Professional Documents

Culture Documents

Lecture 4-8

Lecture 4-8

Uploaded by

Enas SakrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 4-8

Lecture 4-8

Uploaded by

Enas SakrCopyright:

Available Formats

Weaving design 1

Lecture 4: weaving process

Shed forming mechanism

Types of Looms Motions

The conversion of warp sheet into fabric by interlacing with weft yarn requires the

basic operations to be carried out on loom in a specific order. It involves the

primary motions, secondary motions and the stop motions.

Loom has three types of motion:

➢ Primary motion

➢ Secondary motion

➢ Tertiary motion or Stop motion

A. Primary motions of loom

The primary loom motions include the following three operations:

1. Shedding: - It is the process of separating the warp yarns into two layers to form

a tunnel which is called shed, is known as shedding.

2. Picking: - The method of passing the weft threads through warp yarn is called

picking.

3. Beat up: - The process in which yarns are sent to the fell of the cloth is called

beat up.

B. Secondary motions of loom

The secondary motions facilitate the weaving of fabric in a continuous way. These

include:

1. Let off: This motion provides warp sheet to the weaving area at the required rate

and under constant tension by unwinding it from weaver’s beam.

2. Take-up: This motion draws fabric from the weaving area at a uniform rate to

produce the required pick spacing and wind it onto a roller.

C. Tertiary motion or Stop motions of loom:

Tertiary motion is not necessary for fabric production. But these motions are used

in the interest of quality and productivity; stopping the loom immediately in case of

some problem. The tertiary motions are:

1. Warp stop motion.

2. Weft stop motion.

3. Reed stops motion.

Dr. Enas Mahammad | 2023/2024

1

Weaving design 2

Lecture 4: weaving process

Shed forming mechanism

Each warp thread passes through an eyelet (or heddle eye) in a Heald (heddle).

Healds are mounted in staves to make a harness.

The following Figure shows a two-harness loom in which adjacent warp yarns are

threaded through mails in different harnesses. Alternate warp threads pass through

alternate healds so that the weft thread passes over and then under alternate warp

threads in a plain weave fabric.

The reed frame contains evenly spaced wires. Each warp yarn passes through

one space in the reed, and so the yarns are kept evenly separated. The shed is the space

between warp threads through which the weft yarn passes. Looms raise and lower the

harnesses. Looms can have two or more harnesses. The more harnesses a loom has,

the more complex the patterns that can be woven. In multi-harness looms, individual

warp yarns are threaded through no more than one heald mail. In Jacquard looms,

each warp yarn is in an individual heald. The healds are not in harnesses but can move

independently under the control of the Jacquard mechanism. Hence Jacquard looms

can make a great variety of patterns.

The weaving cycles

1- Shedding motion

Shedding is the first operation of the weaving cycle. Depending on the design to be

woven, one or more of the shafts (or healds) in the loom are raised, while the

remainder stay in the lowered position. A space between the two sets of warp yarns,

a shed, is thus formed, where the weft is inserted. It is controlled by the motion of

the heald frame (harness) according to weave design and pattern of assigning warp

ends to frames (DID) to generate desired fabrics structures.

Dr. Enas Mahammad | 2023/2024

2

Weaving design 3

Lecture 4: weaving process

Shed forming mechanism

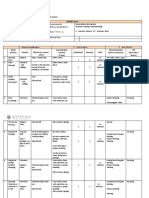

There are three types of shedding mechanisms which convert the design instructions

into the movement of the heald frames; these are cam (tappet), dobby and jacquard.

The lift of the heald frames can achieved by using a cam or dobby mechanisms. In

the jacquard loom, is no heald frame to be driven but each heddle is attached to a

wire or cord.

Cam(tappet) Dobby Jacquard

This device is a system of Dobby is a shedding This device has no shafts,

tappets and cams that mechanism placed on the top instead a harness consisting of

cause shafts to be raised to of the loom in order to as many cords as there are ends

form the shed. produce figured patterns by in the warp sheet connects each

using large number of healds end to the Jacquard mechanism

than the capacity of a tappet. above the loom

The bulkiness of the It is capable of having up to Each warp yarn can be raised

arrangement limits the 28-36 shafts independently of all the others

loom to a maximum of This is a compact,

eight shafts. electronically controlled

shedding device.

The simplest & least more complex and versatile The most complex and versatile

versatile of the shedding shedding motion. of shedding mechanisms.

mechanisms.

As a tappet loom usually Since a dobby loom can have With a Jacquard shedding

has no more than 8 shafts, up to 28 shafts, a much motion, the greatest weave

this represented the greater weave repeat is repeat is possible as each warp

maximum size of its weave possible, permitting more yarn is individually controlled.

repeat. complicated designs.

Structures are restricted to Designs may incorporate All forms and shapes in designs

plain weaves, simple twill two or more basic weaves and highly intricate patterns can

and simple satin and sateen and/or their variations be created.

weaves.

Dr. Enas Mahammad | 2023/2024

3

Weaving design 4

Lecture 4: weaving process

Shed forming mechanism

2- weft insertion motion: -

Picking is inserting the weft yarn once the

shed has been formed. A single weft yarn,

passed from one side of the loom to the other,

is called one pick. This motion follows the

shedding motion. On conventional looms the

filling yarn is inserted by means of shuttle on

which a pirn is mounted.

3- Beat-up motion

The newly inserted yarn or pick is pushed at

high force to the fell of the cloth by the reed.

4- Warp and weft control (take up & let off)

To ensure the continuity of the weaving process, the woven fabric is collected on a

roll called the “cloth roll”. Cloth roll is rotated by the take up motion to collect a

fabric length that equals the space between two picks.

At the same time, the warp is released or fed through the loom to substitute for the

amount of fabric that is taken up by the cloth roll. The motion that releases the warp

is called the let-off motion.

Dr. Enas Mahammad | 2023/2024

4

You might also like

- Top Notch Fundamentals Unit 6 AssessmentDocument7 pagesTop Notch Fundamentals Unit 6 AssessmentDanilo Echeverri Carmona75% (4)

- Shirley of Hollywood - Hot Lingerie & Stockings Collection Catalog 2018Document212 pagesShirley of Hollywood - Hot Lingerie & Stockings Collection Catalog 2018Ronald Swaneveld100% (1)

- Movie Review Examples Devils Wear PradaDocument23 pagesMovie Review Examples Devils Wear Pradaauni fildzahNo ratings yet

- GATE Textile Fibres Study Material Book 2 FabricDocument15 pagesGATE Textile Fibres Study Material Book 2 FabricSantosh100% (2)

- Sustainable Companies Report - H&M Vs Forever 21Document26 pagesSustainable Companies Report - H&M Vs Forever 21Abirami VadivelNo ratings yet

- Technique of Fabric ConstructionDocument21 pagesTechnique of Fabric ConstructionDayananda YengkhomNo ratings yet

- Textile BasicsDocument11 pagesTextile BasicsPriyank AcharyaNo ratings yet

- Weavingpptbyaumi 151129194316 Lva1 App6892Document27 pagesWeavingpptbyaumi 151129194316 Lva1 App6892aqsa imranNo ratings yet

- Weaving TechnologyDocument26 pagesWeaving TechnologyimmmranNo ratings yet

- Weaving TechnologyDocument47 pagesWeaving TechnologyMohammed shohag islam100% (3)

- Study On Rapier Weaving Mechanism.Document11 pagesStudy On Rapier Weaving Mechanism.Naimul HasanNo ratings yet

- Weavingtechnologyv1 100301224438 Phpapp02Document26 pagesWeavingtechnologyv1 100301224438 Phpapp02Anonymous Pt7NHkat9No ratings yet

- Weaving - 01 - Primary Motions of WeavingDocument15 pagesWeaving - 01 - Primary Motions of WeavingChamal JayasingheNo ratings yet

- Introducción (1) : Principio Del Tejido & Telar de LanzaderaDocument22 pagesIntroducción (1) : Principio Del Tejido & Telar de LanzaderaWILLYCALSINANo ratings yet

- PL Chapter 5Document8 pagesPL Chapter 5kaleabandebet7No ratings yet

- Sujan (201 042 811)Document11 pagesSujan (201 042 811)Sujonjisan SHNo ratings yet

- Shyamoli Textile Engineering College: Affiliated by University of DhakaDocument18 pagesShyamoli Textile Engineering College: Affiliated by University of DhakaMehzabeen ShahidyNo ratings yet

- BAB I Textile Technology - WEAVINGDocument6 pagesBAB I Textile Technology - WEAVINGscetropies hakimNo ratings yet

- Process Sequence of WeavingDocument55 pagesProcess Sequence of WeavingMehzabeen ShahidyNo ratings yet

- FM-III Unit 3Document72 pagesFM-III Unit 3Jjeerryyy NikharNo ratings yet

- R&P (AutoRecovered) (AutoRecovered)Document21 pagesR&P (AutoRecovered) (AutoRecovered)RAYMOND URASSANo ratings yet

- Advanced Warp KnittingDocument15 pagesAdvanced Warp KnittingNazim Uddin RayhanNo ratings yet

- Session 5Document12 pagesSession 5ARYAN RATHORENo ratings yet

- Woven Fabric Formation Technique - Part 1Document29 pagesWoven Fabric Formation Technique - Part 1ramstexNo ratings yet

- TAX 3530 Fibre To Fabric TMA 3Document8 pagesTAX 3530 Fibre To Fabric TMA 3M.P.S.M CoorayNo ratings yet

- Carding ProcessDocument2 pagesCarding ProcessShaheryar ShahidNo ratings yet

- Center For Textile Function, MPSTME, NMIMSDocument29 pagesCenter For Textile Function, MPSTME, NMIMSCHetan ChaudhariNo ratings yet

- Mahin - 193003051 (WT ct3)Document8 pagesMahin - 193003051 (WT ct3)MahinNo ratings yet

- Dobby Handloom Weaver PDFDocument35 pagesDobby Handloom Weaver PDFsammers100% (1)

- Fabric Manufacturing - I Unit 1Document28 pagesFabric Manufacturing - I Unit 1nikitaNo ratings yet

- Weaving - WikipediaDocument73 pagesWeaving - WikipediaAnirudha karNo ratings yet

- 1998 02 6 Vogel eDocument4 pages1998 02 6 Vogel edavino_msNo ratings yet

- GoodDocument22 pagesGoodRuchira WijesenaNo ratings yet

- Lecture 2 WeavingDocument73 pagesLecture 2 WeavingNoor Ul AinNo ratings yet

- All Lab ReportDocument31 pagesAll Lab ReportMuneeb Tahir100% (4)

- Jacquard Handloom WeaverDocument37 pagesJacquard Handloom WeaverSammers Hbr0% (1)

- Warp Insertion KnitsDocument17 pagesWarp Insertion KnitsPriyanshurajscribdNo ratings yet

- The Knitting Compendium 3Document22 pagesThe Knitting Compendium 3kathirvelus9408No ratings yet

- Development of Woven FabricsDocument11 pagesDevelopment of Woven FabricsJoyDipuSahaNo ratings yet

- Chapter 10 Textile ProcessesDocument62 pagesChapter 10 Textile ProcessesJann Paulo MendozaNo ratings yet

- Weaving & It's TypesDocument17 pagesWeaving & It's Typesliza100% (2)

- Knitting Process: Escorts Advanced Textiles Distributor of Dupont PakistanDocument57 pagesKnitting Process: Escorts Advanced Textiles Distributor of Dupont PakistanJazib YaseenNo ratings yet

- Weaving 1Document3 pagesWeaving 1Renie TripathiNo ratings yet

- Weaving Report, MolefeDocument12 pagesWeaving Report, MolefesecuuulNo ratings yet

- 2Document102 pages2jennygraceshaliniNo ratings yet

- Kniotting - IDocument26 pagesKniotting - IMd.Shoeb Alom RoxyNo ratings yet

- Doublecrop14Fabric Structure and DesignDocument70 pagesDoublecrop14Fabric Structure and DesignRākēśḥ ŚḥāNo ratings yet

- Looms: By-Aditi Padhy FDVDocument17 pagesLooms: By-Aditi Padhy FDVAditiNo ratings yet

- A Brief Guide To Hand Weaving LoomsDocument4 pagesA Brief Guide To Hand Weaving Loomsbevan pontNo ratings yet

- Chapter 1-3Document24 pagesChapter 1-3Mehmet AlNo ratings yet

- 6 Sem. B.Tech (Fashion & Apparel Technology) : PCFT 4304 Knitting & Non WovenDocument20 pages6 Sem. B.Tech (Fashion & Apparel Technology) : PCFT 4304 Knitting & Non WovenBebi WakaNo ratings yet

- Malimo enDocument24 pagesMalimo enHari Tham KhanNo ratings yet

- Karl Miller Guide For Technical TextileDocument36 pagesKarl Miller Guide For Technical TextileihabosmanNo ratings yet

- Types of Looms and WeavesDocument13 pagesTypes of Looms and WeavesGOWTHAM CHANDRUNo ratings yet

- LoomDocument23 pagesLoomAditi KNo ratings yet

- Art of WeavingDocument27 pagesArt of WeavingninuNo ratings yet

- Aditya Itp FinalDocument56 pagesAditya Itp FinalAjay Kumar100% (2)

- Description and The Use and Application of MaterialsDocument11 pagesDescription and The Use and Application of MaterialsGelborion LeendonNo ratings yet

- Theory of Silk Weaving A Treatise on the Construction and Application of Weaves, and the Decomposition and Calculation of Broad and Narrow, Plain, Novelty and Jacquard Silk FabricsFrom EverandTheory of Silk Weaving A Treatise on the Construction and Application of Weaves, and the Decomposition and Calculation of Broad and Narrow, Plain, Novelty and Jacquard Silk FabricsRating: 5 out of 5 stars5/5 (1)

- Knitting for Beginners: The Ultimate Craft Guide. Learn How to Knit Following Illustrated Practical Examples and Create Amazing ProjectsFrom EverandKnitting for Beginners: The Ultimate Craft Guide. Learn How to Knit Following Illustrated Practical Examples and Create Amazing ProjectsNo ratings yet

- Subject Name: Textile Testing and Quality Control-2Document7 pagesSubject Name: Textile Testing and Quality Control-2Ahasn HabibNo ratings yet

- Tadano Mobile Crane Atf 500xl 1 Operating Service Maintenance ManualDocument22 pagesTadano Mobile Crane Atf 500xl 1 Operating Service Maintenance Manualangelawatkins210685tce100% (127)

- Women's Baguette Bag FENDI 24SDocument1 pageWomen's Baguette Bag FENDI 24SnaroapotterheadNo ratings yet

- Uniform Policy: Cool WeatherDocument4 pagesUniform Policy: Cool Weatherkato fredNo ratings yet

- Bed BathingDocument83 pagesBed BathingErika Agramon100% (1)

- Designation Wise Approved Dress Code RevisedDocument9 pagesDesignation Wise Approved Dress Code RevisedRahul JalauniaNo ratings yet

- Name: Class: Teacher:: Put Your Photo HereDocument31 pagesName: Class: Teacher:: Put Your Photo HereValmirBameNo ratings yet

- Media MagDocument3 pagesMedia Magapi-565909247No ratings yet

- Elsa Crochet Toddler Doll Now With Pattern!: Annie 88Document9 pagesElsa Crochet Toddler Doll Now With Pattern!: Annie 88danielaNo ratings yet

- The Personal Property of John Wayne Signature Auction - Heritage Auctions #7045Document348 pagesThe Personal Property of John Wayne Signature Auction - Heritage Auctions #7045Heritage Auctions100% (1)

- Describe Your House: Lan Anh - THT Utc GR: Utc Đ I Cương Môn Phái (THT Utc)Document3 pagesDescribe Your House: Lan Anh - THT Utc GR: Utc Đ I Cương Môn Phái (THT Utc)thai vanNo ratings yet

- Personal Protective Equipment (PPE)Document22 pagesPersonal Protective Equipment (PPE)redaNo ratings yet

- Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Brush Pilling TesterDocument6 pagesPilling Resistance and Other Related Surface Changes of Textile Fabrics: Brush Pilling TesterSur VaniNo ratings yet

- AVA Lingerie Autumn Winter Collection Catalog 2018 2019Document23 pagesAVA Lingerie Autumn Winter Collection Catalog 2018 2019Ti MiNo ratings yet

- List of NOUNS in Detroit: Become HumanDocument11 pagesList of NOUNS in Detroit: Become HumannuraziemahjoibiNo ratings yet

- Laundry & Pressing ListDocument13 pagesLaundry & Pressing ListScarlette Byuti Enriquez-DiagbelNo ratings yet

- APA Style Student Report Template 7th EditionDocument5 pagesAPA Style Student Report Template 7th EditionConsuelo PlazaNo ratings yet

- Textile Wet Processing UNIT-4Document6 pagesTextile Wet Processing UNIT-4Chaarvi SaranyaNo ratings yet

- Rolling With My Stepbrothers A Reverse Harem Romance Sylvie Haas All ChapterDocument67 pagesRolling With My Stepbrothers A Reverse Harem Romance Sylvie Haas All Chapterlloyd.bradley120100% (10)

- I Love My Bedroom!!: Read and Answer The QuestionsDocument2 pagesI Love My Bedroom!!: Read and Answer The Questionsmelissa petroNo ratings yet

- st3 Gram U06Document3 pagesst3 Gram U06Marcel CurielNo ratings yet

- Hirarc Sep HK 2015Document9 pagesHirarc Sep HK 2015moganNo ratings yet

- Present Simple ContinuousDocument4 pagesPresent Simple ContinuousGiangNo ratings yet

- Product CostingDocument58 pagesProduct CostingPrafful MehraNo ratings yet

- 2021 Holiday Consumer Protection GuideDocument61 pages2021 Holiday Consumer Protection GuidePeterBurkeNo ratings yet

- Jteft 08 00313Document5 pagesJteft 08 00313Shane DorianNo ratings yet