Professional Documents

Culture Documents

k33900 k33780 k33781 k33800 - Existent Gum Evaporation Bath - Technical Datasheet

k33900 k33780 k33781 k33800 - Existent Gum Evaporation Bath - Technical Datasheet

Uploaded by

parkyh6Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

k33900 k33780 k33781 k33800 - Existent Gum Evaporation Bath - Technical Datasheet

k33900 k33780 k33781 k33800 - Existent Gum Evaporation Bath - Technical Datasheet

Uploaded by

parkyh6Copyright:

Available Formats

Existent Gum in Fuels by Jet Evaporation

test method

Gum formed during fuel storage can deposit on induction system

surfaces, intake valves, stems and guides. To test for gum

content, a 50mL sample is evaporated in an aluminum block bath

for a specified period under controlled conditions of temperature

and flow of air (aviation and motor gasolines) or steam (aircraft

turbine fuel).

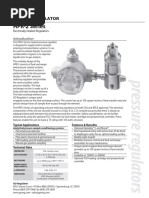

existent gum test apparatus

Evaporates aircraft turbine fuel and motor and aviation gasoline

samples under controlled conditions in accordance with ASTM

specifications. Consists of a high temperature evaporation bath with

100mL test beakers and, for aircraft turbine fuels, a steam generator

and steam superheater.

evaporation baths

• Conforming to ASTM D381 and related specifications

• Choice of three-unit and six-unit models

• Safety top assembly allows for easy positioning and connection

of all conical adapters to the bath K33900 Existent Gum Evaporation Bath

• Digital flowmeter for accurate and precise air flow measurement

• Built-in steam superheater

• Microprocessor programmable high accuracy temperature control specifications

• Built-in pressure regulator Conforms to the specifications of: ASTM D381; IP 131; IP 540;

Electrically heated baths for determining existent gum in aircraft ISO 6246; DIN 51784; FTM 791-3302; NF M 07-004

turbine fuels by steam-jet evaporation and in motor and aviation

Testing Capacity

gasolines by air-jet evaporation. Fully insulated, aluminum block

K33900: 6 sample beakers

design assures safe, efficient high temperature operation. Equipped

K33780 and K33781: 3 sample beakers

with air/steam pressure regulator with gauge and a digital flowmeter

Maximum Temperature: 475˚F (246˚C)

for adjusting air flow per ASTM specifications. Stainless steel

Temperature Control Stability: 1˚F ( 0.5˚C)

jets deliver air or steam flow to the test wells through removable

Bath Configuration: machined aluminum block with multiple

brass conical adapters. Microprocessor PID control provides

cartridge heaters

quick temperature stabilization without overshoot, and the bath

is protected by an overtemperature control circuit that interrupts Heater Range

power should bath temperature exceed a programmed cut-off point. K33900: 0-3000W

Dual LED displays provide actual and setpoint temperature values K33780 and K33781: 0-1500W

in ˚C/˚F format. Communications software (RS232, etc.), ramp-to- Superheater: (Model K33900 only) Superheating chamber and

set and other enhanced features are available as extra cost options. condensate trap constructed of stainless steel. Solid state

Contact your Koehler representative for information. thermoregulator (0-550˚F)

Heater Range: 0-3000W

Model K33900 with Built-in Superheater–Six-unit bath with a built- Electrical Requirements

in thermostatically controlled superheater which delivers dried K33900: 220-240V 50/60Hz, Single Phase, 30A

steam to the bath inlet for steam-jet method testing of aircraft K33780: 115V 60Hz, Single Phase, 13.0A

turbine fuels. Has digital indicating solid state bath temperature K33781: 220-240V 50/60Hz, Single Phase, 6.8A

control with digital setpoint and display.

Model K33780/K33781 – Three-unit bath without built-in Included Accessories Conical Brass Adapters for air/steam jets

superheater. All controls are housed in the bath cabinet. Dimensions lxwxh,in.(cm)

K33900 21”x20.5”x28” (53.34x52.07x71.12)

ordering information Net Weight 230 lbs (104.3kg)

catalog no. description K33780/K33781 32.5x11x19 (83x28x48)

K33900 Existent Gum Evaporation Bath, 6-Unit with Superheater, Net Weight 85 lbs (38.6kg)

220-240V 50/60Hz Shipping Information: Shipping Weight/Dimension

K33780 Existent Gum Evaporation Bath, 3-Unit, 115V 60Hz K33900 313 lbs (142kg) / 17.2 Cu. ft.

K33781 Existent Gum Evaporation Bath, 3-Unit, 220-240V 50/60Hz K33780/K33781 140 lbs (63.5kg) / 8.3 Cu. ft.

85 Corporate Drive, Holtsville, New York 11742

1-800-878-9070 (in u.s. only) TEL: +1 631 589 3800 FAX: +1 631 589 3815

Email: sales@koehlerinstrument.com www.koehlerinstrument.com

©

2021 Koehler Instrument Company, Inc.

Existent Gum in Fuels by Jet Evaporation

steam generator

• For steam-jet method testing of aircraft turbine fuels

• Meets output requirements of three-unit and six-unit

evaporation baths

• Electrically heated for clean, efficient operation and ease

of installation

•Meets applicable ASME, NEC standards; UL listed, CSA approved

Electrically heated boiler provides instantaneous and reserve steam

capacity for steam-jet evaporation tests. Easy to install and operate;

electrical heating eliminates the need for on-site fuel combustion.

Requires only a water feed source and electrical hook-up. Ruggedly

constructed, with long life industrial grade incoloy heating element.

Includes a full range of safety features: automatic water level control

and low water cut-off; steam safety valve; high-limit pressure cut-out K33810 Steam Superheater

with manual reset; steam pressure gauge.

specifications accessories

Output: 54.1 lbs steam/hr at 212˚F catalog no. description qty

Bhp Rating: 1.83 K33710 Sample Beaker, 100mL spun copper, 50x78mm 6

kW Rating: 18 332-002-017 Sample Beaker, Borosilicate Glass, 100mL

Dimensions lxwxh,in.(cm) 250-000-03F ASTM 3F Thermometer Range: 20 to 760˚F 2

20x28x36 (51x71x91) 250-000-03C ASTM 3C Thermometer Range: –5 to +400˚C

Net Weight: 185 lbs (83.9kg) K33810 Steam Superheater

Provides dry superheated steam for evaporation

Shipping Information baths not equipped with a built-in superheater. Use

Shipping Weight: 200 lbs (91kg) together with an outside steam source for steam-jet

Dimensions: 18 Cu. ft. method testing of aircraft turbine fuels. Superheating

chamber and condensate trap are constructed entirely of

ordering information stainless steel. Solid state temperature controller adjusts

catalog no. description between 0-550˚F. Equipped with steam inlet and outlet

K33850 Steam Boiler, 120/240V 60Hz, Three Phase connections and condensate drain valve. Steel exterior

K33850/208601 Steam Boiler, 208V 60Hz, Single Phase, 87A has a chemical resistant polyurethane enamel finish.

K33850/208603 Steam Boiler, 208V 60Hz, Three Phase, 50A Dimensions 5x27x9.5” (13x70x24cm).

K33850/240601 Steam Boiler, 240V 60Hz, Single Phase, 75A Shipping Weight: 23 lbs (10.4kg)

K33850/240603 Steam Boiler, 240V 60Hz, Three Phase, 43A 220-240V 50/60Hz, Single Phase, 6.8A

K33850/380603 Steam Boiler, 380V 50/60Hz, Three Phase, 27A

K33850/415503 Steam Boiler, 415V 50Hz, Three Phase, 25A

K33850/480603 Steam Boiler, 480V 60Hz, Three Phase, 22A test apparatus for steam jet method

Other electrical configurations for the Steam Boiler are available.

Please inquire with Koehler Customer Service for additional information. ordering information

catalog no. description qty

K33900 Existent Gum Evaporation Bath 1

K33850 Series Steam Boiler 1

K33710 Sample Beaker (or 332-002-017) 6

250-000-03F ASTM 3F Thermometer. Range: +20 to +215˚F 2

250-000-03C ASTM 3C Thermometer. Range: –5 to +400˚C

85 Corporate Drive, Holtsville, New York 11742

1-800-878-9070 (in u.s. only) TEL: +1 631 589 3800 FAX: +1 631 589 3815

Email: sales@koehlerinstrument.com www.koehlerinstrument.com

©

2021 Koehler Instrument Company, Inc.

You might also like

- Complete Igcse Physics PPT CompilationDocument185 pagesComplete Igcse Physics PPT CompilationKareem Elhag100% (4)

- Superctrical BoilerDocument43 pagesSuperctrical Boilerak_thimiri100% (1)

- S220-Rankine Cycle Steam TurbineDocument3 pagesS220-Rankine Cycle Steam TurbineMuhammad RehanNo ratings yet

- HydrologyDocument496 pagesHydrologySara Senior Castaño100% (1)

- K48319 - Total Sediment TesterDocument1 pageK48319 - Total Sediment Testerwilfred gomezNo ratings yet

- Steam GeneratorDocument2 pagesSteam GeneratorAbdul Hafeez AkramNo ratings yet

- JamJoom Pharma - Technical Offer - 113Document8 pagesJamJoom Pharma - Technical Offer - 113Ramy MahmoudNo ratings yet

- Three - Pass Fire Tube Boilers: Economizer AdvantagesDocument2 pagesThree - Pass Fire Tube Boilers: Economizer AdvantagesAmita PatelNo ratings yet

- CBH-400 SpecsDocument2 pagesCBH-400 SpecsLevi WranglerNo ratings yet

- X341allegatoDEPLIANT1-2X XC-K enDocument6 pagesX341allegatoDEPLIANT1-2X XC-K endaboo sanatNo ratings yet

- ECT ECL ECS NewDocument2 pagesECT ECL ECS NewToph TophNo ratings yet

- Steam Heat ExchangerDocument2 pagesSteam Heat ExchangerAbdul Hafeez AkramNo ratings yet

- K19400 - K19410 Technical DatasheetDocument1 pageK19400 - K19410 Technical DatasheetManta SystemsNo ratings yet

- Fuel Cell PricesDocument11 pagesFuel Cell PricesengshimaaNo ratings yet

- Agilent 6890n DatasheetDocument5 pagesAgilent 6890n DatasheetMayar SayedNo ratings yet

- Specs Perkin Elmer 5100Document3 pagesSpecs Perkin Elmer 5100HamidNo ratings yet

- 07 Calorifiers 06 ExA EnglDocument68 pages07 Calorifiers 06 ExA EnglbaczonifNo ratings yet

- PAC1000D-S RefDocument2 pagesPAC1000D-S Refyassiroutisket2No ratings yet

- Flarecatcher 10000-65 - Spec SheetDocument1 pageFlarecatcher 10000-65 - Spec SheetjohnNo ratings yet

- Trampas de Vapor Armstrong, Series880 PDFDocument2 pagesTrampas de Vapor Armstrong, Series880 PDFLuis Guillermo Gallardo BoscanNo ratings yet

- Boiler Presentation660 MWDocument32 pagesBoiler Presentation660 MWJayaraman Kamaraj100% (1)

- Husk Based Power Plant 6T 32 KG FBC With Single Stage Turbine - For Finance, Subsidy & Project Related Support Contact - 9861458008Document28 pagesHusk Based Power Plant 6T 32 KG FBC With Single Stage Turbine - For Finance, Subsidy & Project Related Support Contact - 9861458008Radha Krishna SahooNo ratings yet

- Refrigeration Test RigDocument1 pageRefrigeration Test RigVirender Rana0% (1)

- Ficha Tecnica - Generador A Vapor AK11Document2 pagesFicha Tecnica - Generador A Vapor AK11PEDRO APOLONo ratings yet

- 6890 GC Site Preparation ChecklistDocument4 pages6890 GC Site Preparation Checklistigor_239934024No ratings yet

- Commercial Gas Water Heaters: BTR-151 (A) BTR-201 (A)Document2 pagesCommercial Gas Water Heaters: BTR-151 (A) BTR-201 (A)Viswanath NeswaNo ratings yet

- VPR Electrode BrochureDocument5 pagesVPR Electrode BrochureTayachew BerhanNo ratings yet

- 349 Advance Us CT Boiler DesDocument6 pages349 Advance Us CT Boiler DesRobin IndiaNo ratings yet

- Fulton Vantage Technical DataDocument6 pagesFulton Vantage Technical DatajrodNo ratings yet

- 600 Instrumentation and ControlDocument35 pages600 Instrumentation and ControlALI YILMAZNo ratings yet

- Heavy Duty Commercial Electric Storage SolutionDocument2 pagesHeavy Duty Commercial Electric Storage SolutionAlejandro DominadoNo ratings yet

- hpr2 Regulator For Model 933 Analyzer PN 300-9478Document7 pageshpr2 Regulator For Model 933 Analyzer PN 300-9478Jose JohnNo ratings yet

- Evaporation Bath: Manual and Semi-Automatic Analysers: Gum - RubberDocument1 pageEvaporation Bath: Manual and Semi-Automatic Analysers: Gum - RubberJorge EpbNo ratings yet

- Specification: Electronic Level TransmitterDocument11 pagesSpecification: Electronic Level TransmitterTushar BhingradiyaNo ratings yet

- LKV3000, LKV4000, LKV5000 - Kinematic Viscosity Bath - Technical DatasheetDocument1 pageLKV3000, LKV4000, LKV5000 - Kinematic Viscosity Bath - Technical Datasheetmoh_ichwanuddinNo ratings yet

- Belaria® Fit (53) TechnicalDocument4 pagesBelaria® Fit (53) TechnicalperoprviNo ratings yet

- Waste Heat Recovery Power Generation: Eagle Group S.A.EDocument16 pagesWaste Heat Recovery Power Generation: Eagle Group S.A.EAMIRNo ratings yet

- Technical PG620 (Rev)Document7 pagesTechnical PG620 (Rev)W Winarto100% (1)

- Delta Performance MVDocument36 pagesDelta Performance MVJosé MacedoNo ratings yet

- Ecotherm: Clean Steam GeneratorDocument4 pagesEcotherm: Clean Steam GeneratorbcjalNo ratings yet

- Air Release Value Apparatus Technical DatasheetDocument1 pageAir Release Value Apparatus Technical DatasheetPhoebe Jean MalapayNo ratings yet

- Caldeira PEGASUS F2Document5 pagesCaldeira PEGASUS F2goncalo30No ratings yet

- Turbopower Web BrochureDocument5 pagesTurbopower Web BrochureBia AkramNo ratings yet

- CT2850-CT3150S (60 HZ)Document3 pagesCT2850-CT3150S (60 HZ)Rani OsmanNo ratings yet

- lc140 EngDocument2 pageslc140 EnganassNo ratings yet

- K10200, K10290 - Automatic Aniline Point - Technical DatasheetDocument2 pagesK10200, K10290 - Automatic Aniline Point - Technical DatasheetEzequiel AguilarNo ratings yet

- kjl-6000ss OperatorsmanualDocument4 pageskjl-6000ss OperatorsmanualSantiago MatuteNo ratings yet

- Carrier38CKC 50HzDocument20 pagesCarrier38CKC 50HzAaron LeveyNo ratings yet

- An Introduction To High Temperature Water Heating Plants R1Document39 pagesAn Introduction To High Temperature Water Heating Plants R1Kenn WahhNo ratings yet

- PS 438919566en W4600H enDocument4 pagesPS 438919566en W4600H enTiến NguyễnNo ratings yet

- Ovens For Laboratories & IndustryDocument32 pagesOvens For Laboratories & IndustryShashank TiwariNo ratings yet

- 660 MW Sipat BoilerDocument88 pages660 MW Sipat BoilerKrishnan Santhanaraj100% (4)

- 660 MW Sipat BoilerDocument88 pages660 MW Sipat BoilerTochi Krishna Abhishek100% (4)

- 660 MW Sipat BoilerDocument88 pages660 MW Sipat BoilerNavneet SinghNo ratings yet

- NTPC (National Thermal Power Corporation) Sipat Boiler-Haxxo24 I IDocument88 pagesNTPC (National Thermal Power Corporation) Sipat Boiler-Haxxo24 I Ihaxxo24100% (2)

- Boiler Data Sheet PDFDocument1 pageBoiler Data Sheet PDFpeter mackey mamani mamanchuraNo ratings yet

- Cloud PointDocument3 pagesCloud PointsitaNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- 5th Released Science EOGDocument28 pages5th Released Science EOGMrs. Carriker80% (5)

- Optimization of Cooling TowersDocument49 pagesOptimization of Cooling TowersKhalil LasferNo ratings yet

- Evaporation 2Document14 pagesEvaporation 2ShubhVishwasNo ratings yet

- Basic Notes On Exothermic and EndothermicDocument19 pagesBasic Notes On Exothermic and Endothermicsayma_akhter5074No ratings yet

- Gr5 Wk25 Water CycleDocument2 pagesGr5 Wk25 Water CycleDANIELA SIMONELLI0% (1)

- DLP 7Es-WATER-CYCLEDocument8 pagesDLP 7Es-WATER-CYCLEAbi Roces100% (3)

- 9 EvaporationDocument82 pages9 Evaporationsanjay YadavNo ratings yet

- Science Activity Sheets - 4th QuarterDocument23 pagesScience Activity Sheets - 4th QuarterJeniffer De LeonNo ratings yet

- Class 9 Matter in Our Surroundings McqsDocument3 pagesClass 9 Matter in Our Surroundings McqsHariharan VIIA1No ratings yet

- General Chemistry 2: Intermolecular ForcesDocument28 pagesGeneral Chemistry 2: Intermolecular Forcesilike uNo ratings yet

- Interesting Facts About OceansDocument34 pagesInteresting Facts About OceansRavindr KumarNo ratings yet

- Matter Unit OverviewDocument19 pagesMatter Unit Overviewapi-419130508No ratings yet

- IPE Plate 3Document29 pagesIPE Plate 3Lee Anthony ChingNo ratings yet

- Class 10 p1 Thermal PhysicsDocument10 pagesClass 10 p1 Thermal PhysicsSameer Abu MunsharNo ratings yet

- CH 7 Heat Transfer New 1-15Document15 pagesCH 7 Heat Transfer New 1-15aliNo ratings yet

- Boiling Heat Transfer ExpDocument22 pagesBoiling Heat Transfer ExpMahesh Vp0% (1)

- Grade 7 Note On Separating TechniquesDocument8 pagesGrade 7 Note On Separating TechniquesBadass PolapainNo ratings yet

- Characterization Factors: Evaluation of Oil StockDocument65 pagesCharacterization Factors: Evaluation of Oil StockHasan AsifNo ratings yet

- Translate Section 13 - Analysis of The Basic Vapor Compression Refrigeration CycleDocument69 pagesTranslate Section 13 - Analysis of The Basic Vapor Compression Refrigeration CycleBeautYy PakpahanNo ratings yet

- Heat Transfer in Wiped Film EvaporatorsDocument4 pagesHeat Transfer in Wiped Film EvaporatorsAlexNo ratings yet

- ) : 3 - (Problems 8 Assignment No.: Solve The Following ProblemsDocument8 pages) : 3 - (Problems 8 Assignment No.: Solve The Following ProblemsMohNajiNo ratings yet

- Cooling TowerDocument8 pagesCooling TowerHemant PatilNo ratings yet

- Solids: Notes 1 Chapter 1: The Particulate Nature of Matter Solids, Liquids and GasesDocument7 pagesSolids: Notes 1 Chapter 1: The Particulate Nature of Matter Solids, Liquids and GasesQfkjfksNo ratings yet

- Spin Coating ProcessDocument7 pagesSpin Coating ProcessFelipe GarcíaNo ratings yet

- Science Second Grading Summative TestDocument2 pagesScience Second Grading Summative TestMonica Morales Maaño100% (2)

- TD 390 Report 2019 PDFDocument53 pagesTD 390 Report 2019 PDFCherub KapoorNo ratings yet

- National Geographic Readers Water (Melissa Stewart)Document52 pagesNational Geographic Readers Water (Melissa Stewart)dellindia100% (1)

- Integration of Thermal Energy Storage in BuildingsDocument134 pagesIntegration of Thermal Energy Storage in Buildingsabdoo13100% (1)