The Ory Vs Pra Cti CeDocument4 pagesDurability of Reinforced Concrete Structures, The Ory Vs Pra Cti Ceمحمد ابراهيمNo ratings yet

- Unyielding SupportDocument15 pagesUnyielding Supportمحمد ابراهيمNo ratings yet

- Unyielding SupportDocument15 pagesUnyielding Supportمحمد ابراهيمNo ratings yet

- Building Code of Pakistan 2021 - Fawad NajamDocument14 pagesBuilding Code of Pakistan 2021 - Fawad NajamSajjad HussainNo ratings yet

- HPKM Column Shoe Installation Construction Site ACIDocument2 pagesHPKM Column Shoe Installation Construction Site ACIIndra Kusumajati Raj SuwedaNo ratings yet

- Toaz - Info Sample Pert CPM L L PRDocument3 pagesToaz - Info Sample Pert CPM L L PRAl Patrick Dela CalzadaNo ratings yet

- Silo 3 (Version 1) BDocument6 pagesSilo 3 (Version 1) BNattida KIRATISAEVEENo ratings yet

- General Specification (Blank)Document2 pagesGeneral Specification (Blank)Mark Gil Amesola Ganub100% (1)

- B Checking, Inspection and Loading Test at SiteDocument7 pagesB Checking, Inspection and Loading Test at SiteĐinh Duy QuangNo ratings yet

- Scope of Work Tools Activities Hand Tool Power Tool Equpment Heavy EquipmentDocument10 pagesScope of Work Tools Activities Hand Tool Power Tool Equpment Heavy EquipmentBEA GNo ratings yet

- As Built Layout-As Built LayoutDocument1 pageAs Built Layout-As Built LayoutMaster MunnaNo ratings yet

- Final Extra Work BoqDocument1 pageFinal Extra Work BoqchetanjtNo ratings yet

- Pour CardDocument2 pagesPour Cardsuchendra singhNo ratings yet

- Columns and Axes Layout AssignmentDocument4 pagesColumns and Axes Layout AssignmentEfremWakjiraHodeNo ratings yet

- Soil Support Testing With DCP ToolsDocument2 pagesSoil Support Testing With DCP Toolsdana setiawanNo ratings yet

- Quality Checklist For Site Works: #Unknown!Document1 pageQuality Checklist For Site Works: #Unknown!adnan-651358No ratings yet

- Assignment 4: Diaphragm WallDocument7 pagesAssignment 4: Diaphragm WallTAWDE KOMALNo ratings yet

- Form Hydrostatic TestDocument2 pagesForm Hydrostatic TestHBr26No ratings yet

- BOQ - Retaining Wall0001Document2 pagesBOQ - Retaining Wall0001Victor OmotoriogunNo ratings yet

- Lift Master Schedule R1Document1 pageLift Master Schedule R1Syed Faris Bin Syed ZainuddinNo ratings yet

- C/S of Staircase (SCALE-1:25) : Pradeep YadavDocument1 pageC/S of Staircase (SCALE-1:25) : Pradeep YadavRVNLPKG6B VBL-GTLM100% (1)

- Transpo ReflectionDocument3 pagesTranspo ReflectionMae PaviaNo ratings yet

- DSS Site Visit ReportDocument13 pagesDSS Site Visit Report39 - Deep MandokarNo ratings yet

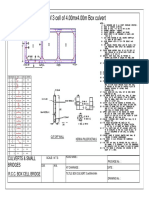

- Reinforcement Detailed of 3 Cell of 4.00mx4.00m Box CulvertDocument1 pageReinforcement Detailed of 3 Cell of 4.00mx4.00m Box CulvertHarshit DubeyNo ratings yet

- Cement Bond EvaluationDocument7 pagesCement Bond EvaluationFaizal WALIYNo ratings yet

- Road RL Adjustment (A4)Document3 pagesRoad RL Adjustment (A4)AbiNo ratings yet

- DerrickDocument3 pagesDerrickdawit amsaluNo ratings yet

- Armand-Macapagong CVDocument1 pageArmand-Macapagong CVGracie S. VergaraNo ratings yet

- List CecDocument51 pagesList Cecajeez86No ratings yet

- Ce24 Lesson 2Document63 pagesCe24 Lesson 2movieboxpro482No ratings yet

- Abri Jardin NoticeDocument24 pagesAbri Jardin Noticejessicalycee72No ratings yet

- Bce Unit-IDocument8 pagesBce Unit-Ireshma sulthanaNo ratings yet