Professional Documents

Culture Documents

Electronics Module G10 Q1 Week 6 1 PDF

Electronics Module G10 Q1 Week 6 1 PDF

Uploaded by

Florence FernandezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electronics Module G10 Q1 Week 6 1 PDF

Electronics Module G10 Q1 Week 6 1 PDF

Uploaded by

Florence FernandezCopyright:

Available Formats

WHOLE BRAIN LEARNING SYSTEM

OUTCOME-BASED EDUCATION

Science, Technology and Engineering (STE) Program

GRADE

ELECTRONICS 10

QUARTER I

LEARNING

MODULE WEEK 6

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 0

Module in Electronics

Science, Technology and Engineering

(STE) Program

QUARTER I

WEEK 6

Electronic Hand Tools

Development Team

Writer: Richard F. Aison

Editor: Ponciano S. Raspado

Reviewer: Hamilton C. Remigio

Management Team: Vilma D. Eda, CESO V

Arnel S. Bandiola Lourdes B. Arucan

Juanito V. Labao Flenie A. Galicinao

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 1

What I Need to Know

This module in Electronics contains information and suggested learning activities

that provides you understanding on the knowledge, skills and desirable attitudes required in

assembling consumer electronic products and systems.

In order to benefit much from this module, you should learn the uses of tools

according to the tasks to be undertaken. You should also be able to apply proper soldering

techniques.

Most Essential Learning Competencies:

1. Use different tools and equipment in electronics.

2. Apply proper soldering techniques.

Learning Objectives:

1. Classify different electronic hand tools.

2. Use different tools and equipment in electronics according to the tasks to be

undertaken.

What I Know

Pre-Test:

Directions: Arrange the following statements according to their proper sequence. Write the

number for every step. Begin with number 1 as the first step, number 2 as the

second step, and so on. Use a whole sheet of paper for your answers.

Procedure in Using a Soldering Iron

Preparing the soldering iron:

________ Place the soldering iron on the stand before plugging it.

________ Wipe the tip of the soldering iron on the wet damp sponge.

________ Melt a little solder (soldering lead – 60/40) on the tip of the iron.

________ Wipe again the tip of the soldering iron on the wet damp sponge.

________ Wait for a few minutes for the soldering iron to attain its operating temperature of

about 4000C.

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 2

Soldering technique:

________ Feed a little solder onto the joint.

________ Touch the soldering iron onto the joint to be made.

________ Hold the soldering iron like a pen near the base of the handle.

________ Inspect the joint closely. It should look shiny with a volcano shape.

________ Remove the solder, then the soldering iron while keeping the joint still.

Lesson

Classification of

1 Hand Tools

What’s In

Activity 1

JUMBLED WORDS

Directions: Arrange the jumbled words in a correct form that corresponds to some of the

safety requirements with the use of personal protective equipment hand tool

design, selection, and setup. Write your answers in a separate sheet of paper.

1. TIEWHG -

2. CENALAB –

3. UETEOTQ TLORONC –

4. RGPI -

5. NSAP –

What’s New

TECHNICAL TERMS

Active State It is a condition of a semiconductor device that is working.

Alternating Current It is an electric current that is continually varying in value and

reversing its direction of flow at regular interval.

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 3

Anode It is a positive electrode of semiconductor device.

Biasing Current It is a current supply needed by the semiconductor in order to

work properly.

Capacitance It is a property that exits whenever two conductors are

separated by insulating material, permitting the storage of

electricity.

Capacitor It is a component designed intentionally to have a definite

amount of capacitance.

Cathode It is a negative electrode of semi-conductor devices.

Circuit It is an arrangement of one or more complete paths of

electron flow.

Conductor It is a wire, cable, or other body or medium that is suitable for

carrying electric current.

Couple This is to connect two circuits so signals are transferred from

one to the other.

Current It is the rate of transfer of electricity from one point to another.

Cut-off State It is a condition of a semiconductor device that is not working.

DC Milli-Ammeter It is an instrument that measures the amount of direct current

flow in a component or circuit.

Desoldering It is a process of unsoldering unwanted parts or components

in the circuit with the support of soldering tool.

Dielectric Material It is a material that serves as insulator with poor electric

conductivity.

Direct Current It is an electric current that flows in one direction.

Discrete Components They are separated components.

Junction It is a hybrid of an electronic circuit enclosed in a single

package having an output that varies directly proportional to

the input.

Ohmmeter It is an instrument that measures the amount of resistance in

certain component or circuits.

PCB It is a Printed Circuit Board or (PCB) which is actually printed

wiring boards that have components inserted into the hole

and soldered to form its circuit connection.

Quiescent Point It is the least amount of operating current of semi-conductor

in order to work properly.

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 4

Resistance It is the opposition that a component or material offers to the

flow current.

Resistor It is a component designed intentionally to have a definite

amount of resistance.

Soldering It is a process of joining two metals caused by heat

Soldering Technique It is a right process in which the solder (lead) is being applied

in a connection or in the printed circuit board.

Splicing It is defined as a joint that connect two lengths of conductor.

Voltage It is the electrical pressure that exist between two points and

capable of producing a flow of current when a close circuit is

connected between the points.

Voltmeter It is an instrument that measures the amount of electromotive

force in a component or circuit.

What is It

BASIC ELECTRONIC HAND TOOLS

DRIVING TOOLS

Screwdriver. It is a device specifically designed to insert and tighten or to loosen and remove

screws. A screwdriver comprises a head or tip which engages with a screw, a mechanism to

apply torque by rotating the tip and some way to position and support the screwdriver. A typical

hand screwdriver comprises an approximately cylindrical handle of a size and shape to be

held by a human hand and an axial shaft fixed to the handle, the tip of which is shaped to fit a

particular type of screw. The handle and shaft allow the screwdriver to be positioned and

supported when rotated to apply torque.

Flat Screwdriver. It is used to drive or fasten negative slotted screws.

Figure 1. Flat Screwdriver

Source: IA- Electronics LM Grade 7 & 8

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 5

Phillips Screwdriver. It is used to drive or fasten positive slotted screws. It is a screwdriver

that could take greater torque and can provide tighter fastenings.

Figure 2. Philips Screwdriver

Source: IA- Electronics LM Grade 7 & 8

Hex (Allen Wrench). It is used to drive or fasten hexagonal screws. The head has a hexagonal

hole turned by an Allen key. An Allen key is a hexagonal shaped wrench bent in letter-L. The

Allen key was invented by an American, Gilbert F. Heublein.

Figure 3. Allen Wrench

Source: IA- Electronics LM Grade 7 & 8

Precision Screwdriver Set. It is a set of small screw drivers composed of slotted and

Philips screwdrivers.

Figure 4. Precision Screwdriver Set

Source: IA- Electronics LM Grade 7 & 8

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 6

SOLDERING TOOLS

Soldering Iron. It is a device used for applying heat to melt solder in attaching two metal

parts. A soldering iron is composed of a heated metal tip and an insulated handle. Heating is

often achieved electrically, by passing a current, supplied through an electrical cord, through

a heating element. For electrical work, wires are usually soldered to printed circuit boards,

other wires, or small terminals. A low-power iron (15-30 Watts) is suitable for this work.

Figure 5. Soldering Iron

Source: IA- Electronics LM Grade 7 & 8

Some soldering irons have interchangeable tips for different types of work. Fine round

or chisel tips are typically used for electronics work. A new tip needs to be coated, heated,

and then covered with solder before its first use. This procedure is called "tinning". The tinning

forms a liquid layer which facilitates the transfer of heat to the work piece. A dirty tip does not

transfer heat well. The tip needs to be kept coated with a shiny layer of solder by occasional

wiping and applying solder directly to the tip.

Soldering Tool Stand. It is a place of the soldering iron to keep them away from flammable

materials. The stand often also comes with a sponge and flux pot for cleaning the tip.

Figure 6. Soldering Stand

Source: IA- Electronics LM Grade 7 & 8

Desoldering tool. It is used for the removal of solder and components from a circuit when

troubleshooting, repair purposes and to save components. Electronic components are often

mounted on a circuit board and it is usually desirable to avoid damaging the circuit board,

surrounding components, and the component being removed.

Figure 7. De-soldering Tool

Source: IA- Electronics LM Grade 7 & 8

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 7

SPLICING TOOLS

Long Nose. It is used for holding, bending and stretching the lead of electronic component or

connecting wire.

Figure 8. Long Nose

Source: IA- Electronics LM Grade 7 & 8

Side Cutter. It is a wire-cutting plier, though they are not used to grab or turn anything, but

are used to cut wire.

Figure 9. Side Cutter

Source: IA- Electronics LM Grade 7 & 8

Wire Stripper. It is a pair of opposing blades much like scissors or wire cutters. The addition

of a center notch makes it easier to cut the insulation without cutting the wire. This type of

wire stripper is used by rotating it around the insulation while applying pressure in order to

make a cut around the insulation. Since the insulation is not bonded with the wire, it will be

pulled easily at the end.

Figure 10. Wire Stripper

Source: IA- Electronics LM Grade 7 & 8

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 8

BORING TOOLS

12 Volt Mini-Drill. It is used to bore or drill holes in the printed circuit board (pcb).

Figure 11. 12-Volt Mini-Drill

Source: IA- Electronics LM Grade 7 & 8

Portable Electric Drill. It is used for boring hole/s in the plastic chassis or metal chassis with

the used of drill bits.

Figure 12. Portable Electric Drill

Source: IA- Electronics LM Grade 7 & 8

FILES

Metal File. It is a hand tool used to shape metals by grinding. A file series of sharp, parallel

ridges or teeth. Most files have a narrow, pointed tang at one end to which a handle can be

fitted.

Flat Files. They are parallel in width and tapered in thickness. They are used for flat surfaces

and edges.

Half Round Files. They are tapers in width and thickness, coming to a point, and are narrower

than a standard half round which are used for filing inside of rings.

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 9

Round Files. They are also called rat-tail files gradually tapered and are used for many tasks

that require a round tool, such as enlarging round holes or cutting a scalloped edge.

Figure 13. Different Type of File

Source: IA- Electronics LM Grade 7 & 8

CUTTING TOOLS

Utility Knife. It is a common tool used in cutting various trades and crafts for a variety of

purposes.

Figure 14. Utility Knife

Source: IA- Electronics LM Grade 7 & 8

Hacksaws. They are used for cutting metal. Some of them have pistol grips which keep the

hacksaw firm and easy to grip. The small hand-held hacksaws consist of a metal arch with a

handle that fits around a narrow, rigid blade. The blade has many small saw teeth along one

side. It can either be attached such that the teeth face away from the handle, resulting in

sawing action by pushing, or be attached such that the teeth face toward the handle, resulting

in sawing action by pulling. On the push stroke, the arch will bend a little, releasing the tension

on the blade. The blade is normally quite brittle; so extra care is needed to be taken to prevent

brittle fracture of the blade.

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 10

Figure 15. Hacksaw

Source: IA- Electronics LM Grade 7 & 8

AUXILLARY TOOLS

Ball-peen Hammer It is a type of hammer used in metalworking. The ball-peen hammer

remains useful for many tasks such as tapping punches and chisels. The original function of

the hammer was to "peen" riveted or welded material so that it will exhibit the same elastic

behavior as the surrounding material. Specifically, striking the metal imparts a stress at the

point of impact which results in strain-hardening of that area. Strain hardening raises the

elastic limit of a material into the plastic range without affecting its ultimate strength. A strain-

hardened material will not deform under the same low stresses as a non-hardened material.

Most metals can be "worked" by such methods until they lose all of their ductile characteristics

and become strong but brittle.

Figure 16. Ball-peen Hammer

Source: IA- Electronics LM Grade 7 & 8

Magnifying Glass It is a convex lens which is used to produce a magnified image of an object.

The lens is usually mounted in a frame with a handle (see image). Roger Bacon is the original

inventor of the magnifying glass. A magnifying glass works by creating a magnified virtual

image of an object behind the lens. The distance between the lens and the object must be

shorter than the focal length of the lens for this to occur. Otherwise, the image appears smaller

and inverted, and can be used to project images onto surfaces. The framed lens may be

mounted on a stand, keeping the lens at the right distance from the table, and therefore at the

right distance from the object on the table. The latter applies if the object is small and also if

the height is adjustable. Some magnifying glasses are foldable with built-in light

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 11

Figure 17. Magnifying Glass

Source: IA- Electronics LM Grade 7 & 8

Paint Brush. It is made of bristles set in handle used for cleaning dirty parts of a circuit or an

object.

Figure 18. Paint Brush

Source: IA- Electronics LM Grade 7 & 8

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 12

Lesson Using Appropriate Basic

2 Electronics Hand Tools Based

on Safety Requirements

Use of Appropriate Electronic Hand Tools Based on Safety Requirements Procedure in

Using a Flat File

1. Position the metal file near the edges of the object (metal) you want to smoothen.

2. Hold the handle of the file steadily.

3. Lay the file sideways on the object work, and carefully push or pull it across the work.

4. Continue on pushing or pulling it across the work until you attain the desired smoothness of

the surface.

Procedure in Using a Hacksaw

1. Position the hacksaw blade near the object (metal) where you want to cut it. Mark a straight

line where hacksaw blade will pass.

2. Hold the handle steadily.

3. Lay the saw teeth along the surface of the object work and carefully push or pulling it across

the work.

4. Continue on pushing or pulling it across the work until you attain a complete cut of the metal.

Procedure in Using a Soldering Iron

1. Preparing the soldering iron:

a. Place the soldering iron on the stand before plugging it.

b. Wait a few minutes for the soldering iron to attain its operating temperature of about 400 0C.

c. Wipe the tip of the soldering iron on the wet damp sponge.

d. Melt a little solder (soldering lead – 60/40) on the tip of the iron.

e. Wipe again the tip of the soldering iron on the wet damp sponge.

2. Soldering technique:

a. Hold the soldering iron like a pen near the base of the handle.

b. Touch the soldering iron onto the joint to be made.

c. Feed a little solder onto the joint.

d. Remove the solder, then the soldering iron while keeping the joint still.

e. Inspect the joint closely. It should look shiny with a volcano shape.

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 13

What’s More

Safety Requirements with the Use of Personal Protective Equipment

Hand Tool Design, Selection, and Setup

1. Weight. Use the lightest weight tool possible to avoid injury. Excessively heavy tools should

be equipped with the use of mechanical support and attached hoses should be supported.

Support and equip tools with the use of mechanical support so you don't need to hold

them continuously while working. If a mechanical support cannot be provided, the work

station should be designed so you can put the tool down or rest in a holster when it is not

in use.

Figure 19. Weight Tool

Source: IA- Electronics LM Grade 7 & 8

2. Balance. Additional force is required to use a badly balanced tool. The tool's center of

gravity should be closed to the body, to the handles, and in line with the center of the hands

holding the tool. Also, the weight of an unsupported hose can unbalance a tool.

Figure 20. Balancing

Source: IA- Electronics LM Grade 7 & 8

3. Torque Control. High torque requires a lot of force to keep the tool from rotating out of your

hand. Torque settings should be set to the minimum required by job specifications,

especially for in-line and pistol-shaped tools.

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 14

Figure 21. Torque Control

Source: IA- Electronics LM Grade 7 & 8

4. Grip. Tool handles should allow stable and efficient grip. The handle should be cylindrical

or oval in shape, with a diameter of between 1.25 and 1.75 inches. Tool handles should

contact as much of the hand and fingers as possible. Grips should be made of non-slip

compressible and non-conductive material. However, if the task requires fine

manipulations, a small handle and a precision grip are preferred. Handles should not press

on the base of the palm. Use tools with long handles or handles which are large and

rounded enough to distribute the force over a large area of the palm. Avoid form-fitting

handles (handles with finger grooves), since they may not fit the hand size of every user.

Handles should be kept clean of slippery grease, oil, or sweat.

Figure 22. Improper and Proper Gripping

Source: IA- Electronics LM Grade 7 & 8

5. Span. For two-handled manual tools, like scissors, the open span should be about 4 inches

and the closed span should be about 1.5 inches.

Figure 23. Span

Source: IA- Electronics LM Grade 7 & 8

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 15

6. Spring-loaded handles. A spring-loaded mechanism saves muscular effort and reduces

mechanical stress on the backs and sides of fingers for such tools as scissors, pliers, and

other manual cutting and gripping tools which have to be opened and closed repeatedly

during use.

Figure 24. Spring-loaded handles

Source: IA- Electronics LM Grade 7 & 8

7. Choose the right tool shape. Pistol-shaped tools should be used on a vertical surface or

on a horizontal surface below waist height. Bend the tool, not the wrist.

8. Avoid bending over your work.

Figure 25. Improper and Proper Bending

Source: IA- Electronics LM Grade 7 & 8

9. Avoid overhead work. Use a ladder to reduce the need for outstretched arms.

Figure 26. Avoid overhead work

Source: IA- Electronics LM Grade 7 & 8

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 16

10. Keep the elbows close to the body.

Figure 27. Keep the elbows close to the body

Source: IA- Electronics LM Grade 7 & 8

11. Tilt the work surface instead of the wrist.

Figure 28. Tilt the work surface instead of the wrist

Source: IA- Electronics LM Grade 7 & 8

12. Stand with your weight evenly distributed between feet. When standing for long

periods of time, rest one foot on a sturdy

Figure 29. Standing with your weight

Source: IA- Electronics LM Grade 7 & 8

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 17

13. Sit up straight so the chair offers good back support. Adjust the chair back so that it

will support the natural curve of the lower back. Adjust the seat height to allow thighs to

be in parallel to the floor.

Figure 30. Improper and Proper Sitting

Source: IA- Electronics LM Grade 7 & 8

What I Have Learned

It is necessary to familiarize ourselves with the classification of electronic hand tools

and the safety requirements on the use of personal protective equipment hand tool design,

selection, and setup as well as applying proper soldering techniques.

What I Can Do

ACTIVITY 2

Directions: Draw the following electronic hand tools on a long bond paper and label them.

1. Portable Electric Drill 7. Flat Screw Driver

2. Soldering Stand 8. Long Nose

3. Soldering Iron 9. Side Cutter

4. Desoldering Pump 10. Hacksaw

5. Wire Stripper 11. Paint Brush

6. 12 Volts Mini-Drill 12. Magnifying Glass

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 18

Assessment

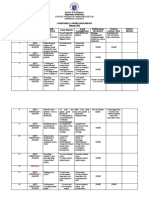

A. Safety Requirement Procedure

Directions: Write the safety requirement procedure indicated in each number on a separate

sheet of paper.

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 19

B. Matching Type.

Directions: Match the given tools (Column A) with their corresponding functions (Column B).

Write the letter of your choice on a separate sheet of paper.

Column A Column B

1. Ball-peen Hammer A. It is used for applying heat to melt solder in attaching

two metal parts.

2. Paint Brush B. It is used to cut wire.

3. Soldering Iron C. It is useful for many tasks such as tapping punches

and chisels.

4. 12 Volt Mini-Drill D. It is used for holding, bending and stretching the lead

of electronic component or connecting wire.

5. Side Cutter E. It is used to produce a magnified image of an object.

6. Magnifying Glass F. It is used for cleaning dirty parts of a circuit or an

object.

7. Long Nose G. It is a place of the soldering iron to keep them away

from flammable materials.

8. Portable Electric Drill H. It is used for the removal of solder and components

from a circuit when trouble-shooting, repair purposes,

and to save components.

9. Soldering Stand I. It is used for boring hole/s in the plastic chassis or

metal chassis with the used of drill bits.

10. De-soldering Tool J. It is used to bore or drill holes in the printed circuit

board.

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 20

21 Electronics (Grade 10) Self-Learning Module MELC-Aligned WBLS-OBE

ASSESSMENT

B. Matching Type

A.

1) Avoid bending over your work 1. c 6. e

2) Use a ladder to reduce the need for outstretched arms 2. f 7. d

3. a 8. i

3) Sit up straight so the chair offers good back support. 4. j 9. g

4) Stand with weight evenly distributed between feet 5. b 10. h

5) Torque settings should be set to the minimum level as

required by the job specifications

ACTIVITY 2

ACTIVITY 1

JUMBLED WORDS

1.WEIGHT

2. BALANCE

3. TORQUE CONTROL

4. GRIP

5. SPAN

PRE-ASSESSMENT

Preparing the soldering iron: Soldering technique:

2 2

5 1

3 3

1 5

4 4

Answer Key

References

Buban, Peter & Schmitt, Marshall. (1972). Technical Electricity and Electronics. New York: Mc

Graw-Hill.

Grob, Bernard. (1977). Basic Electronics, 4th Edition. New York: Mc Graw-Hill Company.

Grob, Bernard. (1982). Electronics Circuits and Application; USA: McGraw-Hill Company.

Markus, John. (1945). Electronics Dictionary, 4th Edition. New York: McGraw-Hill Company.

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 22

For inquiries or feedback, please write or call:

Department of Education – Schools Division of Laoag City

Curriculum Implementation Division

Brgy. 23 San Matias, Laoag City, 2900

Contact Number: (077)-771-3678

Email Address: laoag.city@deped.gov.ph

WBLS-OBE MELC-Aligned Self-Learning Module Electronics (Grade 10) 23

You might also like

- MOSFET Cross-Reference Search - Equivalent TransistorsDocument1 pageMOSFET Cross-Reference Search - Equivalent TransistorsFuadNo ratings yet

- CSS 11 - Module 5 - Plan and Prepare Termination Connection of Electrical WiringDocument17 pagesCSS 11 - Module 5 - Plan and Prepare Termination Connection of Electrical WiringJoy100% (1)

- About PCBDocument13 pagesAbout PCBRussel Matthew EspirituNo ratings yet

- Unit 3 - Introduction To Industrial Arts Part 2 (IEIAT - TLEHE8)Document8 pagesUnit 3 - Introduction To Industrial Arts Part 2 (IEIAT - TLEHE8)Vendivel Kristine100% (1)

- MR. Roboto: Submitted byDocument8 pagesMR. Roboto: Submitted bySherina Mae GonzalesNo ratings yet

- TLE IA EP9 Week 2 RecoveredDocument4 pagesTLE IA EP9 Week 2 Recovereddainegarano64No ratings yet

- CSS 8Document26 pagesCSS 8bernardocathlynnNo ratings yet

- Topic 1 - Electronics FundamentalsDocument12 pagesTopic 1 - Electronics FundamentalsKiro Da rareNo ratings yet

- DC CircuitsDocument32 pagesDC CircuitsBreanna Monique Tao-onNo ratings yet

- Lesson 7 Lo1Document49 pagesLesson 7 Lo1septephanie ayesha celsoNo ratings yet

- Computer Systems Servicing (NCII) Quarter 4 Module 1 Testing Electronic Components (Tec)Document12 pagesComputer Systems Servicing (NCII) Quarter 4 Module 1 Testing Electronic Components (Tec)Xyreel LagurasNo ratings yet

- Electronic Products Assembly and Servicing Grade 11: 1 Semester - Midterm Week 4 Module 3Document54 pagesElectronic Products Assembly and Servicing Grade 11: 1 Semester - Midterm Week 4 Module 3CHESTER ALLAN MENDEZ100% (4)

- Workshop Training Manual COURSE: WS1020: Central Workshop Indian Institute of Technology Madras CHENNAI - 600036, INDIADocument44 pagesWorkshop Training Manual COURSE: WS1020: Central Workshop Indian Institute of Technology Madras CHENNAI - 600036, INDIAhariharanhemanthNo ratings yet

- Css 11 Ncii Quarter 3 Module 6 Plan and Prepare TerminationDocument16 pagesCss 11 Ncii Quarter 3 Module 6 Plan and Prepare TerminationR TECH100% (1)

- Preparing and Interpreting Technical Drawing: Terminating and Connecting Electrical Wiring and Electronics CircuitDocument4 pagesPreparing and Interpreting Technical Drawing: Terminating and Connecting Electrical Wiring and Electronics Circuitfadzram joefoxNo ratings yet

- Tle Q1Document12 pagesTle Q1Dummy DummuNo ratings yet

- Electronic Components (Active vs. Passive)Document5 pagesElectronic Components (Active vs. Passive)Djinn CooNo ratings yet

- Experiment-1: Laboratory ManualDocument29 pagesExperiment-1: Laboratory ManualANKIT Dhanka 21EBKEC005No ratings yet

- TLE 7 - Q3-Week 3-4: Technology and Livelihood Education Automotive Servicing Exploratory Wenefredo L. Pinca AuthorDocument10 pagesTLE 7 - Q3-Week 3-4: Technology and Livelihood Education Automotive Servicing Exploratory Wenefredo L. Pinca AuthorDupaya Arianne P.No ratings yet

- Assignment 3 (Writing Module of Instruction Along Qualifications)Document11 pagesAssignment 3 (Writing Module of Instruction Along Qualifications)Charlton Benedict BernabeNo ratings yet

- Week 6Document5 pagesWeek 6Tuyac RegañonNo ratings yet

- Information Sheets 6.1.4Document12 pagesInformation Sheets 6.1.4api-196541959No ratings yet

- MTE SensordsDocument29 pagesMTE SensordsNafees RakibNo ratings yet

- Supplementary Learning Materials: ElectronicsDocument9 pagesSupplementary Learning Materials: ElectronicsCRISTINA TAGUILIDNo ratings yet

- Electronic ComponentsDocument3 pagesElectronic ComponentsAudelio CerezoNo ratings yet

- Consumer Electronics ServicingDocument90 pagesConsumer Electronics Servicingmae ann dujerteNo ratings yet

- Ass 1Document3 pagesAss 1Rodney MacansantosNo ratings yet

- Lab ManualDocument33 pagesLab ManualsimeeraataaddeseeNo ratings yet

- BEE Lab 2 FDocument5 pagesBEE Lab 2 FGlenn Ezekiel MiralNo ratings yet

- Electric CircuitDocument21 pagesElectric CircuitElishaNo ratings yet

- Module 6 - Terminating and ConnectingDocument44 pagesModule 6 - Terminating and ConnectingMary Jane Blanco FioNo ratings yet

- 2 Basic Electronics - Electronic Components and Equipments.Document36 pages2 Basic Electronics - Electronic Components and Equipments.anon_475597919No ratings yet

- Sign & SymbolsDocument31 pagesSign & SymbolsKate UbiñaNo ratings yet

- Electronics1 Laboratory Manual PDFDocument61 pagesElectronics1 Laboratory Manual PDFmalini72No ratings yet

- Electronic Workbench PracticlesDocument23 pagesElectronic Workbench Practiclesapi-394738731No ratings yet

- Basic Electronics (ES-112)Document29 pagesBasic Electronics (ES-112)Bharat LalNo ratings yet

- TLE-Computer Systems Servicing 7 Third: PanimulaDocument4 pagesTLE-Computer Systems Servicing 7 Third: PanimulaFlorinda Gagasa100% (1)

- Q3 Week7 CSS LeDocument5 pagesQ3 Week7 CSS LeChe MadridejosNo ratings yet

- Q2 Module 2 Activities: Grade 9 Seatwork ActivityDocument5 pagesQ2 Module 2 Activities: Grade 9 Seatwork ActivityIsiah Milan GloriNo ratings yet

- UntitledDocument21 pagesUntitledLeomar AfallaNo ratings yet

- Final Output CenDocument10 pagesFinal Output CenJeruel GabrielNo ratings yet

- 21dcs133 Experiment 1Document9 pages21dcs133 Experiment 1Yash 18No ratings yet

- 1 Basic Electronics P1 NotesDocument18 pages1 Basic Electronics P1 NotesEphraem RobinNo ratings yet

- WS 1020Document44 pagesWS 1020Sunil Sree NathNo ratings yet

- LO 1:-Plan and Prepare To Construct/ Electrical/electronic CircuitsDocument36 pagesLO 1:-Plan and Prepare To Construct/ Electrical/electronic CircuitsLeta SKNo ratings yet

- IoT Module 2Document18 pagesIoT Module 2Lujain AmroNo ratings yet

- Eec 115 Experiment I & IiDocument12 pagesEec 115 Experiment I & IiOreoluwa OmiyaleNo ratings yet

- Instrumentation and Control: Experiment No. 1: Introduction To TinkercadDocument9 pagesInstrumentation and Control: Experiment No. 1: Introduction To TinkercadEme DumlaoNo ratings yet

- Basic Electronics L1Document19 pagesBasic Electronics L1msellereneNo ratings yet

- Emw Final ReportDocument25 pagesEmw Final ReportOm BankarNo ratings yet

- Practical Report: Building A Power SupplyDocument6 pagesPractical Report: Building A Power SupplyRynardt VogelNo ratings yet

- Full Report ET2Document15 pagesFull Report ET2NurulSyafiqahNo ratings yet

- Electronic Technology: Lesson 1Document393 pagesElectronic Technology: Lesson 1Ali MohammedNo ratings yet

- Safety Rules in An Electrical Worksho1Document29 pagesSafety Rules in An Electrical Worksho1Arfan KhanNo ratings yet

- K To 12 Electronics (Week 3)Document15 pagesK To 12 Electronics (Week 3)Roxanne RodrigoNo ratings yet

- Lab 1Document3 pagesLab 1Khurshed AlamNo ratings yet

- Bài 2,3 Thí Nghiệm Trang Bị ĐiệnDocument37 pagesBài 2,3 Thí Nghiệm Trang Bị ĐiệnNguyen TrongNo ratings yet

- Module-Week 5Document2 pagesModule-Week 5Maria Christina ManzanoNo ratings yet

- PT1-2 AnnissaDocument6 pagesPT1-2 AnnissaAnnissa PacaldoNo ratings yet

- Letter of RequestDocument27 pagesLetter of Requestreyvin.constantinoNo ratings yet

- Co3 Hand Outs 2023-2024Document2 pagesCo3 Hand Outs 2023-2024Florence FernandezNo ratings yet

- Performance Task - Understanding Normal Distribution - Content Order - Submission RequirementsDocument3 pagesPerformance Task - Understanding Normal Distribution - Content Order - Submission RequirementsFlorence FernandezNo ratings yet

- Creative Tech 7 Qiii Exam 2023-2024Document3 pagesCreative Tech 7 Qiii Exam 2023-2024Florence FernandezNo ratings yet

- Performance Task StatsDocument4 pagesPerformance Task StatsFlorence FernandezNo ratings yet

- DLL Week 5Document3 pagesDLL Week 5Florence FernandezNo ratings yet

- DLL Technical Drafting W2Document2 pagesDLL Technical Drafting W2Florence FernandezNo ratings yet

- Certificate of Completion: Libertine R. Mantos, EddDocument2 pagesCertificate of Completion: Libertine R. Mantos, EddFlorence FernandezNo ratings yet

- Electronics Module G10 Q4 Week 1 2Document26 pagesElectronics Module G10 Q4 Week 1 2Florence FernandezNo ratings yet

- STE Form-01Document1 pageSTE Form-01Florence FernandezNo ratings yet

- Horticulture 2019 2020 1st ExamDocument2 pagesHorticulture 2019 2020 1st ExamFlorence FernandezNo ratings yet

- Tle8 Week 4Document3 pagesTle8 Week 4Florence FernandezNo ratings yet

- Journal Week 2Document2 pagesJournal Week 2Florence FernandezNo ratings yet

- Arapon Monitoring Observation Report 2021Document4 pagesArapon Monitoring Observation Report 2021Florence FernandezNo ratings yet

- 4477 X 2Document1 page4477 X 2Florence FernandezNo ratings yet

- Brigada EBONALODocument3 pagesBrigada EBONALOFlorence FernandezNo ratings yet

- AWARDSDocument2 pagesAWARDSFlorence FernandezNo ratings yet

- Third AwardsDocument1 pageThird AwardsFlorence FernandezNo ratings yet

- Lesson Plan in EnglishDocument4 pagesLesson Plan in EnglishFlorence FernandezNo ratings yet

- Brigada-Dela CernaDocument4 pagesBrigada-Dela CernaFlorence FernandezNo ratings yet

- Brigada ARAPONDocument3 pagesBrigada ARAPONFlorence FernandezNo ratings yet

- Bulleted DIVISION ACHIEVEMENT TEST SY 2022-2023 TLE 8Document3 pagesBulleted DIVISION ACHIEVEMENT TEST SY 2022-2023 TLE 8Florence FernandezNo ratings yet

- Quarter IiDocument4 pagesQuarter IiFlorence FernandezNo ratings yet

- Answer Key Entrance ExamDocument1 pageAnswer Key Entrance ExamFlorence FernandezNo ratings yet

- Tle Q2-2Document3 pagesTle Q2-2Florence FernandezNo ratings yet

- Accomplishment ReportDocument4 pagesAccomplishment ReportFlorence FernandezNo ratings yet

- Entrance ExamDocument4 pagesEntrance ExamFlorence FernandezNo ratings yet

- TEYL - Section BDocument19 pagesTEYL - Section BFlorence FernandezNo ratings yet

- Tle Q2-3Document2 pagesTle Q2-3Florence FernandezNo ratings yet

- Big Ideas - Electromagnetism and ElectronicsDocument26 pagesBig Ideas - Electromagnetism and ElectronicsKhushal Gupta100% (1)

- Certificate: Aarushi JawaDocument13 pagesCertificate: Aarushi JawapiyushNo ratings yet

- Tutorial 1 - Dr. Rob Stephen-Optimising Line Design PDFDocument74 pagesTutorial 1 - Dr. Rob Stephen-Optimising Line Design PDFOktarico PradanaNo ratings yet

- Iot Based Smart Irrigation SystemDocument5 pagesIot Based Smart Irrigation SystemReddy RNo ratings yet

- Government College of Engineering - Bargur Department of Electrical &electronics EngineeringDocument28 pagesGovernment College of Engineering - Bargur Department of Electrical &electronics EngineeringNishant SinghNo ratings yet

- Awwa C213Document32 pagesAwwa C213Renzo Portugal100% (3)

- L01 PDFDocument49 pagesL01 PDFShreyaNo ratings yet

- Platinum Resistance Thermometer User's Guide: Hart ScientificDocument14 pagesPlatinum Resistance Thermometer User's Guide: Hart ScientificRafael GarzónNo ratings yet

- Date: 3/17/2009: CM2180A Electronic Subsystem Data SheetDocument1 pageDate: 3/17/2009: CM2180A Electronic Subsystem Data SheetCristhian Junior Acosta ParadaNo ratings yet

- 2.4.temperature MeasurementnewDocument48 pages2.4.temperature MeasurementnewIroshiniNo ratings yet

- Xiaomi M365 Mi Scooter 2 Classic-Pro - Research of Spare MOSFETs - v1.0.4 Final - 2019-09-30Document1 pageXiaomi M365 Mi Scooter 2 Classic-Pro - Research of Spare MOSFETs - v1.0.4 Final - 2019-09-30JGSoftNo ratings yet

- 000-SSP 873003 How To Read Wiring Diagrams (EN)Document83 pages000-SSP 873003 How To Read Wiring Diagrams (EN)Oscar CaballeroNo ratings yet

- Dasar Pemilihan MaterialDocument7 pagesDasar Pemilihan MaterialjizanNo ratings yet

- JEE Main 2023-24 Current Electricity Revision Notes - Free PDF DownloadDocument10 pagesJEE Main 2023-24 Current Electricity Revision Notes - Free PDF Downloadaryan.aru2006No ratings yet

- Accelerator Pedal Position (APP) SensorDocument14 pagesAccelerator Pedal Position (APP) SensorivanNo ratings yet

- Classified Examples of Electrical Engineering 1928Document103 pagesClassified Examples of Electrical Engineering 1928dominicrochford3068No ratings yet

- (April 11-12, 2023) LESSON PLAN in SCIENCE 5Document6 pages(April 11-12, 2023) LESSON PLAN in SCIENCE 5clyde alfarasNo ratings yet

- Compact Round Stranded Aluminum Conductors Using Single Input Wire ConstructionDocument4 pagesCompact Round Stranded Aluminum Conductors Using Single Input Wire ConstructionHanh-Trang DangNo ratings yet

- PosterDocument1 pagePosterAnuj ChowdhuryNo ratings yet

- G2!56!0375 SpecificationsDocument2 pagesG2!56!0375 SpecificationsMuhammad BalyanNo ratings yet

- Triac Power and Thermal Calculations - WAN004 - Rev04Document16 pagesTriac Power and Thermal Calculations - WAN004 - Rev04Jesse GomezNo ratings yet

- 65nm CMOS Process Data SheetDocument1 page65nm CMOS Process Data SheetBlmjdb Abdelhafid0% (1)

- Screenshot 2023-01-04 at 7.33.08 PMDocument50 pagesScreenshot 2023-01-04 at 7.33.08 PMSiti Norakma SyuhadaNo ratings yet

- High Frequency Behaviour of ComponentsDocument20 pagesHigh Frequency Behaviour of ComponentsjascnjNo ratings yet

- FAULT CODE 4176 - Aftertreatment Selective Catalyst Reduction Air Assist Valve - Voltage Above Normal or Shorted To High SourceDocument7 pagesFAULT CODE 4176 - Aftertreatment Selective Catalyst Reduction Air Assist Valve - Voltage Above Normal or Shorted To High SourceAvs ElectronNo ratings yet

- Advanced Monolithic Systems: Rohs CompliantDocument8 pagesAdvanced Monolithic Systems: Rohs CompliantVicente MiróNo ratings yet

- Super ConductorsDocument19 pagesSuper ConductorsDhanez JNo ratings yet

- Modeling of SiC MOSFET in MatlabSimulinkDocument5 pagesModeling of SiC MOSFET in MatlabSimulinkDaniel Labiano AnduezaNo ratings yet

- Ds - PDF Circuito Integrado Driver Par La Bobina D IgnicionDocument8 pagesDs - PDF Circuito Integrado Driver Par La Bobina D Ignicionjavy_846058987No ratings yet