Professional Documents

Culture Documents

078-010-ngm 2016 - Pile Tip Bearing Capacity Van Baars

078-010-ngm 2016 - Pile Tip Bearing Capacity Van Baars

Uploaded by

shogunromCopyright:

Available Formats

You might also like

- Sans 1200 HDocument3 pagesSans 1200 HfilipeNo ratings yet

- Barbosa-Cruz & M.F. Randolph (ISFOG 2005)Document8 pagesBarbosa-Cruz & M.F. Randolph (ISFOG 2005)Pablo Cesar TrejoNo ratings yet

- 2018 - The Bearing Capacity of Shallow Foundations On SlopesDocument8 pages2018 - The Bearing Capacity of Shallow Foundations On SlopesPranavaDartNo ratings yet

- The Inclination and Shape Factors For The Bearing Capacity of FootingsDocument8 pagesThe Inclination and Shape Factors For The Bearing Capacity of FootingsSaleh HassanNo ratings yet

- Loadingtests ON by Clay": Theories For Failure Load Under Plates On ClayDocument19 pagesLoadingtests ON by Clay": Theories For Failure Load Under Plates On ClayEMERSON FARLEY DURAN CARRENONo ratings yet

- The Bearing Capacity of Footings On Coarse SoilsDocument11 pagesThe Bearing Capacity of Footings On Coarse SoilsMattNo ratings yet

- 04 Bra EstrupDocument6 pages04 Bra EstrupcjpwdesignNo ratings yet

- Calculating Methodology of Large Base Slabs Compressible Strata Capacity and Foundation SettlementDocument8 pagesCalculating Methodology of Large Base Slabs Compressible Strata Capacity and Foundation SettlementAbdelmoez ElgarfNo ratings yet

- Foundation Design With PressuremeterDocument44 pagesFoundation Design With Pressuremeter류태하No ratings yet

- P.499 - Simplified Analysis For Tunnel Supports PDFDocument20 pagesP.499 - Simplified Analysis For Tunnel Supports PDFAleksandar SpasojevicNo ratings yet

- Analysis of Self-Boring Pressuremeter Tests in Overconsolidated ClaysDocument5 pagesAnalysis of Self-Boring Pressuremeter Tests in Overconsolidated ClaystangkokhongNo ratings yet

- Lateral Response o F PilesDocument1 pageLateral Response o F PilesFernando FanteNo ratings yet

- 10Document12 pages10rowatersNo ratings yet

- 6 Foundation Design With Pressuremeter 2009 639Document44 pages6 Foundation Design With Pressuremeter 2009 639Hem ShahiNo ratings yet

- Face Stability Analysis of Circular Tunnels Driven by A Pressurized ShieldDocument16 pagesFace Stability Analysis of Circular Tunnels Driven by A Pressurized ShieldbambokarambaNo ratings yet

- 1998 Russo PDFDocument17 pages1998 Russo PDFMUHAMMAD AHMAD JAMILNo ratings yet

- Sobie Recent Research On The Bearing Capacity of Founbl4TionsDocument11 pagesSobie Recent Research On The Bearing Capacity of Founbl4TionsSaraswati NoorNo ratings yet

- Velloso - Piles Subjected To Horizontal Loads Due To Asymmetrical Surcharges On The SurfaceDocument5 pagesVelloso - Piles Subjected To Horizontal Loads Due To Asymmetrical Surcharges On The SurfaceMarcelaMarquesNo ratings yet

- Load and Settlement Behaviors of Pile-Raft Foundation in Soft Soil of Post-ConsolidationDocument5 pagesLoad and Settlement Behaviors of Pile-Raft Foundation in Soft Soil of Post-ConsolidationBRAYAN GERARDO AREVALO MENDOZANo ratings yet

- Leca&dormieuxDocument26 pagesLeca&dormieuxIslam-Lotfi Hadj-ArabNo ratings yet

- On The Ground Response Curve: by Pieter A. Vermeer, Thomas Marcher and Nico RuseDocument8 pagesOn The Ground Response Curve: by Pieter A. Vermeer, Thomas Marcher and Nico RuseJonathan CobbNo ratings yet

- Effect of Soil Deformability On RigidityDocument11 pagesEffect of Soil Deformability On RigidityCesar Basantes AvalosNo ratings yet

- A Method For Predicting The Effect of Piles On Slope BehaviourDocument13 pagesA Method For Predicting The Effect of Piles On Slope BehaviourMatteo IzziNo ratings yet

- Dickin 1985Document21 pagesDickin 1985Cesar Alberto RuverNo ratings yet

- Face Stability Analysis of Shallow Circular Tunnels in Cohesive-Frictional SoilsDocument14 pagesFace Stability Analysis of Shallow Circular Tunnels in Cohesive-Frictional SoilsRonald Cornejo MarmanilloNo ratings yet

- Gill Geology Cross SectionDocument18 pagesGill Geology Cross SectionziqriiqbalNo ratings yet

- Allowable Bearing Capacity of Shallow FoundationsDocument16 pagesAllowable Bearing Capacity of Shallow Foundationskyle_obiNo ratings yet

- 1979 - Einstein-Schwarz - Simplified Analysis For Tunnel SupportsDocument21 pages1979 - Einstein-Schwarz - Simplified Analysis For Tunnel SupportsReza OsgouiNo ratings yet

- RaftDocument8 pagesRaftKamarajanNo ratings yet

- 1 s2.0 S0886779817311914 MainDocument15 pages1 s2.0 S0886779817311914 Maina4abhirawatNo ratings yet

- Initial Soil Springs Stiffness For Laterally Loaded Piles PDFDocument7 pagesInitial Soil Springs Stiffness For Laterally Loaded Piles PDFmagdyamdbNo ratings yet

- Combined Footing DesignDocument29 pagesCombined Footing DesignIddrisu NajeedNo ratings yet

- 1950 - Skempton and Bishop - The Measurement of The Shear Strength of SoilsDocument20 pages1950 - Skempton and Bishop - The Measurement of The Shear Strength of SoilsGregory Alvarado Chavez100% (1)

- Design and Performance of Deep Excavations in Soft ClaysDocument27 pagesDesign and Performance of Deep Excavations in Soft ClaysBryanAndrésNewballNo ratings yet

- Trench Stability in Cohesive Soil: September 2011Document7 pagesTrench Stability in Cohesive Soil: September 2011SanaaNo ratings yet

- 1 s2.0 S0267726102002129 MainDocument9 pages1 s2.0 S0267726102002129 Main305 SREEKANTH REDDYNo ratings yet

- STAL Isbn STAL190090Document8 pagesSTAL Isbn STAL190090Joel GarciaNo ratings yet

- Piles in Lateral Spreading: A Simple Method Versus Centrifuge ExperimentsDocument12 pagesPiles in Lateral Spreading: A Simple Method Versus Centrifuge ExperimentsManuel Alvarez MNo ratings yet

- Pubb-0534-L-For A Correct Interpretation of Ground Reaction CurvesDocument6 pagesPubb-0534-L-For A Correct Interpretation of Ground Reaction CurvesSimoneNo ratings yet

- Shallow Foundations (Rafts)Document15 pagesShallow Foundations (Rafts)bogdan tanasoiu100% (1)

- Broms (2016)Document17 pagesBroms (2016)Luis Fernando SoaresNo ratings yet

- Bearing Capacity of Shallow FoundationDocument59 pagesBearing Capacity of Shallow FoundationSyafiq Azman100% (1)

- Discussion on Size Effect of Footing in Ultimate Bearing Cap 2016 Soils andDocument11 pagesDiscussion on Size Effect of Footing in Ultimate Bearing Cap 2016 Soils andthalesgmaiaNo ratings yet

- 1987-Seismic Response of Earth Dams Some RecentDocument46 pages1987-Seismic Response of Earth Dams Some RecentANES1434No ratings yet

- 202 Soil Profile From CPTDocument21 pages202 Soil Profile From CPTSapria AdiNo ratings yet

- 6 - Budijanto Widjaja-UNPARDocument5 pages6 - Budijanto Widjaja-UNPARMuhammad LutfhiNo ratings yet

- On Stability Analysis of Slurry-Wall Trenches: Plaxis PracticeDocument6 pagesOn Stability Analysis of Slurry-Wall Trenches: Plaxis PracticeVetriselvan ArumugamNo ratings yet

- SSI Introduction PDFDocument29 pagesSSI Introduction PDFdesigner STRNo ratings yet

- 03-10-FArtor NQ Cap de Pilas Sergio Antonio Martinez GalvanDocument9 pages03-10-FArtor NQ Cap de Pilas Sergio Antonio Martinez GalvanJOSE LUIS GONZALEZNo ratings yet

- Analysis of Dilatometer Test in ClayDocument8 pagesAnalysis of Dilatometer Test in ClayMarcus ViniciusNo ratings yet

- Influence of Anchor Inclination On Pull-Out Resistance of ClaysDocument6 pagesInfluence of Anchor Inclination On Pull-Out Resistance of ClaysSen HuNo ratings yet

- PileDesign Example02Document17 pagesPileDesign Example02HumayunKabirNo ratings yet

- Hird 1992Document13 pagesHird 1992yutubpremiummmm01No ratings yet

- Trench Stability in Cohesive SoilDocument6 pagesTrench Stability in Cohesive SoilShahab KhaledNo ratings yet

- Stability Coefficients For Earth SlopesDocument25 pagesStability Coefficients For Earth SlopesDaniel Felipe Rodriguez RamirezNo ratings yet

- A Treatise on the Differential Geometry of Curves and SurfacesFrom EverandA Treatise on the Differential Geometry of Curves and SurfacesNo ratings yet

- March/April 2016 Cadillac Area Business MagazineDocument16 pagesMarch/April 2016 Cadillac Area Business MagazineCadillac Area Chamber of CommerceNo ratings yet

- 1osh LeadsDocument72 pages1osh Leadssaskiamogale100% (1)

- POLGOVSEA - MOD 1 - IntroDocument30 pagesPOLGOVSEA - MOD 1 - IntroBryan MarasiganNo ratings yet

- Dodla Dairy Hyderabad Field Visit 1Document23 pagesDodla Dairy Hyderabad Field Visit 1studartzofficialNo ratings yet

- Manual Serviço - Aiwa NSX-D77, NSX-T76, NSX-T77Document48 pagesManual Serviço - Aiwa NSX-D77, NSX-T76, NSX-T77fabioferraoNo ratings yet

- Dhaka University Affiliated Colleges: Third Year Syllabus Department of MathematicsDocument8 pagesDhaka University Affiliated Colleges: Third Year Syllabus Department of MathematicsHasibul Hassan ShantoNo ratings yet

- Detail 6 Connection of Purlins To Rb-1 9Document1 pageDetail 6 Connection of Purlins To Rb-1 9Fritz NatividadNo ratings yet

- Steel Body - Lever Hoists: A e B A e B A e BDocument1 pageSteel Body - Lever Hoists: A e B A e B A e BtylerlhsmithNo ratings yet

- Power Bank ppt-3-3Document20 pagesPower Bank ppt-3-3Apoorva RNo ratings yet

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitErln LimaNo ratings yet

- Pa Pi Pu Pe Po: HandakuonDocument23 pagesPa Pi Pu Pe Po: HandakuonmnmrznNo ratings yet

- Data Base Proyek KonstruksiDocument913 pagesData Base Proyek KonstruksiZefanyaNo ratings yet

- EC506 Wireless Gateway User Manual ENGDocument48 pagesEC506 Wireless Gateway User Manual ENGcy5170No ratings yet

- Standard Kessel Cat - Gral.Document40 pagesStandard Kessel Cat - Gral.Marcelo ResckNo ratings yet

- Best Practices SQL Server For OpenText Content Server 10.5Document44 pagesBest Practices SQL Server For OpenText Content Server 10.5peptaNo ratings yet

- A5 - Nivel TestDocument8 pagesA5 - Nivel TestValerie StephensNo ratings yet

- Energy Research Institute - Wang SichengDocument17 pagesEnergy Research Institute - Wang SichengADB_SAEN_ProjectsNo ratings yet

- Rumah-Rumah Tahfizh Di Kota Banjarmasin Profil Pro PDFDocument14 pagesRumah-Rumah Tahfizh Di Kota Banjarmasin Profil Pro PDFJuhdan TrueNo ratings yet

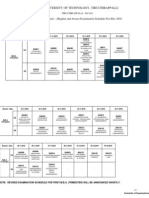

- Anna University of Technology, TiruchirappalliDocument2 pagesAnna University of Technology, TiruchirappallisanjeevrksNo ratings yet

- Agent Application Form - NIADocument3 pagesAgent Application Form - NIASiva KumarrNo ratings yet

- MBA Interviews (Undergraduation Questions)Document14 pagesMBA Interviews (Undergraduation Questions)anshshah1310No ratings yet

- Module 5 Introduction To Stochastic Processes Eec605Document89 pagesModule 5 Introduction To Stochastic Processes Eec605daniel developerNo ratings yet

- New M Tech Programme in Computer Science and Engineering Artificial Intelligence Data Analytics Self Financing Mode Admissions 2023 - 0Document6 pagesNew M Tech Programme in Computer Science and Engineering Artificial Intelligence Data Analytics Self Financing Mode Admissions 2023 - 0Himesh KumarNo ratings yet

- EWESDocument10 pagesEWESPratham KatariyaNo ratings yet

- At EgmrDocument1 pageAt EgmrQasim ButtNo ratings yet

- Pressform Refractory PRINT Brochure PDFDocument44 pagesPressform Refractory PRINT Brochure PDFravikumarangNo ratings yet

- List of Companies With Contact Details For Global VillageDocument5 pagesList of Companies With Contact Details For Global VillagemadhutkNo ratings yet

- Apurba MazumdarDocument2 pagesApurba MazumdarDRIVECURENo ratings yet

078-010-ngm 2016 - Pile Tip Bearing Capacity Van Baars

078-010-ngm 2016 - Pile Tip Bearing Capacity Van Baars

Uploaded by

shogunromOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

078-010-ngm 2016 - Pile Tip Bearing Capacity Van Baars

078-010-ngm 2016 - Pile Tip Bearing Capacity Van Baars

Uploaded by

shogunromCopyright:

Available Formats

NGM 2016 Reykjavik

Proceedings of the 17th Nordic Geotechnical Meeting

Challenges in Nordic Geotechnic 25th – 28th of May

The influence of the shaft friction and pile shape on the pile tip

bearing capacity

Stefan Van Baars

University of Luxembourg, Luxembourg, stefan.vanbaars@uni.lu

ABSTRACT

In 1920 Prandtl published an analytical solution for the bearing capacity of a maximum strip load

on an infinite half-space, based on a sliding soil part, with three sliding zones, which is nowadays

called the Prandtl-wedge. This solution was extended by Reissner with a surrounding surcharge.

Terzaghi wrote the formula with bearing capacity factors and Meyerhof extended this formula

with both inclination factors and shape factors.

Because of these developments for shallow foundations, many geotechnical researchers thought

that failure of a pile tip in a deep sand layer will also show a Prandtl-wedge type of failure and

that the stresses on a pile tip are also constant and do not depend on the shape and size of the pile

tip. This would imply that a Cone Penetration Test (CPT) gives the same stress as a real pile tip,

and can be used without a reduction for calculating the bearing capacity of a real pile.

Field tests show however that a bearing capacity of a pile tip, based on unreduced CPT data, is

too high. Therefore this problem has been modelled and studied, with Finite Element Modelling.

Several remarkable results were found. There is no Prandtl-wedge type of failure at the pile tip,

but a general zone of plasticity. Also the stresses below the pile tip are not constant, but higher

near the centre of the pile. The difference in bearing capacity between CPT and real pile does not

depend on the shape and size of the pile tip, but more on the difference of the definitions of failure

between CPT and pile.

Additional calculations show that the pile shaft friction does not influence the stresses at the pile

tip, but the normal stresses on the pile tip do influence the shear stresses along the shaft.

Keywords: Bearing capacity, Pile Foundations, Cone Penetration Test.

the sliding soil part into three zones (see

1 INTRODUCTION Figure 1):

1.1 Prandtl-Reissner Zone 1: A triangular zone below the strip

In 1920, Ludwig Prandtl published an load. Here the largest principal stress is in

analytical solution for the bearing capacity of the vertical direction.

a soil under a limit pressure, p, causing

kinematic failure of the weightless infinite Zone 2: A wedge with the shape of a

half-space underneath. The strength of the logarithmic spiral, in which the principal

half-space is given by the angle of internal stresses rotate through 90 from Zone 1 to

friction, , and the cohesion, c. The solution Zone 3. The pitch of the sliding surface

equals the angle of internal friction; ,

was extended by Reissner in 1924 with a

surrounding surcharge, q. Prandtl subdivided creating a smooth transition between Zone

1 and Zone 3.

IGS 711 NGM 2016 - Proceedings

Modelling, analysis and design

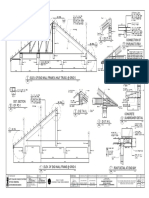

Figure 1 The wedge of Prandtl.

Zone 3: A triangular zone adjacent to the p sq qN q , (2)

strip load. Here the largest principal stress

is in the horizontal direction. in which the surcharge bearing capacity

factor is given as (see figure 1):

1.2 Meyerhof 2

r

Keverling Buisman (1940) and Terzaghi N q K p 3 K p e tan (3)

(1943) extended the Prandtl-Reissner formula r1

for the soil weight, . And in 1953 Meyerhof

was the first to propose equations for inclined 1 sin

with: K p .

loads. He was also the first in 1963 to write 1 sin

the formula for the (vertical) bearing capacity

pv with bearing capacity factors (N), This means that the stresses on the pile tip

inclination factors (i) and shape factors (s), will also be constant and depend only on the

for the three independent bearing friction angle of the soil, the vertical effective

components; cohesion (c), surcharge (q) and stress near the pile tip, and its shape factor

soil-weight (), in a way it is still used and not on the shape and size of the pile tip.

nowadays: This would imply that a Cone Penetration

Test will produce the same average stress as

pv ic sc cNc iq sq qNq i s 12 BN . (1) a real pile and can in principle be used

without a reduction or a scale factor for the

calculation of the bearing capacity of a pile,

1.3 Pile tip just as Boonstra (1940) showed with his field

Because of this analytical solution for tests and just as is assumed in many pile

shallow foundations, many researchers (for bearing capacity predicting models, such as

example Meyerhof, 1951) thought that a pile the model of Van Mierlo & Koppejan (1952).

tip in a deep sand layer will also show a

Prandtl-wedge type of failure mechanism and

1.4 Validation

equation 1 can be used.

The solution of the surcharge bearing

In this article only vertically loaded deep pile capacity factor Nq (equation 3) has been

tips are considered (so the influence of the checked by Van Baars (2015) with finite

soil weight can be neglected), in cohesionless element calculations, and found to be correct.

soils, which means that this equation can be But this does not proof that the Meyerhof

reduced to: equation can also be used for pile tips,

because the analytical solution is based on a

Prandtl-wedge failure mechanism, while for

NGM 2016 - Proceedings 712 IGS

The influence of the shaft friction and pile shape on the pile tip bearing capacity

circular shallow foundations and pile pile size, and not due to second order effects

foundations (see also paragraph “4 Failure of for example a complex soil model.

mechanism”) another failure mechanism is Therefore the pile is a wished-in-place pile;

found. Besides, the finite element no installation effects are added. For the

calculations also show that the solutions of same reason, no large strain corrections have

the surcharge shape factor of both Meyerhof been made, even though large deformations

(1963) and also De Beer / Brinch Hansen were applied; First because Plaxis cannot

(1970) are not accurate and should be more model correctly the flow of a plastic soil,

like (see Tapper et al, 2015): around a pile tip at large displacements.

Second because not the exact stresses are

sq 1 0.55 B / L , (4) sought, but the failure mechanisms and the

relative differences between two or three

options.

in which B and L are the width and depth of

the pile tip, so for square pile tips: B / L = 1.

Both the pile tip and the pile shaft have been

modelled by a displacement controlled line or

Another big problem is that many researchers

soil boundary, without any interface. This

(Jardine et al, 2005, Lehane et al, 2005,

represents an infinite stiff and rough pile. For

Clausen et al, 2005) and recent field tests

each calculation step an additional pile

(Van Tol et al., 1994, 2010, 2012) show that

displacement of 1 mm has been chosen.

a calculated bearing capacity based on

The advantage is of this method is that this

unreduced Cone Penetration Test data, can be

calculation is very simple and very stable,

more than 30% higher than measured.

and the push in force is simply the same as

the total reaction force which is standard

2 FINITE ELEMENT MODELLING registered.

The disadvantage is that it is unknown how

In order to find the reason for all this, a pile much of this force comes from the tip

has been modelled and studied. With the resistance and how much from the shaft.

software code Plaxis, displacement

controlled, non-updated mesh, 2D axial-

symmetric, finite element calculations have 3 SHAPE AND SIZE OF PILE TIP

been made. In all cases a 10 m deep pile in

The first step was to investigate the influence

dry sand has been modelled with a Mohr-

of the shape of the pile tip. First four almost

Coulomb model, using the soil parameters

identical calculations have been made: two

listed in table 1.

calculations with normal (flat) pile tips and

two with sharp pile tips (pile tip angle

Table 1 Soil parameters.

Parameter Value 45 ). Two of them were calculations

Friction angle 35 with only the pile tip pushed down and two

with both the tip and shaft pushed down

Dilatancy angle 0 (vertical displacement controlled boundary;

Cohesion c0 no horizontal displacements).

Young’s modulus E 50,000 kPa Figure 2 shows that the difference in force

Poisson’s ratio 0.3 between a sharp and a normal (flat) pile tip

Unit weight 20 kN/m3 can be neglected. Also three different pile

diameters have been tested.

Since the circumference of the shaft is scaled

Higher-order 15-node elements have been

in a different way as the area of the pile tip,

used. The element sizes can be seen in Figure

only the pushing down of the pile tip has

4.

been modelled here (so with free

The idea is to keep the calculation as simple

displacements for the shaft).

as possible so that differences between two

calculations are caused by the change of a

IGS 713 NGM 2016 - Proceedings

Modelling, analysis and design

Figure 3 Influence of the shape of the pile tip Figure 2 Influence of the pile tip diameter.

Figure 3 shows the average vertical stress growing stresses with displacement is very

important, since the cone resistance is

below the pile tip v versus the vertical

defined for a (failing) pile tip at an infinite

displacement uv divided by the pile tip displacement, while the bearing capacity of a

diameter D, proofing that the curves are the real pile is defined for a pile tip at only 10%

same for all three pile diameters, just as the displacement of (the size of) the pile tip. This

Prandtl solution would predict. difference in definition of failure explains at

least a substantial part of the 30% difference

of the stresses at the pile tip between the cone

3.1 Continuously growing stresses

(at infinite displacement) and a pile (at only

The phenomenon of the continuously 10% displacement).

Figure 4 Failing mechanism: growing total plastic zone.

NGM 2016 - Proceedings 714 IGS

The influence of the shaft friction and pile shape on the pile tip bearing capacity

4 FAILURE MECHANISM

Figure 4, on the previous page, shows the

relative shear stress rel after large pile

displacements uv; 2.2 times (on the left) and

4.4 times (on the right) the pile diameter D.

This relative shear stress is defined as the

radius of the circle of Mohr divided by the

radius of a circle touching the Coulomb line,

which means plasticity or failure of the soil,

or a relative shear stress of “1”.

The failure zone in this figure is not like a

Prandtl-wedge. In fact there is an ever

growing plastic zone below the pile tip and

all along the pile shaft. The fact that the zone

is growing, means that the vertical stress (the

bearing capacity) is also growing with the Figure 5 Bearing capacity of the shaft and the tip.

displacement. This ever growing bearing

capacity was already noticed from figure 2,

but follows also from figure 5, which shows

the push-in bearing capacity of the shaft and

the tip individually (2nd and 3rd line from

below), but also together (2nd line from

above). Two other lines show the pull-out

force of the shaft alone (lowest line) and the

summation of the tip push in and the shaft

pulled out (3rd line from above).

The highest (dashed) line is found by simply

summing up the push-in force of both the pile

tip and the pile shaft.

The 3rd line from above is found by summing

up the push-in force of the pile tip and the

pull-out force of the pile shaft. One could Figure 6 The normal stress below the pile tip.

think that for a calculation with both the pile

tip and the shaft moving down at the same

time, the upper dashed line will be found, but

instead the bearing capacity (2nd and straight

line) has been found to be clearly lower.

This proofs that the pile shaft and tip

influence each other a lot, causing a strong

non-linearity or reduction in the bearing

capacity.

The question arises if this reduction of the

bearing capacity exists because the shaft

influences the pile tip or because the tip

influences the shaft, or maybe even both.

This question will be solved in the next

paragraph.

Figure 7 The shear stress along the shaft.

IGS 715 NGM 2016 - Proceedings

Modelling, analysis and design

5 STRESSES ALONG THE TIP AND understood. In fact even the type of failure

SHAFT mechanism around the pile tip is still a point

of discussion.

The previous calculations were displacement A conclusion following from the numerical

controlled, which means that only a single calculations is that, the shear stresses along

total force results from the calculations, and the pile shaft do not influence the stresses at

not two independent forces: the force at the the pile tip, but visa-verso the normal stresses

tip and the force along the shaft. at the pile tip do influence the shear stresses

Therefore the normal stresses along the (flat) along the shaft.

tip have been plotted (Figure 6) and also the Another conclusion from the numerical

shear stresses along the shaft (Figure 7), for calculations, and as expected from the

both a calculation in which only the tip has Prandtl theory, is that the shape and size of

been pushed down and also a calculation in the pile tip do not matter. But according to

which both tip and shaft have been pushed this research, there is no Prandtl-wedge type

down for a large displacement ( uz / D 2 ). of failure at the pile tip, but a zone of

These figures show that the normal stresses plasticity. And the stresses below the pile tip

below the tip are (almost) not influenced by are not as given by the Prantl theory constant,

the shaft, but that the shear stresses along the but higher near the centre of the pile.

shaft are influenced by the tip. The outcome that the shape of the pile has no

Figure 6 also shows that the normal stresses influence is already what is used in practise;

below the pile tip are not constant, but higher the stresses measured with a sharp cone are

near the centre of the pile, unlike the assumed to be the same for a flat tip of a

Meyerhof equation. foundation pile.

The dotted line in Figure 7 named “expected” The outcome that the size does not matter

is the shear stress related to the vertical might look in contradiction with the field

effective stress v and the horizontal earth tests, but before concluding this, first future

pressure K 0 , according to: tests should compensate for the difference in

failing definition (the 10% displacement rule

for a real pile versus the infinite displacement

rz tan v K0 , (5) for a Cone Penetration Test).

with: v z and: K0 1 sin . 7 REFERENCES

Figure 7 shows that most of the pile shaft has Bustamente, M. & Gianeslli, L. (1982) Pile bearing

less shear friction than expected, except near capacity prediction by means of static penetrometer

CPT. Second European Symposium on Penetration

the tip, but also that the pile tip has a big Testing, Amsterdam 24-27 May 1982.

influence on the shaft: the pile tip is pushing Brinch Hansen, J. A (1970) Revised and extended

down the surrounding soil and reduces in this formula for bearing capacity, Bulletin No 28, Danish

way the shear stresses along the shaft. Geotechnical Institute Copenhagen, 5-11.

Caquot, A. and Kérisel, J. (1953). Sur le terme de

surface dans le calcul des fondations en milieu

6 CONCLUSIONS pulvérulents, Third International conference on Soil

Mechanics and Foundation Engineering, Zürich, pp.

According to field tests, large differences are 336–337.

found between the normal stresses on the Chen, W. F. (1975) Limit analysis and soil

plasticity, Elsevier.

cone in a CPT test, and the normal stresses De Beer, E. E. (1970). “Experimental

on the tip of a foundation pile, while a good determination of the shape factors and the bearing

scientific explanation cannot be given. Also capacity factors of sand.” Geotechnique, 20, 387– 411.

the influence of the pile size (scale effect), Eurocode 7, NEN 9997-1 (nl) Geotechnical design

the influence of the installation (driving or of structures - Part 1: General rules, 107-113

Fang, Hsai-Yang (1990) Foundation Engineering

pushing), the influence of the pile tip on the Handbook, Kluwer, Norwell-USA / Dordrecht-NL

pile shaft and visa-versa and the influence of Hjiaj, M. Lyamin, A.V, Sloan, S.W. (2005)

the horizontal soil stresses are not completely Numerical limit analysis solutions for the bearing

NGM 2016 - Proceedings 716 IGS

The influence of the shaft friction and pile shape on the pile tip bearing capacity

capacity factor N, International Journal of Solids and Yu, H.S., Salgado, R., Sloan, S.W., Kim, J.M.

Structures, No 42, 1681–1704 (1998) Limit analysis versus limit equilibrium for

Keverling Buisman, A. S. (1940). slope stability, Journ. Geotechnical and

Grondmechanica, Waltman, Delft, the Netherlands, Geoenvironmental Eng., Jan. 1998, Vol 124, No 1, pp

243 1–11

Meyerhof, G. G. (1951) The ultimate bearing

capacity of foundations, Géotechnique, 2, 301-332

Meyerhof, G. G. (1953) The bearing capacity of

foundations under eccentric and inclined loads, in

Proc. III intl. Conf. on Soil Mechanics Found. Eng.,

Zürich, Switzerland, 1, 440-445

Meyerhof, G. G. (1963) Some recent research on

the bearing capacity of foundations, Canadian

Geotech. J. , 1(1), 16-26

Meyerhof, G. G. (1965) Shallow foundations,

Journal of the Soil Mechanics and Foundations

Division ASCE, Vol. 91, No. 2, March/April 1965,

21-32

Michalowski, R. L. (1997) “An estimate of the

influence of soil weight on bearing capacity using

limit analysis.” Soils and Foundations, 37(4), 57–64.

Prandtl, L. (1920) “Über die Härte plastischer

Körper.” Nachrichten von der Königlichen

Gesellschaft der Wissenschaften zu Göttingen,

Mathematisch.-physikalische Klasse, 74–85.

Reissner, H. (1924) “Zum Erddruckproblem.”

Proc., 1st Int. Congress for Applied Mechanics, C. B.

Biezeno and J. M. Burgers, eds., Delft, The

Netherlands, 295–311.

Tapper, L., Martin, C.M. , Byrne, B.W. Lehane,

B.M. (2015) Undrained vertical bearing capacity of

perforated shallow foundations, Frontiers in Offshore

Geotechnics, Fig. 7, 816

Terzaghi, K. (1943) Theoretical soil mechanics, J.

Wiley, New York.

Van Baars, S. (2014) The inclination and shape

factors for the bearing capacity of footings, Soils and

Foundations, ISSN: 0038-0806, Vol.54, No.5, October

2014

Van Baars, S. (2015) The bearing capacity of

footings on cohesionless soils, send for publication to

The electronic journal of geotechnical engineering

Van Mierlo, J.C. and Koppejan, A.W. (1952)

“Lengte en draagvermogen van heipalen”, Bouw 3,

1952

Van Tol, A.F.( 1994), Hoe betrouwbaar is de

paalfundering, Intreerede 3-6-1994, TU Delft, in

Dutch

Van Tol, A. F., Stoevelaar, R., Rietdijk, J. (2010)

Draagvermogen van geheide palen in internationale

Context, Geotechniek, Dec. 2010

Van Tol, A.F. (2012) Draagkracht

funderingspalen, een up-date. Geotechniek Special

Dec 2012

Vesic, A. S. (1973) Analysis of ultimate loads of

shallow foundations. J. Soil Mech. Found. Div., 99(1),

53.

Vesic, A. S. (1975) Bearing capacity of shallow

foundations, H.F. Winterkorn, H.Y. Fang (Eds.),

Foundation Engineering Handbook, Van Nostrand

Reinhold, New York (1975), pp. 121–147

IGS 717 NGM 2016 - Proceedings

Modelling, analysis and design

NGM 2016 - Proceedings 718 IGS

You might also like

- Sans 1200 HDocument3 pagesSans 1200 HfilipeNo ratings yet

- Barbosa-Cruz & M.F. Randolph (ISFOG 2005)Document8 pagesBarbosa-Cruz & M.F. Randolph (ISFOG 2005)Pablo Cesar TrejoNo ratings yet

- 2018 - The Bearing Capacity of Shallow Foundations On SlopesDocument8 pages2018 - The Bearing Capacity of Shallow Foundations On SlopesPranavaDartNo ratings yet

- The Inclination and Shape Factors For The Bearing Capacity of FootingsDocument8 pagesThe Inclination and Shape Factors For The Bearing Capacity of FootingsSaleh HassanNo ratings yet

- Loadingtests ON by Clay": Theories For Failure Load Under Plates On ClayDocument19 pagesLoadingtests ON by Clay": Theories For Failure Load Under Plates On ClayEMERSON FARLEY DURAN CARRENONo ratings yet

- The Bearing Capacity of Footings On Coarse SoilsDocument11 pagesThe Bearing Capacity of Footings On Coarse SoilsMattNo ratings yet

- 04 Bra EstrupDocument6 pages04 Bra EstrupcjpwdesignNo ratings yet

- Calculating Methodology of Large Base Slabs Compressible Strata Capacity and Foundation SettlementDocument8 pagesCalculating Methodology of Large Base Slabs Compressible Strata Capacity and Foundation SettlementAbdelmoez ElgarfNo ratings yet

- Foundation Design With PressuremeterDocument44 pagesFoundation Design With Pressuremeter류태하No ratings yet

- P.499 - Simplified Analysis For Tunnel Supports PDFDocument20 pagesP.499 - Simplified Analysis For Tunnel Supports PDFAleksandar SpasojevicNo ratings yet

- Analysis of Self-Boring Pressuremeter Tests in Overconsolidated ClaysDocument5 pagesAnalysis of Self-Boring Pressuremeter Tests in Overconsolidated ClaystangkokhongNo ratings yet

- Lateral Response o F PilesDocument1 pageLateral Response o F PilesFernando FanteNo ratings yet

- 10Document12 pages10rowatersNo ratings yet

- 6 Foundation Design With Pressuremeter 2009 639Document44 pages6 Foundation Design With Pressuremeter 2009 639Hem ShahiNo ratings yet

- Face Stability Analysis of Circular Tunnels Driven by A Pressurized ShieldDocument16 pagesFace Stability Analysis of Circular Tunnels Driven by A Pressurized ShieldbambokarambaNo ratings yet

- 1998 Russo PDFDocument17 pages1998 Russo PDFMUHAMMAD AHMAD JAMILNo ratings yet

- Sobie Recent Research On The Bearing Capacity of Founbl4TionsDocument11 pagesSobie Recent Research On The Bearing Capacity of Founbl4TionsSaraswati NoorNo ratings yet

- Velloso - Piles Subjected To Horizontal Loads Due To Asymmetrical Surcharges On The SurfaceDocument5 pagesVelloso - Piles Subjected To Horizontal Loads Due To Asymmetrical Surcharges On The SurfaceMarcelaMarquesNo ratings yet

- Load and Settlement Behaviors of Pile-Raft Foundation in Soft Soil of Post-ConsolidationDocument5 pagesLoad and Settlement Behaviors of Pile-Raft Foundation in Soft Soil of Post-ConsolidationBRAYAN GERARDO AREVALO MENDOZANo ratings yet

- Leca&dormieuxDocument26 pagesLeca&dormieuxIslam-Lotfi Hadj-ArabNo ratings yet

- On The Ground Response Curve: by Pieter A. Vermeer, Thomas Marcher and Nico RuseDocument8 pagesOn The Ground Response Curve: by Pieter A. Vermeer, Thomas Marcher and Nico RuseJonathan CobbNo ratings yet

- Effect of Soil Deformability On RigidityDocument11 pagesEffect of Soil Deformability On RigidityCesar Basantes AvalosNo ratings yet

- A Method For Predicting The Effect of Piles On Slope BehaviourDocument13 pagesA Method For Predicting The Effect of Piles On Slope BehaviourMatteo IzziNo ratings yet

- Dickin 1985Document21 pagesDickin 1985Cesar Alberto RuverNo ratings yet

- Face Stability Analysis of Shallow Circular Tunnels in Cohesive-Frictional SoilsDocument14 pagesFace Stability Analysis of Shallow Circular Tunnels in Cohesive-Frictional SoilsRonald Cornejo MarmanilloNo ratings yet

- Gill Geology Cross SectionDocument18 pagesGill Geology Cross SectionziqriiqbalNo ratings yet

- Allowable Bearing Capacity of Shallow FoundationsDocument16 pagesAllowable Bearing Capacity of Shallow Foundationskyle_obiNo ratings yet

- 1979 - Einstein-Schwarz - Simplified Analysis For Tunnel SupportsDocument21 pages1979 - Einstein-Schwarz - Simplified Analysis For Tunnel SupportsReza OsgouiNo ratings yet

- RaftDocument8 pagesRaftKamarajanNo ratings yet

- 1 s2.0 S0886779817311914 MainDocument15 pages1 s2.0 S0886779817311914 Maina4abhirawatNo ratings yet

- Initial Soil Springs Stiffness For Laterally Loaded Piles PDFDocument7 pagesInitial Soil Springs Stiffness For Laterally Loaded Piles PDFmagdyamdbNo ratings yet

- Combined Footing DesignDocument29 pagesCombined Footing DesignIddrisu NajeedNo ratings yet

- 1950 - Skempton and Bishop - The Measurement of The Shear Strength of SoilsDocument20 pages1950 - Skempton and Bishop - The Measurement of The Shear Strength of SoilsGregory Alvarado Chavez100% (1)

- Design and Performance of Deep Excavations in Soft ClaysDocument27 pagesDesign and Performance of Deep Excavations in Soft ClaysBryanAndrésNewballNo ratings yet

- Trench Stability in Cohesive Soil: September 2011Document7 pagesTrench Stability in Cohesive Soil: September 2011SanaaNo ratings yet

- 1 s2.0 S0267726102002129 MainDocument9 pages1 s2.0 S0267726102002129 Main305 SREEKANTH REDDYNo ratings yet

- STAL Isbn STAL190090Document8 pagesSTAL Isbn STAL190090Joel GarciaNo ratings yet

- Piles in Lateral Spreading: A Simple Method Versus Centrifuge ExperimentsDocument12 pagesPiles in Lateral Spreading: A Simple Method Versus Centrifuge ExperimentsManuel Alvarez MNo ratings yet

- Pubb-0534-L-For A Correct Interpretation of Ground Reaction CurvesDocument6 pagesPubb-0534-L-For A Correct Interpretation of Ground Reaction CurvesSimoneNo ratings yet

- Shallow Foundations (Rafts)Document15 pagesShallow Foundations (Rafts)bogdan tanasoiu100% (1)

- Broms (2016)Document17 pagesBroms (2016)Luis Fernando SoaresNo ratings yet

- Bearing Capacity of Shallow FoundationDocument59 pagesBearing Capacity of Shallow FoundationSyafiq Azman100% (1)

- Discussion on Size Effect of Footing in Ultimate Bearing Cap 2016 Soils andDocument11 pagesDiscussion on Size Effect of Footing in Ultimate Bearing Cap 2016 Soils andthalesgmaiaNo ratings yet

- 1987-Seismic Response of Earth Dams Some RecentDocument46 pages1987-Seismic Response of Earth Dams Some RecentANES1434No ratings yet

- 202 Soil Profile From CPTDocument21 pages202 Soil Profile From CPTSapria AdiNo ratings yet

- 6 - Budijanto Widjaja-UNPARDocument5 pages6 - Budijanto Widjaja-UNPARMuhammad LutfhiNo ratings yet

- On Stability Analysis of Slurry-Wall Trenches: Plaxis PracticeDocument6 pagesOn Stability Analysis of Slurry-Wall Trenches: Plaxis PracticeVetriselvan ArumugamNo ratings yet

- SSI Introduction PDFDocument29 pagesSSI Introduction PDFdesigner STRNo ratings yet

- 03-10-FArtor NQ Cap de Pilas Sergio Antonio Martinez GalvanDocument9 pages03-10-FArtor NQ Cap de Pilas Sergio Antonio Martinez GalvanJOSE LUIS GONZALEZNo ratings yet

- Analysis of Dilatometer Test in ClayDocument8 pagesAnalysis of Dilatometer Test in ClayMarcus ViniciusNo ratings yet

- Influence of Anchor Inclination On Pull-Out Resistance of ClaysDocument6 pagesInfluence of Anchor Inclination On Pull-Out Resistance of ClaysSen HuNo ratings yet

- PileDesign Example02Document17 pagesPileDesign Example02HumayunKabirNo ratings yet

- Hird 1992Document13 pagesHird 1992yutubpremiummmm01No ratings yet

- Trench Stability in Cohesive SoilDocument6 pagesTrench Stability in Cohesive SoilShahab KhaledNo ratings yet

- Stability Coefficients For Earth SlopesDocument25 pagesStability Coefficients For Earth SlopesDaniel Felipe Rodriguez RamirezNo ratings yet

- A Treatise on the Differential Geometry of Curves and SurfacesFrom EverandA Treatise on the Differential Geometry of Curves and SurfacesNo ratings yet

- March/April 2016 Cadillac Area Business MagazineDocument16 pagesMarch/April 2016 Cadillac Area Business MagazineCadillac Area Chamber of CommerceNo ratings yet

- 1osh LeadsDocument72 pages1osh Leadssaskiamogale100% (1)

- POLGOVSEA - MOD 1 - IntroDocument30 pagesPOLGOVSEA - MOD 1 - IntroBryan MarasiganNo ratings yet

- Dodla Dairy Hyderabad Field Visit 1Document23 pagesDodla Dairy Hyderabad Field Visit 1studartzofficialNo ratings yet

- Manual Serviço - Aiwa NSX-D77, NSX-T76, NSX-T77Document48 pagesManual Serviço - Aiwa NSX-D77, NSX-T76, NSX-T77fabioferraoNo ratings yet

- Dhaka University Affiliated Colleges: Third Year Syllabus Department of MathematicsDocument8 pagesDhaka University Affiliated Colleges: Third Year Syllabus Department of MathematicsHasibul Hassan ShantoNo ratings yet

- Detail 6 Connection of Purlins To Rb-1 9Document1 pageDetail 6 Connection of Purlins To Rb-1 9Fritz NatividadNo ratings yet

- Steel Body - Lever Hoists: A e B A e B A e BDocument1 pageSteel Body - Lever Hoists: A e B A e B A e BtylerlhsmithNo ratings yet

- Power Bank ppt-3-3Document20 pagesPower Bank ppt-3-3Apoorva RNo ratings yet

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitErln LimaNo ratings yet

- Pa Pi Pu Pe Po: HandakuonDocument23 pagesPa Pi Pu Pe Po: HandakuonmnmrznNo ratings yet

- Data Base Proyek KonstruksiDocument913 pagesData Base Proyek KonstruksiZefanyaNo ratings yet

- EC506 Wireless Gateway User Manual ENGDocument48 pagesEC506 Wireless Gateway User Manual ENGcy5170No ratings yet

- Standard Kessel Cat - Gral.Document40 pagesStandard Kessel Cat - Gral.Marcelo ResckNo ratings yet

- Best Practices SQL Server For OpenText Content Server 10.5Document44 pagesBest Practices SQL Server For OpenText Content Server 10.5peptaNo ratings yet

- A5 - Nivel TestDocument8 pagesA5 - Nivel TestValerie StephensNo ratings yet

- Energy Research Institute - Wang SichengDocument17 pagesEnergy Research Institute - Wang SichengADB_SAEN_ProjectsNo ratings yet

- Rumah-Rumah Tahfizh Di Kota Banjarmasin Profil Pro PDFDocument14 pagesRumah-Rumah Tahfizh Di Kota Banjarmasin Profil Pro PDFJuhdan TrueNo ratings yet

- Anna University of Technology, TiruchirappalliDocument2 pagesAnna University of Technology, TiruchirappallisanjeevrksNo ratings yet

- Agent Application Form - NIADocument3 pagesAgent Application Form - NIASiva KumarrNo ratings yet

- MBA Interviews (Undergraduation Questions)Document14 pagesMBA Interviews (Undergraduation Questions)anshshah1310No ratings yet

- Module 5 Introduction To Stochastic Processes Eec605Document89 pagesModule 5 Introduction To Stochastic Processes Eec605daniel developerNo ratings yet

- New M Tech Programme in Computer Science and Engineering Artificial Intelligence Data Analytics Self Financing Mode Admissions 2023 - 0Document6 pagesNew M Tech Programme in Computer Science and Engineering Artificial Intelligence Data Analytics Self Financing Mode Admissions 2023 - 0Himesh KumarNo ratings yet

- EWESDocument10 pagesEWESPratham KatariyaNo ratings yet

- At EgmrDocument1 pageAt EgmrQasim ButtNo ratings yet

- Pressform Refractory PRINT Brochure PDFDocument44 pagesPressform Refractory PRINT Brochure PDFravikumarangNo ratings yet

- List of Companies With Contact Details For Global VillageDocument5 pagesList of Companies With Contact Details For Global VillagemadhutkNo ratings yet

- Apurba MazumdarDocument2 pagesApurba MazumdarDRIVECURENo ratings yet