Professional Documents

Culture Documents

TM DC DFE Brochure Lo-Res

TM DC DFE Brochure Lo-Res

Uploaded by

Ashutosh GuptaCopyright:

Available Formats

You might also like

- ACS880 Joe+ChenDocument61 pagesACS880 Joe+Chensunil varmaNo ratings yet

- Compass Software: Features and HighlightsDocument2 pagesCompass Software: Features and HighlightsHector Ernesto Cordero AmaroNo ratings yet

- D-M Catalogue 2019 v35Document120 pagesD-M Catalogue 2019 v35sreeramu100% (1)

- Paper Machine Drive System PMC800: Engineered Solutions For SuccessDocument12 pagesPaper Machine Drive System PMC800: Engineered Solutions For SuccessvictorhugomunozhNo ratings yet

- Huawei CloudEngine 6881 Switch DatasheetDocument14 pagesHuawei CloudEngine 6881 Switch DatasheetJoelinho CrushNo ratings yet

- ACS480 Catalog 3AUA0000204668 RevF EN 15-9-2021 LowresDocument40 pagesACS480 Catalog 3AUA0000204668 RevF EN 15-9-2021 LowresNeryNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument14 pagesCloudEngine 6881 Series Data Center Switches Data SheetEduardo SoberanisNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument14 pagesCloudEngine 6881 Series Data Center Switches Data SheetRiqo SetyoNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument14 pagesCloudEngine 6881 Series Data Center Switches Data SheetwhocaresscribdNo ratings yet

- ACS880 CatalogueDocument52 pagesACS880 CatalogueJauhary HarrysNo ratings yet

- Tech Brief AKD Solution 06 11 FinalDocument2 pagesTech Brief AKD Solution 06 11 FinalIan Bruno Rodriguez CenturionNo ratings yet

- Abb Acs380 Acs880 Catalog en Reva 3aua0000187460 0106Document36 pagesAbb Acs380 Acs880 Catalog en Reva 3aua0000187460 0106Er Amandeep SinghNo ratings yet

- Acs880 01manual PDFDocument24 pagesAcs880 01manual PDFsihamuNo ratings yet

- 2.2.1 Ach580 For Hvac Catalog 3aua0000186691 Revf enDocument37 pages2.2.1 Ach580 For Hvac Catalog 3aua0000186691 Revf enTrunghieu LeNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument13 pagesCloudEngine 6881 Series Data Center Switches Data SheetDaniel DoyharzabalNo ratings yet

- Sppa T3000Document6 pagesSppa T3000Dipti Bhanja100% (1)

- Abb PLC Phtc02u en WebDocument181 pagesAbb PLC Phtc02u en Webwarmaster81No ratings yet

- ACS580 - MV - 3BHT490775R0001 - REV - D - EN - 2021 - 08 - 10 - Lowres 3.3 KV To 11 KV, 200 KW To 6300 KWDocument32 pagesACS580 - MV - 3BHT490775R0001 - REV - D - EN - 2021 - 08 - 10 - Lowres 3.3 KV To 11 KV, 200 KW To 6300 KWМиланNo ratings yet

- Move Up To Higher Productivity: Advant OCSDocument4 pagesMove Up To Higher Productivity: Advant OCSMohamedCoulibalyNo ratings yet

- ACH480 ACH580 For HVAC Catalog 3AUA0000231852 RevB ENDocument48 pagesACH480 ACH580 For HVAC Catalog 3AUA0000231852 RevB ENvery sygnaNo ratings yet

- ACS880 Single Drives Catalog 3AUA0000098111 en RevJDocument44 pagesACS880 Single Drives Catalog 3AUA0000098111 en RevJQIUPEILINNo ratings yet

- Catalog AC500 ECoDocument14 pagesCatalog AC500 ECoFIRMANSYAHNo ratings yet

- ABB ACS580MV Flyer 3bht490774r0001 Rev. A - enDocument2 pagesABB ACS580MV Flyer 3bht490774r0001 Rev. A - enRadu BabauNo ratings yet

- SPPA-T3000 Distributed Control SystemDocument9 pagesSPPA-T3000 Distributed Control SystemMohamed HassanNo ratings yet

- SIPROTEC Processbus V3 ProfileDocument2 pagesSIPROTEC Processbus V3 ProfileCarlos PintoNo ratings yet

- Huawei CloudEngine 6863E Switch DatasheetDocument13 pagesHuawei CloudEngine 6863E Switch DatasheetJuan Francisco AriasNo ratings yet

- ABB Power Plant AutomationDocument8 pagesABB Power Plant Automationooszachooo100% (1)

- Anexo 6Document3 pagesAnexo 6Ivan Perez UvalleNo ratings yet

- Multidrive ABB (3AUA0000139404 - REVF)Document40 pagesMultidrive ABB (3AUA0000139404 - REVF)ING_MBMNo ratings yet

- Drive Low Voltage AC Drives: ACS 800 Catalogue Related Tools and AccessoriesDocument28 pagesDrive Low Voltage AC Drives: ACS 800 Catalogue Related Tools and Accessoriesvuthahor316864No ratings yet

- ABB Industrial Drives: ACS880, Drive Modules 0.55 To 3200 KW CatalogDocument48 pagesABB Industrial Drives: ACS880, Drive Modules 0.55 To 3200 KW CatalogPero MivanovNo ratings yet

- 3ADW000192R0401 DCS800 Technical Catalog e DDocument28 pages3ADW000192R0401 DCS800 Technical Catalog e DSunil singhNo ratings yet

- ABB Low Voltage Drives CapabilitiesDocument8 pagesABB Low Voltage Drives CapabilitiesTrần ĐìnhNo ratings yet

- ACS880 07 FlyerDocument2 pagesACS880 07 Flyerbogner22No ratings yet

- Newtec NOP1760 MDM6000 High Speed SystemDocument4 pagesNewtec NOP1760 MDM6000 High Speed SystemmiltonzxNo ratings yet

- CloudEngine 6850 Series Data Center Switches Data SheetDocument13 pagesCloudEngine 6850 Series Data Center Switches Data SheetTrckNo ratings yet

- Abb Acs580 CatalogDocument36 pagesAbb Acs580 CatalogroyclhorNo ratings yet

- ABB Ability™ System 800xa: Control Builder A Advant® Master System EngineeringDocument4 pagesABB Ability™ System 800xa: Control Builder A Advant® Master System Engineeringazizi202No ratings yet

- Preventive Maintenance, Fault Tracing and Case StudyDocument81 pagesPreventive Maintenance, Fault Tracing and Case Studyjagdish choudharyNo ratings yet

- 2VAA003956 en D Symphony Plus SD Series Control and IO LRDocument27 pages2VAA003956 en D Symphony Plus SD Series Control and IO LRThe Hoang100% (1)

- 1.-Automation Products v3Document100 pages1.-Automation Products v3Juan SanchezNo ratings yet

- Installation and MaintenanceDocument59 pagesInstallation and MaintenanceBruno LopesNo ratings yet

- Huawei CloudEngine 6863E Switch DatasheetDocument13 pagesHuawei CloudEngine 6863E Switch DatasheetHichem ManUtdNo ratings yet

- 3BDD013090 H en Freelance Version 2013 - Distributed Control System For Process Applications PDFDocument16 pages3BDD013090 H en Freelance Version 2013 - Distributed Control System For Process Applications PDFAdelmoKarigNo ratings yet

- WhatsNew Freelance 2019 USDocument4 pagesWhatsNew Freelance 2019 USmistysagarNo ratings yet

- Industrial Servo DrivesDocument6 pagesIndustrial Servo DrivesKornélIllyésNo ratings yet

- AC 800PEC Sales BrochureDocument12 pagesAC 800PEC Sales BrochureMohd Lutfi MahaliNo ratings yet

- MapecDocument2 pagesMapecGustavo SuletaNo ratings yet

- ABB Industrial Drives: ACS880, Single Drives 0.55 To 250 KW CatalogDocument32 pagesABB Industrial Drives: ACS880, Single Drives 0.55 To 250 KW Catalogbakien-canNo ratings yet

- ABB ACS800 Drives PDFDocument52 pagesABB ACS800 Drives PDFrobertoNo ratings yet

- Revista Intech 75 - IsADocument86 pagesRevista Intech 75 - IsACarlos Eduardo Wotchoski NunesNo ratings yet

- ACS 310 CatalogueDocument32 pagesACS 310 CatalogueMạnh Khương TrầnNo ratings yet

- ABB ASM PMDrives Datasheet 9AKK108468A1063Document3 pagesABB ASM PMDrives Datasheet 9AKK108468A1063thomi dhiaNo ratings yet

- JVL AC Servo Controllers AMC10, AMC11 and AMC12Document4 pagesJVL AC Servo Controllers AMC10, AMC11 and AMC12ElectromateNo ratings yet

- IPLOOK IKEPC 500 Series Product InformationDocument4 pagesIPLOOK IKEPC 500 Series Product InformationIPLOOK TechnologiesNo ratings yet

- CloudEngine 6863 Data Center Switch DatasheetDocument13 pagesCloudEngine 6863 Data Center Switch DatasheetRiqo SetyoNo ratings yet

- CloudEngine 6850 Series Data Center Switches Data SheetDocument14 pagesCloudEngine 6850 Series Data Center Switches Data Sheetremart24No ratings yet

- Advance PLC Programming Course V2019 Chapter 02 PDFDocument38 pagesAdvance PLC Programming Course V2019 Chapter 02 PDFRomel AganNo ratings yet

- g5.rss Product DescriptionDocument4 pagesg5.rss Product DescriptionTrần Danh VũNo ratings yet

- Documentation Technique Marquage CEDocument1 pageDocumentation Technique Marquage CEHyacinthe KOSSINo ratings yet

- 1 Running Head: Grant Proposal Strategic PlanDocument6 pages1 Running Head: Grant Proposal Strategic PlanJoseph WainainaNo ratings yet

- Layton7e PPT ch08Document20 pagesLayton7e PPT ch08Cyan SeaNo ratings yet

- Avon Products, Inc.: A Case Narrative in Company Relations With Customers and SuppliersDocument13 pagesAvon Products, Inc.: A Case Narrative in Company Relations With Customers and SuppliersAndreea IoanaNo ratings yet

- Order ConfirmationDocument1 pageOrder ConfirmationfarwaNo ratings yet

- Affidavit of No Business OperationDocument2 pagesAffidavit of No Business OperationMarty CachaperoNo ratings yet

- America The Story of US Great Depression New DealDocument2 pagesAmerica The Story of US Great Depression New DealTori JemesNo ratings yet

- The Prevention of UnemploymentDocument17 pagesThe Prevention of UnemploymentPedro Alberto Herrera LedesmaNo ratings yet

- ReaQta - Lead ReportDocument152 pagesReaQta - Lead ReportLeogem Magalona100% (1)

- Chapters 1-3 Oct.-5Document37 pagesChapters 1-3 Oct.-5Erica FlorentinoNo ratings yet

- Precious M. Resaba: ProfileDocument2 pagesPrecious M. Resaba: ProfileaishwaryaNo ratings yet

- SHS EntrepreneurshipDocument56 pagesSHS EntrepreneurshipKc Joy Agana FerrerNo ratings yet

- Unit 7 Global Cost of Capital and Capital Structure: Sanjay Ghimire Tu-SomDocument27 pagesUnit 7 Global Cost of Capital and Capital Structure: Sanjay Ghimire Tu-SomMotiram paudelNo ratings yet

- CIBOK Sample PDFDocument43 pagesCIBOK Sample PDFArham KhanNo ratings yet

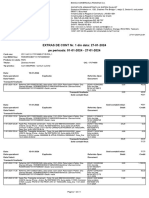

- Pe Perioada: 01-01-2024 - 27-01-2024 EXTRAS DE CONT Nr. 1 Din Data: 27-01-2024Document4 pagesPe Perioada: 01-01-2024 - 27-01-2024 EXTRAS DE CONT Nr. 1 Din Data: 27-01-2024andrei.zbercea04No ratings yet

- Rift Valley University Bishoftu Campus MBA ProgramDocument6 pagesRift Valley University Bishoftu Campus MBA ProgramBedri M AhmeduNo ratings yet

- Modern Urban and Regional Economics: Philip MccannDocument25 pagesModern Urban and Regional Economics: Philip MccannDeri Syaeful RohmanNo ratings yet

- Dissertation On Leadership DevelopmentDocument7 pagesDissertation On Leadership DevelopmentCustomPapersCleveland100% (1)

- Muthoga 2019 Commercial BanksDocument66 pagesMuthoga 2019 Commercial Banksvenice paula navarroNo ratings yet

- Ebook Leadership Team Coaching in Practice Case Studies On Developing High Performing Teams 2Nd Edition Peter Hawkins Online PDF All ChapterDocument70 pagesEbook Leadership Team Coaching in Practice Case Studies On Developing High Performing Teams 2Nd Edition Peter Hawkins Online PDF All Chapterfred.auten370100% (8)

- Revised Guidelines On Blue RevolutionDocument60 pagesRevised Guidelines On Blue RevolutionkartikgoyalNo ratings yet

- Case Study LogitechDocument2 pagesCase Study LogitechAryanNo ratings yet

- 1 - Economy of The Mauryan Period PDFDocument12 pages1 - Economy of The Mauryan Period PDFdrexter124100% (3)

- M.C. Mehta and Anr Vs Union of India & Ors On 20 December, 1986 Equivalent Citations: 1987 AIR 1086, 1987 SCR (1) 819 Bench: Bhagwati, P.N. (CJ)Document3 pagesM.C. Mehta and Anr Vs Union of India & Ors On 20 December, 1986 Equivalent Citations: 1987 AIR 1086, 1987 SCR (1) 819 Bench: Bhagwati, P.N. (CJ)Prakher ShuklaNo ratings yet

- Nyaribari Chache Secondary School Bursary Form Fy 2022 - 2023Document6 pagesNyaribari Chache Secondary School Bursary Form Fy 2022 - 2023wonderland cyberNo ratings yet

- Vijay MalikDocument4 pagesVijay MalikJerry LouisNo ratings yet

- Project Report at BajajDocument59 pagesProject Report at Bajajammu ps100% (2)

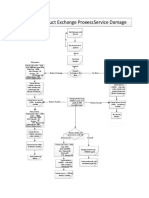

- Product Exchange Process - Service Damage: Old Product Old ProductDocument2 pagesProduct Exchange Process - Service Damage: Old Product Old ProductsameerjaleesNo ratings yet

- REIT LawDocument23 pagesREIT LawriasibuloNo ratings yet

- Trade Data Structure and Basics of Trade Analytics: Biswajit NagDocument33 pagesTrade Data Structure and Basics of Trade Analytics: Biswajit Nagyashd99No ratings yet

TM DC DFE Brochure Lo-Res

TM DC DFE Brochure Lo-Res

Uploaded by

Ashutosh GuptaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TM DC DFE Brochure Lo-Res

TM DC DFE Brochure Lo-Res

Uploaded by

Ashutosh GuptaCopyright:

Available Formats

—

P U L P A N D PA P E R

GE-to-ABB drives upgrade

Modernizing your GE drives to ABB’s

latest and proven system ensures

world-class uptime and lifecycle

support. By leveraging a Dlan+

communication protocol adapter,

mills can take advantage of a phased

modernization path that will provide

supportable, modernized application

controls and HMIs, as well as

enhanced diagnostics and intuitive

navigation for system monitoring.

— Overview Features

Dlan+ communication

protocol adapter ABB has an unmatched history of providing our cus- • ABB’s latest and proven system software standards

developed for GE-to-ABB tomers with the most effective investment protection • New touchscreen HMI breaks down warnings/

drives modernization

in the industry. As such, promptly after ABB acquired diagnostics and shows system interlocks and

GE’s Industrial Systems, we developed a moderniza- permissives in an intuitive manner

tion path for GE’s existing drives system architecture. • High-level diagnostics have face plates both for

operation and navigation to the ABB global pulp

The majority of GE’s installed base uses the Dlan+ and paper software standards

(Arcnet) communication protocol, which is the basis

for the upgrade path. The PE1364DLAN+ adapter con- Benefits

verts the Dlan+ protocol to an ABB protocol and with • Lifecycle support for GE installed base

its built-in firmware, allows the transfer of all data • Minimized spending for over-time drives architec-

from the new ABB master controller (AC800M) to ture modernization

existing GE drives. This enables a cost-effective, step- • World-class machine uptime and reliability

wise approach to modernization that gives mills ac- • Flexibility in system evolution plan

cess to new controls, benefits and lifecycle support

while optimizing budget spend year-over-year instead

of all at once.

The evolution plan can be completed at the drive level

by retrofits, with an all new drives lineup, or a hybrid

of both.

New ABB HMI

CB2000

DCS

Dlan+ ABB

PE1364

module

AC800M

DC2000 AC2000 Master

(DDCS)

— 2500 KVA 2500 KVA

An example paper 13.8/.480 13.8/.480 Ethernet

D/Y D/Y

machine configuration; Machine

the same concept can PLC

Drives tools System IBA

be used for winders. computer 800 xA Datalogger

Migration path The number of modernization phases is dependent

Prior to proposal development, a system audit is rec- on the system size and quantity of lineups. A proven

ommended and performed by ABB system drives approach is to replace one lineup at a time so that the

specialists who are knowledgeable on both new ABB mill’s infrastructure remains the same at the trans-

systems and GE drive systems equipment. formers that feed each lineup.

Typically, the first phase consists of installing the

adapter with an all new ABB coordinated drives con-

trol and operational HMI’s that have state-of-the-art

—

diagnostics that are more modern and advanced than Contact your ABB pulp and paper

the decades-old software tools of the incumbent sys-

tem. This immediate upgrade in user functionality

account manager today to determine

translates to better system performance. the appropriate modernization

approach for your mill.

— — —

ABB Oy ABB Inc. The information provided in this data sheet

Process Industry 579 Executive Campus Drive contains descriptions or characterizations

P.O.Box 94 Westerville, Ohio 43082, USA of performance which may change as a re-

FI-00381 Helsinki, Finland Tel: +1 614 818 6300 sult of further development of the products.

9AKK107985

Telephone +358 10 22 11 Availability and technical specifications are

Fax +358 10 22 24267 subject to change without notice.

Copyright© 2020 ABB. All rights reserved.

abb.com/pulpandpaper

You might also like

- ACS880 Joe+ChenDocument61 pagesACS880 Joe+Chensunil varmaNo ratings yet

- Compass Software: Features and HighlightsDocument2 pagesCompass Software: Features and HighlightsHector Ernesto Cordero AmaroNo ratings yet

- D-M Catalogue 2019 v35Document120 pagesD-M Catalogue 2019 v35sreeramu100% (1)

- Paper Machine Drive System PMC800: Engineered Solutions For SuccessDocument12 pagesPaper Machine Drive System PMC800: Engineered Solutions For SuccessvictorhugomunozhNo ratings yet

- Huawei CloudEngine 6881 Switch DatasheetDocument14 pagesHuawei CloudEngine 6881 Switch DatasheetJoelinho CrushNo ratings yet

- ACS480 Catalog 3AUA0000204668 RevF EN 15-9-2021 LowresDocument40 pagesACS480 Catalog 3AUA0000204668 RevF EN 15-9-2021 LowresNeryNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument14 pagesCloudEngine 6881 Series Data Center Switches Data SheetEduardo SoberanisNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument14 pagesCloudEngine 6881 Series Data Center Switches Data SheetRiqo SetyoNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument14 pagesCloudEngine 6881 Series Data Center Switches Data SheetwhocaresscribdNo ratings yet

- ACS880 CatalogueDocument52 pagesACS880 CatalogueJauhary HarrysNo ratings yet

- Tech Brief AKD Solution 06 11 FinalDocument2 pagesTech Brief AKD Solution 06 11 FinalIan Bruno Rodriguez CenturionNo ratings yet

- Abb Acs380 Acs880 Catalog en Reva 3aua0000187460 0106Document36 pagesAbb Acs380 Acs880 Catalog en Reva 3aua0000187460 0106Er Amandeep SinghNo ratings yet

- Acs880 01manual PDFDocument24 pagesAcs880 01manual PDFsihamuNo ratings yet

- 2.2.1 Ach580 For Hvac Catalog 3aua0000186691 Revf enDocument37 pages2.2.1 Ach580 For Hvac Catalog 3aua0000186691 Revf enTrunghieu LeNo ratings yet

- CloudEngine 6881 Series Data Center Switches Data SheetDocument13 pagesCloudEngine 6881 Series Data Center Switches Data SheetDaniel DoyharzabalNo ratings yet

- Sppa T3000Document6 pagesSppa T3000Dipti Bhanja100% (1)

- Abb PLC Phtc02u en WebDocument181 pagesAbb PLC Phtc02u en Webwarmaster81No ratings yet

- ACS580 - MV - 3BHT490775R0001 - REV - D - EN - 2021 - 08 - 10 - Lowres 3.3 KV To 11 KV, 200 KW To 6300 KWDocument32 pagesACS580 - MV - 3BHT490775R0001 - REV - D - EN - 2021 - 08 - 10 - Lowres 3.3 KV To 11 KV, 200 KW To 6300 KWМиланNo ratings yet

- Move Up To Higher Productivity: Advant OCSDocument4 pagesMove Up To Higher Productivity: Advant OCSMohamedCoulibalyNo ratings yet

- ACH480 ACH580 For HVAC Catalog 3AUA0000231852 RevB ENDocument48 pagesACH480 ACH580 For HVAC Catalog 3AUA0000231852 RevB ENvery sygnaNo ratings yet

- ACS880 Single Drives Catalog 3AUA0000098111 en RevJDocument44 pagesACS880 Single Drives Catalog 3AUA0000098111 en RevJQIUPEILINNo ratings yet

- Catalog AC500 ECoDocument14 pagesCatalog AC500 ECoFIRMANSYAHNo ratings yet

- ABB ACS580MV Flyer 3bht490774r0001 Rev. A - enDocument2 pagesABB ACS580MV Flyer 3bht490774r0001 Rev. A - enRadu BabauNo ratings yet

- SPPA-T3000 Distributed Control SystemDocument9 pagesSPPA-T3000 Distributed Control SystemMohamed HassanNo ratings yet

- SIPROTEC Processbus V3 ProfileDocument2 pagesSIPROTEC Processbus V3 ProfileCarlos PintoNo ratings yet

- Huawei CloudEngine 6863E Switch DatasheetDocument13 pagesHuawei CloudEngine 6863E Switch DatasheetJuan Francisco AriasNo ratings yet

- ABB Power Plant AutomationDocument8 pagesABB Power Plant Automationooszachooo100% (1)

- Anexo 6Document3 pagesAnexo 6Ivan Perez UvalleNo ratings yet

- Multidrive ABB (3AUA0000139404 - REVF)Document40 pagesMultidrive ABB (3AUA0000139404 - REVF)ING_MBMNo ratings yet

- Drive Low Voltage AC Drives: ACS 800 Catalogue Related Tools and AccessoriesDocument28 pagesDrive Low Voltage AC Drives: ACS 800 Catalogue Related Tools and Accessoriesvuthahor316864No ratings yet

- ABB Industrial Drives: ACS880, Drive Modules 0.55 To 3200 KW CatalogDocument48 pagesABB Industrial Drives: ACS880, Drive Modules 0.55 To 3200 KW CatalogPero MivanovNo ratings yet

- 3ADW000192R0401 DCS800 Technical Catalog e DDocument28 pages3ADW000192R0401 DCS800 Technical Catalog e DSunil singhNo ratings yet

- ABB Low Voltage Drives CapabilitiesDocument8 pagesABB Low Voltage Drives CapabilitiesTrần ĐìnhNo ratings yet

- ACS880 07 FlyerDocument2 pagesACS880 07 Flyerbogner22No ratings yet

- Newtec NOP1760 MDM6000 High Speed SystemDocument4 pagesNewtec NOP1760 MDM6000 High Speed SystemmiltonzxNo ratings yet

- CloudEngine 6850 Series Data Center Switches Data SheetDocument13 pagesCloudEngine 6850 Series Data Center Switches Data SheetTrckNo ratings yet

- Abb Acs580 CatalogDocument36 pagesAbb Acs580 CatalogroyclhorNo ratings yet

- ABB Ability™ System 800xa: Control Builder A Advant® Master System EngineeringDocument4 pagesABB Ability™ System 800xa: Control Builder A Advant® Master System Engineeringazizi202No ratings yet

- Preventive Maintenance, Fault Tracing and Case StudyDocument81 pagesPreventive Maintenance, Fault Tracing and Case Studyjagdish choudharyNo ratings yet

- 2VAA003956 en D Symphony Plus SD Series Control and IO LRDocument27 pages2VAA003956 en D Symphony Plus SD Series Control and IO LRThe Hoang100% (1)

- 1.-Automation Products v3Document100 pages1.-Automation Products v3Juan SanchezNo ratings yet

- Installation and MaintenanceDocument59 pagesInstallation and MaintenanceBruno LopesNo ratings yet

- Huawei CloudEngine 6863E Switch DatasheetDocument13 pagesHuawei CloudEngine 6863E Switch DatasheetHichem ManUtdNo ratings yet

- 3BDD013090 H en Freelance Version 2013 - Distributed Control System For Process Applications PDFDocument16 pages3BDD013090 H en Freelance Version 2013 - Distributed Control System For Process Applications PDFAdelmoKarigNo ratings yet

- WhatsNew Freelance 2019 USDocument4 pagesWhatsNew Freelance 2019 USmistysagarNo ratings yet

- Industrial Servo DrivesDocument6 pagesIndustrial Servo DrivesKornélIllyésNo ratings yet

- AC 800PEC Sales BrochureDocument12 pagesAC 800PEC Sales BrochureMohd Lutfi MahaliNo ratings yet

- MapecDocument2 pagesMapecGustavo SuletaNo ratings yet

- ABB Industrial Drives: ACS880, Single Drives 0.55 To 250 KW CatalogDocument32 pagesABB Industrial Drives: ACS880, Single Drives 0.55 To 250 KW Catalogbakien-canNo ratings yet

- ABB ACS800 Drives PDFDocument52 pagesABB ACS800 Drives PDFrobertoNo ratings yet

- Revista Intech 75 - IsADocument86 pagesRevista Intech 75 - IsACarlos Eduardo Wotchoski NunesNo ratings yet

- ACS 310 CatalogueDocument32 pagesACS 310 CatalogueMạnh Khương TrầnNo ratings yet

- ABB ASM PMDrives Datasheet 9AKK108468A1063Document3 pagesABB ASM PMDrives Datasheet 9AKK108468A1063thomi dhiaNo ratings yet

- JVL AC Servo Controllers AMC10, AMC11 and AMC12Document4 pagesJVL AC Servo Controllers AMC10, AMC11 and AMC12ElectromateNo ratings yet

- IPLOOK IKEPC 500 Series Product InformationDocument4 pagesIPLOOK IKEPC 500 Series Product InformationIPLOOK TechnologiesNo ratings yet

- CloudEngine 6863 Data Center Switch DatasheetDocument13 pagesCloudEngine 6863 Data Center Switch DatasheetRiqo SetyoNo ratings yet

- CloudEngine 6850 Series Data Center Switches Data SheetDocument14 pagesCloudEngine 6850 Series Data Center Switches Data Sheetremart24No ratings yet

- Advance PLC Programming Course V2019 Chapter 02 PDFDocument38 pagesAdvance PLC Programming Course V2019 Chapter 02 PDFRomel AganNo ratings yet

- g5.rss Product DescriptionDocument4 pagesg5.rss Product DescriptionTrần Danh VũNo ratings yet

- Documentation Technique Marquage CEDocument1 pageDocumentation Technique Marquage CEHyacinthe KOSSINo ratings yet

- 1 Running Head: Grant Proposal Strategic PlanDocument6 pages1 Running Head: Grant Proposal Strategic PlanJoseph WainainaNo ratings yet

- Layton7e PPT ch08Document20 pagesLayton7e PPT ch08Cyan SeaNo ratings yet

- Avon Products, Inc.: A Case Narrative in Company Relations With Customers and SuppliersDocument13 pagesAvon Products, Inc.: A Case Narrative in Company Relations With Customers and SuppliersAndreea IoanaNo ratings yet

- Order ConfirmationDocument1 pageOrder ConfirmationfarwaNo ratings yet

- Affidavit of No Business OperationDocument2 pagesAffidavit of No Business OperationMarty CachaperoNo ratings yet

- America The Story of US Great Depression New DealDocument2 pagesAmerica The Story of US Great Depression New DealTori JemesNo ratings yet

- The Prevention of UnemploymentDocument17 pagesThe Prevention of UnemploymentPedro Alberto Herrera LedesmaNo ratings yet

- ReaQta - Lead ReportDocument152 pagesReaQta - Lead ReportLeogem Magalona100% (1)

- Chapters 1-3 Oct.-5Document37 pagesChapters 1-3 Oct.-5Erica FlorentinoNo ratings yet

- Precious M. Resaba: ProfileDocument2 pagesPrecious M. Resaba: ProfileaishwaryaNo ratings yet

- SHS EntrepreneurshipDocument56 pagesSHS EntrepreneurshipKc Joy Agana FerrerNo ratings yet

- Unit 7 Global Cost of Capital and Capital Structure: Sanjay Ghimire Tu-SomDocument27 pagesUnit 7 Global Cost of Capital and Capital Structure: Sanjay Ghimire Tu-SomMotiram paudelNo ratings yet

- CIBOK Sample PDFDocument43 pagesCIBOK Sample PDFArham KhanNo ratings yet

- Pe Perioada: 01-01-2024 - 27-01-2024 EXTRAS DE CONT Nr. 1 Din Data: 27-01-2024Document4 pagesPe Perioada: 01-01-2024 - 27-01-2024 EXTRAS DE CONT Nr. 1 Din Data: 27-01-2024andrei.zbercea04No ratings yet

- Rift Valley University Bishoftu Campus MBA ProgramDocument6 pagesRift Valley University Bishoftu Campus MBA ProgramBedri M AhmeduNo ratings yet

- Modern Urban and Regional Economics: Philip MccannDocument25 pagesModern Urban and Regional Economics: Philip MccannDeri Syaeful RohmanNo ratings yet

- Dissertation On Leadership DevelopmentDocument7 pagesDissertation On Leadership DevelopmentCustomPapersCleveland100% (1)

- Muthoga 2019 Commercial BanksDocument66 pagesMuthoga 2019 Commercial Banksvenice paula navarroNo ratings yet

- Ebook Leadership Team Coaching in Practice Case Studies On Developing High Performing Teams 2Nd Edition Peter Hawkins Online PDF All ChapterDocument70 pagesEbook Leadership Team Coaching in Practice Case Studies On Developing High Performing Teams 2Nd Edition Peter Hawkins Online PDF All Chapterfred.auten370100% (8)

- Revised Guidelines On Blue RevolutionDocument60 pagesRevised Guidelines On Blue RevolutionkartikgoyalNo ratings yet

- Case Study LogitechDocument2 pagesCase Study LogitechAryanNo ratings yet

- 1 - Economy of The Mauryan Period PDFDocument12 pages1 - Economy of The Mauryan Period PDFdrexter124100% (3)

- M.C. Mehta and Anr Vs Union of India & Ors On 20 December, 1986 Equivalent Citations: 1987 AIR 1086, 1987 SCR (1) 819 Bench: Bhagwati, P.N. (CJ)Document3 pagesM.C. Mehta and Anr Vs Union of India & Ors On 20 December, 1986 Equivalent Citations: 1987 AIR 1086, 1987 SCR (1) 819 Bench: Bhagwati, P.N. (CJ)Prakher ShuklaNo ratings yet

- Nyaribari Chache Secondary School Bursary Form Fy 2022 - 2023Document6 pagesNyaribari Chache Secondary School Bursary Form Fy 2022 - 2023wonderland cyberNo ratings yet

- Vijay MalikDocument4 pagesVijay MalikJerry LouisNo ratings yet

- Project Report at BajajDocument59 pagesProject Report at Bajajammu ps100% (2)

- Product Exchange Process - Service Damage: Old Product Old ProductDocument2 pagesProduct Exchange Process - Service Damage: Old Product Old ProductsameerjaleesNo ratings yet

- REIT LawDocument23 pagesREIT LawriasibuloNo ratings yet

- Trade Data Structure and Basics of Trade Analytics: Biswajit NagDocument33 pagesTrade Data Structure and Basics of Trade Analytics: Biswajit Nagyashd99No ratings yet