Professional Documents

Culture Documents

BK 916 TR Datasheet

BK 916 TR Datasheet

Uploaded by

Maxim Kostyuchenko0 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

BK-916-TR-datasheet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views1 pageBK 916 TR Datasheet

BK 916 TR Datasheet

Uploaded by

Maxim KostyuchenkoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

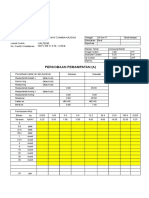

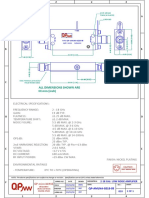

07/19/18 C Dim. 9.60 was 9.50 T.B. B.S.

Changed Positive contact pad

size

08/14/18 D Added Drop test result T.B. B.S.

15.60 [0.61] 10/24/18 E Dim. 15.60 was 15.30 T.B. B.S.

Dim. 13.80 was 13.50

Dim. 3.70 was 3.60

13.80 [0.54]

2.1 [0.08]

+

2.0 [0.08]

9.60 [0.38]

1.0 [0.04]

2.4 [0.09] 17.8 [0.70]

0.9 [0.04] 2.5 [0.10]

4 pls

3.70 [0.15] 2.5 [0.10]

4 pls

Ø10.2 [Ø0.40] PCB LAYOUT

NOTES: NEG. CONTACT PAD, NICKEL OR GOLD PLATED

1. MATERIAL:

0.25mm PHOSPHOR BRONZE, NICKEL PLATED OVERALL.

ROHS 2 COMPLIANT

TEMPERATURE RANGE: -40°C TO +270°C

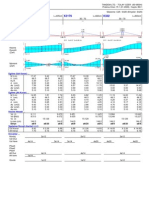

* VIBRATION TEST: 10-50-10 HZ SWEEPED IN 60 SECONDS

X,Y,Z DIRECTION: 1 HOUR EACH DIRECTION

* RESULT: NO DISLODGEMENT OF THE CELL OR DAMAGE

NO DISCONTINUITY OVER 10 MICRO-SECONDS

* SHOCK TEST: HALF SINE WAVE ACCELERATION 150G.

6 MILLISECONDS

3 SHOCK PULSES EACH DIRECTION PER

AXIS, TOTAL OF 18 PULSES

* RESULT: NO EVIDENCE OF PHYSICAL DAMAGE

* DROP TEST: MOUNTED ON BOARD AND DROPPED 1 TIME PER

DIRECTION FROM 1m HIGH TO WOODEN FLOOR

* RESULTS: NO DISLODGEMENT OF THE CELL, NO DAMAGE TO THE

HOLDERS

You might also like

- 9015 - Assessment GuideDocument65 pages9015 - Assessment Guideirene hulkNo ratings yet

- Outrigger Load CalculatorDocument1 pageOutrigger Load CalculatorYasser Fathi100% (2)

- ESQ 04 Mechanics G Value, ProjectilesDocument8 pagesESQ 04 Mechanics G Value, ProjectilesJack BornNo ratings yet

- Misr Raymond Foundations: Soil Investigation DepartmentDocument2 pagesMisr Raymond Foundations: Soil Investigation Departmentm.askarNo ratings yet

- Estimate of A Reservoir - 2.5x2.5x2.5Document4 pagesEstimate of A Reservoir - 2.5x2.5x2.5Engr'Shemaiah JimenezNo ratings yet

- Cone Penetration Test SNI - 2827: 2008: Data Pembacaan SondirDocument1 pageCone Penetration Test SNI - 2827: 2008: Data Pembacaan SondirFajar Adi NugrohoNo ratings yet

- Pressure Drop in A Pipe - LiquidDocument5 pagesPressure Drop in A Pipe - Liquidamancredo2702No ratings yet

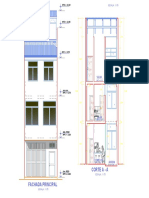

- ARQUITECTÓNICODocument1 pageARQUITECTÓNICOBrandon CTNo ratings yet

- Pipe DistribuidoresDocument4 pagesPipe Distribuidoresjunaidmateen2345No ratings yet

- Daily Chemistry Report 31.01.2021.Document2 pagesDaily Chemistry Report 31.01.2021.Shobhit SrivastavaNo ratings yet

- Name of Work:-C/O L/R Kanrari To Chadiyar Sub Head:Laying Soling, C/O Pipe Culvert & Side Drain GP KatharDocument6 pagesName of Work:-C/O L/R Kanrari To Chadiyar Sub Head:Laying Soling, C/O Pipe Culvert & Side Drain GP KatharPankaj ThakurNo ratings yet

- 2.1 Vigas AereasDocument12 pages2.1 Vigas Aereasvictor sanchezNo ratings yet

- Elevacion 1Document1 pageElevacion 1DaJ98No ratings yet

- Outrigger Load CalculatorDocument1 pageOutrigger Load Calculatormuhammad lukmanNo ratings yet

- Global Lab 08/02/2022 Ta Ta 'Project (6) C:/... /Temp/TA TA 'PROJECT (6) .PIT PIT-W 2009 - 2Document2 pagesGlobal Lab 08/02/2022 Ta Ta 'Project (6) C:/... /Temp/TA TA 'PROJECT (6) .PIT PIT-W 2009 - 2Sabyasachi BangalNo ratings yet

- Slab Formwork CalculationDocument13 pagesSlab Formwork CalculationPrakash Singh RawalNo ratings yet

- Star Rates For DO (REV 6)Document144 pagesStar Rates For DO (REV 6)rajeshkerkar111No ratings yet

- Jemb1 Bh1Document33 pagesJemb1 Bh1Erwin PrayogaNo ratings yet

- RAB - Jembatan 8 X 4 X 3 Meter - FinalDocument21 pagesRAB - Jembatan 8 X 4 X 3 Meter - Finaldinonino tobingNo ratings yet

- Canal Quantity EstimateDocument8 pagesCanal Quantity Estimatek82tgnqtgxNo ratings yet

- Program CanalDocument5 pagesProgram CanalShem ArguillaNo ratings yet

- CBR Tak TerendamDocument31 pagesCBR Tak TerendamAnka EkelnikoNo ratings yet

- MOH Ratnapura02Document29 pagesMOH Ratnapura02isurupushNo ratings yet

- CA0C10000Document8 pagesCA0C10000roshni mehraNo ratings yet

- Outrigger Load CalculatorDocument1 pageOutrigger Load CalculatorAbram Wicaksana PutraNo ratings yet

- SBRS-3XGLWDocument1 pageSBRS-3XGLWVICTOR FQNo ratings yet

- Free Fall ReportDocument8 pagesFree Fall ReportwanzalezNo ratings yet

- Name of Project No of Rooms Length of Room Breadth of RoomDocument14 pagesName of Project No of Rooms Length of Room Breadth of RoomSaroj AcharyaNo ratings yet

- ChamberDocument5 pagesChamberChief Engineer PMUNo ratings yet

- TB 1 Asulait 1Document2 pagesTB 1 Asulait 1Enos LiufetoNo ratings yet

- Project: Cadangan Klinik Kesihatan 4 Dengan Kuarters, Pengkalan Hulu, Hulu Perak, Perak (Ibs Sepenuhnya)Document9 pagesProject: Cadangan Klinik Kesihatan 4 Dengan Kuarters, Pengkalan Hulu, Hulu Perak, Perak (Ibs Sepenuhnya)faiz salimNo ratings yet

- Global Lab 08/02/2022 Ta Ta 'Project (5) C:/... /Temp/TA TA 'PROJECT (5) .PIT PIT-W 2009 - 2Document2 pagesGlobal Lab 08/02/2022 Ta Ta 'Project (5) C:/... /Temp/TA TA 'PROJECT (5) .PIT PIT-W 2009 - 2Sabyasachi BangalNo ratings yet

- Global Lab 08/02/2022 Ta Ta 'Project (5) C:/... /Temp/TA TA 'PROJECT (5) .PIT PIT-W 2009 - 2Document2 pagesGlobal Lab 08/02/2022 Ta Ta 'Project (5) C:/... /Temp/TA TA 'PROJECT (5) .PIT PIT-W 2009 - 2Sabyasachi BangalNo ratings yet

- 245KV PTP FoundationDocument1 page245KV PTP Foundationrenz canlasNo ratings yet

- Two Stage Evaporator: InputsDocument5 pagesTwo Stage Evaporator: InputsHina JagnikNo ratings yet

- Calculations For Runoff Drain SizeDocument5 pagesCalculations For Runoff Drain Sizevedesh30No ratings yet

- Wind Design CalculatorDocument9 pagesWind Design CalculatorMuhammad rifaiNo ratings yet

- (E and CV) Graph Consolidation TestDocument8 pages(E and CV) Graph Consolidation TestazwarNo ratings yet

- Description Location (Grid Line) # Length (M) Width (M) Height (M)Document46 pagesDescription Location (Grid Line) # Length (M) Width (M) Height (M)Gani AnosaNo ratings yet

- Soil Testing CalculationDocument5 pagesSoil Testing CalculationAmit Kumar PaulNo ratings yet

- WASHER LayoutDocument8 pagesWASHER LayoutMuralidhara BangaloreNo ratings yet

- Panch. Ghar .Amritsar 2022Document49 pagesPanch. Ghar .Amritsar 2022Amit GargNo ratings yet

- Kayseri burhan-BeamDesDocument173 pagesKayseri burhan-BeamDesbrkn8No ratings yet

- 27-2-Q - Sieve TestDocument15 pages27-2-Q - Sieve TestWafik AlhajiNo ratings yet

- Sheet Mid 000Document20 pagesSheet Mid 000kareemshdefat00No ratings yet

- LOADMASTER X5 8665 Front Symphony - 'Lightship'Document7 pagesLOADMASTER X5 8665 Front Symphony - 'Lightship'yagyabajpaiNo ratings yet

- All Dimensions Shown Are IN MM (Inch) : Ø2.5 (Ø0.10) Thru (4 Places) GroundDocument1 pageAll Dimensions Shown Are IN MM (Inch) : Ø2.5 (Ø0.10) Thru (4 Places) GroundTribu Vaquero JimenezNo ratings yet

- Evaco 2 FDocument5 pagesEvaco 2 Fsahil gohadNo ratings yet

- Lab Tanah - Data Exel Kel.2Document14 pagesLab Tanah - Data Exel Kel.2Cindy KartikaNo ratings yet

- Dcielab: D65-10: Customer NameDocument1 pageDcielab: D65-10: Customer NameJimmy LiNo ratings yet

- Project Name: Calculation For Hot Water Circulation PumpDocument1 pageProject Name: Calculation For Hot Water Circulation PumpJohn ANo ratings yet

- Piso 4: Diseño A FlexiónDocument2 pagesPiso 4: Diseño A FlexiónDiego SuntaNo ratings yet

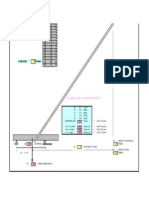

- Skema Dan Denah TeleponDocument7 pagesSkema Dan Denah TeleponIyz HaniuddinNo ratings yet

- New Ews Ra 2010 2011Document9 pagesNew Ews Ra 2010 2011SarinNo ratings yet

- (E and CV) Graph Consolidation TestDocument8 pages(E and CV) Graph Consolidation TestazwarNo ratings yet

- Depth Cone Resistance Sleeve Friction FR Estimated Soil (M) (KG/CM) CR/SF 90%.FR Unclassified "CR" (KG/CM) "SF" (KG/CM)Document8 pagesDepth Cone Resistance Sleeve Friction FR Estimated Soil (M) (KG/CM) CR/SF 90%.FR Unclassified "CR" (KG/CM) "SF" (KG/CM)Kheymal officialNo ratings yet

- BBS - Retaining Wall ProblemDocument9 pagesBBS - Retaining Wall ProblemBenoy BenjaminNo ratings yet

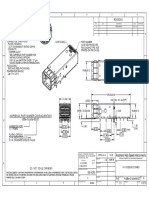

- Revisions: Amphenol Part Number Confuguration UE86-G1636-00X3TDocument3 pagesRevisions: Amphenol Part Number Confuguration UE86-G1636-00X3Tkkk ghgfhgfNo ratings yet

- For Gate EstimateDocument6 pagesFor Gate EstimateMarkko Buaya TalonNo ratings yet

- SPT N corrected BEARING CAPACITYمعدل 1Document25 pagesSPT N corrected BEARING CAPACITYمعدل 1ammarsteel68No ratings yet

- CB2C010F0Document7 pagesCB2C010F0roshni mehraNo ratings yet

- Social Welfare Agency AdministrationDocument22 pagesSocial Welfare Agency AdministrationMechisedec BalacuitNo ratings yet

- Department of Education: Kitcharao Central Elementary SchoolDocument3 pagesDepartment of Education: Kitcharao Central Elementary SchoolMalou EvangelioNo ratings yet

- Weber - Profile & Guide EN 2020Document48 pagesWeber - Profile & Guide EN 2020sandipbharNo ratings yet

- Sukuna Is Pulling His Fire Arrow Technique From The CURSED REALMDocument6 pagesSukuna Is Pulling His Fire Arrow Technique From The CURSED REALMAjay WangnanNo ratings yet

- Wolves, Lambs, Leopards and Goats: A Journey in Faith, Science, Business and Christian MinistryDocument23 pagesWolves, Lambs, Leopards and Goats: A Journey in Faith, Science, Business and Christian Ministryapi-27310546No ratings yet

- KTLTC - Phạm Thịnh Phát -31211021082Document14 pagesKTLTC - Phạm Thịnh Phát -31211021082phatpham.31211021082No ratings yet

- Base Isolation - Seismic and WindsDocument2 pagesBase Isolation - Seismic and WindskamakshiNo ratings yet

- Fluid Flow: Wes Bussman, PH.D., Demetris Venizelos, PH.D., and R. Robert HayesDocument29 pagesFluid Flow: Wes Bussman, PH.D., Demetris Venizelos, PH.D., and R. Robert HayesrezaimamNo ratings yet

- Allen Aiot Major QP PaperDocument36 pagesAllen Aiot Major QP PaperAbhishek GahaneNo ratings yet

- Half Bridge Converter PaperDocument6 pagesHalf Bridge Converter PaperAryaNo ratings yet

- Sample Qualitative PHD ThesisDocument5 pagesSample Qualitative PHD ThesisFindSomeoneToWriteMyPaperSingapore100% (2)

- Mindray BC-3000Plus - Operation ManualDocument325 pagesMindray BC-3000Plus - Operation ManualEstefany Carreño Salazar94% (16)

- From: Roth, L., Understanding Architecture: Its Elements, History and MeaningDocument19 pagesFrom: Roth, L., Understanding Architecture: Its Elements, History and Meaningjoseph arao-araoNo ratings yet

- Lab Spot SpeedDocument11 pagesLab Spot SpeedshazwanNo ratings yet

- Expressions and EquarionsDocument7 pagesExpressions and Equarionsapi-540102596No ratings yet

- USP 1228 DepyrogenationDocument5 pagesUSP 1228 Depyrogenationmustafa huseiny100% (1)

- SMUN 2019 Position Paper UNESCO Mexico (AL)Document3 pagesSMUN 2019 Position Paper UNESCO Mexico (AL)Nafila HisaraNo ratings yet

- Befa QP Cse.22Document4 pagesBefa QP Cse.22Chavalla DeekshithaNo ratings yet

- Civil Engineering AssistentDocument10 pagesCivil Engineering Assistenthitesh pawarNo ratings yet

- Crack The Code: Left: RightDocument2 pagesCrack The Code: Left: RightRuben Delos SantosNo ratings yet

- Digital SAT - Practice Test 1Document14 pagesDigital SAT - Practice Test 1Azure Pear HaNo ratings yet

- KuantitatifDocument16 pagesKuantitatifbertaNo ratings yet

- Textbook Nonequilibrium Statistical Physics A Modern Perspective 1St Edition Roberto Livi Ebook All Chapter PDFDocument53 pagesTextbook Nonequilibrium Statistical Physics A Modern Perspective 1St Edition Roberto Livi Ebook All Chapter PDFdiane.bulter566100% (11)

- Jobs To Be Done - JOB STATEMENT CANVAS - JOKULL - Helge Tenno - WlinkDocument1 pageJobs To Be Done - JOB STATEMENT CANVAS - JOKULL - Helge Tenno - WlinkbrisNo ratings yet

- Formal Letter To The EditorDocument2 pagesFormal Letter To The Editormelibosky 24No ratings yet

- Chemical Engineering & Processing: Process Intensi Fication: SciencedirectDocument11 pagesChemical Engineering & Processing: Process Intensi Fication: SciencedirectAYALEYDENNo ratings yet

- Mass, Force and Torque MeasurementDocument32 pagesMass, Force and Torque MeasurementSufyn SufynNo ratings yet

- Book - Contributor - EN (Limited) v1.1 PDFDocument6 pagesBook - Contributor - EN (Limited) v1.1 PDFSamir2020No ratings yet