Professional Documents

Culture Documents

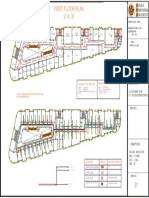

Bhilwara - Fob 100424

Bhilwara - Fob 100424

Uploaded by

adhirachnaCopyright:

Available Formats

You might also like

- Anexo 8.3B Diagramas y EquiposDocument62 pagesAnexo 8.3B Diagramas y Equiposcsoublett786No ratings yet

- PRTAPUDocument1 pagePRTAPUShivam VermaNo ratings yet

- AD SHENDE PLINTH BEAM RC 02 CEAD R0 25-11-2021-ModelDocument1 pageAD SHENDE PLINTH BEAM RC 02 CEAD R0 25-11-2021-Modelswapnil bokadeNo ratings yet

- Contour MapDocument1 pageContour MapJitender KumarNo ratings yet

- Wragby New Layout 3Document1 pageWragby New Layout 3Daniel CryerNo ratings yet

- Ilovepdf MergedDocument12 pagesIlovepdf MergedFan FollowingNo ratings yet

- Acciona Beata Building 1 Structural 1 SignedDocument8 pagesAcciona Beata Building 1 Structural 1 Signedodelcarmen.supcNo ratings yet

- As Built Drawing: This AreaDocument1 pageAs Built Drawing: This AreaTôn Huỳnh ĐoànNo ratings yet

- Hwi Apo6br Ge LLD 0002Document1 pageHwi Apo6br Ge LLD 0002Nideesh RobertNo ratings yet

- M&e Es SLD 500001Document1 pageM&e Es SLD 500001Tengku Azaha Tengku IsmailNo ratings yet

- 09-08-2023 - Banquet Hall OUTDOOR DECK.Document2 pages09-08-2023 - Banquet Hall OUTDOOR DECK.ds18.albertcastroNo ratings yet

- Right Side Elevationworking (Azamgarh) - 6july23-ModelDocument1 pageRight Side Elevationworking (Azamgarh) - 6july23-ModelDhairya pratap singhNo ratings yet

- PLDM Plumbing FCD PlanDocument34 pagesPLDM Plumbing FCD PlanNon Etabas GadnatamNo ratings yet

- Table - : WidthDocument1 pageTable - : WidthTABIBI11No ratings yet

- Site Plan PRTDocument1 pageSite Plan PRTAmarnathNo ratings yet

- JPS-KCB-KHI-DT-01 - Rev ADocument1 pageJPS-KCB-KHI-DT-01 - Rev AAnbazhagan AnnaduraiNo ratings yet

- Crete: Site Development PlanDocument1 pageCrete: Site Development PlanDonald Usaraga BulawinNo ratings yet

- BPCL AGAR - Revised Plan (A0)Document1 pageBPCL AGAR - Revised Plan (A0)bijendraNo ratings yet

- 65391-Jacked-Cooling-R0 2Document12 pages65391-Jacked-Cooling-R0 2ramesh_madkatte1082No ratings yet

- 35ah - SD - RPDS - Sanskardham - Ground Floor Toilet Detail - R1 - 05.12.2023Document1 page35ah - SD - RPDS - Sanskardham - Ground Floor Toilet Detail - R1 - 05.12.2023zaketpatelNo ratings yet

- Compressed Air G.FDocument1 pageCompressed Air G.Fnicoatencio082397No ratings yet

- 3 - Architectural Drawings - Part 2Document9 pages3 - Architectural Drawings - Part 2princessharengarciaNo ratings yet

- Air 1Document1 pageAir 1saipNo ratings yet

- BC Sheet 02 O&BR FlooringDocument1 pageBC Sheet 02 O&BR FlooringAmisha SolankiNo ratings yet

- Zibagwe OffDocument1 pageZibagwe OffdereramichaelNo ratings yet

- 09 MMMMMMMMMMMDocument1 page09 MMMMMMMMMMMUrvashi SindhiNo ratings yet

- Ad-90.0-E-02057-Pdf Lighting Protection Details 1Document1 pageAd-90.0-E-02057-Pdf Lighting Protection Details 1mcaslamNo ratings yet

- Offshore Supply Vessel: ProfileDocument1 pageOffshore Supply Vessel: ProfileAswin Sathian100% (1)

- Mt. Jaya Raya 5600 DWT Work Breakdown Structure: Side ViewDocument1 pageMt. Jaya Raya 5600 DWT Work Breakdown Structure: Side ViewPradipta Jati KumaraNo ratings yet

- Side View: Mt. Jaya Raya 5600 DWT Work Breakdown StructureDocument1 pageSide View: Mt. Jaya Raya 5600 DWT Work Breakdown StructurePradipta Jati KumaraNo ratings yet

- Ec2-02b Second Floor Auxiliary LayoutDocument1 pageEc2-02b Second Floor Auxiliary LayoutSEDFREY DELA CRUZNo ratings yet

- S030-Typical Civil Work DetailsDocument1 pageS030-Typical Civil Work DetailsWNo ratings yet

- Portfolio - Celestino, RhineDocument8 pagesPortfolio - Celestino, RhineAnonymous 9I5RViWz8UNo ratings yet

- Ir El 01Document2 pagesIr El 01Ahmad SaqqaNo ratings yet

- Ad 2Document1 pageAd 2Tania Ossandon MarquezadoNo ratings yet

- MF Perth C01 SiteDocument1 pageMF Perth C01 Sitevp8mcyp7crNo ratings yet

- CEDARDocument32 pagesCEDARjossan doplaynaNo ratings yet

- Iitp - LT - Acoustics - 303 SeatingDocument1 pageIitp - LT - Acoustics - 303 Seatingsumant giriNo ratings yet

- Legend:: 09 01 2020 Electrical System Design of A Commercial BuildingDocument1 pageLegend:: 09 01 2020 Electrical System Design of A Commercial BuildingMarkLloydValleNo ratings yet

- 02 02 CYBER TRAINING CENTRE AND CONTROL ROOM - FURNIURE LAYOUT-ModelDocument1 page02 02 CYBER TRAINING CENTRE AND CONTROL ROOM - FURNIURE LAYOUT-Modelvishal bhiseNo ratings yet

- MRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3Document1 pageMRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3arman gauNo ratings yet

- SuperblokDocument1 pageSuperblokArsitektur GamingNo ratings yet

- Dimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 007Document1 pageDimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 007Wijaya GultomNo ratings yet

- Sample 2Document1 pageSample 2Md SuruzzamanNo ratings yet

- First Floor Plan (LVL 3) : Submitted To:-Ar. Amandeep Kaur Ar - Naveen Suresh ChomalDocument1 pageFirst Floor Plan (LVL 3) : Submitted To:-Ar. Amandeep Kaur Ar - Naveen Suresh ChomalDharaniNo ratings yet

- Ec1-02b Second Floor Fdas LayoutDocument1 pageEc1-02b Second Floor Fdas LayoutSEDFREY DELA CRUZNo ratings yet

- Yashashwini Residential Project Sheet1 ModelDocument1 pageYashashwini Residential Project Sheet1 ModelNaina RewatkarNo ratings yet

- Progress Report (16-12-23)Document1 pageProgress Report (16-12-23)Wijaya GultomNo ratings yet

- Ground Floor Storm Drainage and Plumbing LayoutDocument1 pageGround Floor Storm Drainage and Plumbing LayoutMarianneNo ratings yet

- A31.1 Fourth Floor Furniture Wing-1Document1 pageA31.1 Fourth Floor Furniture Wing-1Azkagul 28No ratings yet

- A31.1 Fourth Floor Furniture Wing-1Document1 pageA31.1 Fourth Floor Furniture Wing-1Azkagul 28No ratings yet

- Iitp LT Acoustics 204 SeatingDocument1 pageIitp LT Acoustics 204 Seatingsumant giriNo ratings yet

- Iitp - LT - Acoustics - 156 SeatingDocument1 pageIitp - LT - Acoustics - 156 Seatingsumant giriNo ratings yet

- Pelan Aras 2: PlazaDocument1 pagePelan Aras 2: PlazamohdkhidirNo ratings yet

- (R12) ROB 503 - 30M Span-FinalDocument1 page(R12) ROB 503 - 30M Span-FinalAnil PanjwaniNo ratings yet

- 04) - 55-10-801-234-North Sector AL HAYERDocument1 page04) - 55-10-801-234-North Sector AL HAYERAmro HarasisNo ratings yet

- 984d CP Official Plan Map 03 OP ROW AODADocument1 page984d CP Official Plan Map 03 OP ROW AODAmunaf.lulatNo ratings yet

- Guu 508: Site Planning of An Urban Area: EntryDocument1 pageGuu 508: Site Planning of An Urban Area: EntryvandniNo ratings yet

- DFDDocument7 pagesDFDPramod KumarNo ratings yet

- Pseudosteady-State Flow Equation and Productivity Index For A Well With Noncircular Drainage AreaDocument3 pagesPseudosteady-State Flow Equation and Productivity Index For A Well With Noncircular Drainage AreaChristian PradaNo ratings yet

- High Strength Non-Electric DetonatorsDocument2 pagesHigh Strength Non-Electric Detonatorsjavier gonzalezNo ratings yet

- CV DV ETL DevDocument2 pagesCV DV ETL DevDeepakVyasNo ratings yet

- Processing of Heavy OilsDocument9 pagesProcessing of Heavy Oilsmohammed salmanNo ratings yet

- Interior Design: Case StudyDocument32 pagesInterior Design: Case StudyrazzakhNo ratings yet

- Non-Metallic Sheathed CableDocument21 pagesNon-Metallic Sheathed CableJeremiah Gonzales67% (3)

- Daruma FrameworkDocument400 pagesDaruma FrameworkPietro BragaNo ratings yet

- Parts List - UTAX CD1465 - CD1480 - ENG - Rev52DDocument115 pagesParts List - UTAX CD1465 - CD1480 - ENG - Rev52DApostolis SakkasNo ratings yet

- OSYM PASSAGES 1 (Oklu AçDocument147 pagesOSYM PASSAGES 1 (Oklu AçSinan EkerNo ratings yet

- BEST Series Build-Up Evaluation Shut-In Tool: A New Level of Accuracy in Dynamic Reservoir EvaluationDocument2 pagesBEST Series Build-Up Evaluation Shut-In Tool: A New Level of Accuracy in Dynamic Reservoir EvaluationFabio ParceroNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document19 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Erick lizana neyra100% (1)

- 7629Document125 pages7629Mark JohnsonNo ratings yet

- Unit 7Document2 pagesUnit 7Sarah AuliaNo ratings yet

- Debug1214 TIPS - JUALAN - CEPAT - LAKU - DI - SHOPEE - 100 - TRI PDFDocument3 pagesDebug1214 TIPS - JUALAN - CEPAT - LAKU - DI - SHOPEE - 100 - TRI PDFAaron BaharyNo ratings yet

- Price ListDocument18 pagesPrice ListSam RyanNo ratings yet

- 2023 JOT Summer Additional Article 15Document30 pages2023 JOT Summer Additional Article 15Faisal MumtazNo ratings yet

- Agitador MecanicoDocument1 pageAgitador Mecanicoakarcz6731No ratings yet

- Evolution of An EQ Design2Document9 pagesEvolution of An EQ Design2atiqulaNo ratings yet

- Chapter 5Document23 pagesChapter 5Tefera Temesgen100% (1)

- SolaFrame 750 Datasheet RevGDocument6 pagesSolaFrame 750 Datasheet RevGAunonymous LlamaNo ratings yet

- Bullet Train 3-3Document4 pagesBullet Train 3-3Pradumna KasaudhanNo ratings yet

- Financier Onboarding PPT - RevisedDocument9 pagesFinancier Onboarding PPT - RevisedAanchal ParkerNo ratings yet

- Online BMW Parts CatalogDocument2 pagesOnline BMW Parts CatalogGerardo CasasNo ratings yet

- Cooling Tower ReportDocument9 pagesCooling Tower ReportdmufqiNo ratings yet

- FIT4 TbrochureDocument2 pagesFIT4 TbrochuredoubleclickchixNo ratings yet

- Naresh 2 PageDocument3 pagesNaresh 2 Pagenaresh_kollojuNo ratings yet

- Structural SlabDocument3 pagesStructural SlabAddrien DanielNo ratings yet

- Ark Platform Pl4000 Brochure Rev-00Document6 pagesArk Platform Pl4000 Brochure Rev-00Murat ArıkanNo ratings yet

Bhilwara - Fob 100424

Bhilwara - Fob 100424

Uploaded by

adhirachnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bhilwara - Fob 100424

Bhilwara - Fob 100424

Uploaded by

adhirachnaCopyright:

Available Formats

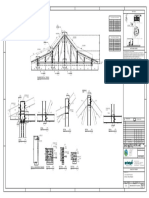

NOTE:-

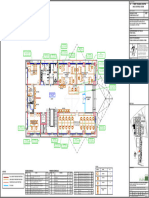

RECTANGULAR POST

LANDING

ROOF SHED 1. ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE SPECIFIED.

TO FOB HOLLOW PIPE

3000

2000 LANDING (98x48x4) 2. PROPOSED WORK SHOWN IN RED , DISMANTLED WORK SHOWN IN GREEN , PHASE -2 WORK SHOWN IN MAGENT& FUTURE WORK SHOWN IN YELLOW ( IN KEY PLAN )

1000

SLOP 1:12 2000

LANDING 3. FEASIBILITY OF THIS STRUCTURE SHALL BE CHECKED AT SITE IN EVERY RESPECT BY ENGINEER INCHARGE BEFORE STARTING THE WORK. ANY DISCREPANCYNOTED SHALL BE BROUGHT OUT

SLOP 1:12 2000 INTO THE NOTICE OF DESIGNER.

SLOP 1:12 2000

LANDING 4. FOR STRUCTURAL DETAILS , REFER RDSO DRAWING NO. B-10438 (ALL SHEETS).

3000

9000 LANDING 5. ELECTRICAL ESTIMATE TO BE INCLUDED IN ENGINEERING MAIN ESTIMATE.

150 MM THICK SLAB

SLOP 1:12 2000

9000 2000 LANDING 6. ALL ELECTRICAL FITTING SHOULD BE CONFIRM TO RELEVANT STANDARD SPECIFICATION AS PER THE ELECTRICITY RULE - 2005 & ACT. 2003.

6435

SLOP 1:12

1000

5695

9000 7. FOR LEVEL OF ILLUMINATION,THE DIRECTIVE ISSUED VIDE ( E E M). RAILWAY BOARD'S LETTER NO. 2004 / ELECT. / 9 / G / 109 / 1. DATED :- 18.05.2007 MAY BE FOLLOWED AND ENERGY EFFICIENT

4945

SLOP 1:12 2000

4195

9000

LIGHT TO BE USED.

3445

SLOP 1:12

2695

2 ISMC 250 @ 400 2 ISMC 250 @ 400 2 ISMC 250 @ 400 9000

8. SUITABLE PROTECTIVE SCREEN SHALL BE PROVIDED FOR 25KV TRACTION AS PER RDSO DRG. NO. ETI/C/0068 OR LATEST WORK WILL BE DONE - BY EXECUTIVE AGENCY OF ENGINEERING DEPTT.).

1945

2 ISMC 250 @ 400

1195

9000 2 ISMC 250 @ 400 SLOP 1:12

H. P.F. LEVEL H. P.F. LEVEL H. P.F. LEVEL H. P.F. LEVEL H. P.F. LEVEL

2 ISMC 250 @ 400

H. P.F. LEVEL

9000

H. P.F. LEVEL

9. PCE'S SANCTION WILL BE TAKEN BEFORE STARTING EXECUTION OF WORKS, AS PER R.B. LETTER NO. 2022/TRANS CELL/CIVIL/CRS, DT. 21.06.2022.

10. THE WORK WILL BE CARRIED OUT IN PRESENCE OF SIGNAL STAFF TO AVOID ANY DAMAGE TO THE CABLES FOR THAT PRIOR INFORMATION WILL BE GIVEN.

11. TRAFFIC AND POWER BLOCK SHALL BE PLANNED DURING EXECUTION OF WORK AFFECTING SAFETY OF EXISTING RUNNING LINES. THE SAME SHOULD BE PUT UP AT LEAST 21 DAYS BEFORE

2690

2690

2690

2690

2690

2690

2690

14340

250 250 250 250 250 250 250 TAKING UP THE WORK.

300

12. FLOOR OF FOB SHALL BE FINISHED WITH NON-SLIPPERY TILES/GRANITE STONE.

2250 2250 2250 2250 2250 2250 2250 13. STEEL STRUCTURE ( COLUMNS & GIRDERS ) SHOULD BE METALLIZED AS PER IRS B-2001 SPECIFICATION.

2400

10000 11000 11000 11000 11000 11000 11000 15340 14. TO PROMOTE SAFETY HAND RAIL SHALL BE PAINTED DURABLE BRIGHT YELLOW SO THAT IT IS EASILY VISIBLE.

15. PROPER EARTHING OF STEEL STRUCTURE SHALL BE ENSURED.

91340

16. ENGINEER IN CHARGE HAS TO ENSURE THAT THE MAX. FOUNDATION PRESSURE IS LESS THAN SBC AT FOUNDING LEVEL.

17. A SEPARATE DRAWING OF LAUNCHING SCHEME WITH REQUIREMENT OF TRAFFIC & POWER BLOCKS SHALL BE PREPARED AND GOT APPROVED BY CONCERNING DIVISIONAL & H.Q. OFFICIALS

SECTION AT 'C-C' BEFORE COMMENCEMENT OF WORK.

RECTANGULAR POST

18. ALL STEEL GIRDERS SHALL BE E-350, GRADE-'A' AS PER IS:2062-2011 RECTANGULAR OR SQUARE HOLLOW STRUCTURAL PIPES OF GRADE Yst -310 OR HIGHER TO BE USED AS PER IR :4923-1997.

2 ISMC 250 HOLLOW PIPE

(96x48x4)

19. DURING EXECUTION OF WORK, ALL SAFETY MEASURES TO BE TAKEN FOR PASSENGERS, TRACKS & LABOURS AS PER GUIDELINES ISSUED BY RAILWAY BOARD & NWR.

@ 400

20. AFTER COMPLETION OF WORK, COMPLETION PLAN SHALL BE PREPARED & UPLOADED ON BMS ALONG WITH STRUCTURAL DRAWINGS AND LAUNCHING SCHEME.

21. AFTER COMPLETION OF WORK, SAFETY CERTIFICATE SHALL BE ISSUED BY DIVISION.

LANDING

LANDING

LANDING

LANDING

LANDING

LANDING

LANDING

MASONARY 1:12

ISMB 300

ISMB 300

ISMB 300

ISMB 300

ISMB 300

ISMB 300

ISMB 300

2000

2500

2800

2500

5590

ENTRY ISMC 125

ISMB 500 SLOP RAMP UP TO UP 22. ENSURE MINIMUM CLEARANCE B/W LIVE OHE & DEAD EARTHED PART OF FOB 250MM OR AS PER LATEST ACPM CORRECTION SLIP.

FIRST LANDING

@ 2000MM

23. INCIDENT OF DROPPING OF ANY MATERIAL/LIQUID/WATER ON OHE SHOULD BE AVOIDED.

9000 2000 9000 2000 9000 2000 9000 2000 9000 2000 9000 2000 9000 2000 14340

24. ENSURE THAT NO OHE MAST/STRUCTURE IS WITHIN 10.0M DISTANCE ON BOTH SIDE OF PROPOSED WORK .

10000 11000 11000 11000 11000 11000 11000 15340 25. PROTECTION OF OHE DURING EXECUTION OF WORK SHOULD BE ENSURED AS PER NWR HQ LETTER NO. NWR/HQ OELCT(TR)/30/2020 PART-(L) DT. 01-02.02022.

2400 26. LIFT AS PER N.R.H.Q.E.(P) PLAN NO. P-266-FB/2016 SHEET NO. 1

91340

27. FABRICATION OF STEEL WORKS SHALL BE DONE IN ACCORDANCE WITH IRS B: 2000 SPECIFICATIONS.

PLAN 1:12 LONG RAMP 28. PROTECTIVE SCREEN SHALL BE PROVIDED ALONG THE RAMP TO NEAREST OHE PORTAL / MAST. WORK SHALL BE DONE BY EXECUTING AGENCY.

29. WHEREVER ELECTRIFIED CONDUCTOR / LIVE PART IS ADJACENT TO STAIR CASE WITH CLEAR HORIZONTAL DISTANCE LESS THAN 4.75 M, STAIRS TOWARDS THE CONDUCTOR / LIVE PART SHOULD

BE COVERED BY CORRUGATED SHEET BY ENGG. DEPTT.

30. QAP FOR FABRICATION WORKS SHALL BE PREPARED BY FABRICATOR AND APPROVED BY SR. DEN.

31. ALL C.C. (MIN. M25) TO BE MECHANICALLY MIXED & VIBRATED AND Fe - 500D REINFORCEMENT SHALL BE USED IN ALL R.C.C. WORKS.

32. ALL CLEARANCE SHOULD BE AS PER IR SOD -2022 WITH LATEST CORRECTION SLIP. ANY DEVIATION FROM THIS SHOULD BE REFERRED BACK TO HQ. IMMEDIATELY WITH PROPOSED ALTERATION.

33. STRUCTURAL DETAILS SHOULD BE AS PER RDSO STANDARD DRAWINGS AS MENTIONED IN THE GAD. HOWEVER WHERE ANY DEVIATION FROM RDSO DRG. IS THERE/IN CASE OF MISSING DETAILS

,THE STRUCTURAL DESIGN/DRG SHOULD BE APPROVED BY COMPETENT AUTHORITY.

34. FABRICATION OF COMPONENT OF FOB TO BE DONE IN WORK SHOP AS FAR AS POSSIBLE.

35. AUTOMATIC SUBMERGED ARC WELDING (SAW) SHOULD BE DONE IN FILLET WELDS OF CONNECTION OF FLANGE TO WEB OF MAIN GIRDER OTHER WELDS SHOULD ALSO BE DONE BY S.A.W. TO THE

MAXIMUM EXTENT POSSIBLE. FCAW OR GMAW MAY BE DONE IN CASE WHERE S.A.W. WELDING IS NOT POSSIBLE.

36. WELDING MAY BE DONE IN ACCORDANCE WITH PROVISION GIVEN FOR WELDING IN IRS BRIDGE CODE OR SPECIFICATION/CODES REFERRED IN THIS FOR THIS PURPOSE.

37. ALL WELDS TO BE MADE BY USING APPROVED WELDING PROCEDURE AND BY QUALIFIED WELDERS AS PER PROVISION OF IRS WELDING BRIDGE CODE. WELDERS QUALIFIED FOR PARTICULAR

4005

700

700

700

HAND RAIL PROTECTIVE SCREEN AS PER RDSO WELD POSITION , WELDING TECHNIQUE AND SIZE ONLY SHALL MAKE THE WELD.

TYPE PLAN NO-ETI/C/0068 38. GUIDELINES ISSUED BY HQ NOTE NO. W/22W1 MAJOR UP GRADATION OF STATION, NWR DT.- 05.04.2013 REGARDING CONSTRUCTION, FABRICATION, WELDING, WORKSHOP AND QUALITY CONTROL

3999

OF 12.0M WIDE FOB TO BE STRICTLY FOLLOWED.

6272

39. TEMPORARY MEASURES SUCH AS SHEET PILING ETC. TO BE ENSURED BY SECTIONAL SR DEN DURING EXCAVATION OF FOUNDATION TO SAFEGUARD PASSENGERS AND RUNNING STAFF WITH

4267

PROVIDING PROPER BARRICADING..

3270

MAIN GIRDER-01 MAIN GIRDER-02

2272

1420 1420 1420 1420 28032 1420 1420 40. ALL SAFETY MEASURES SHOULD BE ADOPTED DURING OVER CROWDING EVENTS AT STATIONS TO CHANNELIZE THE PASSENGERS MOVEMENT OR RESTRICTED WIDTH OF RAMP.

1271

18288 5624 11057

SHS 17488 27231 RAIL LEVEL

41. ALLOWABLE BEARING CAPACITY OF SOIL SHALL BE WORKED OUT BY SOIL INVESTIGATION AND IT SHOULD BE MORE THAN 16.0T/SQM. (APPLICABLE ONLY FOR RDSO DRG. NO. B- 10438 /12).

12971 4516 ℄ OF TRACK ℄ OF TRACK ℄ OF TRACK

250X250X10

13466 5012 6120 5013 250 250 250 250 250 42. FROM LEVELS AND STRUCTURAL SECTION ARE TENTATIVE AND MAY CHANGE AS PER SITE CONDITION AND DETAILS DESIGN REFER SEPARATE STRUCTURE DESIGN & DRAWING.

6435

6434

SHS 2000 2000 2000 2000 2000 43. ALL STRUCTURE MEMBERS SHALL BE RECOMMENDED FOR METALIZING FOR CORROSION RESISTANCE.

4285

℄ OF TRACK

6550

500X500X20 5330 6438 5330 44. MAJOR S&T CABLES ARE PRESENT AT PROPOSED LOCATION. S&T CABLES SHOULD BE SHIFTED/RELOCATED IN PRESENCE OF S&T STAFF.

6550

5894

5993

13785 3000 6000 6000 3000 6000 6000

4610

4610

4610 45. S&T SUB ESTIMATE SHOULD BE TAKEN BEFORE COMMENCEMENT OF WORK.

3430

3430

3430

46. SECTIONAL SR. DEN SHALL ENSURE THAT MAXIMUM FOUNDATION PRESSURE IS MORE THAN SBC AT FOUNDATION LEVEL AND AT RELEVANT LEVEL AS APPLICABLE IN REFERRED DRAWING.

SECTION AT 'B-B'

800

H/L P.F: 4 H/L P.F: 3 H/L P.F: 2 H/L P.F: 1

1680 1680 1680 1680 47. FOUNDATION PRESSURE IS......... REFER SEPARATE STRUCTURE DESIGN, DULY APPROVED BY COMPETENT AUTHORITY.

840

840

5250 5300 48. SEPARATE LAUNCH SCHEME TO BE APPROVED BY COMPETENT AUTHORITY BEFORE STARTING OF WORK.

840

100 49. FOR 1:12 STRAIGHT LONG RAMP REFER DRG. NO. CAO/C/JP/5839/DAWR-BKI.

10230 10420 8250 33000

3000 6000 6000 3000 6000 6000 3000 50. MAJOR S&T CABLES ARE PRESENT AT PROPOSED LOCATION, S&T CABLES SHOULD BE SHIFTED/RELOCATED IN PRESENCE OF S&T STAFF.

51. S&T SUBESTIMATE SHOULD BE TAKEN BEFORE COMMENCEMENT OF WORK.

SECTION AT 'A-A' 52. FABRICATION DRAWING TO BE PREPARED SEPARATELY BEFORE STARTING OF GIRDER FABRICATION AND SHALL BE APPROVED BY MINIMUM JAG GRADE OFFICER.

SLOP 1:12 RAMP SLOP 1:12 RAMP SLOP 1:12 RAMP SLOP 1:12 RAMP

2200

THIS DRG. IS PREPARED ON THE BASIS OF RDSO DRG. NO. -RDSO B- 10438 (ALL SHEETS). ALL

℄ OF TRACK ℄ OF TRACK ℄ OF TRACK ℄ OF TRACK RELEVENT NOTES OF THE SAME SHOULD BE FOLLOWED WITH OUT ANY DEVIATION.

2200

H/L P.F: 4 H/L P.F: 3 H/L P.F: 1 UP

H/L P.F: 2 SLOP 1:12 RAMP SLOP 1:12 RAMP SLOP 1:12 RAMP LIST OF DRAWINGS

LANDING

LANDING

S. NO. DESCRIPTION REFER DRG. No.

LANDING

1 DETAILS OF MAIN GIRDER-01 FB-GT/ABSS-02/15-20M/2023/R1

TO AJMER

(SHEET No. 02)

PLAN (RAMP 1:12) 2 DETAILS OF SPLICE JOINT, CAMBER DIAGRAM & WELDING SEQUENCE FOR MAIN FB-GT/ABSS-02/15-20M/2023/R1

GIRDER-01 (SHEET No. 03)

B

10230 1680 1680 10420 1680 5250 5300 1680 8250 STEEL 3 DETAILS OF CROSS GIRDER FOR SPAN OF MAIN GIRDER-01 FB-GT/ABSS-02/15-20M/2023/R1

GIRDER FOR (SHEET No. 04)

LIFT

C 4 TRESTLE PLAN, ELEVATION AND DETAILS FOR SPAN OF MAIN GIRDER-01 SEPARATELY DESIGN

2760

2500 UP

5 FOUNDATION LAYOUT OF TRESTLE FOR SPAN OF MAIN GIRDER-01 SEPARATELY DESIGN

UP

2190

14340

2200 2200 2200 2200

6 DETAILS OF MAIN GIRDER-02 RDSO/B-10438/1 &

1995

3200

RDSO/B-10438/2

LANDING

LANDING

ENTRY FROM

3000

3000

FIRST FLOOR OF 7 DETAILS OF SPLICE JOINT, CAMBER DIAGRAM & WELDING SEQUENCE OF MAIN RDSO/B-10438/3

FOR GIRDER DETAIL REFER RDSO DRG NO. RDSO/B-10438

2000

ISMB 300 2752 BUILDING GIRDER-02

3365

11910 2500

2549

LANDING

12950 8 DETAILS OF CROSS GIRDER FOR SPAN OF MAIN GIRDER-02 RDSO/B-10438/4

SLOP 1:12 RAMP

SLOP 1:12 RAMP

SLOP 1:12 RAMP

SLOP 1:12 RAMP

1210 1210 1210 1210 1210 1210 1210 1210 1210 1210

9 DETAILS OF ROOFING, HAND RAILING & DECK SLAB FOR MAIN SPAN RDSO/B-10438/6

6000

6000

3000

LIFT

SHAFT WPB 20TH: 10 TRESTLE PLAN FOR SPAN OF MAIN GIRDER-02 RDSO/B-10438/7

SHS

600(285.47) STIFN DIVISIONAL RAILWAY MANAGER

250X250X10

11000

PL.TYP.

9000

11 TRESTLE ELEVATION FOR SPAN OF MAIN GIRDER-02 RDSO/B-10438/8R

2426

SHS

2000

PLAN (RAMP 1:12)

PLAN (RAMP 1:12)

500X500X20 12 TRESTLE DETAILS FOR SPAN OF MAIN GIRDER-02 RDSO/B-10438/9 &

H. P.F.

RDSO/B-10438/10R CBE

SLOP 1:12 RAMP

LEVEL

SLOP 1:12 RAMP

SLOP 1:12 RAMP

SLOP 1:12 RAMP

2330 3225 3230 3225 13 TRESTLE ARRANGEMENTS FOR SPAN OF MAIN GIRDER-02 RDSO/B-10438/11

CHIEF PROJECT MANAGER /GSU

1300

6000

6000

600

1200

14 FOUNDATION LAYOUT OF TRESTLE FOR SPAN OF MAIN GIRDER-02 RDSO/B-10438/12 &

2000

ISMB 300 3330

16500 RDSO/B-10438/13

LANDING

LIFT SECTION DY. CE/BR. DESIGN

9997 SECTION AT 'D-D' 15 1 IN 12 STRAIGHT RAMP CAO/C/JP/5839/D-AWR-BKI

2 ISMC 250

@ 400 Sr. DIVISIONAL ENGINEER/CO.

LANDING

LANDING

91340

3000

3000

RECTANGULAR POST

16 1 IN 12 DOGLEGGED RAMP SEPARATELY DESIGN

34560

34560

HOLLOW PIPE

(96x48x4)

XEN BD

11000

SLOP 1:12 RAMP

9000

Sr. DIVISIONAL OPTG. MANAGER

SLOP 1:12 RAMP

SLOP 1:12 RAMP

ISMB 500

UP

C

6000

6000

ISMC 125

@ 2000

N N.S. LEVEL 0.00 M

CONNECTION FROM

NEW PROPOSED FIRST FLOOR OF BUILDING

BUILDING SSE/D & D

SOFT ROCK

ENTRY NEW PROPOSED

Sr. DIVL. SIG. & TELE. ENGINEER

1:12 DOGLEGGED RAMP

2000

ISMB 300 2752 3000

EXISTING BUILDING 17.80 T/M²

ENTRY

4950

LANDING 17319 UP LIFT

SLOP 1:12 RAMP

(2 M X 2 M FOOTING )

SLOP 1:12 RAMP

2190 (2160x1870)

1.00 M

SLOP 1:12 RAMP

SLOP 1:12 RAMP

33000 1740

6000

6000

5330

Sr. DIVISIONAL COMML. MANAGER

8250

9997

SOFT ROCK

5650 H/L P.F 01

2800 1680

2500

10000

19.36 T/M²

EXISTING FOB

5300

2000

9000

(2 M X 2 M FOOTING )

2.00 M

LANDING

LANDING

NEW PROPOSED 12.0 M WIDE FOB

Sr. DIVL. ELECT. ENGINEER(TRD)

5220

3000

3000

TO AJMER TO UDAIPUR CITY

1680 MAST

SOFT ROCK

ENTRY

LIFT

5330

ENTRY

1269

ENTRY

H/L P.F 02 (2160x1870)

D

1560

91340

B 20.96 T/M²

10420

425 425 2500 ENTRY (2 M X 2 M FOOTING )

UP

NEW PROPOSED 1:12 LONG RAMP MAST 3.00 M Sr. DIVISIONAL ELECT. ENGINEER/G

5650

1535

H/L P.F 03

1210 1210 1210 1210 1210 1210 1210 1210 1210 1210

1210 1210 1210 1210 1210 1210 1210 1210 1210 1210

881

1680

1680 BORE LOG DETAIL OF SOIL AT 'BHILWARA' STATION

NEAR PROP. 12.0 WIDE FOB

H/L P.F 04

3225

11910

(SBC :- 19.36 T/M^2 BELOW 2.5M FROM FOUNDING LEVEL FOR

10230

75 MM FOR RAFT FOUNDATION)

NEW PROPOSED Sr.DIVISIONAL ENGINEER/EAST

ENTRY

1:12 DOGLEGGED RAMP 2305

H. Q. E. OFFICER'S SIGN. DIVISIONAL OFFICER'S SIGN.

4950 UP

3230

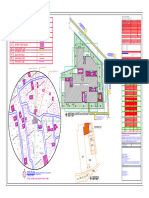

NEW PROPOSED 6000 33000 N.W. RAILWAY AJMER DIVISION AII - COR SECTION

BUILDING LANDING LANDING

LANDING

BHILWARA STATION

3225

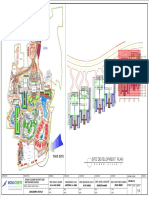

KEY PLAN (NTS) GENERAL ARRANGEMENT DRAWING FOR

PROVISION OF FOOT OVER BRIDGE

1535

425 424 12.0M. WIDE AT 'BHL' STATION (GAD)

2500

2500

D

TO UDAIPUR CITY

SSE/DRG.

5257 (UNDER AMRIT BHARAT STATION

LIFT LIFT

5810 (2160x1870) 5810 (2160x1870) SCHEME)

SCALE:- NOT TO SCALE

..\SEAL.jpg PROPOSAL CHECKED AT SITE AND FOUND FEASIBLE

DIVL. CASE NO. :-

SIGNATURE & SIGNATURE &

SEAL: SEAL:

R1 10-04-24 Change of Span Length(Submission) CANCEL PLAN NO. :-

DESIGN CONSULTANT CONTRACTOR APPROVED

R0 23-02-24

M/S ADHIRACHNA ENGINEERING M/S JCC INFRAPROJECTS BIL JV Sr.NO. DATE DESCRIPTIONS H.Q. DIVL.

N.W. RLY. AJMER DIVL. PLAN NO. :- Sr.DEN - /2024

SOLUTIONS 761

30 , AKLANK HOUSE, TIKAM GANJ, AJMER, SSE/Elect./ SSE/TRD SSE/SIG./ SSE/TELE/ SSE/W/ SSE/P-WAY/CKD CMI/ ADEN/BNW ADEE/TRD

Villa No. 04, Aditi Villas, Jagatpura, Jaipur, Rajasthan-302017 Rajasthan-305001 R E V I S I O N S INIT. N.W. RLY. H.Q.E. PLAN NO. :-

You might also like

- Anexo 8.3B Diagramas y EquiposDocument62 pagesAnexo 8.3B Diagramas y Equiposcsoublett786No ratings yet

- PRTAPUDocument1 pagePRTAPUShivam VermaNo ratings yet

- AD SHENDE PLINTH BEAM RC 02 CEAD R0 25-11-2021-ModelDocument1 pageAD SHENDE PLINTH BEAM RC 02 CEAD R0 25-11-2021-Modelswapnil bokadeNo ratings yet

- Contour MapDocument1 pageContour MapJitender KumarNo ratings yet

- Wragby New Layout 3Document1 pageWragby New Layout 3Daniel CryerNo ratings yet

- Ilovepdf MergedDocument12 pagesIlovepdf MergedFan FollowingNo ratings yet

- Acciona Beata Building 1 Structural 1 SignedDocument8 pagesAcciona Beata Building 1 Structural 1 Signedodelcarmen.supcNo ratings yet

- As Built Drawing: This AreaDocument1 pageAs Built Drawing: This AreaTôn Huỳnh ĐoànNo ratings yet

- Hwi Apo6br Ge LLD 0002Document1 pageHwi Apo6br Ge LLD 0002Nideesh RobertNo ratings yet

- M&e Es SLD 500001Document1 pageM&e Es SLD 500001Tengku Azaha Tengku IsmailNo ratings yet

- 09-08-2023 - Banquet Hall OUTDOOR DECK.Document2 pages09-08-2023 - Banquet Hall OUTDOOR DECK.ds18.albertcastroNo ratings yet

- Right Side Elevationworking (Azamgarh) - 6july23-ModelDocument1 pageRight Side Elevationworking (Azamgarh) - 6july23-ModelDhairya pratap singhNo ratings yet

- PLDM Plumbing FCD PlanDocument34 pagesPLDM Plumbing FCD PlanNon Etabas GadnatamNo ratings yet

- Table - : WidthDocument1 pageTable - : WidthTABIBI11No ratings yet

- Site Plan PRTDocument1 pageSite Plan PRTAmarnathNo ratings yet

- JPS-KCB-KHI-DT-01 - Rev ADocument1 pageJPS-KCB-KHI-DT-01 - Rev AAnbazhagan AnnaduraiNo ratings yet

- Crete: Site Development PlanDocument1 pageCrete: Site Development PlanDonald Usaraga BulawinNo ratings yet

- BPCL AGAR - Revised Plan (A0)Document1 pageBPCL AGAR - Revised Plan (A0)bijendraNo ratings yet

- 65391-Jacked-Cooling-R0 2Document12 pages65391-Jacked-Cooling-R0 2ramesh_madkatte1082No ratings yet

- 35ah - SD - RPDS - Sanskardham - Ground Floor Toilet Detail - R1 - 05.12.2023Document1 page35ah - SD - RPDS - Sanskardham - Ground Floor Toilet Detail - R1 - 05.12.2023zaketpatelNo ratings yet

- Compressed Air G.FDocument1 pageCompressed Air G.Fnicoatencio082397No ratings yet

- 3 - Architectural Drawings - Part 2Document9 pages3 - Architectural Drawings - Part 2princessharengarciaNo ratings yet

- Air 1Document1 pageAir 1saipNo ratings yet

- BC Sheet 02 O&BR FlooringDocument1 pageBC Sheet 02 O&BR FlooringAmisha SolankiNo ratings yet

- Zibagwe OffDocument1 pageZibagwe OffdereramichaelNo ratings yet

- 09 MMMMMMMMMMMDocument1 page09 MMMMMMMMMMMUrvashi SindhiNo ratings yet

- Ad-90.0-E-02057-Pdf Lighting Protection Details 1Document1 pageAd-90.0-E-02057-Pdf Lighting Protection Details 1mcaslamNo ratings yet

- Offshore Supply Vessel: ProfileDocument1 pageOffshore Supply Vessel: ProfileAswin Sathian100% (1)

- Mt. Jaya Raya 5600 DWT Work Breakdown Structure: Side ViewDocument1 pageMt. Jaya Raya 5600 DWT Work Breakdown Structure: Side ViewPradipta Jati KumaraNo ratings yet

- Side View: Mt. Jaya Raya 5600 DWT Work Breakdown StructureDocument1 pageSide View: Mt. Jaya Raya 5600 DWT Work Breakdown StructurePradipta Jati KumaraNo ratings yet

- Ec2-02b Second Floor Auxiliary LayoutDocument1 pageEc2-02b Second Floor Auxiliary LayoutSEDFREY DELA CRUZNo ratings yet

- S030-Typical Civil Work DetailsDocument1 pageS030-Typical Civil Work DetailsWNo ratings yet

- Portfolio - Celestino, RhineDocument8 pagesPortfolio - Celestino, RhineAnonymous 9I5RViWz8UNo ratings yet

- Ir El 01Document2 pagesIr El 01Ahmad SaqqaNo ratings yet

- Ad 2Document1 pageAd 2Tania Ossandon MarquezadoNo ratings yet

- MF Perth C01 SiteDocument1 pageMF Perth C01 Sitevp8mcyp7crNo ratings yet

- CEDARDocument32 pagesCEDARjossan doplaynaNo ratings yet

- Iitp - LT - Acoustics - 303 SeatingDocument1 pageIitp - LT - Acoustics - 303 Seatingsumant giriNo ratings yet

- Legend:: 09 01 2020 Electrical System Design of A Commercial BuildingDocument1 pageLegend:: 09 01 2020 Electrical System Design of A Commercial BuildingMarkLloydValleNo ratings yet

- 02 02 CYBER TRAINING CENTRE AND CONTROL ROOM - FURNIURE LAYOUT-ModelDocument1 page02 02 CYBER TRAINING CENTRE AND CONTROL ROOM - FURNIURE LAYOUT-Modelvishal bhiseNo ratings yet

- MRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3Document1 pageMRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3arman gauNo ratings yet

- SuperblokDocument1 pageSuperblokArsitektur GamingNo ratings yet

- Dimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 007Document1 pageDimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 007Wijaya GultomNo ratings yet

- Sample 2Document1 pageSample 2Md SuruzzamanNo ratings yet

- First Floor Plan (LVL 3) : Submitted To:-Ar. Amandeep Kaur Ar - Naveen Suresh ChomalDocument1 pageFirst Floor Plan (LVL 3) : Submitted To:-Ar. Amandeep Kaur Ar - Naveen Suresh ChomalDharaniNo ratings yet

- Ec1-02b Second Floor Fdas LayoutDocument1 pageEc1-02b Second Floor Fdas LayoutSEDFREY DELA CRUZNo ratings yet

- Yashashwini Residential Project Sheet1 ModelDocument1 pageYashashwini Residential Project Sheet1 ModelNaina RewatkarNo ratings yet

- Progress Report (16-12-23)Document1 pageProgress Report (16-12-23)Wijaya GultomNo ratings yet

- Ground Floor Storm Drainage and Plumbing LayoutDocument1 pageGround Floor Storm Drainage and Plumbing LayoutMarianneNo ratings yet

- A31.1 Fourth Floor Furniture Wing-1Document1 pageA31.1 Fourth Floor Furniture Wing-1Azkagul 28No ratings yet

- A31.1 Fourth Floor Furniture Wing-1Document1 pageA31.1 Fourth Floor Furniture Wing-1Azkagul 28No ratings yet

- Iitp LT Acoustics 204 SeatingDocument1 pageIitp LT Acoustics 204 Seatingsumant giriNo ratings yet

- Iitp - LT - Acoustics - 156 SeatingDocument1 pageIitp - LT - Acoustics - 156 Seatingsumant giriNo ratings yet

- Pelan Aras 2: PlazaDocument1 pagePelan Aras 2: PlazamohdkhidirNo ratings yet

- (R12) ROB 503 - 30M Span-FinalDocument1 page(R12) ROB 503 - 30M Span-FinalAnil PanjwaniNo ratings yet

- 04) - 55-10-801-234-North Sector AL HAYERDocument1 page04) - 55-10-801-234-North Sector AL HAYERAmro HarasisNo ratings yet

- 984d CP Official Plan Map 03 OP ROW AODADocument1 page984d CP Official Plan Map 03 OP ROW AODAmunaf.lulatNo ratings yet

- Guu 508: Site Planning of An Urban Area: EntryDocument1 pageGuu 508: Site Planning of An Urban Area: EntryvandniNo ratings yet

- DFDDocument7 pagesDFDPramod KumarNo ratings yet

- Pseudosteady-State Flow Equation and Productivity Index For A Well With Noncircular Drainage AreaDocument3 pagesPseudosteady-State Flow Equation and Productivity Index For A Well With Noncircular Drainage AreaChristian PradaNo ratings yet

- High Strength Non-Electric DetonatorsDocument2 pagesHigh Strength Non-Electric Detonatorsjavier gonzalezNo ratings yet

- CV DV ETL DevDocument2 pagesCV DV ETL DevDeepakVyasNo ratings yet

- Processing of Heavy OilsDocument9 pagesProcessing of Heavy Oilsmohammed salmanNo ratings yet

- Interior Design: Case StudyDocument32 pagesInterior Design: Case StudyrazzakhNo ratings yet

- Non-Metallic Sheathed CableDocument21 pagesNon-Metallic Sheathed CableJeremiah Gonzales67% (3)

- Daruma FrameworkDocument400 pagesDaruma FrameworkPietro BragaNo ratings yet

- Parts List - UTAX CD1465 - CD1480 - ENG - Rev52DDocument115 pagesParts List - UTAX CD1465 - CD1480 - ENG - Rev52DApostolis SakkasNo ratings yet

- OSYM PASSAGES 1 (Oklu AçDocument147 pagesOSYM PASSAGES 1 (Oklu AçSinan EkerNo ratings yet

- BEST Series Build-Up Evaluation Shut-In Tool: A New Level of Accuracy in Dynamic Reservoir EvaluationDocument2 pagesBEST Series Build-Up Evaluation Shut-In Tool: A New Level of Accuracy in Dynamic Reservoir EvaluationFabio ParceroNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document19 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Erick lizana neyra100% (1)

- 7629Document125 pages7629Mark JohnsonNo ratings yet

- Unit 7Document2 pagesUnit 7Sarah AuliaNo ratings yet

- Debug1214 TIPS - JUALAN - CEPAT - LAKU - DI - SHOPEE - 100 - TRI PDFDocument3 pagesDebug1214 TIPS - JUALAN - CEPAT - LAKU - DI - SHOPEE - 100 - TRI PDFAaron BaharyNo ratings yet

- Price ListDocument18 pagesPrice ListSam RyanNo ratings yet

- 2023 JOT Summer Additional Article 15Document30 pages2023 JOT Summer Additional Article 15Faisal MumtazNo ratings yet

- Agitador MecanicoDocument1 pageAgitador Mecanicoakarcz6731No ratings yet

- Evolution of An EQ Design2Document9 pagesEvolution of An EQ Design2atiqulaNo ratings yet

- Chapter 5Document23 pagesChapter 5Tefera Temesgen100% (1)

- SolaFrame 750 Datasheet RevGDocument6 pagesSolaFrame 750 Datasheet RevGAunonymous LlamaNo ratings yet

- Bullet Train 3-3Document4 pagesBullet Train 3-3Pradumna KasaudhanNo ratings yet

- Financier Onboarding PPT - RevisedDocument9 pagesFinancier Onboarding PPT - RevisedAanchal ParkerNo ratings yet

- Online BMW Parts CatalogDocument2 pagesOnline BMW Parts CatalogGerardo CasasNo ratings yet

- Cooling Tower ReportDocument9 pagesCooling Tower ReportdmufqiNo ratings yet

- FIT4 TbrochureDocument2 pagesFIT4 TbrochuredoubleclickchixNo ratings yet

- Naresh 2 PageDocument3 pagesNaresh 2 Pagenaresh_kollojuNo ratings yet

- Structural SlabDocument3 pagesStructural SlabAddrien DanielNo ratings yet

- Ark Platform Pl4000 Brochure Rev-00Document6 pagesArk Platform Pl4000 Brochure Rev-00Murat ArıkanNo ratings yet