Professional Documents

Culture Documents

Instructions For Use of Cat Coolant Conditioner For Aluminum Components

Instructions For Use of Cat Coolant Conditioner For Aluminum Components

Uploaded by

LuisCopyright:

Available Formats

You might also like

- Charging Chart - Charge Determination of Trans-Air Refrigerant & LubricantDocument3 pagesCharging Chart - Charge Determination of Trans-Air Refrigerant & Lubricantnitestar100% (1)

- SR200 - Fluids & LubricantsDocument4 pagesSR200 - Fluids & LubricantsKristomiDerMarine-Ingenieur0% (1)

- Math Teachers Guide 8 QUARTER 3Document66 pagesMath Teachers Guide 8 QUARTER 3Hazel Clemente Carreon68% (82)

- Instructions For Use of Cat Coolant Conditioner For Aluminum ComponentsDocument4 pagesInstructions For Use of Cat Coolant Conditioner For Aluminum Componentsmohamed ghoneemNo ratings yet

- KMT Aqua Dyne Bare Shaft Series 250 - REV 03 10 - L2 PDFDocument2 pagesKMT Aqua Dyne Bare Shaft Series 250 - REV 03 10 - L2 PDFMark1025No ratings yet

- Rocore Shell Tube Catalog PDFDocument8 pagesRocore Shell Tube Catalog PDFOBUS1976No ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Refill CapacitiesDocument3 pagesRefill CapacitiesEbied YoussefNo ratings yet

- Blackmer CompressorsDocument4 pagesBlackmer CompressorsBesan LaduNo ratings yet

- Maintenance Recommendations: Operation and Maintenance ManualDocument10 pagesMaintenance Recommendations: Operation and Maintenance ManualAmy Nur SNo ratings yet

- Safety Critical Parts List: MaintenanceDocument73 pagesSafety Critical Parts List: MaintenanceFelipe BecerraNo ratings yet

- P01use of Fuel & OilDocument1 pageP01use of Fuel & OilAgus DaniNo ratings yet

- Flammable Liquids: CRC Handbook of Laboratory Safety, 5th Edition, Page 265Document7 pagesFlammable Liquids: CRC Handbook of Laboratory Safety, 5th Edition, Page 265Mariano BruniNo ratings yet

- NH L218 - Fluids & LubricantsDocument4 pagesNH L218 - Fluids & LubricantsKristomiDerMarine-Ingenieur100% (1)

- Parts and Materials: Shell and Tube Marine Water ExchangerDocument1 pageParts and Materials: Shell and Tube Marine Water ExchangerAnonymous lIJl27QBXLNo ratings yet

- Lp-Gas Serviceman'S Manual: Now Available in The Rego App!Document56 pagesLp-Gas Serviceman'S Manual: Now Available in The Rego App!Shehab Abu AhmadNo ratings yet

- Climmy TopLine ENG Lindab PDFDocument43 pagesClimmy TopLine ENG Lindab PDFMussawer HasnainNo ratings yet

- 2Ad-Fhv Engine: JdescriptionDocument3 pages2Ad-Fhv Engine: JdescriptionVictor HenNo ratings yet

- Influence of Metallics and EAF Type On Specific Consumptions and ProductivityDocument20 pagesInfluence of Metallics and EAF Type On Specific Consumptions and ProductivityJorge MadiasNo ratings yet

- Oil and Gas - OffshoreDocument3 pagesOil and Gas - OffshorereenkuNo ratings yet

- CoolingDocument32 pagesCoolingapi-3833108No ratings yet

- Chemical List For Train 1 Start UpDocument6 pagesChemical List For Train 1 Start UpMohamed rasheedNo ratings yet

- Extensão de Troca de Oleo - Motores PesadosDocument23 pagesExtensão de Troca de Oleo - Motores PesadosFLAVIO MARTINSNo ratings yet

- No Service Class Rating Pipe Material Corrosion AllowanceDocument4 pagesNo Service Class Rating Pipe Material Corrosion AllowanceAllif ArrozynNo ratings yet

- Cameron BOP Control Systems PDFDocument38 pagesCameron BOP Control Systems PDFcarlosorizaba100% (1)

- Produts and List Prices 2002Document16 pagesProduts and List Prices 2002jonNo ratings yet

- Lubrication Oil Schedule For Boiler ProperDocument6 pagesLubrication Oil Schedule For Boiler ProperAnonymous JtYvKt5XENo ratings yet

- Honeywell L404a D, F L604a L MDocument12 pagesHoneywell L404a D, F L604a L Mcarlos-alberto-uceda-7837No ratings yet

- Produts and List Prices 2004Document16 pagesProduts and List Prices 2004jonNo ratings yet

- Planet Dewy 60 BFRDocument4 pagesPlanet Dewy 60 BFRRaja MatharuNo ratings yet

- Brosur Perkins 60 150kvaDocument2 pagesBrosur Perkins 60 150kvaKanjeng Raden Aryo SaifuNo ratings yet

- TopLine Katalog Original EnglDocument36 pagesTopLine Katalog Original EnglAnonymous KB3AksTpBNo ratings yet

- Technical Service Guide CT LB TWM Uv VH 6990005 EnUS TSG 09-11Document244 pagesTechnical Service Guide CT LB TWM Uv VH 6990005 EnUS TSG 09-11Henry HuayhuaNo ratings yet

- ES Compleat NOAT Data SheetDocument3 pagesES Compleat NOAT Data SheetAntonio Tavara HernandezNo ratings yet

- Vdocuments - MX Cameron Bop Control SystemsDocument38 pagesVdocuments - MX Cameron Bop Control SystemsOPERACIONES TOP OILNo ratings yet

- Regulators 63eg - PDFDocument20 pagesRegulators 63eg - PDFAlberto CastellanosNo ratings yet

- P01use of Fuel & OilDocument1 pageP01use of Fuel & OilAgus DaniNo ratings yet

- Price List LPG Sapphire LPCB 25-11-2019Document8 pagesPrice List LPG Sapphire LPCB 25-11-2019kidmuNo ratings yet

- 160.80-RP1 10-99 YS Style E 100 To 675 TonsDocument20 pages160.80-RP1 10-99 YS Style E 100 To 675 TonsAwo Orumila GiraldolegraNo ratings yet

- GT Class TKGTPSDocument84 pagesGT Class TKGTPSGnanaseharan Arunachalam100% (1)

- Taller de Problemas Capitulo 1Document8 pagesTaller de Problemas Capitulo 1AntonioNo ratings yet

- Mod 80 UlDocument4 pagesMod 80 UlJUAN PABLO VELA GUIMACNo ratings yet

- Steam Systems Basics, Challenges and Troubleshooting: Steve Jalowiec, PE, CHFMDocument32 pagesSteam Systems Basics, Challenges and Troubleshooting: Steve Jalowiec, PE, CHFMHaris Prawoto100% (1)

- 3-Sizing 08 06Document14 pages3-Sizing 08 06paijo_konatNo ratings yet

- Manual AcumuladoresDocument12 pagesManual AcumuladoresHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- Brochure-Chlorine Di-Oxide Generation and Dosing SystemDocument4 pagesBrochure-Chlorine Di-Oxide Generation and Dosing SystemsamirNo ratings yet

- Ekspansi T2 Dan TE2Document16 pagesEkspansi T2 Dan TE2Arfa ZaynNo ratings yet

- T2 TE Expansion ValveDocument16 pagesT2 TE Expansion ValveIvan KurniadiNo ratings yet

- Nissan RB Engine - WikipediaDocument60 pagesNissan RB Engine - WikipediaZedrick Nell100% (2)

- Brochure RHQDocument4 pagesBrochure RHQvcotofanaNo ratings yet

- Filters and CapacitiesDocument3 pagesFilters and CapacitiesbrunofernandesdacostNo ratings yet

- Allyl KlorürDocument8 pagesAllyl KlorürYiğit ErkulNo ratings yet

- Brochure Liquid Cylinders DOT 4LDocument8 pagesBrochure Liquid Cylinders DOT 4LShaheer TariqNo ratings yet

- Liquid Cylinders TWM B014 Rev00Document8 pagesLiquid Cylinders TWM B014 Rev00Mohd ZaidNo ratings yet

- GD-264 Manual PDFDocument9 pagesGD-264 Manual PDFAnonymous srwHCpANo ratings yet

- Tohin Rotary BlowerDocument6 pagesTohin Rotary BlowerSk RegNo ratings yet

- C100 Service Training Manual: Instructor GuideDocument6 pagesC100 Service Training Manual: Instructor GuideDangLuyenNo ratings yet

- Steam Systems Basics, Challenges and TroubleshootingDocument31 pagesSteam Systems Basics, Challenges and Troubleshootingika yuliyani murtiharjonoNo ratings yet

- CL & CLPB Portable Dewars 7-10-12Document8 pagesCL & CLPB Portable Dewars 7-10-12IASET MAROCNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Blower D7R, CATDocument2 pagesBlower D7R, CATLuisNo ratings yet

- Film D7R, CATDocument2 pagesFilm D7R, CATLuisNo ratings yet

- Bomba de agua D7R, CATDocument2 pagesBomba de agua D7R, CATLuisNo ratings yet

- Sensor transmision D7R, CATDocument2 pagesSensor transmision D7R, CATLuisNo ratings yet

- Motor de Traslacion, 262C CaterpillarDocument2 pagesMotor de Traslacion, 262C CaterpillarLuisNo ratings yet

- Amortiguadores de Cabina, 262C CaterpillarDocument2 pagesAmortiguadores de Cabina, 262C CaterpillarLuisNo ratings yet

- Lip Seal InstallDocument5 pagesLip Seal InstallLuisNo ratings yet

- Escobilla de Limpiaparabrizas, 262C CaterpillarDocument4 pagesEscobilla de Limpiaparabrizas, 262C CaterpillarLuisNo ratings yet

- Extractor Tool Deutsch 16Document1 pageExtractor Tool Deutsch 16LuisNo ratings yet

- Control Air DryerDocument23 pagesControl Air DryerGeorgiNo ratings yet

- Sifat Fisiko-Kimia Edible Film Agar - Agar RumputDocument9 pagesSifat Fisiko-Kimia Edible Film Agar - Agar Rumputarsya rizkiNo ratings yet

- Detailed Lesson Plan MomentumDocument10 pagesDetailed Lesson Plan MomentumRenante CruzNo ratings yet

- 1-Surveyor Indonesia Jasa Layanan Service Survey Pemetaan Land Survey Ukur Tanah Ternate-Ternate Maluku UtaraDocument119 pages1-Surveyor Indonesia Jasa Layanan Service Survey Pemetaan Land Survey Ukur Tanah Ternate-Ternate Maluku UtaraEdi SupriyantoNo ratings yet

- ASIAN PaintsDocument13 pagesASIAN PaintsAtlas ShruggedNo ratings yet

- Public Health ClassicsDocument3 pagesPublic Health ClassicsAnaluMendietaNo ratings yet

- Computer Oxford Practical 7th GradeDocument2 pagesComputer Oxford Practical 7th Gradenalayn abbasNo ratings yet

- Weekly Assessment-Week 1: EnglishDocument3 pagesWeekly Assessment-Week 1: EnglishMa Isabella T BallesterosNo ratings yet

- Flame SensorDocument3 pagesFlame Sensorchandrasekar ANo ratings yet

- Modal Verbs Can-Could May-Might - Must-Should - Ought To Shall - WillDocument4 pagesModal Verbs Can-Could May-Might - Must-Should - Ought To Shall - WillDana Elisabeta PironNo ratings yet

- A Report On Solving The Problem of Excessive Trilec e ConsumptionDocument3 pagesA Report On Solving The Problem of Excessive Trilec e ConsumptionMarkNo ratings yet

- Lec3 Convex Function ExerciseDocument4 pagesLec3 Convex Function Exercisezxm1485No ratings yet

- Approach in Developing Environmental Management Plan (EMP) : AbstractDocument12 pagesApproach in Developing Environmental Management Plan (EMP) : AbstractAnandhuMANo ratings yet

- Iso 18254-2015 - ApeoDocument18 pagesIso 18254-2015 - ApeoDoulat RamNo ratings yet

- PepsiCo Roshan Kal InternshipDocument56 pagesPepsiCo Roshan Kal InternshipQamar ZamanNo ratings yet

- S - A - Retailer's Impact Woolworth CaseDocument8 pagesS - A - Retailer's Impact Woolworth CaseKonrad GłowackiNo ratings yet

- Presentations Made EasyDocument1 pagePresentations Made Easyjosheb abetriaNo ratings yet

- The Stage Approach: Developed by W. Huitt (1999)Document39 pagesThe Stage Approach: Developed by W. Huitt (1999)Ruchika AgarwalNo ratings yet

- Iso Awareness Weekend Staff Training Programme: RegistrationDocument12 pagesIso Awareness Weekend Staff Training Programme: RegistrationKakira Lions ClubNo ratings yet

- Encircle The Letter of The Correct Answer. Absolutely No ErasuresDocument2 pagesEncircle The Letter of The Correct Answer. Absolutely No ErasuresARISNo ratings yet

- Topic 12 ReviewDocument15 pagesTopic 12 Reviewchanman209No ratings yet

- P.7 SST Special++ Special Pre - P.L.E ExaminationDocument8 pagesP.7 SST Special++ Special Pre - P.L.E ExaminationSamuel Wagaluka100% (5)

- Mercedes Technical Report July 4 - 2022 Sedar Filing VersionDocument275 pagesMercedes Technical Report July 4 - 2022 Sedar Filing VersionMwChrisNo ratings yet

- Matrix-Theorist and Their ViewsDocument5 pagesMatrix-Theorist and Their Viewsrebekah laydaNo ratings yet

- JEBENS, Holger. The Crisis of AnthropologyDocument24 pagesJEBENS, Holger. The Crisis of AnthropologyBernardoMoraesNo ratings yet

- HSE ManualDocument76 pagesHSE ManualDevi DaasaNo ratings yet

- Quant Question Practice-Test4Document8 pagesQuant Question Practice-Test4Ss AaNo ratings yet

- Special Considerations For Special Populations: Chapter ObjectivesDocument46 pagesSpecial Considerations For Special Populations: Chapter ObjectivesClaudia F de la ArceNo ratings yet

- Philosophical Belief in GodDocument32 pagesPhilosophical Belief in GodZiad Cassim (anti-Sufi)No ratings yet

Instructions For Use of Cat Coolant Conditioner For Aluminum Components

Instructions For Use of Cat Coolant Conditioner For Aluminum Components

Uploaded by

LuisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instructions For Use of Cat Coolant Conditioner For Aluminum Components

Instructions For Use of Cat Coolant Conditioner For Aluminum Components

Uploaded by

LuisCopyright:

Available Formats

Instructions for Use of Cat Coolant Conditioner for Aluminum Components {1350, 1352, 1395} (REHS7296-05)

SMCS - 1350, 1352, 1395 i09741612

Caterpillar Products

All

Revision History:

PPT

Table 1

Revision Summary of Changes

202 -1073

05 Revised part numbers from Table 4 and Table 2.

Part number 369-0804 is replaced by part number 624-3380

04

Part number 369-0805 is replaced by part number 624-3384.

13: 4/04/1 A554

Introduction

This Special Instruction provides guidelines and instructions for use of Cat Coolant Conditioner (CCAC) for use in Aluminum Bar Plate Radiators and Aluminum Tube Fin

4

RE 0:05+ 1

Radiators (Unit Core or Modular). For more information, please review the Information Release Memo, PELJ1330.

Aluminum Dosing Overview

H

© 2 S729 03:00

A compatibility issue exists between aluminum radiators and OAT coolants that contain nitrites. New aluminum radiators require Cat Coolant Conditioner for Aluminum

Components (CCAC) to be added to the coolant to passivate the radiator. CCAC Passivation creates an oxidation coating on the aluminum that prevents the nitrites in the

coolant from reacting with aluminum in the radiator. Without passivation, the nitrite content in the coolant will deplete over time. The nitrites in the coolant help to protect

024 6

against cylinder liner pitting in the engine, prevents color fade in the coolant, and ammonia odor.

The chemical process that protects the nitrite in the solution will occur within 50 to 200 hours of operation. The CCAC is available from your local Caterpillar dealer. Refer to

Cat

Table 4 below for a list of part numbers for various container volumes.

Instruction on Determining the correct Dosage

erp

Note: This Special Instruction applies only when an Organic Acid Technology (OAT) Extended Life Coolant (ELC) that contains nitrites (for example, Cat ELC and

illa

Cat ELI) is used in aluminum core radiators. This Special Instruction does not apply to conventional coolants similar to Cat DEAC, or machine applications with

r In

only copper radiators.

Remove the coolant fill cap, and dispense the appropriate amount of CCAC directly into the cooling system. It is not necessary to begin immediate operation of the engine to

c.

circulate and mix the conditioner with the coolant.

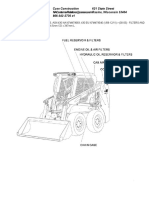

The dosage amounts are based on core technology of Bar Plate vs. Tube Fin. Aluminum modular radiator (AMR) is a modular form of a tube fin radiator (same dosing). The

graphics below help in visual inspection to determine which table of dosing is correct.

If cooling package has multiple bar plate or tube fin cores, adjust recommend CCAC dosing in the table based on number of cores replaced

Example listed below:

150 L system volume with 3 bar plate

Identified the proper table to use per the pictures of core technology & key identifying features

Table references qty: 1 of 2.5oz bottle and 3 of the 1.5 oz bottle = total of 7 oz CCAC dosing

Required CCAC dosing = (CCAC Table) x (Qty of Cores Replaced) / (Total Cores in System)

Required CCAC dosing = (7 oz) x (1/3) = 2.3 oz

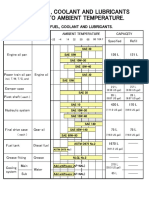

Aluminum Bar Plate Radiator CCAC Dosing

Illustration 1 g07699671

View of tube construction for bar plate

Table 2

CCAC Dosing With Bar Plate Radiators

System Coolant Volume

Number of 624-3384 73.9 mL (2.5 oz) Bottles Required Number of 624-3380 44.4 mL (1.5 oz) Bottles Required

Min Max

30 L (7.9 US gal) 42 L (11.1 US gal) 0 1

42 L (11.1 US gal) 58 L (15.3 US gal) 1 0

58 L (15.3 US gal) 74 L (19.5 US gal) 0 2

74 L (19.5 US gal) 90 L (23.8 US gal) 1 1

90 L (23.8 US gal) 100 L (26.4 US gal) 0 3

100 L (26.4 US gal) 111 L (29.3 US gal) 2 0

111 L (29.3 US gal) 121 L (32.0 US gal) 1 2

121 L (32.0 US gal) 132 L (34.9 US gal) 0 4

132 L (34.9 US gal) 143 L (37.8 US gal) 2 1

143 L (37.8 US gal) 153 L (40.4 US gal) 1 3

153 L (40.4 US gal) 169 L (44.6 US gal) 3 0

169 L (44.6 US gal) 190 L (50.2 US gal) 1 4

190 L (50.2 US gal) 211 L (55.8 US gal) 2 3

211 L (55.8 US gal) 232 L (61.3 US gal) 3 2

232 L (61.3 US gal) 253 L (66.8 US gal) 4 1

253 L (66.8 US gal) 275 L (72.7 US gal) 5 0

275 L (72.7 US gal) 296 L (78.2 US gal) 3 4

296 L (78.2 US gal) 317 L (83.8 US gal) 4 3

317 L (83.8 US gal) 338 L (89.3 US gal) 5 2

338 L (89.3 US gal) 359 L (94.9 US gal) 6 1

359 L (94.9 US gal) 380 L (100.4 US gal) 7 0

Aluminum Tube Fin Radiator and AMR CCAC Dosing

Illustration 2 g07697859

View of tube construction for tube fin

Table 3

CCAC Dosing With Tube Fin Radiators and AMR

System Coolant Volume

Number of 624-3384 73.9 mL (2.5 oz) Bottles Required Number of 624-3380 44.4 mL (1.5 oz) Bottles Required

Min Max

50 L (13.21 US gal) 84 L (22.2 US gal) 0 1

84 L (22.2 US gal) 116 L (30.7 US gal) 1 0

116 L (30.7 US gal) 148 L (39.1 US gal) 0 2

148 L (39.1 US gal) 180 L (47.6 US gal) 1 1

180 L (47.6 US gal) 201 L (53.1 US gal) 0 3

201 L (53.1 US gal) 222 L (58.7 US gal) 2 0

222 L (58.7 US gal) 243 L (64.2 US gal) 1 2

243 L (64.2 US gal) 264 L (69.8 US gal) 0 4

264 L (69.8 US gal) 285 L (75.3 US gal) 2 1

285 L (75.3 US gal) 306 L (80.90 US gal) 1 3

306 L (80.90 US gal) 338 L (89.3 US gal) 3 0

338 L (89.3 US gal) 380 L (100.4 US gal) 1 4

When replacing an Aluminum Modular Radiator core, use 1/3 of the bottle 624-3380 Additive 14.8 mL (0.5 oz) CCAC dosing per core being replaced.

Table 4

CCAC Bottle Part Numbers

Part Number Container Volume

624-3380 44.4 mL (1.5 fl. oz.)

624-3384 73.9 mL (2.5 fl. oz)

PPT-1073A554

2024/04/11

13:39:36+03:00

i04727490

© 2024 Caterpillar Inc.

You might also like

- Charging Chart - Charge Determination of Trans-Air Refrigerant & LubricantDocument3 pagesCharging Chart - Charge Determination of Trans-Air Refrigerant & Lubricantnitestar100% (1)

- SR200 - Fluids & LubricantsDocument4 pagesSR200 - Fluids & LubricantsKristomiDerMarine-Ingenieur0% (1)

- Math Teachers Guide 8 QUARTER 3Document66 pagesMath Teachers Guide 8 QUARTER 3Hazel Clemente Carreon68% (82)

- Instructions For Use of Cat Coolant Conditioner For Aluminum ComponentsDocument4 pagesInstructions For Use of Cat Coolant Conditioner For Aluminum Componentsmohamed ghoneemNo ratings yet

- KMT Aqua Dyne Bare Shaft Series 250 - REV 03 10 - L2 PDFDocument2 pagesKMT Aqua Dyne Bare Shaft Series 250 - REV 03 10 - L2 PDFMark1025No ratings yet

- Rocore Shell Tube Catalog PDFDocument8 pagesRocore Shell Tube Catalog PDFOBUS1976No ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Refill CapacitiesDocument3 pagesRefill CapacitiesEbied YoussefNo ratings yet

- Blackmer CompressorsDocument4 pagesBlackmer CompressorsBesan LaduNo ratings yet

- Maintenance Recommendations: Operation and Maintenance ManualDocument10 pagesMaintenance Recommendations: Operation and Maintenance ManualAmy Nur SNo ratings yet

- Safety Critical Parts List: MaintenanceDocument73 pagesSafety Critical Parts List: MaintenanceFelipe BecerraNo ratings yet

- P01use of Fuel & OilDocument1 pageP01use of Fuel & OilAgus DaniNo ratings yet

- Flammable Liquids: CRC Handbook of Laboratory Safety, 5th Edition, Page 265Document7 pagesFlammable Liquids: CRC Handbook of Laboratory Safety, 5th Edition, Page 265Mariano BruniNo ratings yet

- NH L218 - Fluids & LubricantsDocument4 pagesNH L218 - Fluids & LubricantsKristomiDerMarine-Ingenieur100% (1)

- Parts and Materials: Shell and Tube Marine Water ExchangerDocument1 pageParts and Materials: Shell and Tube Marine Water ExchangerAnonymous lIJl27QBXLNo ratings yet

- Lp-Gas Serviceman'S Manual: Now Available in The Rego App!Document56 pagesLp-Gas Serviceman'S Manual: Now Available in The Rego App!Shehab Abu AhmadNo ratings yet

- Climmy TopLine ENG Lindab PDFDocument43 pagesClimmy TopLine ENG Lindab PDFMussawer HasnainNo ratings yet

- 2Ad-Fhv Engine: JdescriptionDocument3 pages2Ad-Fhv Engine: JdescriptionVictor HenNo ratings yet

- Influence of Metallics and EAF Type On Specific Consumptions and ProductivityDocument20 pagesInfluence of Metallics and EAF Type On Specific Consumptions and ProductivityJorge MadiasNo ratings yet

- Oil and Gas - OffshoreDocument3 pagesOil and Gas - OffshorereenkuNo ratings yet

- CoolingDocument32 pagesCoolingapi-3833108No ratings yet

- Chemical List For Train 1 Start UpDocument6 pagesChemical List For Train 1 Start UpMohamed rasheedNo ratings yet

- Extensão de Troca de Oleo - Motores PesadosDocument23 pagesExtensão de Troca de Oleo - Motores PesadosFLAVIO MARTINSNo ratings yet

- No Service Class Rating Pipe Material Corrosion AllowanceDocument4 pagesNo Service Class Rating Pipe Material Corrosion AllowanceAllif ArrozynNo ratings yet

- Cameron BOP Control Systems PDFDocument38 pagesCameron BOP Control Systems PDFcarlosorizaba100% (1)

- Produts and List Prices 2002Document16 pagesProduts and List Prices 2002jonNo ratings yet

- Lubrication Oil Schedule For Boiler ProperDocument6 pagesLubrication Oil Schedule For Boiler ProperAnonymous JtYvKt5XENo ratings yet

- Honeywell L404a D, F L604a L MDocument12 pagesHoneywell L404a D, F L604a L Mcarlos-alberto-uceda-7837No ratings yet

- Produts and List Prices 2004Document16 pagesProduts and List Prices 2004jonNo ratings yet

- Planet Dewy 60 BFRDocument4 pagesPlanet Dewy 60 BFRRaja MatharuNo ratings yet

- Brosur Perkins 60 150kvaDocument2 pagesBrosur Perkins 60 150kvaKanjeng Raden Aryo SaifuNo ratings yet

- TopLine Katalog Original EnglDocument36 pagesTopLine Katalog Original EnglAnonymous KB3AksTpBNo ratings yet

- Technical Service Guide CT LB TWM Uv VH 6990005 EnUS TSG 09-11Document244 pagesTechnical Service Guide CT LB TWM Uv VH 6990005 EnUS TSG 09-11Henry HuayhuaNo ratings yet

- ES Compleat NOAT Data SheetDocument3 pagesES Compleat NOAT Data SheetAntonio Tavara HernandezNo ratings yet

- Vdocuments - MX Cameron Bop Control SystemsDocument38 pagesVdocuments - MX Cameron Bop Control SystemsOPERACIONES TOP OILNo ratings yet

- Regulators 63eg - PDFDocument20 pagesRegulators 63eg - PDFAlberto CastellanosNo ratings yet

- P01use of Fuel & OilDocument1 pageP01use of Fuel & OilAgus DaniNo ratings yet

- Price List LPG Sapphire LPCB 25-11-2019Document8 pagesPrice List LPG Sapphire LPCB 25-11-2019kidmuNo ratings yet

- 160.80-RP1 10-99 YS Style E 100 To 675 TonsDocument20 pages160.80-RP1 10-99 YS Style E 100 To 675 TonsAwo Orumila GiraldolegraNo ratings yet

- GT Class TKGTPSDocument84 pagesGT Class TKGTPSGnanaseharan Arunachalam100% (1)

- Taller de Problemas Capitulo 1Document8 pagesTaller de Problemas Capitulo 1AntonioNo ratings yet

- Mod 80 UlDocument4 pagesMod 80 UlJUAN PABLO VELA GUIMACNo ratings yet

- Steam Systems Basics, Challenges and Troubleshooting: Steve Jalowiec, PE, CHFMDocument32 pagesSteam Systems Basics, Challenges and Troubleshooting: Steve Jalowiec, PE, CHFMHaris Prawoto100% (1)

- 3-Sizing 08 06Document14 pages3-Sizing 08 06paijo_konatNo ratings yet

- Manual AcumuladoresDocument12 pagesManual AcumuladoresHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- Brochure-Chlorine Di-Oxide Generation and Dosing SystemDocument4 pagesBrochure-Chlorine Di-Oxide Generation and Dosing SystemsamirNo ratings yet

- Ekspansi T2 Dan TE2Document16 pagesEkspansi T2 Dan TE2Arfa ZaynNo ratings yet

- T2 TE Expansion ValveDocument16 pagesT2 TE Expansion ValveIvan KurniadiNo ratings yet

- Nissan RB Engine - WikipediaDocument60 pagesNissan RB Engine - WikipediaZedrick Nell100% (2)

- Brochure RHQDocument4 pagesBrochure RHQvcotofanaNo ratings yet

- Filters and CapacitiesDocument3 pagesFilters and CapacitiesbrunofernandesdacostNo ratings yet

- Allyl KlorürDocument8 pagesAllyl KlorürYiğit ErkulNo ratings yet

- Brochure Liquid Cylinders DOT 4LDocument8 pagesBrochure Liquid Cylinders DOT 4LShaheer TariqNo ratings yet

- Liquid Cylinders TWM B014 Rev00Document8 pagesLiquid Cylinders TWM B014 Rev00Mohd ZaidNo ratings yet

- GD-264 Manual PDFDocument9 pagesGD-264 Manual PDFAnonymous srwHCpANo ratings yet

- Tohin Rotary BlowerDocument6 pagesTohin Rotary BlowerSk RegNo ratings yet

- C100 Service Training Manual: Instructor GuideDocument6 pagesC100 Service Training Manual: Instructor GuideDangLuyenNo ratings yet

- Steam Systems Basics, Challenges and TroubleshootingDocument31 pagesSteam Systems Basics, Challenges and Troubleshootingika yuliyani murtiharjonoNo ratings yet

- CL & CLPB Portable Dewars 7-10-12Document8 pagesCL & CLPB Portable Dewars 7-10-12IASET MAROCNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Blower D7R, CATDocument2 pagesBlower D7R, CATLuisNo ratings yet

- Film D7R, CATDocument2 pagesFilm D7R, CATLuisNo ratings yet

- Bomba de agua D7R, CATDocument2 pagesBomba de agua D7R, CATLuisNo ratings yet

- Sensor transmision D7R, CATDocument2 pagesSensor transmision D7R, CATLuisNo ratings yet

- Motor de Traslacion, 262C CaterpillarDocument2 pagesMotor de Traslacion, 262C CaterpillarLuisNo ratings yet

- Amortiguadores de Cabina, 262C CaterpillarDocument2 pagesAmortiguadores de Cabina, 262C CaterpillarLuisNo ratings yet

- Lip Seal InstallDocument5 pagesLip Seal InstallLuisNo ratings yet

- Escobilla de Limpiaparabrizas, 262C CaterpillarDocument4 pagesEscobilla de Limpiaparabrizas, 262C CaterpillarLuisNo ratings yet

- Extractor Tool Deutsch 16Document1 pageExtractor Tool Deutsch 16LuisNo ratings yet

- Control Air DryerDocument23 pagesControl Air DryerGeorgiNo ratings yet

- Sifat Fisiko-Kimia Edible Film Agar - Agar RumputDocument9 pagesSifat Fisiko-Kimia Edible Film Agar - Agar Rumputarsya rizkiNo ratings yet

- Detailed Lesson Plan MomentumDocument10 pagesDetailed Lesson Plan MomentumRenante CruzNo ratings yet

- 1-Surveyor Indonesia Jasa Layanan Service Survey Pemetaan Land Survey Ukur Tanah Ternate-Ternate Maluku UtaraDocument119 pages1-Surveyor Indonesia Jasa Layanan Service Survey Pemetaan Land Survey Ukur Tanah Ternate-Ternate Maluku UtaraEdi SupriyantoNo ratings yet

- ASIAN PaintsDocument13 pagesASIAN PaintsAtlas ShruggedNo ratings yet

- Public Health ClassicsDocument3 pagesPublic Health ClassicsAnaluMendietaNo ratings yet

- Computer Oxford Practical 7th GradeDocument2 pagesComputer Oxford Practical 7th Gradenalayn abbasNo ratings yet

- Weekly Assessment-Week 1: EnglishDocument3 pagesWeekly Assessment-Week 1: EnglishMa Isabella T BallesterosNo ratings yet

- Flame SensorDocument3 pagesFlame Sensorchandrasekar ANo ratings yet

- Modal Verbs Can-Could May-Might - Must-Should - Ought To Shall - WillDocument4 pagesModal Verbs Can-Could May-Might - Must-Should - Ought To Shall - WillDana Elisabeta PironNo ratings yet

- A Report On Solving The Problem of Excessive Trilec e ConsumptionDocument3 pagesA Report On Solving The Problem of Excessive Trilec e ConsumptionMarkNo ratings yet

- Lec3 Convex Function ExerciseDocument4 pagesLec3 Convex Function Exercisezxm1485No ratings yet

- Approach in Developing Environmental Management Plan (EMP) : AbstractDocument12 pagesApproach in Developing Environmental Management Plan (EMP) : AbstractAnandhuMANo ratings yet

- Iso 18254-2015 - ApeoDocument18 pagesIso 18254-2015 - ApeoDoulat RamNo ratings yet

- PepsiCo Roshan Kal InternshipDocument56 pagesPepsiCo Roshan Kal InternshipQamar ZamanNo ratings yet

- S - A - Retailer's Impact Woolworth CaseDocument8 pagesS - A - Retailer's Impact Woolworth CaseKonrad GłowackiNo ratings yet

- Presentations Made EasyDocument1 pagePresentations Made Easyjosheb abetriaNo ratings yet

- The Stage Approach: Developed by W. Huitt (1999)Document39 pagesThe Stage Approach: Developed by W. Huitt (1999)Ruchika AgarwalNo ratings yet

- Iso Awareness Weekend Staff Training Programme: RegistrationDocument12 pagesIso Awareness Weekend Staff Training Programme: RegistrationKakira Lions ClubNo ratings yet

- Encircle The Letter of The Correct Answer. Absolutely No ErasuresDocument2 pagesEncircle The Letter of The Correct Answer. Absolutely No ErasuresARISNo ratings yet

- Topic 12 ReviewDocument15 pagesTopic 12 Reviewchanman209No ratings yet

- P.7 SST Special++ Special Pre - P.L.E ExaminationDocument8 pagesP.7 SST Special++ Special Pre - P.L.E ExaminationSamuel Wagaluka100% (5)

- Mercedes Technical Report July 4 - 2022 Sedar Filing VersionDocument275 pagesMercedes Technical Report July 4 - 2022 Sedar Filing VersionMwChrisNo ratings yet

- Matrix-Theorist and Their ViewsDocument5 pagesMatrix-Theorist and Their Viewsrebekah laydaNo ratings yet

- JEBENS, Holger. The Crisis of AnthropologyDocument24 pagesJEBENS, Holger. The Crisis of AnthropologyBernardoMoraesNo ratings yet

- HSE ManualDocument76 pagesHSE ManualDevi DaasaNo ratings yet

- Quant Question Practice-Test4Document8 pagesQuant Question Practice-Test4Ss AaNo ratings yet

- Special Considerations For Special Populations: Chapter ObjectivesDocument46 pagesSpecial Considerations For Special Populations: Chapter ObjectivesClaudia F de la ArceNo ratings yet

- Philosophical Belief in GodDocument32 pagesPhilosophical Belief in GodZiad Cassim (anti-Sufi)No ratings yet