Professional Documents

Culture Documents

Pin Pile Frame - b6 - Page 1

Pin Pile Frame - b6 - Page 1

Uploaded by

yannazarethsimoesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pin Pile Frame - b6 - Page 1

Pin Pile Frame - b6 - Page 1

Uploaded by

yannazarethsimoesCopyright:

Available Formats

REFERENCE DOCUMENTS

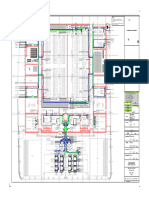

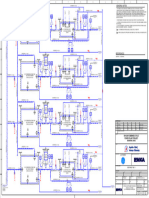

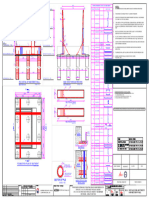

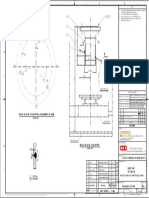

SEE NOTE 2.3 SEE NOTE 2.2

[1] - 300232C-000-RT-5253-0006 - PIN PILE FRAME FOR PLET / TRF ANCHORING GENERAL ARRANGEMENT

[2] - N-2037: PINTURA DE EQUIPAMENTOS SUBMERSOS EM ÁGUA DO MAR

[3] - 300232C-000-SP-5253-0004 - PIN PILE FRAME FOR PLET / TRF ANCHORING DESIGN REPORT

285

[4] - 300232C-000-DW-5253-0003 - TRF PILE GENERAL ARRANGEMENT DRAWING

[5] - BJ 203.0.00546 - ANODE STAND-OFF

1702

1050

BACK VIEW 2722

930

5566

5400 LEFT VIEW (FRAME ONLY)

753 (CoG W/ PIN PILE 11.8m)

798 (CoG W/ PIN PILE 16.5m)

807 (CoG W/ PIN PILE 17.5m)

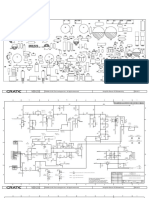

GENERAL NOTES

1- RAW MATERIAL:

1.1- ALL MATERIAL SHALL BE CERTIFICATED.

1.2 - Z-QUALITY REQUIRED: CLASS Z25, WHERE INDICATED.

1.3 - THE MATERIAL MUST PRESENT A 0ºC CHARPY, WHERE INDICATED.

1.4 - THE MATERIAL MUST PRESENT A -40ºC CHARPY, WHERE INDICATED.

1.5 - ACCORDING TO ISO 3506-1 - Gr. 4 - CLASS 70 - C < 0.03%.

2- PART MARKING:

2.1 - PADEYES MARKING - MARK WITH ELECTRODE COATED THE CAPACITY: SWL 55 ton

2.2 - STRUCTURE MARKING - MARK THE DRAWING NUMBER WITH REVISION AND SUPPLIER TRACEABILITY NUMBER,

WHERE INDICATED.

2.3 - FRAME MARKING - MARK WITH ELECTRODE COATED THE CAPACITY: SWL 55 ton.

CoG 3- NONCONFORMITY TREATMENT:

3.1- IN CASE OF SUPPLIER AND THE COMERCIAL PROJECT HAVE NOT NCR FORM, THE NONCONFORMITIES RELATED TO

THIS DRAWING SHALL BE TREATED ACCORDING TO THE PROCEDURE PR FLB 52 EMQ 001.

12.5

4- MACHINING: ( )

4.1- ALL SHARP EDGES, BURRS, WELD SPATTER MUST BE REMOVED.

5- WELDING:

5.1- WELDING PROCEDURE AND WELDERS QUALIFICATION ACCORDING TO AWS D1.1

6- SURFACE TREATMENT:

6.1 - PAITING ACOORDING TO REF. [2].

6.2 - PIN PILE FRAME SHALL BE MARINE EPOXY PAINT WITH MINIMUM DRY FILM THICKNESS OF 450µ, IN ACCORDANCE

WITH REF. [2].

7- NDT:

7.1- FOR WELDING: SURFACE CRACKS:

7.1.1- VISUAL INSPECTION ON 100% OF WELDED JOINTS AS AWS D1.1 PART C SECTION 6.9.

7.1.2- TEST PENETRANTING LIQUID IN 100% OF WELDED JOINTS AS AWS D1.1 PART C SECTION 6.10.

7.2- FOR WELDING: EVALUATION OF DEEP FAILURE:

7.2.1- ULTRASOUND TEST ON 100% FULL PENETRATION WELDED JOINTS ACCORDING TO AWS D 1.1

PART C SECTION 6.13 - CYCLICALLY LOADED NONTUBULAR CONNECTIONS.

8- NOT INDICATED TOLERANCES:

7100

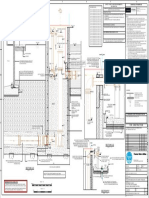

DET.1 8.1- WELDED CONSTRUCTIONS ACCORDING TO ISO 13920-C;

8.2- MACHINING OF DIAMETERS ACCORDING TO ISO 2768-M.

(CoG W/ PIN PILE 11.8m)

(CoG W/ PIN PILE 17.5m)

(CoG W/ PIN PILE 16.5m)

8.3- MACHINING OF LENGTHS ACCORDING TO ISO 2768-C.

2806 (CoG W/ PIN PILE 11.8m) 9- OPERATION AND LIFTING FACILITIES:

(CoG ONLY FRAME)

9.1- WE SUGGEST USING GREEN PIN SHACKLE G2130 - WLL 55Te

9.2- LIFTING MAXIMUM ANGLE: 60º (LEG/BASE).

9.3- WE SUGGEST USING CARGO STRAPS OF 10t.

10- SUPPLIER SUGGESTIONS AND COMPLAINTS:

2808 (CoG W/ PIN PILE 16.5m) 10.1- IF THE SUPPLIER HAS A SUGGESTION FOR IMPROVEMENT ON THE MANUFACTURING PROCESS AND/OR THE

DRAWING ILLUSTRATION, HE MUST COMPLETE AND ISSUE THE DOCUMENT FO EMQ 0007 15. FOR OTHER MATTERS,

SUPPLIER MUST ISSUE THE NON-CONFORMITY REPORT.

9822

9906 11- ALL DIMENSIONS ARE IN MILLIMETER EXCEPT WHERE INDICATED.

9914

9908

12- EME NUMBER: BJ 530.0.00015

13- PIN PILE UNIT WEIGHT:

2814 (CoG W/ PIN PILE 17.5m) 18.0m - 8.3 ton

16.5m - 7.6 ton

11.0m - 5.1 ton

1100

LEFT VIEW (W/ PIN PILE)

900

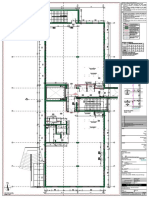

FRAME STRUCTURAL PIN PILE 11800mm

19830

19996

4 5° ASSEMBLY TOTAL WEIGHT IN AIR: 11.8 TON ASSEMBLY TOTAL WEIGHTIN AIR: 35 TON

4 5°

ASSEMBLY TOTAL WEIGHT SUBMERGED: 10.6 TON ASSEMBLY TOTAL WEIGHT SUBMERGED: 30.3 TON

3830

SEE NOTE 9.3

43 ° 43 °

900

1100

7100

PIN PILE 16500mm

ASSEMBLY TOTAL WEIGHT IN AIR: 43.7 TON PIN PILE 17500mm

ASSEMBLY TOTAL WEIGHT SUBMERGED: 37.8 TON ASSEMBLY TOTAL WEIGHT IN AIR: 45.4 TON

ASSEMBLY TOTAL WEIGHT SUBMERGED: 39.3 TON

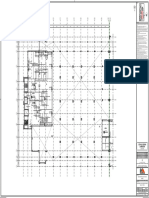

2700 0 ISSUED FOR INFORMATION 18/05/2023 PCO YSI AMA

REV. DESCRIPTION DATE EXEC. CHECK APPROV.

INFORMATION IN THIS DOCUMENT IS PROPERTY OF PETROBRAS, BEING PROHIBITED OUTSIDE OF

PLAN VIEW THEIR PURPOSE

FORM OWNED TO PETROBRAS N-0381 REV. L.

SCALE (1:50) SEE NOTE 9.3 TECHNIPFMC

NUMBERTKP: 300232C-000-DW-5253-0006

SEE NOTE 9.3 CONTRACT Nº: 5900.0120124.21.2

Technical Responsible: André Massa - CREA: 1998032320

DDP

32 CLIENT:

100 BUZIOS

TYP. JOB:

DESENVOLVIMENTO DO SISTEMA DE PRODUÇÃO DE BUZIOS 6

AREA:

CAMPO DE BUZIOS

1085 505 2345 TITLE:

PIN PILE FRAME FOR PLET ANCHORING FABRICATION

PIN PILE AND TESTING SPECIFICATION

23

DET.1 DESIGN

TKP

EXEC.

Pedro Costa

CHECK

Yan Simões

APPROV.

Andre Massa

1 : 15 SCALE SHEET

36 REMOVABLE ANGLE BAR PIN PILE MARKING LIMIT

1:50

NP-1

DRAWING - 1 of

SUB/IPSUB-BUZ/PROJSUB-BUZ-I/PSUB-BUZ-6

4

DATE No.

1:5

A1

841 mm x 594 mm

18/05/2023 -

You might also like

- 2007 Chevrolet Cobalt Service Repair Manual PDFDocument15 pages2007 Chevrolet Cobalt Service Repair Manual PDFfujsjejfksekmem33% (3)

- Customer Specific Requirements MatrixDocument4 pagesCustomer Specific Requirements Matrixhmp9071% (7)

- Project Management Plan Reverse Logistics Midterm PDFDocument10 pagesProject Management Plan Reverse Logistics Midterm PDFramrammithraNo ratings yet

- FGA-CMOP-EN-3140A-SS-DWG-M0006 - Rev 0Document1 pageFGA-CMOP-EN-3140A-SS-DWG-M0006 - Rev 0Gabriela Vanessa Anconeyra MaqueNo ratings yet

- M5N Civ SHP 125 601 BD 4307 2 - R0Document1 pageM5N Civ SHP 125 601 BD 4307 2 - R0Tarek AbulailNo ratings yet

- 1663-43691010-Me-Dwg-7380-00-Cu-Cl2-Bdu-Fru-Assy-1 (R1)Document1 page1663-43691010-Me-Dwg-7380-00-Cu-Cl2-Bdu-Fru-Assy-1 (R1)raacontreras21No ratings yet

- 4139M06017 Default 000Document1 page4139M06017 Default 000gopi krishnaNo ratings yet

- Building 02 - Corridor Smoke Extraction Layout For 2nd FloorDocument1 pageBuilding 02 - Corridor Smoke Extraction Layout For 2nd FloorMTT VIETPRONo ratings yet

- A 120 Builders Works PLanDocument1 pageA 120 Builders Works PLanethelNo ratings yet

- 904-AR-301 Rev 1Document1 page904-AR-301 Rev 1OmarNo ratings yet

- Typical Dec Level QV-4300177 NOTES 6,7 Type NO Note 16 C1Document2 pagesTypical Dec Level QV-4300177 NOTES 6,7 Type NO Note 16 C1Floyd BurgessNo ratings yet

- Garage Mate DrawingDocument1 pageGarage Mate DrawingWael WaelNo ratings yet

- I de 3010.0F 1350 140 EA9 519 Arranjo Sistema OffloadingDocument1 pageI de 3010.0F 1350 140 EA9 519 Arranjo Sistema OffloadingDiego NogueiraNo ratings yet

- Sae Ams-I-23053-2-2000 PDFDocument7 pagesSae Ams-I-23053-2-2000 PDFiipmnpti iipmNo ratings yet

- M5N Civ SHP 125 601 BD 4310 2 - R0Document1 pageM5N Civ SHP 125 601 BD 4310 2 - R0Tarek AbulailNo ratings yet

- M5N Civ SHP 125 601 BD 4311 2 - R0Document1 pageM5N Civ SHP 125 601 BD 4311 2 - R0Tarek AbulailNo ratings yet

- GambarDocument1 pageGambarBudi ArkhaNo ratings yet

- DRP001 Ouf Gal 940110 K Ecr 001 003 S1Document1 pageDRP001 Ouf Gal 940110 K Ecr 001 003 S1pathanNo ratings yet

- M5N Civ SHP 125 601 BD 4308 2 - R0Document1 pageM5N Civ SHP 125 601 BD 4308 2 - R0Tarek AbulailNo ratings yet

- Changes Per All Backcircled: NotesDocument1 pageChanges Per All Backcircled: Notesheri_prasetyadiNo ratings yet

- Residence: Vanity 1200X500mm Open Wardrobe 2545X596mm Cabinet Display Tas 1772X450mm (Pintu Kaca)Document1 pageResidence: Vanity 1200X500mm Open Wardrobe 2545X596mm Cabinet Display Tas 1772X450mm (Pintu Kaca)fackur firmansyahNo ratings yet

- Theatre Work DWG - 25 Aug 2011-3Document1 pageTheatre Work DWG - 25 Aug 2011-3Kenneth MensahNo ratings yet

- Contract / Purchase Order Number Description: CertifiedDocument1 pageContract / Purchase Order Number Description: CertifiedGabriel PulidoNo ratings yet

- Crate V33-212Document7 pagesCrate V33-212Danielo ErréNo ratings yet

- CE New - FSTDocument1 pageCE New - FSTPavanNo ratings yet

- 2LD1 - LADDER - Rev 0Document1 page2LD1 - LADDER - Rev 0yugandher badanaNo ratings yet

- DWC7894 11 06 - 00Document1 pageDWC7894 11 06 - 00nthekkumpuramNo ratings yet

- BTI PlanosDocument18 pagesBTI PlanosHache Reyk KhanNo ratings yet

- Client P.O. No.: Client Dwg. No.:: Krupp Industrial Solutions (USA), IncDocument10 pagesClient P.O. No.: Client Dwg. No.:: Krupp Industrial Solutions (USA), Incjosseph fabianNo ratings yet

- 10ENA01BR003 Sheet3-ModelDocument1 page10ENA01BR003 Sheet3-ModelValesh MonisNo ratings yet

- LOS1-A-2204-OPS-PH1A - Rev 11 - Plan - Builders Work - Level 02Document1 pageLOS1-A-2204-OPS-PH1A - Rev 11 - Plan - Builders Work - Level 02Tosin FamuyiwaNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- 1824 000 SS DST 0040 - 2 - IfcDocument1 page1824 000 SS DST 0040 - 2 - IfcAquiles MartinezNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- DRG-OT-561 - R02 - L-Clamp Assy (Vedang)Document7 pagesDRG-OT-561 - R02 - L-Clamp Assy (Vedang)Puneet SharmaNo ratings yet

- RUB-72-1 Abutment (A1) Reinforcement DetailDocument1 pageRUB-72-1 Abutment (A1) Reinforcement DetailYatin DoshiNo ratings yet

- Mcu Reyes A-008 Ceiling-SectionDocument1 pageMcu Reyes A-008 Ceiling-SectionEom - sanNo ratings yet

- M3SD K003 Gen Hyd01 F Lay 0005 ADocument1 pageM3SD K003 Gen Hyd01 F Lay 0005 AShreyas ChawaleNo ratings yet

- Liebherr TechnicalDocument239 pagesLiebherr TechnicalDavid Chou100% (1)

- Weld MapDocument2 pagesWeld MapPrasanth foustin pereiraNo ratings yet

- ING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741Document1 pageING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741mhazarath murariNo ratings yet

- Cable M12-Picospox 0.5MDocument1 pageCable M12-Picospox 0.5MBoxerpower GasNo ratings yet

- Detail: Scale: NtsDocument1 pageDetail: Scale: NtsANIL PLAMOOTTILNo ratings yet

- Pudpud Hospital Floor PlanDocument1 pagePudpud Hospital Floor PlanvertudazoglynnNo ratings yet

- General Drawing Exchanger N°4Document1 pageGeneral Drawing Exchanger N°4calinvasco190670No ratings yet

- Blind List For 31A10-VSL-001Document2 pagesBlind List For 31A10-VSL-001JITHIN VIJAYANNo ratings yet

- D-EP-P250-1225-1085 - 9 Asbuilt (E-2371) - Hydro Jetting P & IDDocument1 pageD-EP-P250-1225-1085 - 9 Asbuilt (E-2371) - Hydro Jetting P & IDvenkatesh tekkaliNo ratings yet

- FL ModelDocument1 pageFL ModelmanhngoducNo ratings yet

- 220 M6 0330 00001 - Rev4Document1 page220 M6 0330 00001 - Rev4Cristhian Alexander Aguilar ChavezNo ratings yet

- Details of Wall Footing 1 (Wf-1) Detail of Foot TIE BEAM-2 (FB-2)Document1 pageDetails of Wall Footing 1 (Wf-1) Detail of Foot TIE BEAM-2 (FB-2)Charlene Anne Austria VillarozaNo ratings yet

- Component Placing, Electrical: Applicable For W910 and W908Document6 pagesComponent Placing, Electrical: Applicable For W910 and W908tom hengNo ratings yet

- Piping Isometric - 8Document1 pagePiping Isometric - 8CosminMarianNo ratings yet

- 10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Document1 page10-01-2022 - IN201007-FLD-T35-FL-0007 Sheet-2Debasis BarmanNo ratings yet

- Detailed Design Submission: JULY 2021Document1 pageDetailed Design Submission: JULY 2021Gulam MohammedNo ratings yet

- Eep 000097 0102148005 3 ST Det 0669 R02Document1 pageEep 000097 0102148005 3 ST Det 0669 R02Vikram DalalNo ratings yet

- Half Elevation of P.S.C Girder: Construction DrawingsDocument1 pageHalf Elevation of P.S.C Girder: Construction DrawingsAqib JavidNo ratings yet

- Crate V33H SchematicDocument2 pagesCrate V33H SchematicDanielo ErréNo ratings yet

- Upper East 售樓說明書部份 住宅物業的樓面平面圖Document4 pagesUpper East 售樓說明書部份 住宅物業的樓面平面圖Mast JasperNo ratings yet

- So Do Nhat Thu Cac TBA (04-2021)Document1 pageSo Do Nhat Thu Cac TBA (04-2021)An Trường Vũ ĐăngNo ratings yet

- Thermo IEC Multi RF Series Service ManualDocument83 pagesThermo IEC Multi RF Series Service ManualystloveNo ratings yet

- PORTABLE STEPS (2 STEPS) (H 600x600x600 Step 350)Document1 pagePORTABLE STEPS (2 STEPS) (H 600x600x600 Step 350)teklabimno1No ratings yet

- Angel's DocumentDocument36 pagesAngel's DocumentKilanko ifaremiNo ratings yet

- Wago-I/O-System 750: ManualDocument46 pagesWago-I/O-System 750: ManualHaris bayu kurniawanNo ratings yet

- Li ReportDocument47 pagesLi ReportRizal RizalmanNo ratings yet

- CF Risk ReturnDocument13 pagesCF Risk Return979044775No ratings yet

- Mapping Konten DSKP Matematik KSSR Tahun 1 KPD Buku Rujukan PearsonDocument6 pagesMapping Konten DSKP Matematik KSSR Tahun 1 KPD Buku Rujukan PearsonNOR ZAINI BINTI SULAIMAN MoeNo ratings yet

- Vlookup Index Match - StudentsDocument17 pagesVlookup Index Match - StudentsRahul DudejaNo ratings yet

- CODE of PRACTICE - COMPRESSED GAS CYLINDERSDocument5 pagesCODE of PRACTICE - COMPRESSED GAS CYLINDERSAkhilesh Kumar SinghNo ratings yet

- Plasma ProteinsDocument28 pagesPlasma ProteinsAyesha AzamNo ratings yet

- Compliance RegisterDocument2 pagesCompliance RegisterDipjyoti SenNo ratings yet

- India's Data Privacy Bill, 2023Document88 pagesIndia's Data Privacy Bill, 2023taskeen fatimaNo ratings yet

- Dream ReportsDocument2 pagesDream ReportsCarlos ACNo ratings yet

- Girls of Gaming 6 PDFDocument123 pagesGirls of Gaming 6 PDFЗоран БлагојевићNo ratings yet

- Chapter 3 - Enterprise, Business Growth and SizeDocument110 pagesChapter 3 - Enterprise, Business Growth and Sizestorms.wells24No ratings yet

- Modeling of Support Conditions at The Bases of Tall BuildingsDocument6 pagesModeling of Support Conditions at The Bases of Tall BuildingsErik NelsonNo ratings yet

- Tcoa S A0008208710 1-2563780Document5 pagesTcoa S A0008208710 1-2563780Axel BelzitiNo ratings yet

- Rachel Quinlan-Advanced Linear Algebra (Lecture Notes) (2017)Document44 pagesRachel Quinlan-Advanced Linear Algebra (Lecture Notes) (2017)juannaviapNo ratings yet

- RPV 3Document158 pagesRPV 3Melkamu AmusheNo ratings yet

- Release NoteDocument10 pagesRelease NoteyusufNo ratings yet

- Opium 160604163652Document14 pagesOpium 160604163652roberto cabungcagNo ratings yet

- Siteminder 12.51, Platform Support Matrix: Last Updated March 19, 2018Document20 pagesSiteminder 12.51, Platform Support Matrix: Last Updated March 19, 2018MM ARIF MzNo ratings yet

- Biological Classification BioHackDocument15 pagesBiological Classification BioHackAdhithyan M100% (2)

- Cheryl Simons Resume 2013-4Document3 pagesCheryl Simons Resume 2013-4api-298051210No ratings yet

- Team Members: M.Abarna (10PX01) V. Agasthiya Priya (10PX02) K.Ajeesh (10PX03)Document50 pagesTeam Members: M.Abarna (10PX01) V. Agasthiya Priya (10PX02) K.Ajeesh (10PX03)Ashokkumar Gnanasekar NadarNo ratings yet

- Account Opening FormDocument11 pagesAccount Opening FormTotimeh WisdomNo ratings yet

- Directional Control ValvesDocument15 pagesDirectional Control ValvesSuyudi Surya WardayaNo ratings yet

- Marvin Reaction PaperDocument15 pagesMarvin Reaction PaperMarvin SurioNo ratings yet

- Extrinsic RewardDocument6 pagesExtrinsic RewardKhánh NgọcNo ratings yet